葡萄糖碳源制备纳米晶WC-6%Co复合粉的形貌和碳含量

来源期刊:中国有色金属学报(英文版)2018年第4期

论文作者:郭圣达 鲍瑞 杨平 刘亮 易健宏

文章页码:722 - 728

关键词:WC-6%Co复合粉;碳源;热处理参数;碳含量;显微组织

Key words:WC-6%Co composite powder; carbon source; heat-treatment parameter; carbon content; microstructure characteristic

摘 要:利用一种低温合成方法制备纯净的WC-6%Co纳米复合粉末。研究碳源和热处理工艺参数对复合粉显微组织和碳含量的影响。XRD和SEM分析结果表明:由葡萄糖分解出的碳比碳黑具有更高的活性,在氢气氛中加热至900 °C并保温1 h可以合成得到纳米晶WC-Co复合粉。复合粉中的单个WC颗粒被Co相互粘结成细长的带状。碳含量分析结果表明:当热处理温度在800~1000 °C范围内时,总碳含量随着温度的升高而降低;当氢气流量在1.1~1.9 m3/h范围内时,总碳含量和化合碳含量随着氢气流量的增大而增加。

Abstract: Pure WC-6%Co nanosized composite powders were synthesized via a low-temperature method. The effects of carbon source on microstructure characteristic of composite powders were investigated, and the effects of heat-treatment parameter on carbon content of composite powders were also discussed. The results of SEM and XRD revealed that the carbon decomposing from glucose was more active than carbon black. Therefore, WC-Co nanosized composite powders could be synthesized at 900 °C for 1 h under a hydrogen atmosphere. The individual WC grains were bonded together into a long strip under the action of cobalt. The results of carbon analysis revealed that the total carbon content decreased with the increase of the temperature in the range of 800-1000 °C. Moreover, the total carbon content and the compounded carbon increased with the increase of the flow rate of H2 in the range of 1.1-1.9 m3/h.

Trans. Nonferrous Met. Soc. China 28(2018) 722-728

Sheng-da GUO, Rui BAO, Ping YANG, Liang LIU, Jian-hong YI

School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China

Received 7 September 2016; accepted 6 March 2017

Abstract: Pure WC-6%Co nanosized composite powders were synthesized via a low-temperature method. The effects of carbon source on microstructure characteristic of composite powders were investigated, and the effects of heat-treatment parameter on carbon content of composite powders were also discussed. The results of SEM and XRD revealed that the carbon decomposing from glucose was more active than carbon black. Therefore, WC-Co nanosized composite powders could be synthesized at 900 °C for 1 h under a hydrogen atmosphere. The individual WC grains were bonded together into a long strip under the action of cobalt. The results of carbon analysis revealed that the total carbon content decreased with the increase of the temperature in the range of 800-1000 °C. Moreover, the total carbon content and the compounded carbon increased with the increase of the flow rate of H2 in the range of 1.1-1.9 m3/h.

Key words: WC-6%Co composite powder; carbon source; heat-treatment parameter; carbon content; microstructure characteristic

1 Introduction

Ultrafine WC-Co cemented carbides, with an excellent combination of good wear resistance, favorable toughness, high hardness and strength, have been widely used in various applications such as rock drilling tools, cutting tools, and wear parts [1-3]. The excellent mechanical properties of ultrafine WC-Co cemented carbides derive from the complex structure of WC phase, Co phase and the accuracy of composition [4,5]. Previous investigations have demonstrated that obtaining ultrafine-grain or nanoscale WC-Co composite powders with appropriate chemical compositions (such as carbon content) can improve the properties of ultrafine WC-Co cemented carbides obviously [6-8]. Conventionally, WC-Co composite powders are obtained through the following procedures [5]: reducing ammonium paratungstate (APT) or tungsten oxides into pure W powder by hydrogen; carbonizing W to form WC powders at 1300-2000 °C; ball milling mixtures of WC and Co powders in ethanol or acetone. However, the impurity is hard to avoid during the conventional processes [9]. Moreover, abnormal growth of finer WC grain occurs inevitably during the fairly high carbonization temperature treatment [10,11].

