Mechanical behavior and microstructural mechanism of improved disintegrated carbonaceous mudstone

来源期刊:中南大学学报(英文版)2020年第7期

论文作者:高乾丰 曾铃 余慧聪 卞汉兵

文章页码:1992 - 2002

Key words:embankment engineering; carbonaceous mudstone; additive; mechanical properties; microstructure

Abstract: This study aims to improve the mechanical behavior of disintegrated carbonaceous mudstone, which is used as road embankment filler in southwestern China. Triaxial tests were performed on disintegrated carbonaceous mudstone modified by fly ash, cement, and red clay. Then the stress-strain relationships and shear strength parameters were analyzed. The microstructure and mineral composition of the materials were identified via scanning electron microscopy and X-ray diffraction. The results show that the stress-strain relationships changed from strain-hardening to strain-softening when disintegrated carbonaceous mudstone was modified with cement. By contrast, the addition of fly ash and red clay did not change the type of stress-strain relationships. The order of these three additives is cement, red clay and fly ash according to their influences on the cohesion. Disintegrated carbonaceous mudstone without cement all showed bulging failures, and that modified with cement exhibited shear failures or bulging-shear failures. The soil particles of the improved soil were well bonded by cementitious substances, so the microstructure was denser and more stable, which highly enhanced the mechanical behavior of disintegrated carbonaceous mudstone. The findings could offer references for the use of carbonaceous mudstone in embankment engineering.

Cite this article as: ZENG Ling, YU Hui-cong, GAO Qian-feng, BIAN Han-bing. Mechanical behavior and microstructural mechanism of improved disintegrated carbonaceous mudstone [J]. Journal of Central South University, 2020, 27(7): 1992-2002. DOI: https://doi.org/10.1007/s11771-020-4425-8.

J. Cent. South Univ. (2020) 27: 1992-2002

DOI: https://doi.org/10.1007/s11771-020-4425-8

ZENG Ling(曾铃)1, YU Hui-cong(余慧聪)1, GAO Qian-feng(高乾丰)2, BIAN Han-bing(卞汉兵)3

1. School of Civil Engineering, Changsha University of Science & Technology, Changsha 410114, China;

2. Engineering Laboratory of Spatial Information Technology of Highway Geological Disaster Early Warning in Hunan Province, Changsha University of Science & Technology, Changsha 410114, China;

3. Laboratoire de Génie Civil et Géo-environnement, Université de Lille, Lille 5900, France

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract: This study aims to improve the mechanical behavior of disintegrated carbonaceous mudstone, which is used as road embankment filler in southwestern China. Triaxial tests were performed on disintegrated carbonaceous mudstone modified by fly ash, cement, and red clay. Then the stress-strain relationships and shear strength parameters were analyzed. The microstructure and mineral composition of the materials were identified via scanning electron microscopy and X-ray diffraction. The results show that the stress-strain relationships changed from strain-hardening to strain-softening when disintegrated carbonaceous mudstone was modified with cement. By contrast, the addition of fly ash and red clay did not change the type of stress-strain relationships. The order of these three additives is cement, red clay and fly ash according to their influences on the cohesion. Disintegrated carbonaceous mudstone without cement all showed bulging failures, and that modified with cement exhibited shear failures or bulging-shear failures. The soil particles of the improved soil were well bonded by cementitious substances, so the microstructure was denser and more stable, which highly enhanced the mechanical behavior of disintegrated carbonaceous mudstone. The findings could offer references for the use of carbonaceous mudstone in embankment engineering.

Key words: embankment engineering; carbonaceous mudstone; additive; mechanical properties; microstructure

Cite this article as: ZENG Ling, YU Hui-cong, GAO Qian-feng, BIAN Han-bing. Mechanical behavior and microstructural mechanism of improved disintegrated carbonaceous mudstone [J]. Journal of Central South University, 2020, 27(7): 1992-2002. DOI: https://doi.org/10.1007/s11771-020-4425-8.

1 Introduction

Carbonaceous mudstone is a typical soft rock that is extensively distributed in the southwest of China [1, 2]. In this region, carbonaceous mudstone sometimes has to be used to fill road embankment to reduce construction costs. However, this material rapidly softens and disintegrates when meeting water, showing low strength and large deformability [3]. As a result, the road embankment filled with carbonaceous mudstone may show insufficient bearing capacity and resilient modulus [4]. Therefore, the mechanical behavior of carbonaceous mudstone needs to be improved before being used as embankment filler.

