Trans. Nonferrous Met. Soc. China 28(2018) 2102-2106

Grain size based low cycle fatigue life prediction model for nickel-based superalloy

Peng ZHANG1, Qiang ZHU1, Gang CHEN1, He-yong QIN2, Chuan-jie WANG1

1. School of Materials Science and Engineering, Harbin Institute of Technology at Weihai, Weihai 264209, China;

2. Central Iron & Steel Research Institute, Beijing 100081, China

Received 12 June 2017; accepted 8 September 2017

Abstract: Nickel-based superalloys are easy to produce low cycle fatigue (LCF) damage when they are subjected to high temperature and mechanical stresses. Fatigue life prediction of nickel-based superalloys is of great importance for their reliable practical application. To investigate the effects of total strain and grain size on LCF behavior, the high temperature LCF tests were carried out for a nickel-based superalloy. The results show that the fatigue lives decreased with the increase of strain amplitude and grain size. A new LCF life prediction model was established considering the effect of grain size on fatigue life. Error analyses indicate that the prediction accuracy of the new LCF life model is higher than those of Manson-Coffin relationship and Ostergren energy method.

Key words: nickel-based superalloy; low cycle fatigue; life prediction model; grain size

1 Introduction

Nickel-based superalloys have become the key materials for turbine disks in aeroengines due to excellent high temperature strength, hot corrosion resistance, high temperature oxidation resistance and fatigue resistance at elevated temperatures [1-7]. Turbine disks are subjected to the combined effects of mechanical stress and high temperature in the service condition, which can easily produce low cycle fatigue (LCF) damage [8]. A large number of investigators have arrived at a conclusion that microstructures have a significant impact on LCF behavior of nickel-based superalloys. ZHANG et al [9] established a good link between the cyclic/fatigue behavior and microstructures. The fatigue life of the alloy with fine grains is higher than that of the alloy with coarse grains at the same total strain amplitude, which indicates that grain size plays an important role in fatigue behavior. HE et al [10] investigated the effect of γ′ phase on the LCF behavior of a nickel-based superalloy. The fracture modes can be divided into three types due to the deformation of the γ′ phase at different temperatures, which contain crystallographic plane facet fracture in low temperature region, mixed fracture mode in middle temperature region and non-crystallographic fracture in high temperature region. GRIBBIN et al [11] investigated the effect of initial microstructure on LCF life of direct metal laser sintered (DMLS) Inconel 718 superalloy at room temperature. The results revealed that the role of porosity present in the DMLS specimens at low strain amplitudes is not as significant as that at high strain amplitudes. Furthermore, a high content of annealing twins present in the hot isostatic pressing (HIP) material microstructure has a larger effect on shortening the life of the samples than porosity. ZHANG et al [12] investigated the effect of volume fraction of δ phase on the strain-controlled LCF behavior of nickel-based GH4169 alloys at room temperature. The results showed that fatigue life increased with increasing volume fraction of δ phase. QIN et al [13] identified the mechanism of multi-scale fatigue crack propagation of nickel-based alloy GH4169 with different grain sizes by using the specimens with micro-notches. The results indicated that grain size effect on the growth rate of small crack could not be distinguished due to the fluctuation of crack growth rate and the small fatigue crack stage accounted for a larger fraction of the total fatigue life for the specimen with finer grain size.

The LCF life prediction is of great significance for the practical application of nickel-based superalloys. Manson-Coffin relationship [14-16] and Ostergren energy method [17] are always used to predict LCF life. As described above, microstructures of nickel-based superalloys have a significant impact on their LCF behaviors. However, the effect of grain size on fatigue life is not included in these two fatigue life models. In this work, LCF tests were carried out under the condition of different strain amplitudes for nickel-based superalloys with different grain sizes. Considering the effects of fatigue limit and grain size on fatigue resistance, a new LCF life prediction model was established.

