文章编号:1004-0609(2014)10-2497-09

基于响应面法优化激光选区熔化成型CoCrMo合金工艺及其电化学行为

王赟达1,杨永强1,宋长辉1,刘凤美2,麦淑珍1

(1. 华南理工大学 机械与汽车工程学院,广州 510640;

2. 广州有色金属研究院,广州 510650)

摘 要:为了快速直接制造结构复杂、性能优异的个性化医用金属植入体,保证成型件具有良好的组织结构和生物特性,通过激光选区熔化技术对满足ASTMF75要求的CoCrMo合金进行增材制造。通过正交试验和响应曲面设计方法优化致密度工艺参数,观察成型件的微观组织,分析试样在模拟人体体液环境中的耐腐蚀性,并探究热处理工艺对其耐腐蚀性的影响。结果表明:在激光功率168 W、扫描间距0.06 mm、扫描速度550 mm/s时,成型零件的致密度可以达到98.58%,且微观组织均匀。电化学实验结果显示试样的腐蚀电流密度值约为40 μA/cm2,经过退火热处理后,腐蚀电流密度仅为20.86 μA/cm2,其耐腐蚀性能优于铸造CoCrMo合金的,这为选区激光熔化成型CoCrMo合金在医学植入体方面的应用提供了依据。

关键词:CoCrMo合金;激光选区熔化;致密度;响应曲面;耐腐蚀性;热处理

中图分类号:TG665;TH164 文献标志码:A

Process optimization and electrochemical behavior of CoCrMo alloy fabricated by selective laser melting based on response surface method

WANG Yun-da1, YANG Yong-qiang1, SONG Chang-hui1, LIU Feng-mei2, MAI Shu-zhen1

(1. School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China;

2. Guangzhou Research Institute of Nonferrous Metals, Guangzhou 510650, China)

Abstract: In order to directly fabricate personalized medical metallic implants with complex structure and excellent properties and ensure the parts have good microstructure and biological characteristics, the CoCrMo alloy satisfying the requirement of ASTMF75 is fabricated by selective laser melting (SLM) technology. The parameters of relative density were optimized by orthogonal experiment and response surface design. The microstructure of the specimens was observed, and the corrosion characteristic of the samples in simulated body fluid environment was analyzed while the influence of heat treatment process on the corrosion resistance was explored. The results show when the laser power is 168 W, the scanning space is 0.06 mm and the scanning speed is 550 mm/s, the relative density of CoCrMo alloy samples fabricated by SLM can reach 98.58%, and the microstructure is homogeneous. The electrochemical experimental results demonstrate that the corrosion current density value of the sample is about 40 μA/cm2, and becomes only 20.86 μA/cm2 after annealing heat treatment. The corrosion resistance is better than that of fabricated by casting methods, which provides the basis for the application of CoCrMo alloy directly fabricated by SLM in medical implants.

Key words: CoCrMo alloy; selective laser melting; relative density; response surface; corrosion characteristic; heat treatment

增材制造技术(Additive manufacturing,AM)是近些年来新发展起来的一种先进制造工艺,而激光选区熔化(Selective laser melting,SLM)是一种基于激光熔化金属粉末的增材制造技术[1],采用增材制造的基本原理,即先采用计算机设计出零件的三维模型,然后,通过专用软件对三维模型进行切片分层,得到截面的轮廓数据,然后导入快速成型设备,设备根据轮廓数据,控制激光束选择性地熔化各层的金属粉末,逐步堆叠成三维金属零件[2]。与传统的加工方法相比,SLM技术的优势在于能直接制造具有高精度、复杂几何结构、组织致密、机械性能良好的金属零件[2-3]。

SLM技术因其独特的优势,在医学植入体领域逐步得到认可,已经开始用于成型人体的骨骼(如颚骨、颅骨、脊椎等)、软组织(胃、膀胱等)以及手术定位导航模板等[4-5]。铸造CoCrMo合金在人工关节方面的应用开始于 20 世纪30年代,到如今CoCrMo合金仍被认为是最可靠的金属生物兼容性材料之一[6-8],由于其适宜的价格和良好的力学性能,已经在外科植入体以及牙科修复等领域得到了广泛应用[9]。而医用金属材料要满足临床应用,其首要条件是要具备生物相容性和生物安全性,基于生物相容性以及金属离子的毒性等多方面考虑,对医用金属材料耐腐蚀性的研究是必不可少的[10]。