Many scholars have studied the improvement of weak geomaterials for embankment filling. YIN et al [5] and YEUNG et al [6] reported that the mechanical properties of soft rocks could be improved to some extent after the electrochemical treatment. YE et al [7] and PHETCHUAY et al [8] stated that cement kiln dust, carbide slag and sludge ash are able to effectively enhance the strength and durability of weak soils. PHUMMIPHAN et al [9] and SHINAWI [10] used cement, lime, fly ash and other traditional materials to treat various rocks and soils. The influences of these traditional materials on the mechanical properties of rocks and soils were analyzed. ZENG et al [11] and MA et al [12] studied the chemical composition, microstructure, unconfined compressive strength and other properties of improved rocks and soils using chemical, organic and inorganic treatment methods. WEI et al [13] and TABARSA et al [14] reported that sustainable materials such as natural clay, kaolin and nanoclay can help to improve the strength and stiffness of weak geomaterials. The above studies have achieved fruitful results in the improvement of embankment filler properties and promoted the development of soil improvement technologies, but there are still some problems to be studied. First of all, the electrochemical improvement is expensive and may cause environmental pollution, so there are certain limitations on its application. Second, existing research mainly focused on red bed mudstone, sandstone and expansive soil, while very few studies involved the improvement of disintegrated carbonaceous mudstone. As a matter of fact, the deformation and strength of disintegrated carbonaceous mudstone are significantly different from those of other geomaterials. For example, disintegrated carbonaceous mudstone is very permeable and easy to soften. This means that the materials suitable for improving other rock and soil masses are not necessarily applicable to disintegrated carbonaceous mudstone. Inorganic cementitious materials including cement and fly ash have advantages of low prices and easy construction. The addition of clay can reduce the dispersion of mixtures and improve the cement hydration. Thus, the use of fly ash, cement and red clay would be a feasible option to improve the mechanical behavior of disintegrated carbonaceous mudstone.

The current study explores the influences of three materials, i.e., fly ash, cement and red clay, on the mechanical properties of disintegrated carbonaceous mudstone. The mechanical behavior and microstructural change of improved disintegrated carbonaceous mudstone are analyzed, and the mechanism behind the improvement is also discussed. The results will provide references for the construction of road embankments using disintegrated carbonaceous mudstone.

2 Experimental program

2.1 Material properties

2.1.1 Disintegrated carbonaceous mudstone

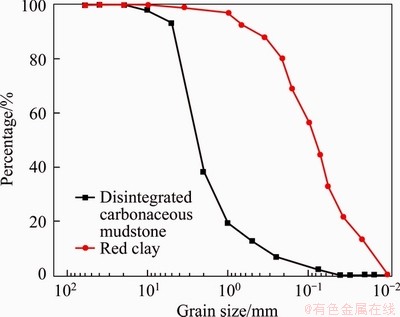

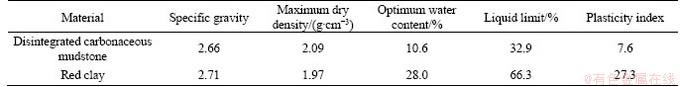

The carbonaceous mudstone was taken from the K9+800 site of the Longlang expressway in Loudi City, China. The raw rock was cut into small pieces with side lengths less than 10 cm and then soaked to make it fully disintegrated in the laboratory. The grain size distribution curve in Figure 1 suggests that the disintegrated carbonaceous mudstone can be classified as coarse- grained soil in accordance with the Chinese specification [15]. X-ray diffraction tests showed that the material contains numerous quartz, muscovite and kaolinite [3]. The chemical composition is basically SiO2, Al2O3, and Fe2O3. The physical properties of disintegrated carbonaceous mudstone are summarized in Table 1.

2.1.2 Red clay

Red clay is a common soil in the southwest of China. It has large porosity, small dry density, and high water content [16]. The red clay was collected from the K17+020 site of the Longlang expressway in Loudi City, China. It contains a majority of kaolinite and illite. Its chemical composition is mainly SiO2, Al2O3, and Fe2O3. The content of silicon and aluminum is generally less than 2%, and the contents of organic matter and soluble salts are minor. The physical properties and the gradation of red clay are shown in Table 1 and Figure 1, respectively. Note that only the fractions less than 2 mm were used to modify disintegrated carbonaceous mudstone.

Figure 1 Grain size distribution curves of disintegrated carbonaceous mudstone and red clay

Table 1 Physical properties of disintegrated carbonaceous mudstone and red clay

2.1.3 Fly ash

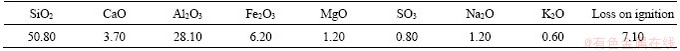

Fly ash, an industrial waste, belongs to the siliceous material rich in clay minerals. It was composed of oxides and inorganic salts of silicon, calcium, aluminum, iron, magnesium, sulfur, sodium, potassium, and other elements (see Table 2). Fly ash particles had a porous honeycomb structure with a porosity of 50%-80%. The particle size of fly ash ranged from 0.5 μm to 300 μm, showing a large specific surface area and high water- adsorption activity. Fly ash can wrap aggregates to form a lubricating layer and fill the voids among aggregates, which helps optimize the gradation of soils.

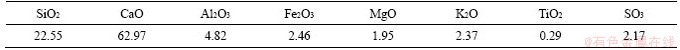

2.1.4 Cement

As a powdery hydraulic gel material, cement generates calcium ions in the hydration process. The hydration products can strongly enhance the strength and water stability of soils. Ordinary Portland cement (P·O42.5) was utilized in this work. It had the characteristics of quick hardening, high early-strength, and good frost resistance. The chemical composition is listed in Table 3.