2 Experimental

The chemical composition (mass fraction, %) of GH4698 superalloy was as follows: C 0.042, Cr 14.50, Mo 3.18, Al 1.70, Ti 2.68, Fe <0.10, Nb 2.02, and Ni the rest. Two kinds of heat treatment procedures were shown as follows:

(1) ((1050 °C, 8 h) + AC) + ((1000 °C, 4 h) + AC) + ((775 °C, 16 h) + AC) + ((700 °C, 16 h) + AC);

(2) ((1100 °C, 8 h) + AC) + ((1000 °C, 4 h) + AC) + ((775 °C, 16 h) + AC) + ((700 °C, 16 h) + AC).

The fatigue specimens selected from heat-treated specimens were machined into 6.350 mm in diameter and 16 mm in gauge length. LCF tests were carried out on an MTS 810 fatigue testing machine (MTS Systems Corporation, Eden Prairie, MN, USA) in air. Experimental program was total axial strain-controlled from 0.3% to 0.8% at constant temperature of 650 °C. The strain ratio was R=-1 and the loading frequency was 0.50 Hz. The fatigue specimens were mechanically ground, polished and chemically etched so as to observe the grain morphology of the GH4698 superalloy by Olympus microscope. The size of the grains was calculated using the intercept method.

3 Modeling of grain size based low cycle fatigue life

A large number of studies demonstrate that there is a linear function relationship between fatigue life and total strain amplitude in double logarithmic coordinates, which is shown in Fig. 1 [18-20]. Therefore, it can be obtained that there is a power function relationship between fatigue life and total strain amplitude in Cartesian coordinates. It can be illustrated as follows:

Nf=m(△εt-b)-n (1)

where Nf is the fatigue life; △εt is the total strain amplitude; b, m and n are material constants to be determined and their values are positive. It can be obtained through the mathematical model that n value determines the rate of change in fatigue life Nf with total strain amplitude △εt and m value influences the order of magnitude of fatigue life Nf.

Fig. 1 Total strain amplitude versus fatigue life

In Eq. (1), Nf will approach infinity when △εt approaches b. It is well known that the alloy may be subjected to unlimited fatigue cycles without fatigue fracture when the applied stress is lower than fatigue limit during fatigue process [21]. It can be inferred that fatigue limit is equivalent to elastic limit. Thus, it can be inferred that b is able to be calculated as follows:

(2)

(2)

where ε-1 is the elastic strain limit; σ-1 is the fatigue limit; and E is the elastic modulus.

Then, Eq. (1) can be shown as follows:

(3)

(3)

As for nickel-based alloys, there is a certain proportional relationship between fatigue limit and tensile strength [22]. Fatigue limit can be described as follows:

σ-1=Pσb (4)

where P is the scale factor; and σb is the tensile strength.

Studies have illustrated that a similar Hall-Patch relationship occurs between tensile strength and grain size [23-25]. Tensile strength can be interpreted as follows:

σb=σb0+kbd-1/2 (5)

where σb0 is the friction stress; kb is a factor related to the alloy; and d is the mean grain size.

Above all, a new fatigue life prediction model considering the effect of grain size on LCF fatigue behavior is established, which is demonstrated as follows:

(6)

(6)

4 Results and discussion

4.1 Parameters determination of grain size based low cycle fatigue life prediction model

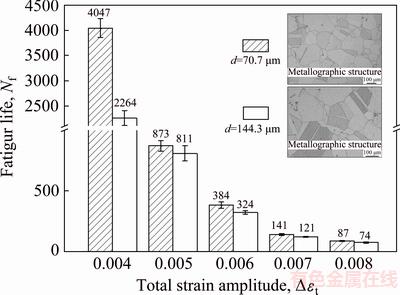

The relationship between the fatigue life and total strain amplitude is shown in Fig. 2 for the alloys with different grain sizes, in which the upper right corner shows the metallographic diagrams. It can be found that fatigue life rapidly decreased with the increase of total strain amplitude. This indicates that the effect of total strain amplitude on LCF behaviors is very significant. When the alloy is subjected to small total strain, it possesses better LCF properties. In addition, the fatigue life of the alloy with grain size of 70.7 μm is higher than that of the alloy with grain size of 144.3 μm at the same total strain amplitude. This shows that microstructures of nickel-based superalloys especially grain size have a significant impact on their LCF lives. In addition, it can be inferred that the tested superalloy with finer grain possesses more excellent fatigue resistance than that with coarser grain.

