文章编号:1004-0609(2014)11-2943-08

富硼渣硫酸法制取硼酸和一水硫酸镁

李 杰1,郭学东1,光 明1,姜 涛2

(1. 内蒙古工业大学 材料科学与工程学院,呼和浩特 010051;

2. 东北大学 材料与冶金学院,沈阳 110004)

摘 要:采用富硼渣硫酸法处理富硼渣,通过单因素试验和正交试验确定了富硼渣硫酸浸出的最佳试验条件。针对硫酸浸出液开发了先高温结晶制取一水硫酸镁再低温结晶制备硼酸工艺。结果表明:浸出温度为99 ℃,酸用量为理论用量的95%,浸出液固比为6:1,浸出时间为90 min时,B浸出率为98.76%,Mg浸出率达到74.32%。通过灰色关联分析理论对Mg的浸出率进行预测,预测值为75.06%,预测结果和实验结果具有较好的一致性。制得的一水硫酸镁纯度为95.42%,硼酸的纯度达到99.27%。

关键词:富硼渣;硫酸浸出;硼酸;一水硫酸镁;浸出率

中图分类号: TD 985 文献标志码:A

Preparation of boric acid and magnesium sulfate monohydrate from boron-rich slag by sulfuric acid leaching method

LI Jie1, GUO Xue-dong1, GUANG Ming1, JIANG Tao2

(1. School of Materials Science and Engineering, Inner Mongolia University of Technology, Hohhot 010051, China;

2. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The sulfuric acid was used to decomposing boron-rich slag. The best test conditions of the boron-rich slag sulfuric acid leaching were determined by single factor and orthogonal experiments. The high temperature crystallization preparation of magnesium sulfate monohydrate and low temperature crystallization preparation boric acid were developed by sulfuric acid leaching solution. The results show that the optimum parameters are leaching temperature of 99 ℃, the sulfuric acid theoretical of 95% dosage, leaching time of 90 min and leaching liquid to solid ratio of 6:1. Under these conditions, the leaching rates of B and Mg are 98.76% and 74.32%, respectively. The leaching rate of Mg predicted by gray relational theory and the predictive value is 75.06%. A good agreement between the actual and predicted results is obtained. The purity of magnesium sulfate monohydrate and boric acid obtained by this method are 95.42% and 99.27%, respectively.

Key words: B-rich slag; sulfuric acid leaching; boric acid; magnesium sulfate monohydrate; leaching rate

我国是世界上硼资源较丰富的国家之一,除青海、西藏等地的天然硼砂之外,58%的硼资源集中在辽宁省,以硼铁矿的形式存在[1-3]。目前,我国用来生产硼砂和硼酸的原料主要是硼镁矿,但经多年开采,硼镁矿储量日趋减少。硼铁矿火法分离工艺技术是具有我国自主知识产权的核心关键技术,硼铁矿火法分离后得到合格的含硼生铁和富硼渣两种重要产品,使有价元素B和Fe得到了充分的分离[4-6]。目前,含硼生铁已成功应用于生产硼铸铁汽缸套及耐磨衬板和磨球等[7-9]。现阶段正在进行含硼生铁直接冶炼硼钢的实验研究工作,并取得初步研究成果。但是,富硼渣中硼的利用还是一个急需解决的问题。如果富硼渣中硼的利用问题能够彻底解决,那么硼铁矿经火法分离所得的含硼生铁和富硼渣都是可利用资源,整个硼铁矿火法分离工艺技术路线贯通,为硼铁矿中硼的利用打开新的局面。因此,富硼渣中硼的利用问题是硼铁矿火法分离工艺技术能否贯通的关键问题。目前,对于富硼渣中硼的利用有两种思路:1) 将富硼渣进行整体利用;2) 将富硼渣中的B提取出来再进行利用。采用富硼渣制备陶瓷材料是目前见于报道的富硼渣整体利用方法。这一方法借鉴现有Sialon材料的制备方法和技术,将富硼渣中SiO2、Al2O3、CaO和MgO经碳热还原氮化法合成先进结构陶瓷α'-Sialon,实现富硼渣多组分整体转型,制备具有富硼渣资源特点的含硼复合材料[10-12],此类研究目前处于起步研究阶段。

