文章编号:1004-0609(2007)09-1516-05

喷射沉积7075Al/SiCp铝基复合材料板材的高温拉伸变形行为

何玉松1,高文理1,陆 政2,张 辉1

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 北京航空材料研究院,北京 100095)

摘 要:当温度为300~450 ℃,应变速率为0.001~0.1 s?1时,在WDW-E200拉伸机上采用单向拉伸实验研究喷射沉积7075Al/SiCp复合材料板材的高温变形行为;分析板材的变形激活能以及流变应力、变形温度和应变速率之间的关系。结果表明:随着变形温度升高和应变速率降低,7075Al/SiCp复合材料板材拉伸流变应力减小;其最大拉伸断裂伸长率由5.03%增加到71.07%;7075Al/SiCp复合材料板材应变速率敏感系数的最大值仅为0.22,在温度为623、673和723 K时其变形激活能分别为380.49、323.42和434.56 kJ/mol,均高于铝的晶格自扩散激活能 (142 kJ/mol)。

关键词:铝基复合材料板材;喷射沉积;高温拉伸;流变应力;变形激活能

中图分类号:TG 146 文献标识码:A

Tensile deformation behavior of spray-deposited 7075Al/SiCp aluminum matrix composite sheet at elevated temperature

HE Yu-song1, GAO Wen-li1, LU Zheng2, ZHANG Hui1

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The elevated temperature deformation behavior of spray deposited 7075Al/SiCp composite sheet was investigated by uniaxial tensile tests on WDW-E200 at temperature ranging from 300 to 450 ℃ and strain rates between 0.001 and 0.1 s?1. The deformation activity energy and relationship between flow stress and deformation temperature as well as strain rate were analyzed. The results indicate that the tensile flow stress of the composite sheet decreases with increasing deformation temperature and decreasing strain rate,while the maximum elongation to failure increases from 5.03% to 71.07%. The maximum strain rate sensitivity exponent of the 7075Al/SiCp composite sheet is found to be merely 0.22, and the hot activation energy varies at different deformation temperatures, the activation energies at temperatures of 623, 673 and 723 K are 380.49, 323.42 and 434.56 kJ/mol, respectively, which are all larger than the activity energy for lattice self-diffusion in Al (142 kJ/mol).

Key words: Al matrix composite sheet; spray deposited; elevated temperature tensile; flow stress; deformation activation energy

铝基复合材料因具有密度低、强度大、弹性模量高、抗氧化性好及对环境稳定等优良综合性能,已经在航天航空,汽车,军事等领域得到广泛应用[1]。但由于增强相颗粒的存在,使得铝基复合材料的加工成形性远低于基体合金,变形机制也变得比较复杂,这将直接导致加工过程的复杂化和生产成本的提高。因而国外Nieh 等[2]发起了对铝基复合材料超塑性行为的研究,以寻求在增强相存在的情况下最好的加工成形条件,Inone等[3]和Han等[4]的研究表明,在合适的变形温度和应变速率条件下铝基复合材料可表现出超塑性行为。这不仅解决了复合材料加工成形难的问题,同时由于加工方法的优化和逐渐成熟,使得其使用范围和应用领域更加广阔。因此,对铝基复合材料变形行为的进一步深入研究十分必要。

目前,国内外对铝基复合材料的变形行为的研究比较多,Tong等[5]研究了PM6013 Al/SiCp复合材料板材的变形行为,Frank等[6]和李红章等[7]研究了喷射沉积7075Al/SiCp复合材料的高温热压缩变形行为,并用Zener-Hollomon双曲线正弦模型来描述7075Al/SiCp复合材料的高温压缩变形行为,但几乎未对喷射沉积7075Al/SiCp复合材料轧制板材的高温拉伸变形行为进行研究。本文作者通过对喷射沉积7075Al/SiCp 复合材料板材进行高温拉伸实验,研究其高温拉伸变形行为,分析各工艺参数之间的影响关系,可以为合理制定各种条件下板材的后续加工工艺提供指导,并为进一步研究喷射沉积7075Al/SiCp复合材料板材的高温成形性以及有限元模拟分析打下基础。