Due to the disadvantages of the conventional method, a large amount of methods have been developed to prepare ultrafine-grain or nanoscale WC-Co composite powders [12,13], such as mechanical ball milling, chemical vapor phase reaction synthesis and co-precipitation. SONG et al [12] demonstrated that WC-Co composite powders with the average particle size of about 300 nm could be obtained by in-situ reduction and carbonization reactions based on carbothermal reduction of metallic oxides and carbon black. QU et al [14] prepared WC powders with the mean particle size of about 200 nm by low-temperature combustion synthesis. LIN et al [15] obtained WC-Co composite powders with the WC mean particle size of approximately 80 nm using an in-situ reduction and carbonization approach in vacuum at 950 °C for 1 h. However, most of these methods were achieved in a laboratory scale, only a few methods have been testified to implement them in industrial applications.

In this work, a method for synthesis of pure nanoscale WC-6%Co composite powders was described. The proposed rapid facile method has the characteristics of more stable, easy-adjusting and cost-effective. The effects of the different carbon sources on morphology of the WC-6%Co nanosized composite powders were investigated. The effects of heat-treatment parameters on carbon contents of the obtained composite powders were discussed as well.

2 Experimental

2.1 Materials and preparation

Ammonium metatungstate (AMT, W≥73%), cobalt acetate (C4H6O4·Co·4H2O), carbon black and glucose (C6H12O6) were used as raw materials. They were of analytical grade and were used directly without further purification. The WC-6%Co nanosized composite powder was fabricated by a simple three-step process involving spray conversion, proper calcination, in situ reduction and carbonization (heat-treatment) processes under a hydrogen atmosphere.

Firstly, AMT, C4H6O4·Co·4H2O and C6H12O6 were dissolved in distilled water to form aqueous solution in a special ratio according to the composition of WC-6%Co. The temperature of intake air and exhaust air were about 240 °C and 100-120 °C respectively. The centrifugal speed was 12000 r/min. Then, the spray dried powders were decomposed during subsequently calcination process at 550 °C for 20 min under a nitrogen atmosphere in tube furnace. The heating rate of the calcination process was 5 °C/min. The transformation from spray dried powders to oxide powders was attributed to the following two reactions [2]:

(NH4)6·(H2W12O40)·XH2O→12WO3+(X+4)H2O↑+6NH3↑ (1)

3Co(CH3COO)2·4H2O→Co3O4+3(CH3)2↑+4CO↑+2CO2↑+12H2O↑ (2)

Lastly, the reduction and carbonization processes were carried out in tube furnace under a hydrogen atmosphere to obtain the WC-Co nanosized composite powders. To reduce the processing time and improve the production efficiency, the reduction and carbonization processes were combined in a one-step operation at 800-1000 °C.

To investigate the effects of carbon sources on the morphology of obtained powders, two groups of composite powders using different raw materials (glucose or carbon black) as carbon source were prepared respectively. The powders were defined as CP-G and CP-C, respectively. The heat-treatment temperature and flow rate of H2 were set to 900 °C and 1.3 m3/h, respectively. Other parameters, such as intake air temperature and centrifugal speed, were the same as those mentioned above.

In order to investigate the effects of heat-treatment temperature and flow rate of H2 on the carbon contents of WC-Co composite powders in the stage of reduction and carbonization process, the heat-treatment temperatures were set to 800, 850, 900, 950 and 1000 °C, respectively. Furthermore, five gas flow rates for H2 of 1.1, 1.3, 1.5, 1.7 and 1.9 m3/h were selected, respectively.