Fig. 2 Relationship between fatigue life and total strain amplitude for alloys with different grain sizes

The experimental determination shows that elastic modulus of the alloy at 650 °C is 178 GPa. In addition, the relationship between tensile strength and grain size of the alloy is shown as follows:

σb=1096.85+186.70d-1/2 (7)

As for the nickel-based alloys, the relationship between tensile strength and fatigue limit is shown as follows [26]:

σ-1=0.35σb (8)

The new LCF life prediction model can be obtained according to Eqs. (6)-(8):

Nf=m(△εt-3.6710×10-4d-1/2-2.1567×10-3)-n (9)

The relationship among the fatigue life of the alloy, the total strain amplitude and grain size was fitted according to Eq. (9). The results are as follows:

Nf =2.49552×10-5·(△εt-3.6710×10-4d-1/2-2.1567×10-3)-2.93617 (10)

4.2 Prediction accuracy analysis

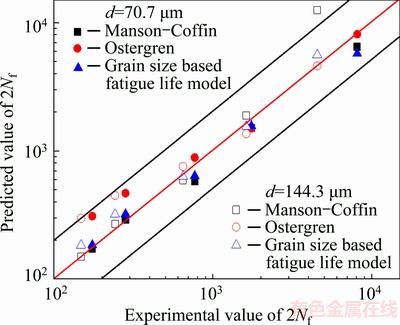

In order to analyze the prediction accuracy of the grain size based fatigue life model, the comparison of fatigue life prediction values and experimental values is illustrated in Fig. 3. The prediction accuracies of Manson-Coffin relationship and Ostergren energy method are also analyzed. It represents a high forecast accuracy that the prediction values are closer to the red line. Two parallel black lines represent two-fold safety factor specified dispersing band. It can be observed that fatigue life predicted values of the grain size based LCF life model are all within two-fold safety factor specified dispersing band, which indicates that the prediction accuracies are high. However, a few fatigue life predicted values of Manson-Coffin relationship and Ostergren energy method are out or on the two-fold safety factor specified dispersing band, which indicates that their prediction accuracies are low.

Fig. 3 Comparison of predicted and experimental fatigue lives

The error analysis method is used to assess the predicted accuracy of LCF life models, which is shown as follows:

Err=lg(Np/Ne) (11)

where Np is the predicted value of LCF life; Ne is experimental value of LCF life; and Err is the error.

Error analysis results of prediction accuracy for LCF life models are shown in Table 1. As for Manson-Coffin relationship, the error of prediction accuracy is up to 44.13% at the total strain amplitude of 0.004 for the alloy with grain size of 144.3 μm. As for Ostergren energy method, the errors of prediction accuracy are up to 21.88% and 24.95% at the total strain amplitudes of 0.007 and 0.008 respectively for the alloy with the grain size of 70.7 μm. In addition, the errors of prediction accuracy are up to 26.81% and 30.23% at the total strain amplitudes of 0.007 and 0.008 respectively for the alloy with grain size of 144.3 μm. However, as for the grain size based fatigue life model, the biggest error of prediction accuracy is 15.07% at the total strain amplitude of 0.004 for the alloy with grain size of 70.7 μm. A conclusion can be drawn that the prediction accuracies of the grain size based fatigue life model are higher than those of Manson-Coffin relationship and Ostergren energy method, which is consistent with the analysis in Fig. 2. The reasons are as follows: (1) △εt will approach zero when Nf approaches infinity in Manson-Coffin relationship because Manson-Coffin relationship does not take the effect of fatigue limit on fatigue life into consideration; (2) Ostergren energy method ignores the deformation damaging that is caused by σ<σ0, where σ equals the gross stress and σ0 equals a positive constant; (3) Manson-Coffin relationship and Ostergren energy method do not consider the effect of grain size on fatigue life. However, both the effects of fatigue limit and grain size on fatigue life have been considered in the grain size based fatigue life model.