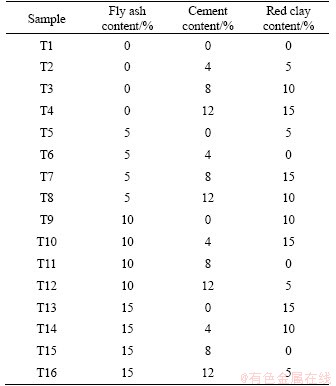

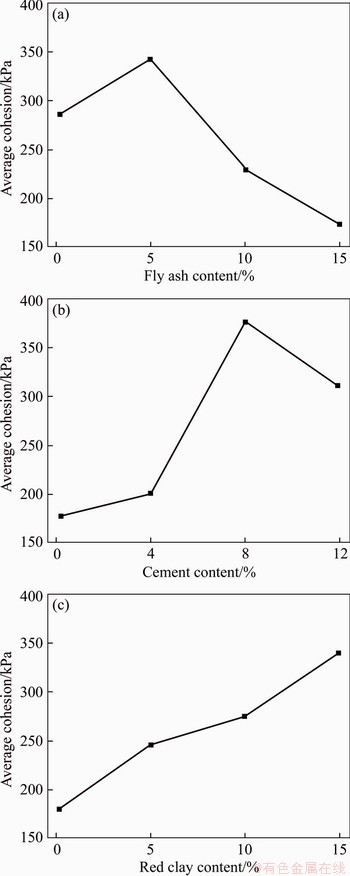

2.2 Orthogonal test scheme

Orthogonal design is a testing method that can efficiently, quickly and economically analyze the influence of various factors on test results. In this study, an orthogonal table including a total of 16 tests and considering three factors and four levels was proposed (Table 4). According to the Chinese standard JTG D30-2015 [17], the degree of compaction of embankment fillers must be ≥90%, so a degree of compaction of 92% was used in the experiment. Since the water content of road embankments usually varies around 10% in southwestern China, a water content of 12% was used to prepare the modified soils. In addition, referring to the literature [18], fly ash contents of 0%, 5%, 10% and 15%, cement contents of 0%, 4%, 8% and 12%, and red clay contents of 0, 5%, 10% and 15% were taken into account.

2.3 Sample preparation

Soil mixture was prepared according to the orthogonal table. Then, the mixture was filled into the sample mold in layers and compacted via the static compaction method [19, 20]. The formed cylindrical samples had diameters of 39.1 mm and heights of 80 mm. Afterward, each sample was saturated under vacuum in a saturator following these steps: 1) the sample in the saturator was placed in a vacuum cylinder, then the air in the vacuum cylinder was evacuated; 2) When the vacuum pressure reached -101.325 kPa, distilled water was allowed filling the vacuum cylinder under a constant vacuum pressure; 3) The evacuation was stopped when the saturator was completely submerged in water, and the sample was remained soaked in water for two days to ensure homogeneity of moisture in the sample; 4) The sample was weighed, and the degree of saturation was calculated. If the saturation was greater than 95%, the saturation was considered completed. Otherwise, the saturation duration must be extended.

2.4 Experimental methods

2.4.1 Triaxial compression test

Unconsolidated undrained triaxial tests were conducted on modified disintegrated carbonaceous mudstone as per the Chinese specification JTG E40-2007 [15]. The triaxial cell is a TSZ full-automatic triaxial testing system. Four levels of confining pressures (i.e., 100, 200, 300 and 400 kPa) were considered, and triaxial shearing was performed at 0.8 mm/min. If the stress-strain curve showed a peak, the test was ceased as the axial strain achieved 5%. If the stress monotonically increased with increasing strain, the test was ceased as the axial strain reached 15%-20% [21].

Table 2 Chemical composition of fly ash (mass fraction, %)

Table 3 Chemical composition of ordinary Portland cement (mass fraction, %)

Table 4 Orthogonal test scheme

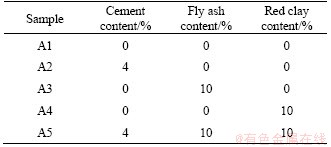

2.4.2 Scanning electron microscopy (SEM) observation

SEM observations were performed on disintegrated carbonaceous mudstone before and after soil modifications. The test scheme is shown in Table 5. The sample preparation method was consistent with that for triaxial tests. After the saturation under vacuum, small samples with volumes of about 1 cm3 were extracted from cylindrical samples. The small samples were then dehydrated by the air drying method [22]. Subsequently, dust was removed from the sample surfaces, and the surfaces for observation were coated with thin gold films (about 3 nm thick) to avoid charge buildup [23, 24]. The microstructure of each small sample was observed using the Hitachi S-3000N scanning electron microscope.

Table 5 SEM observation scheme

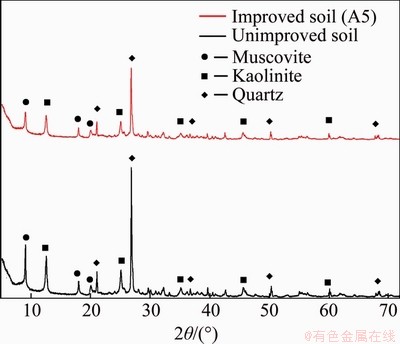

2.4.3 X-ray diffraction (XRD) analysis

Certain broken soils were extracted from the disintegrated carbonaceous mudstone sample (A1) and that modified with 10% fly ash, 4% cement and 10% red clay (A5). After drying, crushing and passing through a 0.075-mm sieve, 10 g soil powder of each sample was taken to fill the sample slot. The surface of the powder was gently squeezed with a glass slide, and excess powder above the surface was crapped off from the sample slot. The above step was repeated several times to flatten the powder surface. Finally, the Rigaku D/Max-2200 XRD apparatus was used to analyze the mineral composition of each sample.