2.2 Characterization

The morphologies of powders were observed by SEM equipped with an EDS attachment (Brand: FEI, Model: MLA650F). The phases of powders were detected by XRD with Cu Kα (λ=0.15406 nm) at a scanning step size of 0.026° in the scan range of 20°-80° (Brand: PANalytical, Model: Empyrean). The total carbon content in the powder was analyzed with a carbon-sulfur analyzer (LECO CS-744). The compounded carbon content was analyzed by a chemical analysis method.

3 Results and discussion

3.1 Microstructure characteristic of obtained powders

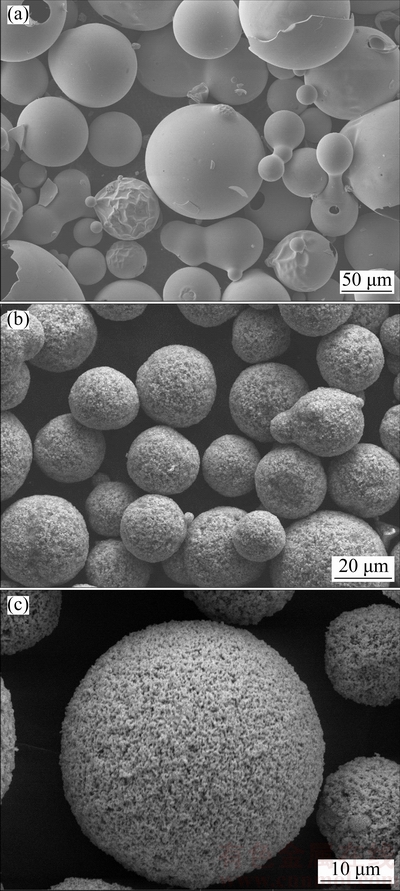

The morphology of powders obtained after spray conversion depicted a hollow spherical structure, and the sphericity of the powders was good, as shown in Fig. 1(a). The mixed solution was dispersed into tiny droplets from the rotating nozzle and dropped down during the spray conversion process. Due to the effect of surface tension, the tiny droplets shrank into spherical shape gradually [16]. This spherical structure feature could be maintained in the following processes (calcination, in situ reduction-carbonization), which illustrated that the calcination, in situ reduction- carbonization processes did not change the morphology of the powders.

It can be seen that the surfaces of powders obtained after spray conversion were smooth from Fig. 1(a). But the surface of powders obtained after calcination process at 550 °C for 20 min became rough (Fig. 1(b)) and even more rough (Fig. 1(c)) obtained after in situ reduction- carbonization process at 900 °C for 60 min. It could be explained as follows. During the calcination and heat- treatment processes, the mixed gas (CO, CO2 and H2) produced by the decomposition reactions of AMT and cobalt acetate, and the gas produced by the reduction of oxide powders escaped from the powder spheres. Therefore, a large number of micro holes were left [17,18], and the surfaces of the powder spheres became rough and even more rough. Moreover, the diameters of as-prepared powders had a decreasing trend after each processing step. The decreasing in the diameter associated with the formation of the new phases and the evaporation of gases.

Fig. 1 Morphology of as-prepared powders obtained after spray conversion (a), proper calcination (b) and in situ reduction-carbonization process (c)

