文章编号:1004-0609(2011)06-1320-08

吹气法制备泡沫铝的性能

范雪柳1,陈 祥1, 2,刘兴男1,李言祥1, 2

(1. 清华大学 机械工程系,北京 100084;

2. 清华大学 教育部先进成形制造重点实验室,北京100084)

摘 要:基于吹气法制备A356基泡沫铝工艺,采用高速搅拌并分批连续加入粉末的方式,避免熔体中颗粒分布不均匀的问题;采用静置吹气头通入压缩空气发泡,通过设计和控制气路,制备出不同孔径、不同壁厚、稳定的泡沫铝。结果表明:A356基泡沫铝是一种典型的塑性泡沫材料,泡孔呈十四面体形状,泡壁较薄,厚度小于150 μm,可控的泡孔平均直径范围很宽,为10~25 mm;泡沫铝在致密化阶段的塑性变形量可达70%以上;不作任何预处理的泡沫铝在高频率声波下的吸声系数可达0.9以上;在泡沫样品后设置0~70 mm空腔,其在低频率声波下的吸声性能显著提高;所制备的泡沫铝具有较好的声学性能和力学性能。

关键词:泡沫铝;吹气法;力学性能;声学性能

中图分类号:TG146.2 文献标志码:A

Properties of aluminum foam prepared by gas injection method

FAN Xue-liu1, CHEN Xiang1, 2, LIU Xing-nan1, LI Yan-xiang1, 2

(1. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Key Laboratory for Advanced Materials Processing Technology, Ministry of Education,

Tsinghua University, Beijing 100084, China)

Abstract: The A356 alloy foams were fabricated by gas injection method. The high-speed stirring and continuous addition of Al2O3 particles were used to solve the problems of non-uniform distribution of Al2O3 particles. The static orifices were designed to blow the compressed air into the aluminum melt by controlling the gas circuit. The stable aluminum foams with different cell sizes and thicknesses were obtained. The compression test results reveal that the A356 alloy foams have typical plastic deformation characters. The pores of aluminum foams are tetrakaidecahedron with thin walls (<150 μm) and the foams with pore sizes of 10-25 mm can be produced. The strain of the plastic deformation of the aluminum foams can reach more than 70% under compression test. The sound absorption coefficient of aluminum foam without any pretreatment at the high frequency of the sound wave can reach 0.9. After setting up the cavity back of the foams, the absorption coefficient can be improved obviously under low frequency waves.

Key words: aluminum foam; gas injection method; mechanical property; acoustic property

近些年来,泡沫金属材料作为一种新型结构和功能材料,越来越多地被人们所关注。以铝及铝合金为基体的泡沫材料,因其特殊的胞状多孔结构,具有优良的物理性能和力学性能,如密度小、比强度高、比刚度高、吸收冲击能量、吸声减振、电磁屏蔽、隔热和阻燃等[1]。

目前国际上制备泡沫铝的方法很多[2],最常见的方法有吹气发泡法[3-4]、熔体发泡法[5-6]、粉末压实熔化法和渗流法等,如日本Shinko Wire公司以熔体发泡法、加拿大Cymat[7]公司和澳大利亚Hütte Klein- Reichenbach[8]公司以吹气法、奥地利Alulight[9]公司以粉末冶金法制备出了大体积泡沫铝。在吹气法工艺方面,Hütte Klein-Reichenbac公司的静态吹气法工艺制备出的泡沫铝孔结构均匀且可控程度高。然而,目前只有采用熔体发泡法制备大块体板材泡沫铝的研究报道[10-12],国内关于吹气法制备泡沫铝的研究多数停留在实验室研究阶段[13-14]。

本文作者以A356铝合金为基体,用吹气法制备出不同孔径、不同壁厚、稳定的泡沫铝,研究了搅拌工艺和发泡工艺,考察了该工艺下泡沫铝的声学性能及力学性能。

1 实验

实验中所用的基体材料主要为纯铝和A356铝合金,其中A356铝合金化学成分如表1所列;陶瓷颗粒选用SiO2和Al2O3,尺寸均为9 μm,加入量为10%(体积分数);发泡气体为空气。

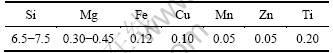

表1 A356铝合金化学成分

Table 1 Chemical composition of A356 alloy (mass fraction, %)