1 实验

实验用7075Al/SiCp复合材料板材坯料(合金成分)为:Al-5.1~6.1Zn-2.1~2.9Mg-1.2~2.0Cu-0.3Mn-0.8~1.2 Ni-0.8Zr,SiC颗粒的平均粒径为15 μm)由湖南大学金属研究所制备的喷射沉积设备制取,先经西南铝加工厂大型挤压机上420 ℃挤压加工成方锭,在方锭上取样后经460 ℃多道次轧制加工得到1.2 mm复合材料板材,再按平行于轧制方向取20 mm×80 mm小块,经线切割加工成为热拉伸实验试样。

实验在WDW?E200微机控制电子万能实验机上进行,在温度为300~450 ℃,应变速率为0.001~0.1 s?1的实验条件下进行高温拉伸实验。采用WDW?E200微机控制电子万能实验机配套的三段加热控温装置对试样进行加热和控温,实验前试样先在设定的温度保温8~10 min,以保证试样各段均温,温度误差控制在±5 ℃。

2 结果和讨论

2.1 喷射沉积7075Al/SiCp复合材料板材的真应力—应变曲线

图1所示为喷射沉积7075Al/SiCp复合材料板材在温度为300~450 ℃和应变速率为0.001~0.1 s?1热拉伸实验条件下的真应力—应变曲线。

图1 不同温度和应变速率时喷射沉积7075Al/SiCp复合材料板材的真应力—应变曲线

Fig.1 True stress—strain curves of spray deposited 7075Al/ SiCp composites sheet at different temperatures and strain rates: (a)  =0.001 s?1; (b)

=0.001 s?1; (b)  =0.01 s?1; (c)

=0.01 s?1; (c)  =0.1 s?1

=0.1 s?1

从图1可以看出:变形初期,流变应力随变形程度的增加,表现出明显的应变硬化趋势,在温度较低时特别明显,其后由于软化抵消过程,流变应力增幅降低;在所有变形温度下,流变应力随着温度的升高而下降,且随温度逐步升高,下降趋势变得平缓;另外,流变应力对应变速率的变化也相当敏感,在整个变形温度条件下,除在温度超过400 ℃条件下,流变应力随应变速率的增加幅度较小外,其他条件下应变速率的增加幅度都很明显;在温度高于400 ℃后,材料发生非常明显的高温蠕变和软化行为,伸长率都较大,且在此条件下,温度对流变应力的影响比应变速率产生的影响更明显,导致在高温时流变应力普遍较低,在各种应变速率变化下没有太明显的改变。

2.2 温度及应变速率与伸长率的关系

温度和应变速率均在一定程度上影响着喷射沉积7075Al/SiCp复合材料板材的最大伸长率,其中温度的影响更为明显。

图2所示为不同温度和应变速率实验条件下喷射沉积7075Al/SiCp复合材料板材的最大伸长率曲线。由图可知:在不同应变速率下,喷射沉积7075Al/SiCp复合材料板材的最大伸长率都随着温度升高而增加,这是高温流变软化以及位错攀移行为所导致。在低应变速率时更加明显,已有很多研究表明铝基复合材料在低应变速率条件下表现出了超塑性性能,并已得到系列研究结果[3?4]。本实验在变形温度为450 ℃,应变速率为0.001 s?1时得到最大伸长率为71.07%,仅表现出一定的超塑性趋势,并没有出现超塑性,但这仍可说明喷射沉积7075Al/SiCp复合材料板材在此实验条件下进行热加工易变形且变形抗力低,成型性好;在同一温度下,随着应变速率的增加,伸长率降低,这是因为拉伸速度较快,塑性变形进行得不充分,且没有足够的时间发生软化过程,同时也因为变形速度快,增强相与基体变形不均匀加剧,增强相阻碍位错滑动,过早产生了裂纹,导致断裂。但在温度为450 ℃时,应变速率在0.1 s?1时的最大伸长率却比应变速率为0.01 s?1时的大,这可能是因为变形速度快,出现一定的热效应,同时发生动态再结晶,变形的扩散过程参与作用以及位错塞积出现重攀移等原因所致,陈振华等[8]和赵明久等[9]的研究也得到类似的结论。