3 Results and discussion

3.1 Mechanical behavior

3.1.1 Stress-strain relationships

Figure 2 depicts the stress-strain curves of two representative samples (i.e., T1 and T12) under different confining pressures. One can note that the deviatoric stress continuously increases as the axial strain increases regardless of the confining pressure, showing strain-hardening characteristics (Figure 2(a)). The deviatoric stress increases rapidly as the axial strain is smaller than 2.5%, and the increase slows down after the axial strain reaches 2.5%. The curve of the sample under a larger confining pressure is above that of the sample under a lower confining pressure, indicating that an increase in confining pressure can considerably enhance the shear strength of disintegrated carbonaceous mudstone.

Figure 2 Stress-strain curves of two samples under different confining pressures:

Unlike the unimproved soil (i.e., T1), the improved soil (i.e., T2) exhibits clear strain-softening characteristics. The peak deviatoric stresses of all the improved soil samples appear at axial strains less than 3.5%. As the confining pressure goes up from 100 to 400 kPa, the reduction of the deviatoric stress after the peak decreases by 72.5%, 67.8%, 61.6% and 54.5%, respectively. This indicates that a larger confining pressure can reduce the shear strength loss of improved soil samples after the peak. Under a confining pressure of 100 kPa, the peak of the stress-strain curve takes place first (at an axial strain of 1.8%), and the residual deviatoric stress is the smallest (only 585.4 kPa).

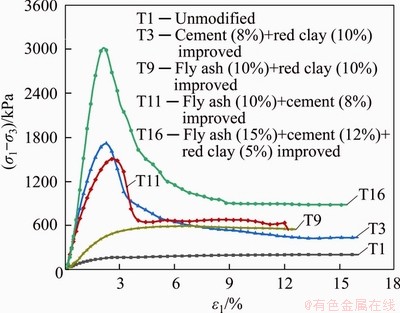

Figure 3 presents the stress-strain curves of the disintegrated carbonaceous mudstone modified by different materials under a confining pressure of 100 kPa. One can note that the soil improved with 10% fly ash and 10% red clay shows a strain- hardening characteristic, which is the same as the unimproved material. By contrast, the modification schemes such as T3, T11 and T16 make the soil exhibit strain-softening characteristics. This is due to the fact that the addition of cement can make the material brittle.

Figure 3 Stress-strain curves of various samples at 100 kPa

Generally, at a given axial strain, the deviatoric stress of the improved soil is larger than that of the unimproved soil. Particularly, the peak deviatoric stress is increased by a maximum of 1383% after the improvement with 15% fly ash, 12% cement and 5% red clay. This suggests that the combined use of the above three additives is better than the use of individual additives regarding the improvement of the shear strength of disintegrated carbonaceous mudstone.

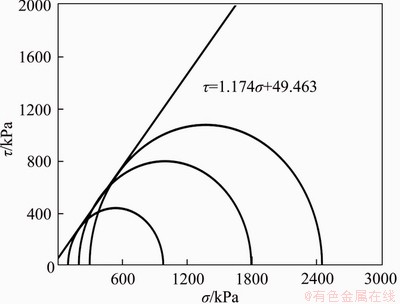

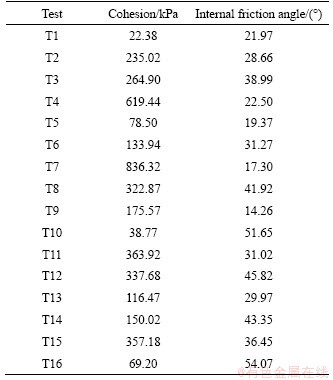

3.1.2 Shear strength parameters

Mohr’s stress circles and strength envelopes are drawn according to the stress-strain curves obtained under various confining pressures. As an example, the diagram of the modified soil (T12) with 10% fly ash, 12% cement, and 5% red clay is presented in Figure 4. Table 6 summarizes the shear strength parameters of different soils. It shows that the cohesion of the improved soil varies from 22.39 to 836.33 kPa and the internal friction angle varies from 14.26° to 54.07°.

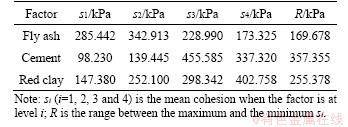

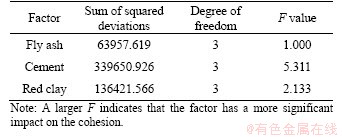

The range analysis and variance analysis were conducted to examine the effects of cement, fly ash, and red clay on the cohesion, as shown in Tables 7 and 8. The variation of the cohesion with different factors is presented in Figure 5. It is noted that all these additives are able to enhance the cohesion of disintegrated carbonaceous mudstone. Among these additives, cement has the most significant influence on the cohesion while fly ash has the least influence on the cohesion. With the increase in fly ash content,the average cohesion of the improved soil increases first and then decreases, and it reaches the maximum when the fly ash content is 5%. With the increase in cement content, the average cohesion of the improved soil goes up and then reduces, and the maximum is reached when the cement content is 8%. In addition, the cohesion is positively correlated with the amount of red clay.