富硼渣的第二种利用思路是对富硼渣中的B进行提取利用。目前,研究人员主要提出了3种富硼渣提B方法:富硼渣碳碱法[13]、富硼渣硫酸法以及富硼渣熔态钠化-热处理-加压水浸法[14]。本研究中富硼渣硫酸法来提取渣中的B和Mg。富硼渣硫酸法[15-17]是用硫酸酸解富硼渣的湿法提B方法,富硼渣中遂安石相(2MgO·B2O3)和镁橄榄石相(2MgO·SiO2)与硫酸反应生成硼酸和硫酸镁,渣中的有价B、Mg资源转移到溶液中,再对溶液中的B、Mg分别提取。硫酸法对富硼渣的活性要求低,目前生产的富硼渣用硫酸浸出,B的浸出率可达90%以上,这为获得较高的B的回收率创造了条件。另外,目前以硼镁矿为原料,用硫酸法来生产硼酸的企业有很多,这也为富硼渣硫酸法提B提供了现实基础。

本文作者采用富硼渣硫酸法提取渣中的B、Mg,工艺上采用先提Mg后提B的方式,与传统的先提B再提Mg的工艺不同。主要是考虑到反应后的溶液经过除Fe、Al步骤后,滤液温度在60~80 ℃,趁热直接进入高压釜先高温结晶提Mg,可充分利用热溶液,节约能源,提Mg后剩余母液再低温结晶硼酸。最终滤液可打入富硼渣酸解工序,滤液中的硼酸和硫酸镁可进行重复回收。

1 实验

1.1 实验原料

实验所用富硼渣取自营口广大实业有限公司,是硼铁矿石经高炉进行硼铁分离后得到的富硼渣。富硼渣的主要化学成分(质量分数)见表1。

表1 富硼渣的主要化学成分

Table 1 Main chemical composition of boron-rich slag (mass fraction, %)

1.2 实验方法

将一定量的富硼渣粉末放入三口烧瓶中,向烧瓶中加入相应液固比的去离子水,将烧瓶放入恒温水浴锅内,烧瓶上安装回流、搅拌装置。恒温水浴锅加热到指定温度后,在搅拌的条件下向烧瓶内滴加浓硫酸,开始时应缓慢加入,富硼渣与硫酸发生剧烈反应,同时产生大量泡沫,滴加硫酸总量的10%左右硫化物基本反应完全,再将未加入的全部硫酸尽快投入到烧瓶中。反应完毕后,反应液趁热过滤,滤饼用90 ℃热水洗涤3次,滤液放入烧杯中。滤饼在120 ℃下烘干,用碱熔法测滤饼中B含量,滤饼中Ca、Mg含量用X射线荧光分析仪测得。

2 结果与分析

富硼渣硫酸浸出过程中,酸用量、浸出温度、浸出时间、浸出液固比、搅拌速度等是影响富硼渣中B、Mg浸出率的主要因素。而酸用量、温度、时间、液固比对富硼渣中B、Mg浸出率影响更为显著,试验中逐一对其研究。

2.1 硫酸用量的影响

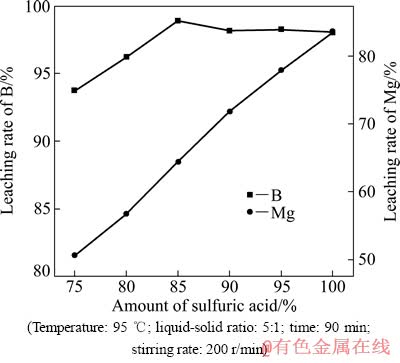

浸出试验中,除硫酸用量外,其余浸出条件分别为:富硼渣20 g,浸出温度95 ℃,浸出时间90 min,浸出液固比5:1,搅拌转速约200 r/min。硫酸用量对富硼渣中B、Mg浸出率影响如图1所示,酸的理论用量为富硼渣中能与硫酸作用的金属阳离子完全转变为硫酸盐时所需的硫酸量。

从图1可知,富硼渣中B浸出率随着酸用量的增加呈先增大后减小的趋势。增大阶段是由于酸量增加起主要作用,酸量增加使得有足够的酸与硼酸镁反应,将B转移到溶液中,但当酸用量超过酸理论用量的90%时,反应液过滤难度随酸用量的增加逐渐增大,过滤困难。这主要是由于酸量增加,与渣中Ca组分的反应增多,生成大量的细小的CaSO4·2H2O晶体,阻碍过滤[18],这也使得部分硼酸残留在滤饼中,这也是B浸出率随着酸用量的增加先增大后减小的原因。而Mg浸出率随着酸用量的增加而增加,从B和Mg浸出率和过滤难易程度上考虑,酸用量不宜超过硫酸理论用量的95%。