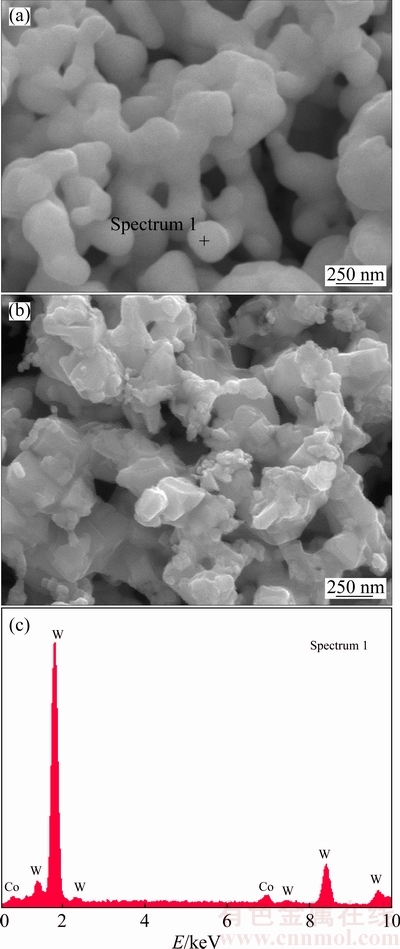

The microstructure of WC-Co composite powders could be observed in Fig. 2. The individual grains were bonded together into a strip under the action of cobalt, as illustrated in Fig. 2(a). Figure 2(b) shows the microstructure of WC grain obtained by dissolving Co from the WC-Co composite powder using H3PO4 and H2O2 mixed solution. It had been indicated that the average grain size of WC was about 0.2 μm. EDS analysis of the selected spectrum 1 in Fig. 2(a) confirmed the formation of WC-Co composite powder, as show in Fig. 2(c).

3.2 Effects of carbon source on morphology and phase constitution

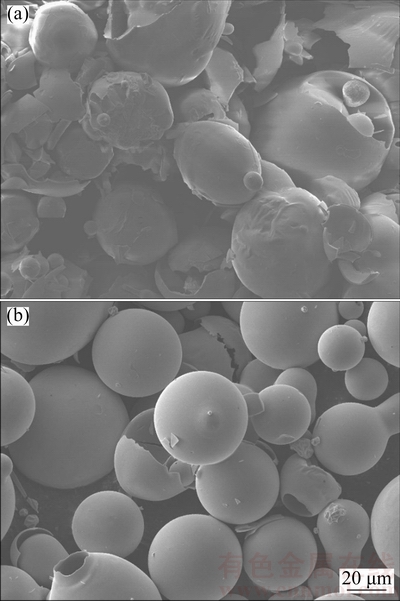

Morphology, phase constitutions of WC-6%Co composite powders fabricated with different carbon sources were characterized by SEM and XRD. Figure 3 shows the morphology of CP-C and CP-G precursor powders obtained after spray conversion. It can be seen that the surface of CP-G was smoother than that of CP-C. During the spray process, the glucose was decomposed into crystalline water and carbon-containing compounds. The smoother surface was due to the attachment of crystalline water.

Fig. 2 SEM images of WC-Co composite powders (a) and WC grains (b), and EDS analysis of spectrum 1 (c)

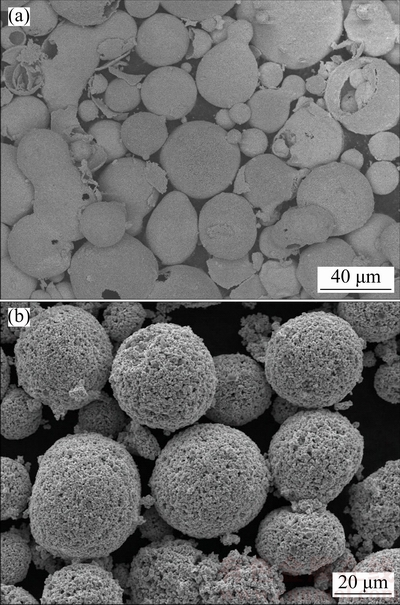

Figure 4 illustrates the morphology of CP-C and CP-G composite powders obtained after in situ heat- treatment. As seen, particles gathered together to form aggregates in all of the two WC-Co composite powders. However, the surface of CP-G composite powders was more rough and porous than that of CP-C, as shown in Figs. 4(a) and (b), respectively. This was probably due to the evaporation of water and the diffusion of CO, CO2 and other gases.