Figure 4 Mohr’s circle and strength envelope of modified soil (T12)

Table 6 Summary of shear strength parameters of different soils

Table 7 Results of range analysis of cohesion

Table 8 Results of variance analysis of cohesion

Figure 5 Variation trend of average cohesion of improved soils

3.1.3 Failure mode

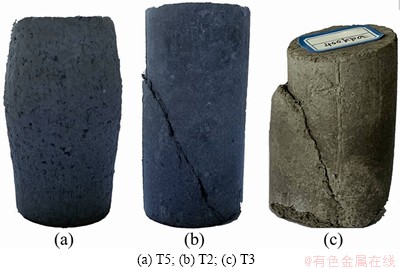

The failure modes of the samples can be divided into three types, i.e., bulging failure, shear failure and bulging-shear failure. If the sample exhibits a bulging failure, its height decreases but the size of the middle cross-section increases, as shown in Figure 6(a). It is a shear failure if the sample shows a clear shear plane while the height of the sample does not change significantly, as shown in Figure 6(b). The bulging-shearing failure is a mixing mode of the bulging failure and shear failure, as shown in Figure 6(c). It is found that the disintegrated carbonaceous mudstone improved by additives including cement shows a shear failure or bulging-shear failure. By contrast, the failure modes of the disintegrated carbonaceous mudstone modified by additives without cement are bulging failures. This indicates that the use of cement will change the failure mode of disintegrated carbonaceous mudstone from bulging failure to shear failure or bulging-shear failure, which is highly adverse to the stability of embankment slopes.

Figure 6 Three typical failure modes of improved soil samples:

3.2 Microscopic interpretation

3.2.1 Analysis of soil microstructure

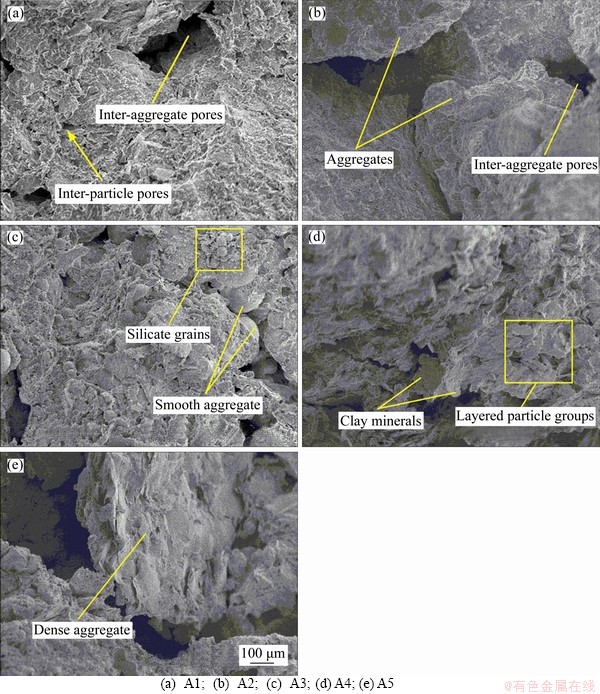

Figure 7 presents the SEM micrographs of different soil samples. It is noted that there are a large number of pores in the unimproved soil, and the pores include both inter-particle pores and inter-aggregate pores (Figure 7(a)). Figure 7(b) shows the micrograph of the modified soil (A2) only with cement. It is noted that the inter-particle pores of the cement-improved soil are effectively filled, and the particles are connected by cementitious substance to form larger aggregates. In this case, the pores are mainly inter-aggregate pores, and the soil forms a dense and stable structure. Figure 7(c) is the micrograph of the modified soil (A3) only with fly ash. It shows that plenty of silicate grains fill the inter-aggregate pores of the fly ash-improved soil, making the soil structure dense. The micrograph in Figure 7(d) depicts that numerous layered particle groups formed by flaky and flat clay particles effectively fill the inter-aggregate pores in the modified soil (A4) only with red clay. It is observed from Figure 7(e) that most of the inter-particle pores in the soil (A5) modified with three materials disappear, leaving larger aggregates. The aggregates have a dense and stable structure, which enhances the strength of the soil.

Comparing the SEM images in Figure 7, one can note that the use of each additive can effectively reduce the pores in disintegrated carbonaceous mudstone. The major difference is that cement mainly reduces the inter-particle pores, while red clay and fly ash highly reduce the inter-aggregate pores. When the three additives are added at the same time, the reduction of the pores in disintegrated carbonaceous mudstone is the most significant.

3.2.2 Analysis of mineral compositions

The XRD patterns of unimproved soil and the soil modified with 10% fly ash, 10% red clay and 4% cement are shown in Figure 8. It is noted that the mineral compositions of the unimproved soil and the improved soil are basically the same, and no obvious new minerals are generated.