图1 硫酸用量与富硼渣中B和Mg浸出率关系

Fig. 1 Influence of sulfuric acid on leaching rates of B and Mg

2.2 浸出温度的影响

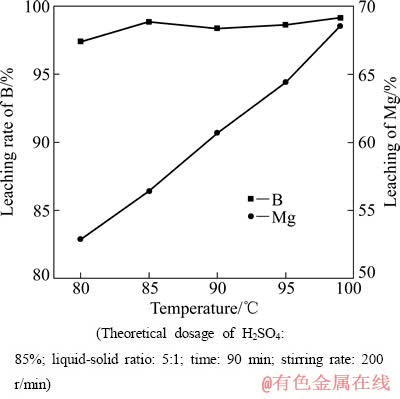

除温度外,其余浸出条件分别为:富硼渣20 g,硫酸用量为理论用量的85%,浸出时间为90 min,浸出液固比为5:1,搅拌转速约200 r/min。

图2所示为常压下温度与B、Mg浸出率的关系。由图2可知,反应温度从80 ℃提高到99 ℃时,B的浸出率变化不大,而且均在95%以上,说明反应温度为80 ℃时,酸解富硼渣就能得到较高的B浸出率。

图2 富硼渣中B和Mg浸出率与温度的关系

Fig. 2 Relationship between leaching rate of B and Mg in B-rich slag and temperature

Mg浸出率随着温度的提高而增大,提高温度使酸浸反应速度加快,在有限的时间内增加了反应速度会使Mg的浸出率逐渐升高。99 ℃为常压下所能达到的最高水浴温度,若考虑加压浸出,进一步提高浸出温度,Mg浸出率还能进一步升高。

2.3 浸出时间的影响

试验中,除浸出时间外,其余浸出条件分别为富硼渣20 g,硫酸用量为理论用量的85%,浸出温度为95 ℃,浸出液固比5:1,搅拌转速约为200 r/min。

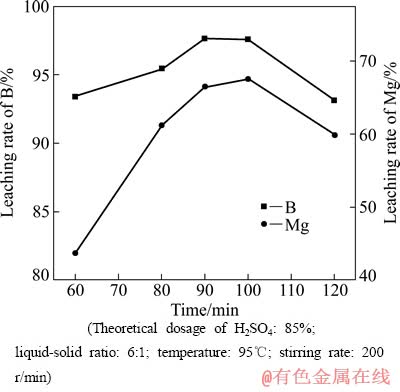

图3 富硼渣中B、Mg浸出率与时间的关系

Fig. 3 Relationship between leaching rate of B and Mg in B-rich slag and time

试验分别在60、80、90、100和120 min进行浸出试验,考察浸出时间对B和Mg浸出率的影响。从图3可以看出,B和Mg浸出率随着时间的增加均先升高后降低。在100 min内,随着时间的延长,反应更大限度的正向进行,B、Mg浸出率升高。但当浸出时间增加至120 min时,B、Mg浸出率迅速下降。这主要是因为浸出时间过长,富硼渣中的Ca组分也被浸取出来,溶液中形成大量难过滤的细小的CaSO4·2H2O晶体,部分B、Mg残留在滤饼内,导致B、Mg浸出率下降。若单独考虑B浸出率,反应时间为60 min时,B浸出率就达到93.4%,但综合考虑B、Mg浸出率时,反应时间以80~100 min为宜。

2.4 浸出液固比的影响

浸出试验中,除反应液固比外,其余浸出条件分别为富硼渣20 g,硫酸用量为理论用量的85%,浸出温度为95 ℃,浸出时间为90 min,搅拌转速约为200 r/min。