VANDENBROUCKE 等[11]从复杂几何结构的角度研究SLM成型医用植入体的可能性,提到通过优化参数可以使得成型硬度、耐腐蚀性和成型精度完全满足临床要求。TAKAICHI等[12]在牙科领域开展CoCrMo合金成型工艺研究,表明CoCrMo合金是一种具有巨大应用前景的医用植入材料。MARECI等[13]应用电化学实验的方法对CoCr合金作为牙科修复体材料的耐腐蚀特性及生物相容性进行了研究,阐明了钴铬合金优越的生物特性。AVERYANOVA等[14]开展CoCr合金的牙冠固定桥的激光选区熔化制造研究。JEVREMOVIC等[15]也对SLM直接制造的可摘除义齿的适用性进行研究,并对SLM成型F75钴铬合金的相关性能进行了测试。

而在SLM成型过程中,金属零件的致密度是最受关注的问题之一,零件内部孔隙的大小直接影响成型件的性能和微观结构,通常情况下激光功率、扫描速度、扫描间距、层厚以及扫描策略对成型质量影响较大[16]。国内外研究人员从改变粉末特性、层间扫描策略、成型室保护气氛围、抑制球化现象等多个方面进行改善SLM成型致密度的研究[17-18]。

但是国内对SLM成型高致密度CoCrMo合金的工艺研究比较少,对耐腐蚀性的研究报告更是甚少。本研究为了获取高致密度高性能的CoCrMo合金成型件,创新性地通过正交试验和响应曲面分析方法优化致密度成型工艺参数,然后结合热处理工艺探究成型件的耐腐蚀性能,将实验结果与传统铸件进行对比,为CoCrMo合金SLM直接制造应用提供了重要依据。

1 实验

1.1 实验设备

实验采用的SLM设备为华南理工大学自主研发的DiMetal-100成型机(见图1),核心部分包括光纤激光器、光路传输单元、密封成型室(包括铺粉机构)、控制系统和工艺软件等。采用SPI连续式200 W光纤激光器,激光的聚焦光斑直径约为70 μm,波长1075 nm,光束质量因子M2≤1.1;振镜式激光扫描,扫描速度10~7000 mm/s;铺粉厚度为20~50 μm;成型最大体积为100 mm×100 mm×120 mm;成型室充入氮气或氩气作为保护气,含氧量可控制在0.1%以下。

图1 SLM 成型原理图及装置图

Fig. 1 SLM manufacturing principle(a) and apparatus(b)

1.2 实验材料

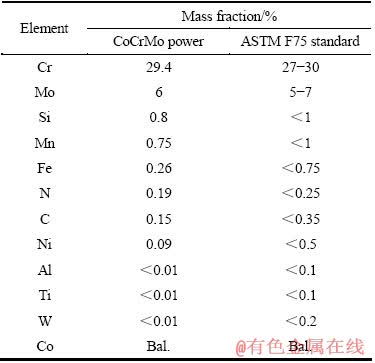

成型材料为英国SANDVIK osprey公司生产的CoCrMo合金金属粉末,成分满足ASTM F75要求,其成分对比如表1所列。粉末以气雾化方式制备,呈球形,如图2所示,其中粒度分布为窄区集中分布,90%的粒径小于22 μm,粉末的平均粒径D50小于28.5 μm。