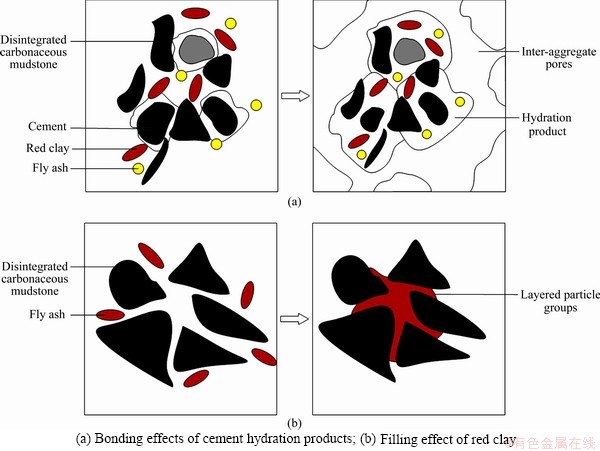

3.2.3 Mechanism behind soil improvements

The mechanism underlying the improvement of disintegrated carbonaceous mudstone by fly ash, cement, and red clay can be divided into the following four aspects:

1) Cement hydration reaction takes place when cement meets the water in soil [25], which can be expressed by:

(1)

(1)

(2)

(2)

Figure 7 Micrographs of unimproved and improved soils:

Figure 8 XRD patterns of unimproved and improved soils

The produced calcium silicate hydrate (CSH) gels can bond fly ash, red clay, disintegrated carbonaceous mudstone and other hydration products to form large aggregates (see Figure 9(a)). This causes the improved soil to become brittle. Moreover, the hydration products can also fill the inter-particle pores (Figure 7(b)), thereby the shear strength of disintegrated carbonaceous mudstone is improved.

2) Fly ash contains plenty of active silica and active alumina, which can react with calcium hydroxide at room temperature [26]. This promotes the cement hydration reaction to produce more stable CSH and calcium aluminate hydrate (CAH) [27]. CAH can serve as cementitious and filling substance (Figure 7(c)). Also, the reaction between CAH and SO42- produces ettringite, further enhancing the strength of the soil. The specific principle is as follows:

(3)

(3)

Figure 9 Schematic of mechanism underlying soil improvements:

(4)

(4)

(5)

(5)

If the fly ash content is larger than 5%, numerous fly ash aggregates are formed due to uneven dispersion, which reduces the activity of fly ash and inhibits the “volcanic ash reaction”. As a result, the amount of CSH and CAH gels is reduced, leading to an increase of inter-aggregate pores. Consequently, the cohesion of the improved soil decreases (see Figure 5).

3) Ion exchange and aggregation effects occur between fly ash (or hydration products) and the ions on the surfaces of clay minerals at certain water contents [28]. Under the wet condition, numerous ions such as Al3+ and K+ present on the surfaces of clay minerals, which react with the hydration products to generate a large number of silicates:

(6)

(6)

(7)

(7)

The generated silicate can adhere to the clay mineral surfaces, and then be wrapped with CSH and CAH gels to form large aggregates, which can effectively increase the cohesion of the improved soil.

4) Red clay contains numerous clay minerals and forms layered particle groups, which can efficiently fill the inter-aggregate pores (see Figures 7(d) and 9(b)). Furthermore, the presence of red clay increases the amount of aluminum, weakening the decomposition of CAH gels. Thus, the cohesion is continuously enhanced as the content of red clay increases (see Figure 5).

4 Conclusions

This is an experimental work on the improvement of disintegrated carbonaceous mudstone with three additives, i.e., fly ash, cement and red clay. The following conclusions can be drawn:

1) The addition of cement leads to the stress- strain relationship changing from strain- hardening to strain-softening. The improved soil has a larger peak deviatoric stress than the unimproved soil. The combined use of the three additives is the most efficient in soil improvements.

2) The cohesion of disintegrated carbonaceous mudstone can be considerably enhanced with the three additives. Among them, cement has the most significant influence on the cohesion, while fly ash has the least influence on the cohesion. The optimal contents of cement and fly ash are 8% and 5%, respectively.

3) Disintegrated carbonaceous mudstone samples without cement show bulging failures, and those modified by additives including cement exhibit shear failures or bulging-shear failures. This indicates that the use of cement will change the failure mode of disintegrated carbonaceous mudstone.

4) The microstructure of the improved soil is denser and more stable. Cementitious substances bond the soil particles to each other, increasing the strength of the improved soil without generating new minerals.

References

[1] FU Hong-yuan, LIU Jie, ZHA Huan-yi. Study of the strength of disintegrated carbonaceous mudstone modified with nano-Al2O3 and cement [J]. Journal of Nanoscience and Nanotechnology, 2020, 20(8): 4839-4845. DOI: 10.1166/jnn. 2020.18486.

[2] ZENG Ling, YAO Xiao-fei, ZHANG Jun-hui, GAO Qian-feng, CHEN Jing-cheng, GUI Yu-tong. Ponded infiltration and spatial -temporal prediction of the water content of silty mudstone [J]. Bulletin of Engineering Geology and the Environment, 2020: 1-13. DOI: 10.1007/ s10064-020-01880-1.