从图4可以看出,液固比在7:1之前时,随着液固比的增大,B浸出率变化不大,且均在95%以上。而Mg浸出率在浸出液固比由4:1增加到6:1时,逐渐增大,液固比的增加使得反应浆液流动性变好,有利于反应进行,提高了Mg的浸出率。当反应液固比继续增大时,B和Mg的浸出率都在减小,这主要是由于随着液固比的增大,酸浓度降低。此时酸浓度在浸出过程中起到了主导作用,酸浓度低导致富硼渣反应不完全,B和Mg浸出率也随之降低。同时,由于酸浓度的降低,反应生成物硅酸形成胶状物,溶液过滤困难。当液固比为9:1和10:1时,在减压条件下抽滤也不能将反应液过滤出来。考虑到B和Mg浸出率以及过滤操作的难易程度,反应液固比为6:1较为适宜。

图4 富硼渣中B、Mg浸出率与液固比的关系

Fig. 4 Relationship between leaching rate of B and Mg and in B-rich slag liquid-solid ratio

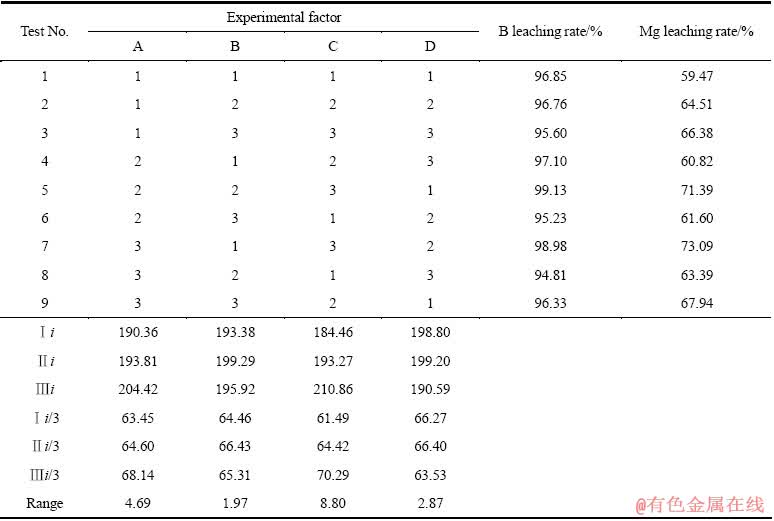

2.5 正交试验

试验中发现,酸浸过程中浸出时间、浸出温度、硫酸用量及反应液固比等都对富硼渣B、Mg浸出率有影响,尤其是对Mg浸出率影响较大。为了选择较适宜的硫酸浸出条件,进行了酸用量、浸出时间、浸出温度、液固比四因素三水平正交试验。所用正交表为L9(34),因素水平表见表2,试验结果见表3(Ⅰi表示正交表中第i列的1水平所对应的数据之和,Ⅰi/3为其平均值;Ⅱi表示正交表中第i列的2水平所对应的数据之和,Ⅱi/3为其平均值;Ⅲi表示正交表中第i列的3水平所对应的数据之和,Ⅲi/3为其平均值。浸出条件:富硼渣20 g,搅拌速度约为200 r/min)。

由表3试验结果数据可以看出,随着各因素水平的改变,B的浸出率变化不大。所以,本试验结果分析中以富硼渣中Mg的浸出率试验结果进行正交试验极差分析。分析表明:酸用量、浸出时间、浸出温度和液固比对Mg浸出率都有很大影响。极差值R的大小顺序为RC>RA>RD>RB,由此可知,影响Mg浸出率的因素由主到次顺序为浸出温度、酸用量、液固比和浸出时间。本试验中最高Mg浸出率条件为A3B2C3D2,即酸用量为理论用量的95%,浸出时间为90 min,浸出温度为99 ℃,反应液固比为6:1。99 ℃是常压下水浴所能达到的最高温度,若考虑加压浸出的话,温度进一步提高,Mg浸出率还有提高空间。

预测和验证:最佳水平被选择后,可通过灰色关联分析理论对实验结果进行预测和验证[19]。通过下面的公式来预测Mg浸出率的最优值:

(1)

(1)

式中:γm为Mg浸出率的总体平均值;γi为最优水平下Mg浸出率的平均值;q为所考察影响因素数量。通过计算,得到灰色关联度的计算值为75.06%。同时,在实验所确定的最佳富硼渣常压浸出工艺条件下进行验证,即在浸出温度99 ℃、硫酸用量为理论用量的95%、浸出液固比为6:1、浸出时间为90 min、搅拌速度约200 r/min条件下,取富硼渣20 g进行浸出试验,Mg浸出率为74.32%。实验结果和预测结果具有较好的一致性。