Fig. 3 SEM images of CP-C (a) and CP-G (b) precursor powders

Fig. 4 SEM images of CP-C (a) and CP-G (b) composite powders

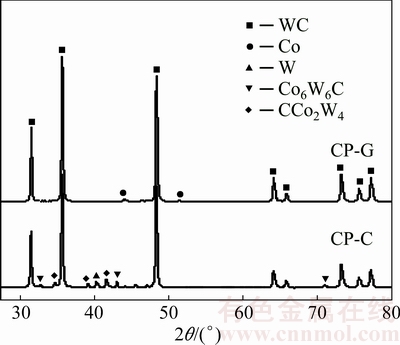

Figure 5 shows the phase constitution of CP-C and CP-G. It can be seen that the phase constitution of CP-G was pure WC and Co. Meanwhile, the intermediate carbides phases (Co6W6C, CCo2W4) and W phase were observed in the CP-C powders, which illustrated that the carbonization of CP-C was not completed under the same conditions. It could be concluded that the carbon decomposed from glucose had a higher activity than carbon black.

Fig. 5 XRD patterns of CP-C and CP-G

3.3 Effects of heat-treatment parameters on carbon content

3.3.1 Heat-treatment temperature

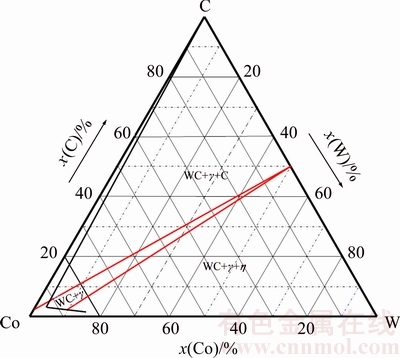

According to the W-C-Co ternary phase diagram shown in Fig. 6, the carbon content width of the two-phase zone of WC and Co has a narrow range [19]. The stoichiometric carbon content in the WC-6%Co composite powder is about 5.765%. Previous investigations have demonstrated that a precise control of carbon content is very important for mechanical properties. The existence of the free carbon or intermediate phase (η phase) reduces the properties of the cemented carbides obviously [20].

Fig. 6 Isothermal section of W-C-Co phase diagram at 1200 °C

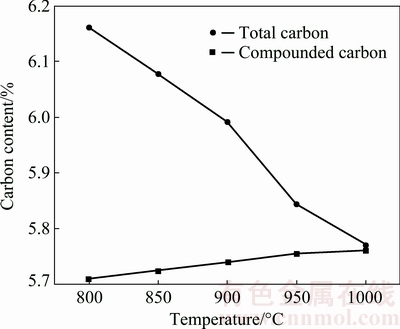

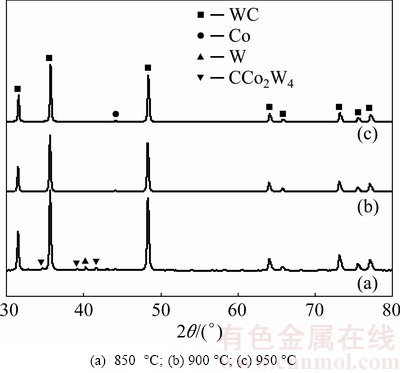

According to the phase constitution results mentioned above (see Fig. 5), it was found that the in situ reduction-carbonization reaction could occur in a relatively low temperature range. Therefore, a series of experiments on heat-treatment temperature were carried out in this work. The relationship between reduction- carbonization temperature in the range of 800-1000 °C and the carbon content is shown in Fig. 7. When the heat-treatment temperature increased to 800 °C or 850 °C, the total carbon contents in formed powders were about 6.161% and 6.077%, respectively, which are larger than the theoretical value (5.765%). Increasing the heat-treatment temperature reduced the total carbon content, but also increased the compounded carbon content in all of the five samples, as indicated in Fig. 7. However, the η phase (CCo2W4) and W phase existed in the powders obtained at 850 °C, as shown in Fig. 8(a). This indicated that the compounded carbon was low, while the free carbon was higher than the allowed value. This result was consistent with the measurement results of the compounded carbon as shown in Fig. 7. It was difficult to properly identify carbon which may be because carbon is amorphous in Fig. 8(a).