首先将纯铝或铝合金放入电阻坩埚炉中熔化,并称取适量粒径9 μm 陶瓷颗粒放入烘干炉,在400 ℃干燥1 h左右。待铝熔体加热熔化至710 ℃左右时,将粉末分批加入合金熔体中,用机械搅拌桨进行高速搅拌,使粉末分布尽量均匀。搅拌时间必须适宜,过长会导致铝熔体过度氧化,产生的氧化物将增加熔体的黏度,影响发泡效果;搅拌时间过短则粉末团聚现象严重,从而影响泡沫的稳定性。待颗粒均匀分散于熔体中,将含有颗粒的熔体转移至发泡坩埚准备吹气发泡。

在吹气法发泡过程中,熔体的温度由热电偶及时准确地监控,以保证制备好的熔体温度保持在670 ℃左右。开通气体后,先调节减压阀以达到所需气压并稳定气压,再用流量控制器监控并调节气流量,用针阀控制气体流动,使气体平稳均匀地通过透气塞进行发泡。通过调节不同气体流量和压力参数,可产生不同孔径大小的气泡。待泡沫充填入收集装置并凝固后即可得到均匀一致的泡沫铝。气体流量的调节范围为10~100 L/h,透气塞出气口前压力范围保持在10~200 kPa。

所制备的泡沫铝样品均采用线切割加工,以保证上下端面的平整以及端面与试样轴线的垂直度。气孔的平均孔径由划线法测得。先实测得到平均弦长,再用公式D=t/0.616[15]计算出泡孔大小。实验中采用Neophot 32光学显微镜观察泡沫铝的微观组织。

泡沫铝的吸声性能由驻波管法测试得到。当声波垂直入射到泡沫铝表面,入射波与反射波传播方向相反,相互叠加后形成驻波,测量驻波的声压极大值pmax和极小值pmin,就可以算出垂直入射吸声系数α,如式(1)所示,实验测试的声频范围为200~1 600 Hz。

(1)

(1)

泡沫铝的压缩性能是在WDW-100微机控制电子万能试验机上进行测试的。测试时,压头以5 mm/min的速率进行单向压缩,加载量和压缩位移通过传感器及电阻应变仪,输入到X—Y函数记录仪,自动记录加载力—位移曲线,处理后得到压缩应力—应变曲线。

2 结果与讨论

2.1 吹气法制备的泡沫铝的形貌特征

影响吹气法制备泡沫铝工艺的因素有很多,如陶瓷颗粒的粒度和加入量、搅拌时间和方式、气流量、气体压力、透气塞孔径及材料等,这些因素都可直接改变泡沫铝的孔径及壁厚,从而影响到泡沫铝的性能。然而,采用吹气法制备的泡沫铝结构及形貌与采用其它方法制备的泡沫铝有很大差别,主要体现在以下几个方面:1) 泡孔呈十四面体形状;2) 泡壁较薄,厚度小于150 μm;3) 可控的泡孔平均直径范围很宽,为10~25 mm。

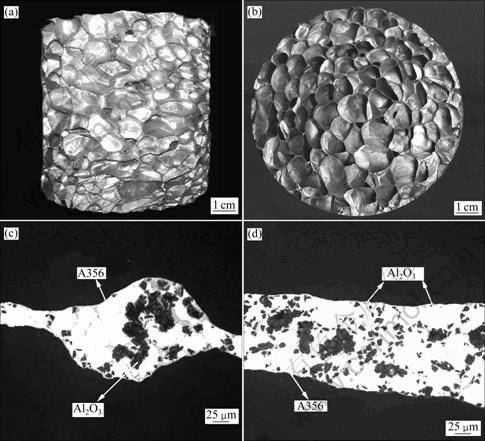

图1所示为吹气法制备的泡沫铝的宏观及微观形貌。从图1(a)和(b)中可以看到:泡孔并不是规则的球形,泡壁表面有一些微孔和裂纹。当陶瓷颗粒分布不均匀时,颗粒团聚处泡壁厚度远大于周围颗粒分布较少处的泡壁(见图1(c));而颗粒分布均匀时,泡壁厚度较均匀(见图(d))。泡壁厚度突变处容易在凝固时破裂,不利于泡沫的稳定。

2.2 陶瓷颗粒及基体材料对吹气发泡工艺的影响

对于泡沫金属的制备,关键问题之一是如何选择材料以获得稳定的泡沫材料。目前,制备泡沫铝常用的陶瓷颗粒为SiC、SiO2和Al2O3,基体材料为纯铝及铝合金,采用不同的颗粒作为增强稳定性材料是为了检验气泡吸附颗粒的能力以及不同颗粒对气泡的稳定作用。

