文章编号:1004-0609(2013)S1-s0605-04

连轧速度对TC4钛合金棒材组织与性能的影响

王 田,陶海林,黄淑阳,雒水会

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:采用不同连轧速度在α+β两相区加热、轧制TC4钛合金小规格棒材,分析在相同轧制温度及变形量下,连轧速度对TC4钛合金棒材组织和性能的影响。结果表明:连轧速度的选择直接影响TC4棒材的组织形态和力学性能,随着轧制速度的提高,晶粒有明显的细化趋势;但当轧制速度超过某一临界轧制速度时,棒材心部会形成过热组织进而影响到棒材的力学性能;在不超过这一临界轧制速度下,形成的TC4小规格棒材组织均匀细小,综合性能优异。

关键词:TC4钛合金;连轧速度;组织;性能

中图分类号:TG146.2 文献标志码:A

Effect of microstructures and properties of TC4 alloy bars on continuous rolling speed

WANG Tian, TAO Hai-lin, HUANG Shu-yang, LUO Shui-hui

(Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The small sizes of TC4 alloy bars were produced by the new type continuous rolling mill at different continuous rolling speeds when TC4 alloy was heated and rolled between α+β phases. The microstructures and mechanical properties of TC alloy bars were tested and analyzed when the rolling speed changed, but the rolling temperature and deformation were the same. After analyzing the effects of microstructures and mechanical properties of TC4 alloy bars at continuous rolling speed, the testing results show that the continuous rolling speed can directly affect the microstructure shapes and mechanical properties. When the rolling speed increases, the grain obviously shows the trend of much finer. When the finished bar rolling speed exceeds the critical rolling speed, the bar center part will form overheated microstructure, and the mechanical properties will be worsened accordingly. When TC4 alloy was rolled at below critical rolling speed, the small size of TC4 bar has fine, homogeneous microstructures and integrated, excellent technical properties.

Key words: TC4 alloy; continuous rolling speed; microstructures; properties

连续式轧机相比传统的横列式轧机具有速度快、大变形和精度高等优点,钛合金连续式轧制过程中,发生以回复、形核、晶粒长大为主的动态再结晶和以位错运动为主的塑性变形,从而使合金的显微组织和力学性能发生变化。热塑性变形过程中通常伴随着动态再结晶的发生,这也是有希望获得细晶和超细晶组织的可行的方法。然而,根据变形参数的不同,动态再结晶在组织演变中表现出不同的特点,一般有连续动态再结晶、不连续动态再结晶和几何动态再结晶。金属或合金的高温变形过程受变形速率、变形温度、变形量等变形参数的控制,因此,变形参数也控制着金属或合金的变形机制的转变[1-2]。

本文作者使用热连轧生产线,通过对变形参数的控制,研究在相同轧制温度及变形量下,连轧速度对TC4钛合金棒材组织、性能的影响。

1 实验

1.1 试验材料

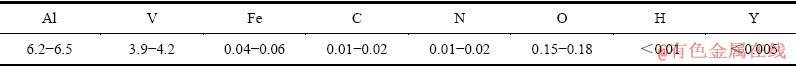

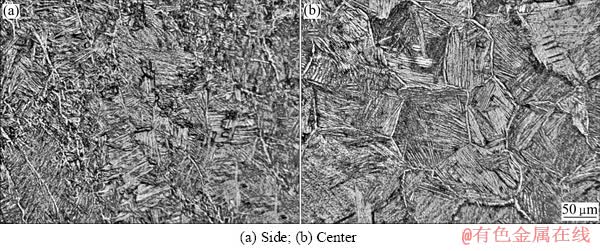

试验原材料采用宝鸡钛业股份有限公司生产的TC4合金铸锭,经开坯、锻造、轧制为d 53 mm的棒坯,其心部为片状组织,晶界α连续,原始β晶内具有不同取性向的α集束[3],边部为部分破碎、存在大量断续状晶界α的细片状组织,相变温度为988 ℃,其化学成分见表1,高倍组织见图1所示。

1.2 试验方法

将TC4合金棒材在α+β两相区温度加热,在热连轧生产线上设定总变形量为95%,经多道次连续轧制为d12 mm的棒材。连轧速度分别设定为v1<v2<v3<v4<v5<v6,对不同连轧速度轧制的棒材取样,进行金相组织分析和力学性能测试。