表1 SLM成型所用粉末材料与ASTM F75标准对比

Table 1 Comparison of powder material manufactured by SLM and ASTM F75 standard

图2 CoCrMo金属粉末微观形貌

Fig. 2 Microphology of CoCrMo metal powder

1.3 实验方法

1.3.1 致密度工艺探究

表2 三因素正交实验设计

Table 2 Design of orthogonal experiment with three factors

表3 Box-Behnken响应曲面设计实验

Table 3 Response surface experiment of Box-Behnken design

影响SLM成型致密度的因素很多,但是考虑的因素不同,建立的模型也各不相同。本研究在课题组前期对316L工艺研究的基础上[16],优选扫描策略为邻层错开隔层正交的方式,加工层厚为0.03 mm。从众多影响致密度的因素中,选取最为关键的激光功率、扫描速度和扫描间距3个因素对CoCrMo合金成型致密度进行工艺探究。首先通过三因素正交试验对一个个孤立的实验点进行分析,探究各因素对CoCrMo合金成型致密度的影响趋势,确定实验因素的合理性;然后通过BBD响应曲面设计方法连续地对实验的各个因素水平进行分析,通过对实验结果进行回归拟合寻求致密度工艺参数的最优化组合,其中析因部分试验次数为12次,中心点重复试验次数为3次,两次实验的方案如表2和3所示。通过 Dimetal-100 SLM成型设备成型10 mm×10 mm×8 mm的CoCrMo合金试样,并且利用排水法测定试样的实际密度ρ,实验采用的分析天平型号为BSA224S,称量精度为1 mg。实际密度的计算公式如下:

(1)

(1)

式中: 为试样在水中的质量;

为试样在水中的质量; 为试样在空气中的质量;

为试样在空气中的质量; 为水的密度(1.0 g/cm3)。试样的实际密度

为水的密度(1.0 g/cm3)。试样的实际密度 与CoCrMo合金的理论密度

与CoCrMo合金的理论密度 (8.29 g/cm3)比值即为成型试样的致密度

(8.29 g/cm3)比值即为成型试样的致密度 (相对密度),

(相对密度),

。

。

采用优化后的工艺参数成型高致密度的CoCrMo合金试样,取4组试样编号为a、b、c、d,其中试样a、c的尺寸参数为1 cm×1 cm×1 cm,试样b、d尺寸参数为0.8 cm×0.8 cm×1 cm。设置热处理对照组,对试样c、d两组试样进行热处理工艺,退火温度1200 ℃,保温一段时间后炉冷。

1.3.2 电化学实验及热处理

选取优化后的工艺参数成型高致密度的CoCrMo合金试样。设置热处理对照组,对部分试样进行热处理工艺,退火温度1200 ℃,保温一段时间后炉冷。完成镶样并用光学显微镜检查镶嵌的密封性,选取密封性良好的试样,对其下表面依次用400号、800号、1200号的水砂纸进行打磨并抛光,将试样放在乙醇和去离子水中浸泡,5 min后干燥处理。

电化学实验使用CHI660D电化学工作站,在室温静态环境中进行,腐蚀介质采用0.9%(质量分数)的NaCl溶液。实验过程采用三电极体系[19-20],以饱和的甘汞电极为参考电极(SCE),铂电极为对电极,CoCrMo合金试样为研究电极,重点测量每一组试样的开路电位和动电位极化曲线。

2 结果与分析

2.1 致密度优化分析

2.1.1 正交试验结果分析

通过测得的致密度数据,进行直观分析可以得到,激光功率为170 W,扫描间距为0.06 mm,扫描速度为500 mm/s时,CoCrMo合金成型致密度为最高值96.98%,对正交试验的结果进行极差分析且通过F检验得到3个因素的影响水平均为显著。由此可以断定,激光功率、扫描速度、扫描间距3个因素均为影响成型致密度的重要因素,正交试验的极差分析结果如图3所示。

图3 正交试验极差分析因素对成型致密度影响

Fig. 3 Effects of fabrication factors on relative density of sample

通过正交实验结果可以得到,在选定的参数范围内,3个因素对CoCrMo合金成型致密度的影响趋势如下:随着激光功率的增加,致密度总体上呈上升趋势,表明在130~170 W的参数范围内,输入的能量使粉末能够完全熔化并逐步填补成型孔隙,提高成型致密度。而激光功率过大或过小均会影响能量的输入,使得粉末熔化不完全或者热应力过大,从而影响粉末的致密度。

随着扫描间距的增加,CoCrMo合金成型致密度总体上呈下降趋势,但是下降速率不同,当扫描间距从0.06 mm增加到0.08 mm时,致密度下降缓慢;而当扫描间距从0.08 mm增加到0.1 mm时,致密度下降速率明显加快。从熔道搭接的角度来分析,根据成型过程中扫描间距与熔道宽度的关系,如图4(阴影部分为熔道搭接区域),可以得到搭接率的计算公式:

(2)

(2)

式中: 表示熔道搭接率;s表示扫描间距;D表示熔池宽度。

表示熔道搭接率;s表示扫描间距;D表示熔池宽度。

图4 扫描间距s与熔道宽度D的关系

Fig. 4 Relationship between scanning space (s) and melting road width (D)

成型的熔池宽度与激光光斑直径d相关(一般D为1.5d ),实际过程中激光光斑往往为确定值,因此,可以通过调节扫描间距的大小来改变熔道的搭接率。当扫描间距在合适的范围内时,熔道与熔道之间搭接面积适宜、效果良好,激光束能量叠加后,使熔道表面能量分布均匀,熔化线深度均匀,成型致密度良好。

随着扫描速度的增加,致密度亦有下降趋势,这是由于随着扫描速度的增加,激光束停留在粉末上的时间变短,使得单位面积上的粉末在瞬间吸收的能量变小,导致熔化不充分,影响致密性,同时,熔池内的液相较少,不足以填补成型中的孔隙,也会对致密度造成影响。如果扫描速度过低,也会使得液相过多,热影响区域过于集中,形成球化现象,不利于改善成型的致密度。

2.1.2 响应曲面实验结果分析

正交试验并不能准确分析各参数连续变化时对成型致密度的影响,但通过正交试验法已经初步断定3个因素对致密度均有影响,且选取的参数可以获得较高的成型致密度,有理由断定在此参数范围内存在最优组合可以获得更高的成型致密度,因此,通过响应曲面设计方案进行拟合分析,确定预测的响应最优值以及相应的实验条件。

通过Design-expert软件对实验结果进行对比建模,选择最佳的拟合模型为完整的二次多项式,可以得到关于致密度的回归方程为

K=0.9178+0.024×A-0.0152×B-0.0114×C-0.008×

A×B+0.0121×A×C-0.0021×B×C+0.0175×A2+

0.00073×B2+0.0052×C2 (3)

式中:A、B、C分别代表激光功率、扫描间距、扫描速度。

方差分析结果取P<0.05为显著项,发现A、B、C、AB、AC、A2均为显著项,进一步表明了3个因素都对致密度都有重要影响,且影响因素之间确实存在交互作用,而拟合结果中失拟项的值为4.34,表明该方程的拟合效果很好,能够比较真实地反映实际问题。为了获得更加精确的结果,对模型进行手动优化,去掉不显著项B2和C2,虽然BC项不显著,但是认为扫描速度与扫描间距对致密度的影响是存在交互作用的,因此,保留BC项。结合实际情况,由于在实验的加工过程中,对于激光功率和扫描速度的调整更加方便,因此强化这两个因素在拟合结果中的重要性,手动增加因子A2C,所得结果的失拟值为5.07,模型更加精确,而此时得到的关于致密度的新的回归方程为

K=0.9212+0.024×A-0.0152×B-0.0092×C-

0.008×A×B+0.0121×A×C-0.0021×B×C+

0.0171×A2-0.0044×A2×C (4)

针对拟合结果,结合残差分析以及数据点的分布规律从更加直观的角度对所得的致密度回归方程进行检验,通过残差的正态概率分布图(见图5)可以看出,所有散点近似线性地分布在直线周围,因此,可以认为残差的分布近似符合正态分布,通过拟合曲线对致密度的预测值与实验的实测值进行对比(见图6)可以看出,二者之间的偏差很小,分布图上的点近似呈一条直线分布,这进一步表明了拟合结果是满足实际要求的,所得到的回归方程的可信度较高。