[3] ZENG Ling, LIU Jie, GAO Qian-feng, BIAN Han-bing. Evolution characteristics of the cracks in the completely disintegrated carbonaceous mudstone subjected to cyclic wetting and drying [J]. Advances in Civil Engineering, 2019, 2019: 1279695. DOI: 10.1155/2019/1279695.

[4] ZENG Ling, YAO Xiao-fei, GAO Qian-feng, BIAN Han-bing, FAN Dian-hua. Use of nanosilica and cement in improving the mechanical behavior of disintegrated carbonaceous mudstone [J]. Journal of Nanoscience and Nanotechnology, 2020, 20(8): 4807-4814. DOI: 10.1166/jnn.2020.18483.

[5] YIN Bo, KANG Tian-he, KANG Jian-ting, CHEN Yue-juan. Experimental and mechanistic research on enhancing the strength and deformation characteristics of fly-ash-cemented filling materials modified by electrochemical treatment [J]. Energy & Fuels, 2018, 32(3): 3614-3626. DOI: 10.1021/acs. energyfuels.7b03113.

[6] YEUNG A T, GU Y Y. A review on techniques to enhance electrochemical remediation of contaminated soils [J]. Journal of Hazardous Materials, 2011, 195: 11-29. DOI: 10.1016/j.jhazmat.2011.08.047.

[7] YE Hao, CHU Cheng-fu, XU Long, GUO Kun-long, LI Dong. Experimental studies on drying-wetting cycle characteristics of expansive soils improved by industrial wastes [J]. Advances in Civil Engineering, 2018: 2321361. DOI: 10.1155/2018/2321361.

[8] PHETCHUAY C, HORPIBULSUK S, ARULRAJAH A, SUKSIRIPATTANAPONG C, UDOMCHAI A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer [J]. Applied Clay Science, 2016, 127-128: 134-142. DOI: 10.1016/j.clay. 2016.04.005.

[9] PHUMMIPHAN I, HORPIBULSUK S, PHOONGERNKHAM T, ARULRAJAH A, SHEN Shui-long. Marginal lateritic soil stabilized with calcium carbide residue and fly ash geopolymers as a sustainable pavement base material [J]. Journal of Materials in Civil Engineering, 2017, 29(2): 04016195. DOI: 10.1061/(ASCE)MT.1943-5533. 0001708.

[10] SHINAWI A E. Instability improvement of the subgrade soils by lime addition at Borg El-Arab, Alexandria, Egypt [J]. Journal of African Earth Sciences, 2017, 130: 195-201. DOI: 10.1016/j.jafrearsci.2017.03.020.

[11] ZENG Ling, XIAO Liu-yi, ZHANG Jun-hui, FU Hong-yuan. The role of nanotechnology in subgrade and pavement engineering: A review [J]. Journal of Nanoscience and Nanotechnology, 2020, 20: 4607-4618. DOI: 10.1166/jnn. 2020.18491.

[12] MA Qin-yong, GAO Chang-hui. Effect of basalt fiber on the dynamic mechanical properties of cement-soil in SHPB test [J]. Journal of Materials in Civil Engineering, 2019, 30(8): 04018185. DOI: 10.1061/(ASCE)MT.1943-5533.0002386.

[13] WEI J Q, MEYER C. Sisal fiber-reinforced cement composite with Portland cement substitution by a combination of metakaolin and nanoclay [J]. Journal of Materials Science, 2014, 49(21): 7604-7619. DOI: 10.1007/ s10853-014-8469-8.

[14] TABARSA A, LATIFI N, MEEHAN C L, MANAHILOH K N. Laboratory investigation and field evaluation of loess improvement using nanoclay–A sustainable material for construction [J]. Construction and Building Materials, 2018, 158: 454-463. DOI: 10.1016/j.conbuildmat.2017.09.096.

[15] The Professional Standards Compilation Group of People’s Republic of China. JTG E40-2007. Test methods of soils for highway engineering [S]. Beijing: China Communications Press, 2007. (in Chinese)

[16] ZHANG Jun-hui, LI Feng, ZENG Ling, PENG Jun-hui, LI Jue. Numerical simulation of the moisture migration of unsaturated clay embankments in southern China considering stress state [J]. Bulletin of Engineering Geology and the Environment, 2020. DOI: 10.1007/s10064-020-01916-6.

[17] The Professional Standards Compilation Group of People's Republic of China. JTG D30-2015. Design standard of highway embankment [S]. Beijing: China Communications Press, 2015. (in Chinese)

[18] SUN Ya-fei, GAO Pei-wei, GENG Fei, LI Hao-ran, ZHANG Li-fang, LIU Hong-wei. Thermal conductivity and mechanical properties of porous concrete materials [J]. Materials Letters, 2017, 209: 349-352. DOI: 10.1016/ j.matlet.2017.08.046.

[19] ZAHNG Jun-hui, PENG Jun-hui, ZENG Ling, LI Jue, LI Feng. Rapid estimation of resilient modulus of subgrade soils using performance-related soil properties [J]. International Journal of Pavement Engineering, 2019: 1-8. DOI: 10.1080/10298436.2019.1643022.