2 结果与分析

2.1 连轧速度对组织形态的影响

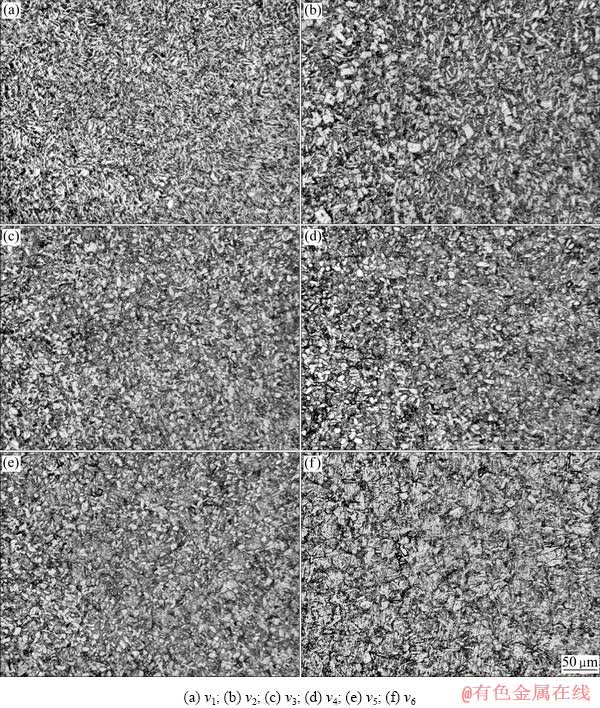

图2所示为总变形量设定为95%采用6种不同

连轧速度轧制的TC4钛合金d 12 mm棒材的高倍组织。从图2可以看出,当连轧速度为v1时,d 53 mm棒坯的魏氏组织经过95%的连续变形,原始β晶界已充分破碎、细化,初生α含量达到90%以上,呈细条状均匀分布。随着连轧速度的提高(v2),形变温升[4-5]导致初生α含量有一定下降,细条状的初生α也逐渐趋于等轴状形态并明显细化。当连轧速度提高至v3 时,初生α完全呈细小等轴状均匀、弥散分布,其含量在75%~80%左右。随着连轧速度进一步提高(v4),形变温升导致初生α含量继续下降;速度继续提高至v5时,初生α含量迅速降低为20%左右,并存在过热倾向;当连轧速度提高至v6时,初生α消失并出现β晶界。

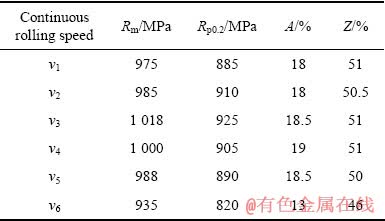

2.2 连轧速度对力学性能的影响

表2所列为采用不同连轧速度生产的TC4钛合金d12 mm棒材的室温力学性能。

从图3中的性能变化趋势可以看出,随着连轧速度从v1提高至v3,棒材的强度指标Rm和Rp0.2均有一定的提高;在连轧速度为v3时,达到最大值,而塑性指标A和Z基本维持不变;随着连轧速度继续从v3提高至v4,棒材的强度指标Rm和Rp0.2开始下降,但降幅不大,塑性指标A和Z仍基本维持不变;当连轧速度超过v5时,棒材的强度指标Rm、Rp0.2与塑性指 标A、Z同时迅速下降;在连轧速度为v6时,达到最低值。

表1 铸锭化学成分

Table 1 Chemical composition of TC4 titanium alloy ingot (mass fraction, %)

图1 TC4合金d 53 mm棒坯的原始组织

Fig. 1 Original microstructures of d 53 mm bar of TC4 titanium alloy

图2 不同连轧速度下TC4钛合金d 12 mm棒材的显微组织

Fig. 2 Microstructures of TC4 titanium alloy bar at different continuous rolling speeds

表2 不同连轧速度下TC4钛合金d12 mm棒材室温力学性能

Table 2 Mechanical properties of d 12 mm bar of TC4 titanium alloy at different continuous rolling speeds and room temperature

图3 不同连轧速度下TC4钛合金d 12 mm棒材性能的变化

Fig. 3 Mechanical properties change of d 12 mm bar of TC4 titanium alloy at different continuous rolling speeds

3 结论

1) 随着连轧速度的提升,TC4钛合金d12 mm棒材高倍组织形态由细条状向等轴状转变并明显细化,在此过程中由于形变温升导致初生α含量有一定下降。在连轧速度为v3时,初生α完全呈细小等轴状均匀、弥散分布,其含量在75%~80%左右,达到最佳组织状态。当连轧速度提高至v5时,初生α含量迅速降低并存在过热倾向,组织开始恶化。

2) 随着连轧速度的提升,TC4钛合金d12 mm棒材力学性能在v3时达到最大,当连轧速度超过v5时,力学性能指标迅速下降。

3) 综合连轧速度对组织性能的影响,当TC4合金棒材在α+β两相区温度轧制、总变形量不超过95%时,连轧速度控制在v3可以获得组织、性能优异的产品。临界轧制速度设定在v5,当连轧速度超过此临界速度,产品的组织会迅速恶化,性能也明显下降。

REFERENCES

[1] 费 跃, 常 辉, 唐 斌, 等. 热轧变形对TB-13合金组织和织构的影响[J]. 中国有色金属学报, 2010, 20(S1): s6-s10.

FEI Yue, CHANG Hui, TANG Bin, et al. Influence of hot rolling deformation on microstructure and texture of TB-13 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s6-s10.

[2] 田宇兴, 李述军, 赫玉琳, 杨 锐. Ti2448合金在不同应变速率下的高温变形机制[J]. 中国有色金属学报, 2010, 20(S1): s83-s86.

TIAN Yu-xing, LI Shu-jun, HAO Yu-lin, YANG Rui. Elevated temperature deformation mechanism of Ti2448 alloy at different strain rates [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s83-s86.

[3] 张宝昌. 有色金属及其热处理[M]. 西安: 西北工业大学出版社, 1993: 105-106.

ZHANG Bao-chang. Nonferrous metal and heat treatment [M]. Xi’an: Northwestern Polytechnical University Press, 1993: 105- 106.

[4] 邵 军. 连轧过程对TC2钛合金显微组织的影响[J].金属世界, 2012(6): 21-24.

SHAO Jun. Effect of Ti-4Al-1.5Mn alloy microstructure on longitudinal continuous rolling process [J]. Metal World, 2012(6): 21-24.

[5] 王 田, 陶海林, 胡宗式, 范 珂. Ti-6Al-4V合金棒材纵向连轧的温度变化分析[J]. 中国有色金属学报, 2010, 20(S1): s789-s791.

WANG Tian, TAO Hai-lin, HU Zong-shi, FAN Ke. Temperature shift of Ti-6Al-4V alloy bars in continuous rolling [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s789-s791.

(编辑 李艳红)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王 田,工程师;电话:0917-3257080;E-mail: wt2002jock@163.com