图5 残差正态概率分布图

Fig. 5 Probability distribution of residual

图6 致密度的预测值与实测值的比较

Fig. 6 Comparison of predicted and actual values of relative density

为了得到更高的CoCrMo合金成型致密度,继续对实验参数进行优化,通过前面的正交试验的理论分析得知扫描间距越小,致密度越高,但此过程必须考虑热应力的影响,控制熔道搭接率不能过高,否则,将会产生过量液滴,导致熔体聚集,不利于改善致密度和表面形貌。该实验中通过计算得到扫描间距为0.06 mm时的熔道搭接率约为42.5%,范围适宜,因此,可以在此基础上进行优化。结合回归方程,选取扫描间距为0.06 mm,在此参数下连续地改变激光功率和扫描速度,探究此时致密度的变化趋势。通过响应曲面分析,可以明显地看出通过合理地选择参数范围,成型致密度可以达到98%以上,如图7所示。同样,选取扫描速度或激光功率为一固定值时,通过改变另外两个因素依然可以获得较高的成型致密度,这也验证了在成型过程中因素之间的交互作用是不可忽略的,任何一个因素的连续变化都可以对致密度产生较大的影响。

通过对各因素水平之间形成的响应曲面进行分析,可以直接在三维曲面上获得因素的响应值以及该参数下所获得的致密度,为了达到最终目的,获得更高的成型致密度,需要对响应曲面进行优化分析。选取致密度为优化因子,在实验参数范围内对图7所表示的响应曲面进行寻优,优化结果如图8所示,最终得到:采用激光功率为168 W,扫描速度为550 mm/s,扫描间距为0.06 mm时,能使成型致密度达到98.6%,并通过工艺得到验证。

2.1.3 显微组织观察

图7 SLM成型CoCrMo合金成型致密度的响应曲面

Fig. 7 Response surface of relative density of SLM CoCrMo alloy

图8 SLM成型CoCrMo合金致密度参数优化结果

Fig. 8 Optimization results of relative density parameters of SLM CoCrMo alloy

图9 SLM成型CoCrMo合金的显微组织

Fig. 9 Microstructures of SLM CoCrMo alloy

通过金相显微镜观察成型件正面形貌以及侧面形貌,如图9所示。由图9可以看出,SLM成型件正面CoCrMo合金组织结构均匀,层与层之间结合致密,鲜有孔洞;在成型件侧面可以看到相邻的熔道成型高低有差异且在同一熔道中也出现起伏现象,这是由于采用邻层错开隔层正交的扫描方式,激光束在扫描第N+1层时,扫描线恰好处于第N层的两条熔道之间。同时,由于加工过程中的误差因素会导致同一层的不同区域成型层厚不同所致,这也会使得成型熔道不平整。但总体上看,成型熔道与熔道之间、层与层之间熔合线搭接紧密,润湿效果良好。

2.2 耐腐蚀性能分析

在优化后的工艺参数下成型高致密度的CoCrMo合金试样,首先将试样进行自腐蚀实验,每个试样测定3次,观察开路电位随时间的变化,随着时间的推移,电位值逐步趋于稳定,1 h后得到SLM成型CoCrMo合金试样的开路电位值如表4所列。然后测量几组试样的塔菲尔动电位极化曲线,实验参数设置如下:灵敏度设为自动,静置时间设置为5 s,扫描速度为5 mV/s,电位范围设为-1.0~1.0 V,测量结果如图10所示。由图10可看出,所得曲线特征明显,符合塔菲尔曲线的变化趋势,表明实验结果的科学性。

在腐蚀过程中,腐蚀体系进行电化学反应时的阳极反应的电流密度以Ja表示,阴极反应的速度以Jk表示,当体系达到稳定时,金属处于自腐蚀状态,Ja=Jk=Jcorr(Jcorr为腐蚀电流密度),体系不会有净的电流积累,处于稳定电位φ。根据法拉第定律,即在电解过程中,阴极上还原物质析出的量与所通过的电流强度和通电时间成正比,因此,可以用阴阳极反应的电流密度代表阴阳极反应的腐蚀速度,而金属自腐蚀状态的腐蚀电流密度即代表了金属的腐蚀速度。