Table 1 Error analysis results of prediction accuracy for LCF life models

Manson-Coffin relationship and Ostergren energy method cannot predict fatigue lives for alloys with different grain sizes under the condition of different total strain amplitudes until the LCF tests are respectively conducted. It will undoubtedly increase extensive consumption of materials and cost of LCF tests. However, the grain size based fatigue life prediction model can predict fatigue lives for alloys with different grain sizes, which only needs a small amount of LCF tests. It can be inferred that the grain size based fatigue life prediction model possesses higher prediction accuracy and wider applicability.

5 Conclusions

1) Total strain-controlled LCF tests were investigated for GH4698 superalloy with different grain sizes. A new LCF life prediction model has been established, which considers the effect of grain size on fatigue life.

2) The LCF behavior is influenced by the material microstructure especially the grain size and applied total strain amplitude. The fatigue lives rapidly decreased with the increase of total strain amplitude. The fatigue resistance of fine-grain superalloy is higher than that of coarse-grain superalloy.

3) The grain size based LCF life prediction model possesses high prediction accuracy. It can predict fatigue life for the alloy with different grain sizes based on a few experiments.

References

[1] LONG Yi-tong, NIE Pu-lin, LI Zhu-guo, HUANG Jian, LI Xiang, XU Xin-mei. Segregation of niobium in laser cladding Inconel 718 superalloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 431-436.

[2] ZHANG Peng, ZHU Qiang, CHEN Gang, WANG Chuan-jie. Review on thermo-mechanical fatigue behavior of nickel-based superalloys [J]. Materials Transactions, 2015, 56(12): 1930-1939.

[3] ZHANG Peng, HU Chao, DING Chao-gang, ZHU Qiang, QIN He-yong. Plastic deformation behavior and processing maps of a Ni-based superalloy [J]. Materials & Design, 2015, 65: 575-584.

[4] LIN Yong-cheng, DENG Jiao, JIANG Yu-qiang, WEN Dong-xu, LIU Guan. Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy [J]. Materials & Design, 2014, 55: 949-957.

[5] LIN Yong-cheng, HE Min, CHEN Ming-song, WEN Dong-xu, CHEN Jian. Effects of initial δ phase (Ni3Nb) on hot tensile deformation behaviors and material constants of Ni-based superalloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 107-117.

[6] SHI Zhao-xia, YAN Xiao-feng, DUAN Chun-hua, ZHAO Ming-han. Effect of strain rate on hot deformation characteristics of GH690 superalloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(3): 538-550.

[7] MALEKI V, OMIDVAR H, RAHIMIPOUR M. Effect of gap size on microstructure of transient liquid phase bonded IN-738LC superalloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 437-447.

[8] ZHANG Peng, ZHU Qiang, HU Chao, WANG Chuan-jie, CHEN Gang, QIN He-yong. Cyclic deformation behavior of a nickel-base superalloy under fatigue loading [J]. Materials & Design, 2015, 69: 12-21.

[9] ZHANG Peng, ZHU Qiang, CHEN Gang, QIN He-yong, WANG Chuan-jie. Effect of heat treatment process on microstructure and fatigue behavior of a nickel-base superalloy [J]. Materials, 2015, 8(9): 6179-6194.

[10] HE Zhi-wu, ZHANG Yang-yang, QIU Wen-hui, SHI Hui-ji, GU Jia-lin. Temperature effect on the low cycle fatigue behavior of a directionally solidified nickel-base superalloy [J]. Materials Science and Engineering A, 2016, 676: 246-252.

[11] GRIBBIN S, BICKNELL J, JORGENSEN L, TSUKROV I, KNEZEVIC M. Low cycle fatigue behavior of direct metal laser sintered Inconel alloy 718 [J]. International Journal of Fatigue, 2016, 93: 156-167.

[12] ZHANG Xian-cheng, LI Hai-cong, ZENG Xu, TU Shan-tung, ZHANG Cheng-cheng, WANG Qiang-qi. Fatigue behavior and bilinear Coffin-Manson plots of Ni-based GH4169 alloy with different volume fractions of δ phase [J]. Materials Science and Engineering A, 2017, 682: 12-22.

[13] QIN Cheng-hua, ZHANG Xian-cheng, YE Shen, TU Shan-tung. Grain size effect on multi-scale fatigue crack growth mechanism of nickel-based alloy GH4169 [J]. Engineering Fracture Mechanics, 2015, 142: 140-153.