2.6 浸出液综合利用试验

富硼渣通过硫酸浸出得到的浸出液中主要成分为MgSO4和H3BO3,其中MgSO4含量约为20%~25%,H3BO3含量约为6%~8%。另外,还有少量的Fe3+、Fe2+、Al3+离子。图5所示为浸出液综合利用工艺的流程图。

表2 富硼渣硫酸法正交试验因素水平表

Table 2 Variables levels of orthogonal experiment during sulfuric acid leaching in B-rich slag

表3 富硼渣硫酸浸出正交试验结果

Table 3 Orthogonal experiment results of sulfuric acid leaching of B-rich slag

图5 富硼渣硫酸浸出液综合利用工艺流程

Fig. 5 Flowchart of utilizing sulfuric acid leaching solution of boron-rich slag

表4 Mg浸出率的理论预测和实验结果

Table 4 Theoretical prediction and experimental results of Mg extraction rate

实验发现,在酸浸过程中富硼渣中70%~80%的铝以Al3+形式进入到溶液里,富硼渣中的FeO有80%~90%以Fe2+转移到溶液中。Fe3、Fe2+、Al3+离子的存在影响硼酸及一水硫酸镁产品的纯度,同时Al3+离子的存在也影响溶液中硼酸含量的测定。所以,这3种离子必须要除去。用双氧水将滤液中Fe2+氧化成在Fe3+,双氧水加入量为氧化富硼渣中全部Fe2+所需双氧水量的90%。加入时伴以缓慢搅拌,使反应完全。然后,在搅拌的条件下,向溶液中加入氧化镁调节滤液的pH值,将滤液pH值调至4~5,Fe3+以Fe(OH)3形式沉淀,Al3+以Al(OH)3形式沉淀,过滤除去得到二次滤液,该过程中发生的主要化学反应为

MgO+H2SO4=MgSO4+H2O (2)

Fe3++3H2O=Fe(OH)3↓+3H+ (3)

Al3++H2O=Al(OH)3↓+3H+ (4)

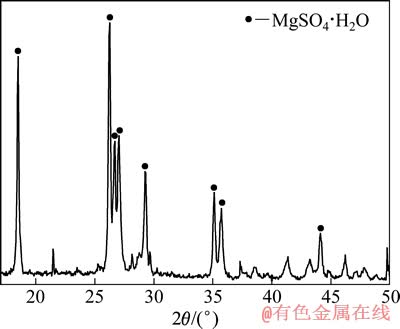

利用硫酸镁和硼酸溶解度的差异性进行B、Mg分离。得到的二次滤液温度在60~80 ℃之间,可直接将二次滤液打入高压釜进行提Mg试验。本试验将高压釜升温至180 ℃,并在此温度下恒温4 h,使一水硫酸镁充分结晶。为了过饱和溶液快速产生晶核,恒温过程中的前30 min对溶液进行搅拌,搅拌速度约为100 r/min。反应完毕后,反应液过滤,滤饼即为一水硫酸镁产品。所得滤液为三次滤液,图6所示为一水硫酸镁的XRD谱。经化学分析,其纯度达到95.42%。

图6 富硼渣硫酸法制得一水硫酸镁的XRD谱

Fig. 6 XRD pattern of MgSO4·H2O obtained from sulfuric acid leaching of B-rich slag

三次滤液在室温下结晶,得到硼酸。剩余的最终滤液含有少量的硼酸和硫酸Mg,可打入酸解工序或经蒸发浓缩进入高压釜提Mg。图7为所得硼酸产品XRD谱。图8所示为富硼渣硫酸法制得的硼酸的SEM像。由图8可见,硼酸结构为片层结构,由此方法制得的硼酸纯度为99.27%。

图7 富硼渣硫酸法制得硼酸的XRD谱

Fig. 7 XRD pattern of boric acid obtained from sulfuric acid leaching of B-rich slag

图8 富硼渣硫酸法制得硼酸的SEM像

Fig. 8 SEM image of boric acid obtained from sulfuric acid leaching of B-rich slag