利用电化学工作站的曲线分析软件对极化曲线测量结果进行特殊分析,测定腐蚀电流值并计算腐蚀电流密度,所得的数据结果如表4所列。而铸造的CoCrMo合金在同浓度溶液中的开路电位一般为-600~-400 mV,腐蚀电流密度大约为60 μA/cm2[21]。结合表中数据可以看出,在相同条件下,SLM成型CoCrMo合金的开路电位与铸造的CoCrMo合金相比差值不明显,但前者的腐蚀电流密度小于后者的,这表明SLM成型CoCrMo合金具有更好的耐腐蚀性能,可以满足医用植入体要求;将表中前两组与后两组数据进行对比可以得出,经过退火处理后,样件的腐蚀电流密度减小,这是由于在退火处理过程中,成型件内部晶粒细化,组织更加均匀,逐步趋于平衡,消除了成型过程中所产生的内应力,使样件的整体性能得到了改善,也进一步表明了热处理工艺可以提高SLM成型CoCrMo合金的耐腐蚀性能。

图10 SLM成型CoCrMo合金极化曲线

Fig. 10 Polarization curves of SLM CoCrMo alloy

表4 SLM成型CoCrMo合金塔菲尔曲线测量结果

Table 4 Measured results of Tafel curves of SLM CoCrMo alloy

3 结论

1) 激光功率、扫描速度和扫描间距对SLM成型致密度有重要影响,且各因素之间存在交互作用,通过非线性拟合得到的致密度回归方程可信度高,当激光功率为168 W,扫描速度为550 mm/s,扫描间距为0.06 mm时,成型的CoCrMo合金致密度可以达到98.6%。

2) 在优化的工艺参数下,SLM成型CoCrMo合金的微观组织均匀,熔道搭接致密,具有良好的组织结构。

3) 在模拟人体体液环境中,SLM成型CoCrMo合金的电化学性能优异,离子析出量低,腐蚀电流密度值小于铸造的CoCrMo合金的,表现出更强的耐腐蚀性能。

4) 热处理工艺可以改善SLM成型CoCrMo合金的耐腐蚀性,在模拟人体体液环境中,经过退火处理的成型件的腐蚀电流密度仅为20.86 μA/cm2,与未经热处理之前相比,耐腐蚀性能提高了一倍。

REFERENCES

[1] 杨永强, 王 迪, 吴伟辉. 金属零件选区激光熔化直接成型技术研究进展[J]. 中国激光, 2011, 38(6): 0601007.

YANG Yong-qiang, WANG Di, WU Wei-hui. Research progress of direct manufacturing of metal parts by selective laser melting [J]. Chinese Journal of Lasers, 2011, 38(6): 0601007.

[2] 苏海军, 尉凯晨, 郭伟, 马菱薇, 于瑞龙, 张 冰, 张 军, 刘 林, 傅恒志. 激光快速成形技术新进展及其在高性能材料加工中的应用[J]. 中国有色金属学报, 2013, 23(6): 1567-1574.

SU Hai-jun, WEI Kai-chen, GUO Wei, MA Ling-wei, YU Rui-long, ZHANG Bing, ZHANG Jun, LIU Lin, FU Heng-zhi. New development of laser rapid forming and its application in high performance materials processing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574.

[3] 孙婷婷, 杨永强, 苏旭彬, 郭明华. 316L不锈钢粉末选区激光熔化成型致密化研究[J]. 激光技术, 2010, 34(4): 443-446.

SUN Ting-ting, YANG Yong-qiang, SU Xu-bin, GUO Ming-hua. Research on densification of 316L stainless steel powder in selective laser melting process[J]. Laser Technology, 2010, 34(4): 443-446.

[4] 章 然, 张子群, 宋志坚. 基于水平集的快速成型技术在颅骨缺损修复中的应用[J]. 中国生物医学工程学报, 2013, 32(3): 373-377.

ZHANG Ran, ZHANG Zi-qun, SONG Zhi-jian. The repair of skull defect applying rapid prototyping based on level set[J]. Chinese Journal of Biomedical Engineering, 2013, 32(3): 373-377.

[5] SU Xu-bin, YANG Yong-qiang, YU Peng, SUN Jian-feng. Development of porous medical implant scaffolds via laser additive manufacturing[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S1): s181-s187.

[6] SIMS C T, STOLOFF N S, HAGEL W C. Superalloys Ⅱ[M]. New York: Willey, 1987: 135-163.

[7] JOHN A D, RICHARD L K, ROBERT P. Cobalt base alloys for biomedical applications[M]. West Conshohocken: Astm International, 1999: 15-20.