[20] ZAHNG Jun-hui, PENG Jun-hui, LIU Wei-zheng, LU Wei-hua. Predicting resilient modulus of fine-grained subgrade soils considering relative compaction and matric suction [J]. Road Materials and Pavement Design, 2019: 1-13. DOI: 10.1080/14680629.2019.1651756.

[21] GAO Qian-feng, ZHAO Dan, ZENG Ling, DONG Hui. A pore size distribution-based microscopic model for evaluating the permeability of clay [J]. KSCE Journal of Civil Engineering, 2019, 23(12): 5002-5011. DOI: 10.1007/s12205-019-2219-z.

[22] HYNNINEN A, KULAVIIR M, KIRSIMAE K. Air-drying is sufficient pre-treatment for in situ visualization of microbes on minerals with scanning electron microscopy [J]. Journal of Microbiological Methods, 2018, 146: 77-82. DOI: 10.1016/j.mimet.2018.02.007.

[23] GAO Qian-feng, HATTAB M, JRAD M, FLEUREAU J M, HICHER P Y. Microstructural organisation of remoulded clays in relation with dilatancy/contractancy phenomena [J]. Acta Geotechnica, 2020, 15(1): 223-243. DOI: 10.1007/s11440- 019-00876-w.

[24] GAO Qian-feng, JRAD M, HATTAB M, FLEUREAU J M, IGHIL AMEUR L. Pore morphology, porosity and pore size distribution in kaolinitic remoulded clays under triaxial loading [J]. International Journal of Geomechanics, 2020, 20(6): 04020057. DOI: 10.1061/(ASCE)GM.1943-5622. 0001682.

[25] LOANNIDOU K, KANDUC M, LI Lun-na, FRENKEL D, DOBNIKAR J, GADO E D. The crucial effect of early-stage gelation on the mechanical properties of cement hydrates [J]. Nature Communications, 2016, 7(1): 1-9. DOI: 10.1038/ ncomms12106.

[26] DING Jian, MA Shu-hua, ZHENG Shi-li, ZHANG Yi, XIE Zong-li, SHEN S R, LIU Zhong-kai. Study of extracting alumina from high-alumina PC fly ash by a hydro-chemical process [J]. Hydrometallurgy, 2016, 161: 58-64. DOI: 10.1016/j.hydromet.2016.01.025.

[27] AHMARI S, REN Xin, TOUFIGH V, ZHANG Lian-yang. Production of geopolymeric binder from blended waste concrete powder and fly ash [J]. Construction and Building Materials, 2012, 35: 718-729. DOI: 10.1016/j.conbuildmat. 2012.04.044.

[28] ZHU Jian-ping, FENG Chun-hua, YIN Hai-bin, ZHANG Zhan-ying, SHAH S P. Effects of colloidal nano boehmite and nano SiO2 on fly ash cement hydration [J]. Construction and Building Materials, 2015, 101: 246-251. DOI: 10.1016/ j.conbuildmat.2015.10.038.

(Edited by HE Yun-bin)

中文导读

改良预崩解炭质泥岩的力学行为及微观机理研究

摘要:预崩解炭质泥岩在中国西南地区常用作路堤填料。为改善预崩解炭质泥岩力学特性,采用粉煤灰、水泥和红黏土对预崩解炭质泥岩进行处理,通过三轴试验分析改良土的应力-应变关系和抗剪强度指标,并利用扫描电镜和X射线衍射表征其微观结构和矿物成分。结果表明,经水泥改良后预崩解炭质泥岩的应力-应变关系曲线由应变硬化型转变为应变软化型,但粉煤灰和红黏土不改变其应力-应变关系类型。三种添加剂对预崩解炭质泥岩黏聚力影响的大小顺序为:水泥>红黏土>粉煤灰。未加水泥的预崩解炭质泥岩均表现为鼓胀破坏,而经水泥改良的预崩解炭质泥岩均表现为剪切破坏或鼓 胀-剪切破坏。由于胶结物能将土颗粒紧密胶结成团,使微观结构更加致密、稳定,因此,改良后预崩解炭质泥岩的力学特性得到显著增强。研究结果可为炭质泥岩在路基工程中的应用提供参考。

关键词:路基工程;炭质泥岩;添加剂;力学特性;微观结构

Foundation item: Projects(51908069, 51908073, 51838001, 51878070) supported by the National Natural Science Foundation of China; Project(2019SK2171) supported by the Key Research and Development Program of Hunan Province, China; Project(2019IC04) supported by the Double First-Class Scientific Research International Cooperation Expansion Project of Changsha University of Science & Technology, China; Project(kfj190605) supported by the Open Fund of Engineering Laboratory of Spatial Information Technology of Highway Geological Disaster Early Warning in Hunan Province (Changsha University of Science & Technology), China; Project(kq1905043) supported by the Training Program for Excellent Young Innovators of Changsha, China; Project(SJCX202017) supported by the Practical Innovation Program for Graduates of Changsha University of Science & Technology, China

Received date: 2020-03-30; Accepted date: 2020-04-26

Corresponding author: GAO Qian-feng, PhD, Lecturer; Tel: +86-15173240865; E-mail: qianfeng.gao@csust.edu.cn; ORCID: 0000- 0003-4844-2345