本试验采用的工艺不同于一般先进行低温结晶制备硼酸,再回收利用硼酸母液的工艺。考虑到反应后的溶液经过除铁、铝步骤后,滤液温度在60~80 ℃,趁热直接进入高压釜先高温结晶提Mg,可充分利用热溶液,节约能源,若浸出液中硫酸镁浓度在25%以上,则硫酸镁一次性收率达到49.6%。提Mg后剩余母液再低温结晶硼酸,硼酸一次收率可达65.8%。最终滤液可打入富硼渣酸解体系,滤液中的硼酸和硫酸镁可进行重复回收利用。整个工艺形成闭路循环,没有废液排放。

3 结论

1) 富硼渣硫酸浸出的最佳酸解条件为:浸出温度为99 ℃,酸用量为理论用量的95%,浸出液固比为6:1,浸出时间为90 min。在此最佳条件下进行试验,B浸出率为98.76%,Mg浸出率达到74.32%。Mg浸出率的实验结果和灰色关联分析预测的结果具有较好的一致性。

2) 极差分析表明:影响Mg浸出率的因素由主到次顺序依次为浸出温度、酸用量、液固比和浸出时间。

3) 开发了富硼渣硫酸浸出液先高温结晶制取一水硫酸镁再低温结晶制备硼酸工艺,此工艺能够有效地回收富硼渣中的B、Mg资源,由此方法制得的一水硫酸镁纯度达到95.42%,硼酸纯度达99.27%。

REFERENCES

[1] 张丽清, 袁本福, 周华峰, 刘志国. 乙醇结晶法提取硼铁矿酸浸液中的硫酸镁[J]. 中南大学学报: 自然科学版, 2013, 44(7): 2681-2687.

ZHANG Li-qing, YUAN Ben-fu, ZHOU Hua-feng, LIU Zhi-guo. Extracting magnesium sulfate from acid-leaching solution of ludwigite by ethanol crystallization[J]. Journal of Central South University: Science and Technology, 2013, 44(7): 2681-2687.

[2] 龚殿婷, 李凤华, 刘素兰, 樊占国. 硼酸的生产应用现状及市场前景[J]. 化学工业与工程技术, 2007, 28(6): 50-53.

GONG Dian-ting, LI Feng-hua, LIU Su-lan, FAN Zhan-guo. Production and application status and market prospects of boric acid[J]. Journal of Chemical Industry and Engineering, 2007, 28(6): 50-53.

[3] 曹 钊, 曹永丹, 桂 富. 硼铁矿资源开发利用研究现状及进展[J]. 矿产综合利用, 2013(2): 17-19.

CAO Zhao, CAO Yong-dan, GUI Fu. Research status and progress of the exploitation and utilization of paigeite ore[J]. Multipurpose Utilization of Mineral Resources, 2013(2): 17-19.

[4] 刘 然, 薛向欣, 姜 涛, 张淑会, 黄大威. 硼铁矿综合利用概况与展望[J]. 矿产综合利用, 2006(2): 33-38.

LIU Ran, XUE Xiang-xin, JIANG Tao, ZHANG Shu-hui, HUANG Da-wei. Comprehensive utilization of ludwigite and its prospect[J]. Multipurpose Utilization of Mineral Resources, 2006(2): 33-38.

[5] DING Y G, WANG J S, WANG G, MA S, XUE Q G. Comprehensive utilization of paigeite ore using iron nugget making process[J]. Journal of Iron and Steel Research, International, 2012, 19(6): 9-13.

[6] 战洪仁, 樊占国, 姜晓峰, 李 杰, 姜 涛. 富硼高炉渣中遂安石相的析出行为[J]. 江苏大学学报: 自然科学版, 2011, 32(1): 47-50.

ZHAN Hong-ren, FAN Zhan-guo, JIANG Xiao-feng, LI Jie, JIANG Tao. Study on phase separation of suanite from boron-rich blast furnace slag[J]. Journal of Jiangsu University: Natural Science Edition, 2011, 32(1): 47-50.

[7] YANG Z D, LIU S L, LI Z F, XUE X X. Oxidation of silicon and boron in boron containing molten iron[J]. Journal of Iron and Steel Research, 2007, 14(6): 32-36.

[8] 安 静, 薛向欣, 姜 涛. 硼铁矿火法分离工艺生态压力研究[J]. 东北大学学报: 自然科学版, 2010, 31(4): 542-545.

AN Jing, XUE Xiang-xin, JIANG Tao. Ecological pressure analysis of thermometallurgical separation process of paigeite ore[J]. Journal of Northeastern University: Natural Science, 2010, 31(4): 542-545.