图2 不同温度和应变速率下喷射沉积7075Al/SiCp复合材料板材的最大伸长率曲线

Fig.2 Maximum elongation values for spray-deposited 7075Al/SiCp composite sheet at different temperatures and stain rates

2.3 应变速率敏感系数和热激活能

应变速率敏感系数和热激活能是材料两个重要的动力学参数,通常被用来描述金属以及金属基复合材料的流变本构行为[10?12]。复合材料的流变特征可用如下关系式描述为[13]

绘出流变应力和应变速率的双对数曲线,m即为曲线斜率值。

金属基复合材料的热激活能可采用Power-Arrhenius模型进行计算[14?15]:

式(3)经化解取对数处理后可写成:

作ln σ与1/T的关系曲线,得到斜率K,则有:

图3所示为真应变为0.05时,不同温度下喷射沉积7075Al/SiCp复合材料板材拉伸流变应力和应变速率关系曲线图,m可由曲线中的斜率得到。

由图3可见,在所有变形温度条件下,流变应力随应变速率的增加而增加。随着温度的升高,m值变大,但其最大值仅为0.22。当温度为450 ℃时候又降低,这跟前面流变应力分析结果一致,低m值表明在该实验条件下并没有发生超塑性,这与伸长率讨论结果也是一致的。

图3 真应变为0.05时喷射沉积7075Al/SiCp复合材料板材应力和应变速率关系

Fig.3 Relationships between stress and stain rate for spray-deposited 7075Al/SiCp composite sheet at fixed true stain of 0.05

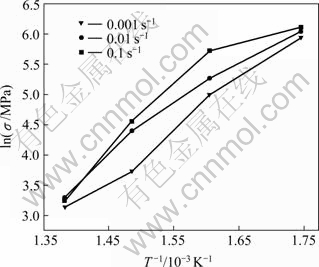

图4所示为喷射沉积7075Al/SiCp复合材料板材的ln σ—T?1关系曲线。通过一元线性回归可得到应变速率分别为0.001 s?1、0.01 s?1、0.1 s?1这3种条件下的斜率。

图4 喷射沉积7075Al/SiCp复合材料板材ln σ与T ?1关系 曲线

Fig.4 Relationships between ln σ and T?1 for spray-deposited 7075Al/SiCp composite sheet

由式(5)可计算出材料在不同变形条件下的激活能,图5所示为喷射沉积7075Al/SiCp复合材料板材在不同温度下的热变形激活能与温度之间的关系。由图5可知,在温度为623、673和723 K时热激活能分别为380.49,323.42和434.56 kJ/mol,其平均值和Ton等[5]的研究结果(370 kJ/mol)比较接近,但均高于铝的晶格自扩散激活能(142 kJ/mol)。由此可见,颗粒增强铝复合材料由于复合相的存在而使得其高温变形机制发生了变化,不能用晶格自扩散理论进行解释[9],其影响机制还有待进一步研究确定。

图5 喷射沉积7075Al/SiCp复合材料板材热变形激活能与变形温度的关系

Fig.5 Relationship between deformation temperature and hot deformation activity energy for spray-deposited 7075Al/SiCp composite sheet

3 结论

1) 在不同温度和变形速率下对喷射沉积7075Al/ SiCp复合材料板材进行高温拉伸实验,研究了温度和变形速率对流变应力的影响,发现高温流变应力随变形温度的升高而降低,随应变速率的增加而增加。

2) 在变形温度为450 ℃、应变速率为0.001 s?1实验条件下,喷射沉积7075Al/SiCp复合材料板材的最大延伸率可达71.07%,其应变速率敏感系数m最大值仅为0.22,说明在本实验条件下材料并没发生超塑性行为,但可表明材料在此条件下具有较好的可加工成型性。

3) 采用Power-Arrhenius模型对喷射沉积7075Al/SiCp复合材料板材在该实验条件下的热激活能进行了计算,结果显示在不同的温度下具有不同的激活能,且在各实验温度下所得激活能均高于铝的晶格自扩散激活能,说明不能用自扩散理论来解释铝复合材料的高温变形机制,颗粒增强铝复合材料由于复合相的存在而使得其高温变形机制发生了变化。

REFERENCES

[1] Srivatsan T S, Ibrahim I A, Mohamed F A, Lavernia J. Processing techniques for particulate-reinforced metal aluminum matrix composites[J]. Journal of Materials Science, 1991, 26(22): 5965?5978.