Fig. 7 Relationship between heat-treatment temperature and carbon content

Fig. 8 XRD patterns of as-prepared powders

The XRD patterns of powders obtained at 900 °C or 950 °C are presented in Figs. 8(b) and (c). They were the same, and there were only WC and Co phases. Moreover, the heat treatment temperature used in our experiments was much lower than the traditional carbonization temperature (about 1300 °C). During the one-step process, some effects of Co on the formation of WC were found in previous studies [21,22]. Firstly, the reaction sequence becomes more complicated with the addition of Co. Secondly, it is found that Co would help the formation of WC, and it is most likely to be related to the catalytic behavior of Co. Thirdly, the presence of Co can decrease the heat-treatment temperature and holding time obviously.

With the increase of the heat treatment temperature, carbon atoms were more likely to diffuse into W. Thus, WC phase was more likely to generate. When the compounded carbon tended to the stoichiometric value, the free carbon reacted with hydrogen to produce methane (CH4) which could be taken away by the hydrogen. The content of the compounded carbon in the powder was almost unchanged when the temperature reached 900 °C.

According to the phase constitution results as indicated in Fig. 8, it was convincing that the in situ reduction-carbonization temperature of 900 °C was suitable for synthesizing the pure WC and Co phases. The heat-treatment temperature was much lower than the traditional carbonization temperature (about 1300 °C) due to the catalytic effect of cobalt [21,22].

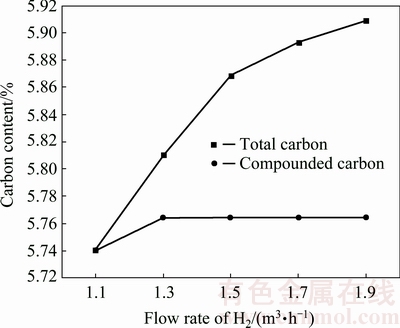

3.3.2 Flow rate of H2

The relationship between the flow rate of H2 in the range of 1.1-1.9 m3/h and the carbon content is shown in Fig. 9. It can be seen that the total and compounded carbon contents increased with the increase of the flow rate within the experimental range. The compounded carbon remained unchanged when the flow rate of H2 was larger than 1.3 m3/h. However, the total carbon content increased from 5.81% with the flow rate of 1.3 m3/h to 5.909% with the flow rate of 1.9 m3/h. Therefore, it could be concluded that the increased carbon content was mainly free of carbon.

Fig. 9 Relationship between flow rate of H2 and carbon content

Tungsten oxide was reduced by H2 during the heat-treatment process, and the reaction products were W and water vapor. When the temperature reached about 700 °C, the water vapor generated from the reduction reaction could react with the carbon element to form CO according to reaction (3). Moreover, the CO gas would be taken away by the hydrogen. Thus, the carbon content decreased with the presence of reaction (3). However, the water vapor would be taken away by hydrogen gas more easily with the increase of the flow rate of H2, which would inhibit reaction (3), so that the total carbon content increased with the increase of the flow rate of H2 in our experiments [23].

C+H2O↑→CO↑H2↑ (3)

4 Conclusions

1) A pure, nanoscale WC-6%Co composite powder without excess carbon or intermediate phase was successfully obtained via a low-temperature method due to the catalytic effect of Co on the formation of WC. The proposed rapid facile method has more stable, easy-adjusting and cost-effective characteristics.

2) The morphology of the obtained powders was spherical, and the individual WC grains were bonded together into a strip under the action of cobalt.

3) The total carbon content decreased with the increase of the heat-treatment temperature in the range of 800-1000 °C. The total and compounded carbon contents increased with the increase of the flow rate of H2 in the range of 1.1-1.9 m3/h.