[14] MANSON S S. Fatigue: A complex subject—Some simple approximation [J]. Experimental Mechanics, 1965, 5: 193-226.

[15] COFFIN L F. A study of the effects of cyclic thermal stresses on a ductile metal [J]. Transactions of American Society of Mechanical Engineers, 1954, 76: 931-950.

[16] BASQUIN O H. The exponential law of endurance tests [J]. Proceedings of American Society for Testing and Materials, 1910, 10: 625-630.

[17] OSTERGREN W J. A damage foundation hold time and frequency effects in elevated temperature low cycle fatigue [J]. Journal of Testing and Evaluation, 1976, 4: 327-339.

[18] ZHENG Cheng-kun, ZHANG Wei-wen, ZHANG Da-tong, LI Yuan-yuan. Low cycle fatigue behavior of T4-treated Al-Zn-Mg-Cu alloys prepared by squeeze casting and gravity die casting [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3505-3514.

[19] LEE D, SHIN I, KIM Y, KOO J M, SEOK C S. A study on thermo mechanical fatigue life prediction of Ni-base superalloy [J]. International Journal of Fatigue, 2014, 62(2): 62-66.

[20] YU Jin-jiang, HAN Guo-ming, CHU Zhao-kuang, SUN Xiao-feng, JIN Tao, HU Zhuang-qi. High temperature thermo-mechanical and low cycle fatigue behaviors of DD32 single crystal superalloy [J]. Materials Science and Engineering A, 2014, 592: 164-172.

[21] LORENZINO P, OKAZAKI S, MATSUNAGA H, MURAKAMI Y. Effect of small defect orientation on fatigue limit of carbon steels [J]. Fatigue & Fracture of Engineering Materials & Structures, 2015, 38(9): 1076-1086.

[22] FROST N E, MARSH K J, POOK L P. Metal fatigue [M]. New York: Courier Corporation, 1974: 40-48.

[23] MARCINKOWSKI M J, LIPSITT H A. The plastic deformation of chromium at low temperatures [J]. Acta Metallurgica, 1962, 10(2): 95-111.

[24] ARMSTRONG R, CODD I, DOUTHWAITE R M, PETCH N J. The plastic deformation of polycrystalline aggregates [J]. Philosophical Magazine, 1962, 7: 45-58.

[25] CONRAD H, SCHOECK G. Cottrell locking and the flow stress in iron [J]. Acta Metallurgica, 1960, 8(11): 791-796.

[26] GROVER H J, GORDON S A, JACKSON L R. Fatigue of metals and structures [M]. London: Bureau of Aeronautics, Department of the Navy, 1954.

基于晶粒尺寸的镍基高温合金低周疲劳寿命预测模型

张 鹏1,朱 强1,陈 刚1,秦鹤勇2,王传杰1

1. 哈尔滨工业大学(威海) 材料科学与工程学院,威海 264209;

2. 钢铁研究总院,北京 100081

摘 要:镍基高温合金在承受高温和机械应力时很容易产生低周疲劳损伤,疲劳寿命预测对于镍基高温合金的实际应用是非常重要的。为了研究总应变和晶粒尺寸对镍基高温合金低周疲劳行为的影响,本文作者对一种镍基高温合金进行高温低周疲劳试验。结果表明,合金的疲劳寿命随应变振幅和晶粒尺寸的增加而减小。建立一个考虑晶粒尺寸对疲劳寿命影响的低周疲劳寿命预测模型。误差分析表明,低周疲劳寿命模型的预测精度高于Manson-Coffin和Ostergren能量法模型的预测精度。

关键词:镍基高温合金;低周疲劳;寿命预测模型;晶粒尺寸

(Edited by Wei-ping CHEN)

Foundation item: Project (51575129) supported by the National Natural Science Foundation of China; Project (J15LA51) supported by Shandong Province Higher Educational Science and Technology Program, China; Project (2017T100238) supported by China Postdoctoral Science Foundation

Corresponding author: Chuan-jie WANG, Tel: +86-631-5687324; E-mail: cjwang@hitwh.edu.cn

DOI: 10.1016/S1003-6326(18)64854-X