图1 吹气法制备泡沫铝的宏观和微观结构

Fig.1 Macro and micro structures of aluminum foams prepared by gas injection method: (a) Profile of foam; (b) Cross section of foam; (c) Cross section of cell wall with inhomogeneous particle dispersion; (d) Cross section of cell wall with homogeneous particle dispersion

通过加入不同陶瓷颗粒实验的对比可以发现,SiC颗粒粉末很难均匀地分散于熔体中,卷入熔体中的粉末经过1 min静置后上浮于熔体表面。SiO2和Al2O3颗粒较容易分散在铝熔体中。图2所示为加入SiO2和Al2O3陶瓷颗粒发泡后的泡壁横截面的金相照片。由于铝和氧的亲合力非常大,当加入SiO2时可发生如下化学反应:

4Al+3SiO2=2Al2O3+3Si (2)

从图2(a)中可以看出:基体中共晶Si的数量增加。对比加入不同颗粒的发泡实验现象,加入SiO2颗粒发泡时,泡沫在上浮及凝固过程中容易坍塌破裂,SiO2颗粒没有很好地促进泡沫的稳定性,因此,选用Al2O3作为吹气法制备泡沫铝的稳定颗粒是最优的选择。

为了排除不同组织如共晶硅对颗粒位置分布的影响,实验中采用纯铝和A356铝合金作为基体材料进行对比。从图2(b)和(c)可以看到,相比以A356为基体的泡沫铝泡壁,以纯铝为基体的泡沫横截面上颗粒含量非常少,颗粒随机地分布在液膜中,实际发泡效果也远不及以A356为原料的发泡效果。

2.3 机械搅拌工艺对颗粒分散性的影响

为了制备均匀一致的泡沫铝,需要使氧化铝颗粒在熔体中均匀分布。采用桨叶倾角为45°的机械搅拌桨进行搅拌,可使熔体产生轴向流动和径向流场,并产生较高的剪切力,使Al2O3颗粒尽可能地分散;同时,沿搅拌轴方向可以产生巨大轴向压力,从而抑制颗粒的上浮。

Al2O3颗粒的添加方式也会对其分散效果有影响。当将Al2O3包成团直接加入熔体中时,Al2O3颗粒容易集中并沉底,很难分散开;而分批次加入Al2O3粉末后,分散效果比较好。搅拌桨的转速也是制备的关键点。通过不同转速的搅拌效果对比,搅拌桨转速越高,熔体流动越剧烈,颗粒分散效果越好。实验结果表明:在900~1 800 r/min的转速下,颗粒分散效果比较好。搅拌工艺共分为如下4种:1) 颗粒与铝锭同时加入,搅拌30 min;2) 将颗粒粉末分成两团一次性加入后高速搅拌,搅拌30 min;3) 颗粒分2批用锡纸包成团加入,每次加入后高速搅拌,先加入一次搅拌10 min,最后再搅拌10 min;4) 分4批连续加入,每次散完后高速搅拌,每加入一次搅拌5 min,分4次,最后再搅拌10 min。实验中通过对比,多批加入陶瓷颗粒并高速搅拌后颗粒分散效果最好,并且没有出现颗粒粉末上浮现象。

图2 加入SiO2和Al2O3陶瓷颗粒发泡后泡壁横截面的金相照片

Fig.2 Optical micrographs of aluminum foam cell walls by adding SiO2 and Al2O3 particles: (a) A356 alloy with SiO2 particles; (b) A356 alloy with Al2O3 particles; (c) Pure aluminum with Al2O3 particles