[2] Nieh T G, Henshall C A, Wadsworth J. Superplasticity at high strain rates in a SiC whisker reinforced Al alloy[J]. Scripta Metallurgica, 1984, 18(12): 1405?1408.

[3] Mabuchi M, Higashi K, Inoue K, Tanimura S. Experimental investigation of superplastic behavior in a 20 vol % Si3N4p5052 aluminum composite[J]. Scripta Metallurgica et Materialia, 1992, 26(12): 1839?1844.

[4] Han B Q, Chan K C, Yue T M, Lau W S. Theoretical model for high-strain-rate superplastic behavior of particulate reinforced metal matrix composites[J]. Scripta Metallurgica et Materialia, 1995, 33(6): 925?930.

[5] Tong G Q, Chan K C. Deformation behavior of a PM Al6013/15SiCp composite sheet at elevated temperature[J]. Materials Letters, 1999, 38: 326?330.

[6] Frank Su Y H, Chen Y C, Tsao Chi Y A. Workability of spray-formed 7075 Al alloy reinforced with SiCp at elevated temperatures[J]. Mater Sci Eng A, 2004, A364: 296?304.

[7] 李红章, 张 辉, 陈振华, 何玉松. 7075Al/SiCp复合材料的热压缩变形流变应力和组织行为[J]. 材料导报, 2006, 20(F05): 271?272.

LI Hong-zhang, ZHANG Hui, CHEN Zhen-hua, HE Yu-song. Flow stress and structure behavior of 7075Al/SiCp composites during hot compression deformation[J]. Materials Review, 2006, 20(F05): 271?272.

[8] 邓学峰, 张 辉, 陈振华. 耐热铝合金(FVS0812)板材温拉伸本构方程[J]. 塑性工程学报, 2006, 13(3): 84?85.

DENG Xue-feng, ZHANG Hui, CHEN Zhen-hua. Tensile deformation behaviour of heat resistance aluminum (FVS0812) sheet at elevated temperature[J]. Journal of Plasticity Engineering, 2006, 13(3): 84?85.

[9] 赵明久, 刘 越, 毕 敬. 碳化硅颗粒增强铝基复合材料(SiCp/2024Al)的热变形行为[J]. 金属学报, 2003, 39(2): 221?224.

ZHAO Ming-jiu, LIU Yue, BI Jing. Hot deformation behavior of silicon carbide particulate reinforced 2024 aluminum based composite[J]. Acta Metallurgica Sinica, 2003, 39(2): 221?224.

[10] Xia X, Sakaris P, McQueen H J. Hot deformation and recrystallization behaviour of a SiCp/6061 Al composite[J]. Metal/Matrix Composites, 1993, 1: 157?162.

[11] Prasad Y V R K, Sastry D H, Deevi S C. Hot working behavior of extruded powder products of B2 iron aluminide alloys [J]. Mater Sci Eng A, 2001, 311: 42?46.

[12] Mauchi M, Higashi K. Constitutive equation of a superplastic Al-Zn-Mg composite reinforced with Si3N4 whisker[J]. Mater Trans, 1995, 36(2): 420?425.

[13] Han B Q, Chan K C, Yue T M, Lau W S. High temperature deformation behavior of Al 2124-SiCp composites[J]. Journal of Materials Processing Technology, 1997, 63: 395?398.

[14] Prasad Y V R K, Sesharyulu T. Modelling of hot deformation for microstructural control [J]. Int Mater Rev, 1998, 43(6): 243?245.

[15] Pickens J R, Langan T J, Englang R O, Liebson M. Study of the hot-working behavior of SiC-Al alloy composites and their matrix alloys by hot torsion testing [J]. Metall Trans A, 1987, A18: 303?312.

基金项目:国家民口配套资助项目(20051248043)

收稿日期:2007-01-23;修订日期:2007-05-28

通讯作者:高文理,副教授,博士;电话:0731-8821610;E-mail:wenligaohd@hnu.cn

(编辑 龙怀中)