References

[1] XIE Chen-hui, HUANG Ji-wu, TANG Yun-feng, GU Li-ning. Effects of deep cryogenic treatment on microstructure and properties of WC-11Co cemented carbides with various carbon contents [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3023-3028.

[2] SU Wei, SUN Ye-xi, YANG Hai-lin, ZHANG Xian-qi, RUAN Jian-ming. Effects of TaC on microstructure and mechanical properties of coarse grained WC-9Co cemented carbides [J]. Transactions of Nonferrous Metals Society of China, 2015, 25:1194-1199.

[3] LI Xiao-feng, LIU Yong, WEI Wei, DU Meng, LI Kai-yang, ZHOU Jian-hua, FU Kun. Influence of NbC and VC on micro-structures and mechanical properties of WC-Co functionally graded cemented carbides [J]. Materials and Design, 2016, 90: 562-567.

[4] KANERVA U, KARHU M, LAGERBOM J,  A, HONKANENC M, TURUNEN E, LAITINEN T. Chemical synthesis of WC–Co from water-soluble precursors: The effect of carbon and cobalt additions to WC synthesis [J]. International Journal of Refractory Metals and Hard Materials, 2016, 56: 69-75.

A, HONKANENC M, TURUNEN E, LAITINEN T. Chemical synthesis of WC–Co from water-soluble precursors: The effect of carbon and cobalt additions to WC synthesis [J]. International Journal of Refractory Metals and Hard Materials, 2016, 56: 69-75.

[5] KONYASHIN I, RIES B, LACHMANN F, FRY A T. A novel sintering technique for fabrication of functionally gradient WC-Co cemented carbides [J]. Journal of Materials Science, 2012, 47: 7072-7084.

[6] FERNANDES C M, SENOS A M R. Cemented carbide phase diagrams: A review [J]. International Journal of Refractory Metals and Hard Materials, 2011, 29: 405-418.

[7] RAIHANUZZAMAN R M, XIE Zong-han, HONG S J, GHOMASHCHI R. Powder refinement, consolidation and mechanical properties of cemented carbides—An overview [J]. Powder Technology, 2014, 261: 1-13.

[8] GAO Yang, SONG Xiao-yang, LIU Xue-mei, WEI Chong-bin, WANG Hai-bin, GUO Guang-sheng. On the formation of WC1-X in nanocrystalline cemented carbides [J]. Scripta Materialia, 2013, 68: 108-110.

[9] YANG Qiu-ming, YANG Jiao-gao, YANG Hai-lin, SU Wei, RUAN Jian-min. Synthesis and characterization of WC-Co nanosized composite powders with in situ carbon and gas carbon sources [J]. Metals and Materials International, 2016, 4: 663-669.

[10] SHI Xiao-liang, SHAO Gang-qin, DUAN Xin-long. Characterizations of WC-10Co nanocomposite powders and subsequently sinterhip sintered cemented carbide [J]. Materials Characterization, 2006, 57: 358-370.

[11] LIN Hua, TAO Bo-wan, XIONG Jie, LI Qing. Synthesis and characterization of WC-VC-Co nanocomposite powders through thermal-processing of a core-shell precursor [J]. Ceramics International, 2013, 39: 9671-9675.

[12] WEI Chong-bin, SONG Xiao-yan, FU Jun, LIU Xue-mei, WANG Hai-bin. Effect of heat-treatment of in-situ synthesized composite powder on properties of sintered cemented car-bides [J]. Materials Science and Engineering A, 2013, 566: 96-101.

[13] MAHMOODAN M, ALIAKBARZADEH H, GHOLAMIPOUR R. Sintering of WC-10%Co nano powders containing TaC and VC grain growth inhibitors [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1080-1084.

[14] LI Ping, LIU Zhi-wei, CUI Li-qun, ZHAI Fu-qiang, WAN Qi, LI Zi-liang, FANG Z Z, VOLINSKY A A, QU Xuan-hui. Tungsten carbide synthesized by low-temperature combustion as gas diffusion electrode catalyst [J]. International Journal of Hydrogen Energy, 2014, 39: 10911-10920.