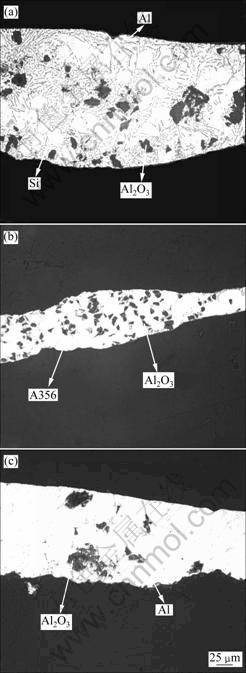

图3所示为添加Al2O3颗粒后分别采用工艺1、2、4、5搅拌后熔体中颗粒分散的金相照片。将颗粒随铝锭一同加入并高速搅拌后,熔体中颗粒团聚现象很严重,颗粒分散也不均匀(见图3(a));而将颗粒分2批加入后,团聚现象有所减少,然而颗粒分布仍然不均匀,部分区域颗粒很少(见图3(b))。颗粒团聚使得其有效利用率降低,同时也不利于气泡上升及泡沫凝固过程中的稳定性。因此,增加加入次数,并减小每次的加入量,在相同时间内,分批次越多,颗粒分散性才能越好,但过多的分批次加入没有必要。分4次和分8次加入陶瓷颗粒并高速搅拌后,陶瓷颗粒分散效果均比较好(见图3(c)和3(d))。

2.4 气路及吹气装置设计对气泡大小的影响

密度及气孔大小等因素直接影响泡沫铝的性能。为了控制气孔大小、得到均匀一致的泡沫材料,发泡过程中参数的设置尤为重要。有学者通过水系实验考察了流量与气泡大小的关系,证明流量、气室体积、出气嘴口径与生成的气泡大小存在紧密的联系[16-19]。

在吹气法制备泡沫铝工艺中,气体流量严重地影响着泡沫铝的孔径大小。图4所示为在不同流量下用单孔透气塞制备泡沫铝时气体流量与气泡直径的关系。

从图4可以看到,气体流量越大则孔径越大。然而当流量增大到一定值,生成的气泡大小不一,孔径增大趋势不明显。同时,透气塞的孔径越大,生成的气泡脱离气嘴时的直径越大,因此,产生的泡沫铝孔径也越大。在气体流量一定的情况下,透气塞的结构和材料直接影响着泡沫孔径的大小。TADAKI和MAEDA[19]指出,当气室体积足够小或足够大的时候,气室体积并不影响气泡大小,气室压力直接影响气泡的生成及脱离过程。

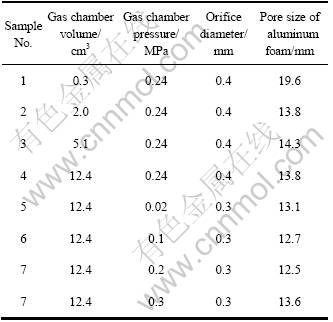

表2所列为不同气室体积及气室压力对孔径大小的影响。从表2可以看出,当气室体积小于13 cm3、压力小于0.3 MPa时,气室体积对孔径大小没有显著的影响。在实际工业生产中,透气塞使用的是多孔结构,因此有效气室体积比较小。当透气塞与铝合金熔体浸润时,泡沫铝的孔径较小;不浸润时孔径较大。因此,选用与铝合金熔体浸润的耐热不锈钢作为透气塞的材料。总之,对一定结构参数的透气塞,通过控制流量和气室压力,可以得到不同孔径大小的泡沫铝。图5所示为不同孔径大小的泡沫样品图。可见孔径越大,泡孔形状越不规则,泡孔表面出现宏观裂纹。

图3 不同搅拌速度下添加Al2O3颗粒后颗粒分散的金相照片

Fig.3 Optical micrographs showing Al2O3 particle dispersion under different stirring processes: (a) Adding particles and aluminum together at high stirring speed; (b) Dividing particles into 2 packs and adding them into aluminum melt at high stirring speed; (c) Dividing particles into 4 packs and adding them into aluminum melt at high stirring speed; (d) Dividing particles into 8 packs and adding them into aluminum melt at high stirring speed

图4 气体流量对孔径大小的影响

Fig.4 Effect of gas flow on pore size of foams

表2 不同气室体积及气室压力对孔径大小的影响

Table 2 Effect of gas chamber volume and pressure on pore size of foams

图5 不同孔径大小的泡沫铝样品

Fig.5 Photos of aluminum foams with different pore sizes: (a) 14.4 mm; (b) 16.0 mm; (c) 18.0 mm; (d) 21.3 mm

2.5 泡沫铝的吸声及压缩性能

2.5.1 吸声性能

图6所示为吹气法制备的泡沫铝的吸声性能。不同平均孔径的泡沫铝吸声性能如图6(a)所示。随着气泡孔径的增加,吸声系数上升,同时共振频率向高频移动,泡沫铝在高频时的吸声性能更好,吸声系数接近1。从图6(b)可以看到,对于同一孔径和孔隙率的泡沫铝,增加泡沫铝样品的厚度可以使共振频率向低频移动,然而厚度的增加对吸声系数峰值的影响较小,因此,在实际工程应用中,增加泡沫铝样品的厚度并不能显著改善吸声性能。然而,在泡沫铝背后设置空腔可以显著改善泡沫铝的吸声性能。从图6(c)和(d)可以看到,当泡沫铝背后的空腔厚度由0逐渐增加至 70 mm时,共振频率向低频移动,并且中低频吸声系数显著增高。