[9] 安庆龙, 牛秋林, 明伟伟, 陈 明. 高强度合金硼铸铁组织成分与切削性能研究[J]. 上海交通大学学报, 2012, 46 (7): 1049-1058.

AN Qing-long, NIU Qiu-lin, MING Wei-wei, CHEN Ming. Study on microstructure, chemical gradient and machinablity of high-strength alloy boron cast iron[J]. Journal of Shanghai Jiaotong University, 2012, 46 (7): 1049-1058.

[10] 巫俊斌, 姜 涛, 薛向欣, 李 江. 配料组成对富硼渣合成(Ca,Mg)α′-Sialon/BN陶瓷粉体的影响[J]. 东北大学学报: 自然科学版, 2009, 30(20): 221-237.

WU Jun-bin, JIANG Tao, XUE Xiang-xin, LI Jiang. Effect of initial composition on(Ca,Mg)α′-Sialon/BN powder synthesized from boron-rich slag[J]. Journal of Northeastern University: Natural Science, 2009, 30(20): 221-237.

[11] JIANG T, WU J B, XUE X X, DUAN P N, CHU M S. Carbothermal formation and microstructural evolution of  powders from boron-rich blast furnace slag[J]. Advanced Powder Technology, 2012, 23(3): 406-413.

powders from boron-rich blast furnace slag[J]. Advanced Powder Technology, 2012, 23(3): 406-413.

[12] JIANG T, XUE X X. Synthesis of (Ca, Mg)-α′-Sialon-AlN-BN powders from boron-rich blast furnace slag by microwave carbothermal reduction-nitridation[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2984-2990.

[13] 安 静, 薛向欣, 姜 涛. 硼铁矿火法分离过程的生命周期环境影响评价[J].过程工程学报, 2010, 10(2): 321-326.

AN Jing, XUE Xiang-xin, JIANG Tao. Life cycle environmental impact assessment of pyrometallurgical separation process of paigeite ore[J]. The Chinese Journal of Process Engineering, 2010, 10(2): 321-326.

[14] 李 杰, 樊占国. 富硼渣钠化法制备硼硼砂的实验研究[J]. 材料科学与工艺, 2011, 19(1): 144-148.

LI Jie, FAN Zhan-guo. Experimental study on preparation of borax from boron-rich slag by adding sodium carbonate[J]. Materials Science and Technology, 2011, 19(1): 144-148.

[15] 刘素兰, 陈 吉, 张显鹏. 富硼渣硫酸浸出试验研究[J]. 东北大学学报: 自然科学版, 1996, 17(4): 378-380.

LIU Su-lan, CHEN Ji, ZHANG Xian-peng. Sdudy on leaching boron-rich slag with H2SO4[J]. Journal of Northeastern University: Natural Science, 1996, 17(4): 378-380.

[16] 李 杰, 许哲峰, 李 岩, 李英楠, 姜 涛. 富硼渣盐酸法制取硼酸和氢氧化镁[J]. 中南大学学报: 自然科学版, 2012, 43(11): 4171-4176.

LI Jie, XU Zhe-feng, LI Yan, LI Ying-nan, JIANG Tao. Preparation of boric acid and magnesium hydroxide from boron-rich slag by hydrochloric acid leaching method[J]. Journal of Central South University: Science and Technology, 2012, 43(11): 4171-4176.

[17] LI Jie, FAN Zhan-guo, LIU Yan-li, LIU Su-lan, JIANG Tao, XI Zheng-ping. Preparation of boric acid from low-grade ascharite and recovery of magnesium sulfate[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1161-1165.

[18] 尹书青. 富硼渣和硬硼钙石酸解制硼酸工艺的研究. [D]. 大连: 大连理工大学, 2011.

YIN Shu-qing. Research on leaching process of boron-rich slag and colemanite by acid[D]. Dalian: Dalian University of Technology, 2011.

[19] SUBBAYA K M, SURESHA B, RAJENDRA N, VARADARAJAN Y S. Grey-based Taguchi approach for wear assessment of SiC Filled carbon-epoxy composites[J]. Materials and Design, 2012, 41:124-130.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374052);内蒙古自治区自然科学基金项目(2012MS0604)

收稿日期:2014-03-21;修订日期:2014-09-10

通信作者:李 杰,副教授,博士;电话:0471-6577297;E-mail:42069084@qq.com