[15] LIN Hua, SUN Jian-chun, LI Chun-hong, HE Hong, QIN Li-zhao, LI Qing. A facile route to synthesize WC-Co nano-composite powders and properties of sintered bulk [J]. Journal of Alloys and Compounds, 2016, 682: 531-536.

[16] LIU Bai-xiong, WANG Jin-shu, LI Hong-yi, WU Jun-shu, ZHOU Mei-ling, ZUO Tie-yong. Facile synthesis of hierarchical hollow mesoporous Ag/WO3 spheres with high photocatalytic performance [J]. Journal of Nanoscience and Nanotechnology, 2013, 13: 1-16.

[17] ZHU Er-tao, YANG Jian-gao, DAI Yu, ZHANG Xiang, DENG Jun-wang, GUO Sheng-da. Reaction mechanism of W-Co oxide powders prepared by spray drying-calcination method [J]. Materials Science and Engineering of Powder Metallurgy, 2015, 20: 175-181. (in Chinese)

[18] SADAKANE M, SASAKI K, KUNIOKU H, OHTANI B, ABE R, UEDA W. Preparation of 3-D ordered macroporous tungsten oxides and nanocrystalline particulate tungsten oxides using a colloidal crystal template method, and their structural characterization and application as photocatalysts under visible light irradiation [J]. Journal of Materials Chemistry, 2010, 20: 1811-1818.

[19] BAO Rui, YI Jian-hong. Effects of sintering atmosphere on microwave prepared WC–8wt.%Co cemented carbide [J]. International Journal of Refractory Metals and Hard Materials, 2013, 41: 315-321.

[20] ALIBERT C H. Sintering features of cemented carbides WC–Co processed from fine powders [J]. International Journal of Refractory Metals and Hard Materials, 2001, 19: 53-61.

[21] ZAWRAH M F. Synthesis and characterization of WC–Co nanocomposites by novel chemical method [J]. Ceramics International, 2007, 33: 155-161.

[22] LIN Hua, TAO Bo-wan, LI Qing, LI Yan-rong. In situ synthesis of WC–Co nanocomposite powder via core–shell structure formation [J]. Materials Research Bulletin, 2012, 47: 3283-3286.

[23] YANG Jian-gao, TANG Dun-qiang, CHEN Hao. Cemented carbide [M]. Changsha: Central South University Press, 2012: 136-142. (in Chinese).

郭圣达,鲍 瑞,杨 平,刘 亮,易健宏

昆明理工大学 材料科学与工程学院,昆明 650093

摘 要:利用一种低温合成方法制备纯净的WC-6%Co纳米复合粉末。研究碳源和热处理工艺参数对复合粉显微组织和碳含量的影响。XRD和SEM分析结果表明:由葡萄糖分解出的碳比碳黑具有更高的活性,在氢气氛中加热至900 °C并保温1 h可以合成得到纳米晶WC-Co复合粉。复合粉中的单个WC颗粒被Co相互粘结成细长的带状。碳含量分析结果表明:当热处理温度在800~1000 °C范围内时,总碳含量随着温度的升高而降低;当氢气流量在1.1~1.9 m3/h范围内时,总碳含量和化合碳含量随着氢气流量的增大而增加。

关键词:WC-6%Co复合粉;碳源;热处理参数;碳含量;显微组织

(Edited by Xiang-qun LI)

Foundation item: Project (51274107) supported by the National Natural Science Foundation of China; Project (2015FB127) supported by the Yunnan Natural Science Foundation, China; Project (2016P20151130003) supported by Analysis Foundation of Kunming University of Science and Technology, China

Corresponding author: Jian-hong YI; Tel: +86-871-65916977; E-mail: yijianhong2007@sohu.com

DOI: 10.1016/S1003-6326(18)64704-1