2.5.2 压缩性能

图7所示为泡沫铝压缩变形特性曲线。压缩开始时,试样最薄弱的地方(如泡孔压缩区或骨架破裂区)首先开始变形,并逐渐将变形传递给其它部分。由图7可以看出,泡沫在压缩过程中经历了弹性变形、塑性变形及致密化3个阶段。从所得到的应力—应变曲线来看,泡沫屈服应力小于0.2 MPa,屈服平台很长,孔隙率为96.2%和95.8%的试样在应变0.7~0.8以及孔隙率为92.2%的试样在0.6~0.7时进入致密化阶段。

泡沫密度越小,孔隙率越小,屈服应力越小。与熔体发泡法制备的泡沫铝压缩力学性能[20]对比,吹气法制备的泡沫铝塑性屈服应力小,变形量大,压缩过程中没有碎屑产生。根据式(3),泡沫金属的压缩吸能性大小可用单位体积的泡沫材料被压缩到致密段的过程中所吸收的能量W来表示,即

(3)

(3)

能量吸收效率指在相同的应变时,实际泡沫金属能量吸收与理想泡沫金属能量吸收的比值。因此,对于实验所测结果,尽管屈服平台很长,屈服应力较小,导致能量吸收W较小。因此,有必要进行进一步研究以提高泡沫铝的屈服强度。

图6 泡沫铝的吸声性能

Fig.6 Sound absorption coefficient of aluminum foams: (a) Foam with different diameters, porosity of 97.6% and thickness of 20 mm; (b) Foam with different thicknesses, porosity of 95.2% and diameter of 14.0 mm; (c) Foam with different back cavities, porosity of 95.5%, diameter of 10.4 mm and thickness of 20 mm; (d) Foam with different back cavities, porosity of 97.6%, diameter of 14.4mm and thickness of 20 mm

图7 泡沫铝压缩过程应力—应变曲线

Fig.7 Stress—strain curves of aluminum foams under compression test

3 结论

1) 在吹气法制备泡沫铝工艺中,基体材料和陶瓷颗粒的不同选择直接影响了吹气发泡效果。以纯铝为基体材料或以SiO2为陶瓷颗粒时,发泡效果较差。分批加入陶瓷颗粒并高速机械搅拌可以使颗粒分散均匀,从而得到均匀一致的泡沫铝样品。

2) 用特定参数的吹气装置,通过调节气体压力及流量,可以控制泡沫铝平均孔径大小:标准状态下气体流量越大,则孔径越大。同时,增大透气塞的孔径也可以使泡沫铝平均孔径增大。当透气塞气室体积小于13 cm3时,气室体积对对孔径的影响不大。

3) 吹气法制备的泡沫铝的结构形貌与用其它方法制备的泡沫铝不同:A356基泡沫铝是一种典型的塑性泡沫材料,到致密化阶段其塑性变形量可达到70%以上。

4) 在吸声性能方面,不作任何预处理的泡沫铝在高频率声波下的吸声系数可达到0.9以上;泡沫铝平均孔径的增加可使吸声系数上升,同时使共振频率向高频移动,在高频声波下能够吸收更多的声能。同时,在泡沫铝背后设置空腔,而不是增加泡沫铝的厚度,可以显著改善泡沫铝的吸声性能。

REFERENCES

[1] MANUFACTURE B J. Characterization and application of cellular metals and metal foams[J]. Progress in Materials Science, 2001, 46(6): 553-559.

[2] 陈 祥, 李言祥. 金属泡沫材料研究进展[J]. 材料导报, 2003(5): 5-9.

CHEN Xiang, LI Yan-xiang. Porous metal: Research advances and applications[J]. Materials Review, 2003(5): 5-9.

[3] CA J I, CA K L D, CA S H C J. (A1C)Lightweight foamed metal and its production: CA 19902066421[P]. 1991.

[4] CA N S, CA K J K, CA M R G. Method and apparatus for low pressure aluminum foam casting: US 20040863384[P]. 2004.