[8] DAVIS J R. ASM specialty handbook: nickel, cobalt, and their alloys[M]. ASM International Materials Park: The Materials Information Society, 1997: 653-654.

[9] NIINOMI M. Metals for biomedical devices[M]. Oxford: Woodhead publishing In Materials, 2010: 355-378.

[10] XIN Xian-zhen, XIANG Nan, CHEN Jie, XU Dan, WEI Bin. Corrosion characteristics of a selective laser melted Co-Cr dental alloy under physiological conditions[J]. Journal of Materials Science, 2012, 47(12): 4813-4820.

[11] VANDENBROUCKE B, KRUTH J P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts[J]. Rapid Prototyping Journal, 2007, 13(4): 196-203.

[12] TAKAICHI A, SUYALATU, NAKAMOTO T, JOKO N, NOMURA N, TSUTSUMI Y, MIGITA S, DOI H, KUROSU S, CHIBA A, WAKABAYASHI N, IGARASHI Y, HANAWA T. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 21: 67-76.

[13] MARECI D, SUTIMAN D, CAILEAN A,BOLAT G. Comparative corrosion study of Ag-Pd and Co-Cr alloys used in dental applications[J]. Bulletin of Materials Science, 2010, 33(4): 491-500.

[14] AVERYANOVA M, BERTRAND P, VERQUIN B. Manufacture of Co-Cr dental crowns and bridges by selective laser melting technology[J]. Virtual and Physical Prototyping, 2011, 6(3): 179-185.

[15] JEVREMOVIC D, PUSKAR T, KOSEC B, VUKELIC D, BUDAK I, ALEKSANDROVIC S, EGBEER D, WILLIAMS R. The analysis of the mechanical properties of F75 Co-Cr alloy for use in selective laser melting (SLM) manufacturing of removable partial dentures (RPD)[J]. Metallurgija, 2012, 51: 171-174.

[16] 王 迪, 杨永强, 吴伟辉. 光纤激光选区熔化316L不锈钢工艺优化[J]. 中国激光, 2009, 36(12): 3233-3239.

WANG Di, YANG Yong-qiang, WU Wei-hui. Process optimization for 316L stainless steel by fiber laser selective melting[J]. Chinese Journal of Laser, 2009, 36(12): 3233-3239.

[17] MORGAN R, SUTCLIFFE C J, O’NEILL W. Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives[J]. Journal of Materials Science, 2004, 39: 1195-1205.

[18] MUMTA K A, ERASENTHIRAN P, HOPKINSON N. High density selective laser melting of Waspaloy[J]. Journal of Materials Processing Technology, 2008, 195: 77-87.

[19] ZHANG Xin, LI Yong-jun, ZHANG Kui, WANG Chang-shun, LI Hong-wei, MA Ming-long, ZHANG Bao-dong. Corrosion and electrochemical behavior of Mg-Y alloys in 3.5%NaCl solution[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1226-1236.

[20] 贺 甜, 谭澄宇, 唐 娟, 郑 勇. 铜经MBT和HQ钝化处理后在 3.5%NaCl溶液中的电化学行为[J]. 中国有色金属学报, 2013, 23(5): 1388-1395.

HE Tian, TAN Cheng-yu, TANG Juan, ZHENG Yong. Electrochemical behavior of copper passivated by MBT and HQ in 3.5%NaCl solution[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1388-1395.

[21] 刘 冶. 激光快速成型钴铬合金机械性能及耐腐蚀性研究[D]. 西安: 第四军医大学, 2010: 38-46.

LIU Ye. A study on mechanical property and corrosion characteristics of Co-Cr alloy fabricated by laser rapid forming method[D]. Xi’an: The Fourth Military Medical University, 2010: 38-46.

(编辑 李艳红)

基金项目:国家自然科学基金仪器专项(81327001);国家自然科学基金资助项目(51275179);广东省对外科技合作项目(2012B050100013)

收稿日期:2014-03-04;修订日期:2014-07-07

通信作者:杨永强,教授,博士;电话:020-87111036;E-mail: meyqyang@scut.edu.cn