[5] MIYOSHI T, ITOH M, AKIYAMA S, KITAHARA A. ALPORAS aluminum foam: Production process, properties, and applications[J]. Advanced Engineering Materials, 2000, 2(4): 179-183.

[6] RAJ R E, DANIEL B. Aluminum melt foam processing for light-weight structures[J]. Materials and Manufacturing Processes, 2007, 22(4): 525-530.

[7] Cymat Technologies Ltd. Technical manual for cymat[EB/OL]. http://www.cymat.com/PDFs/TechManual2009.pdf. 2009.

[8] AT D F, AT F H, AT L D. Device and process for producing metal foam: US 20020170538[P]. 2003.

[9] Alulight International Gmbh. Product information[EB/OL]. http://www.alulight.com/en/downloads/alulight_datasheets_en2006.pdf. 2006.

[10] 袁文文, 陈 祥, 刘 源, 李言祥. 熔体发泡法批量制备泡沫铝板材关键技术的研究[J]. 稀有金属材料与工程, 2009, 38(z3): 306-310.

YUAN Wen-wen, CHEN Xiang, LIU Yuan, LI Yan-xiang. Research on key technologies for batch preparation of aluminum foam slabs by melt foaming process[J]. Rare Metal Materials and Engineering, 2009, 38(z3): 306-310.

[11] 罗洪杰, 姚广春, 张晓明, 魏 莉. 熔体发泡法制备泡沫铝材工艺探讨[J]. 轻金属, 2003(9): 51-53.

LUO Hong-jie, YAO Guang-chun, ZHANG Xiao-ming, WEI Li. Technical discussion of producing foam aluminium by foaming method of molten aluminium[J]. Light Metal, 2003(9): 51-53.

[12] 杨 昊, 张迎元. 泡沫铝产业化的瓶颈 —— 发泡剂[J]. 特种铸造及有色合金, 2008(2): 204-207.

YANG Hao, ZHANG Ying-yuan. The bottleneck of industrialization for aluminum foam—Vesicant[J]. Special Casting & Nonferrous Alloys, 2008(2): 204-207.

[13] 王 倩, 徐方明, 许庆彦, 熊守美. 熔体吹气发泡法制备泡沫铝研究[J]. 铸造, 2007(8): 814-818.

WANG Qian, XU Fang-ming, XU Qing-yan, XIONG Shou-mei. Study on aluminum foam by gas injection foaming[J]. Foundry, 2007(8): 814-818.

[14] 刘 红. 吹气搅拌法制备泡沫铝工艺的气泡—金属熔体两相流的实验研究和数值模拟[D]. 大连: 大连理工大学, 2006.

LIU Hong. Experimental study and numerical simulation on bubble-melt two-phase flow with gas injection and mechanical stirring relevant to the aluminum foam processing[D]. Dalian: Dalian University of Technology, 2006.

[15] 刘培生. 多孔材料孔径及孔径分布的测定方法[J]. 钛工业进展, 2006(2): 29-34.

LIU Pei-sheng. Determining methods for aperture and aperture distribution of porous materials[J]. Titanium Industry Process, 2006(2): 29-34.

[16] IRONS G A, GUTHRIE R. Bubble formation at nozzles in pig-iron[J]. Metallurgical Transactions B-Process Metallurgy, 1978, 9(1): 101-110.

[17] SANO M, MORI K. Bubble formation from single nozzles in liquid-metals[J]. Transactions of THE Japan Institute of Metals, 1976, 17(6): 344-352.

[18] DAVIDSON L, AMICK E H. Formation of gas bubbles at horizontal orifices[J]. AICHE Journal, 1956, 2(3): 337-342.

[19] TADAKI T, MAEDA S. The size of bubbles from single orifices[J]. Chemical Engineering, 1963, 1(1): 55-60.

[20] 王 斌, 何德坪, 舒光冀. 泡沫Al合金的压缩性能及其能量吸收[J]. 金属学报, 2000, 36(10): 1037-1040.

WANG Bin, HE De-ping, SHU Guang-ji. Compressive property and energy absorption of foamed Al alloy[J]. Acta Metallurgica Sinica, 2000, 36(10): 1037-1040.

(编辑 龙怀中)

基金项目: 浙江省科技计划资助项目(2009C31049)

收稿日期:2010-06-22;修订日期:2010-08-04

通信作者:陈 祥,副教授,博士;E-mail: xchen@tsinghua.edu.cn