文章编号:1004-0609(2013)06-1523-07

不同冷压压力下Fe-Cu基金刚石复合材料超薄切锯胎体的组织和致密化机理

李文生,董洪峰,路 阳,张 杰,褚 克

(兰州理工大学 甘肃省有色金属新材料国家重点实验室,兰州 730050)

摘 要:采用单轴模压法,以Fe-Cu基单元素混合粉末为原材料,在不同冷压压力下制备Fe-Cu基金刚石复合材料超薄切锯胎体压坯;利用显微硬度仪、阿基米德原理和OM、SEM表征冷压坯的显微硬度、组织和密度,研究不同压力下冷压坯的致密化机理。结果表明:随着冷压压力的增大,压坯中粉末的变形不均匀,粉末间摩擦力不断发生变化,制约了粉末颗粒的结合方式、显微硬度、排布及胎体密度。

关键词:金刚石复合材料超薄切锯;Fe-Cu基胎体;单轴模压法;致密化

中图分类号:TF 124 文献标志码:A

Microstructure and densification mechanism of Fe-Cu based diamond composite ultra thin sawing matrixes at different cold pressures

LI Wen-sheng, DONG Hong-feng, LU Yang, ZHANG Jie, CHU Ke

(State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: A green sample of Fe-Cu-based diamond composite ultra thin sawing matrixes was prepared by cold uniaxial compaction technology at different cold pressures using Cu-Fe based single element mixed powder as raw materials. The microstructure, density and densification mechanism of the green were investigated by microhardness tester, Archimedes principle, OM and SEM. The results show that the non uniform deformation and changing friction force of inter-powders in green samples occur with increasing pressure, which determines bonding mode, microhardness, arrangement of powders and green densities.

Key words: diamond composite ultra thin sawing; Fe-Cu-based matrix; cold uniaxial compaction; densification

金属基金刚石复合材料工磨具有锋利、近净成型性、切削效率高等特点,已广泛应用于加工石材、陶瓷、半导体等脆硬材料[1]。为提高金刚石工磨具的切削性能,许多学者采用Co、Mo和WC等作为包镶金刚石磨粒的胎体组成材料[2-3]。近年来,金刚石复合材料制品市场竞争激烈,产品价格下跌,而传统的Co基或WC基金刚石工磨具制品成本较高,限制了其应用。因此,人们热衷于研究低成本金刚石工磨具,Fe-Cu基金刚石工磨具由于制备成本低廉、切削性能优良等特点而得到广泛应用[4-5]。

工磨具厚度影响加工效率和精度,降低其厚度可提高原材料利用率和经济效益。因此,在金刚石工磨具材料的技术指标中,除切削性能、力学性能外,工磨具厚度也是非金属脆硬材料特别是精细材料(如宝石、铁氧体、半导体等)加工行业所关心的关键指标。金刚石超薄切锯材料生产大多属商业机密[6],至今仍没有关于其制备工艺及性能研究方面的文献报道。

金属基胎体性能决定工磨具的使用性能,传统的金刚石工磨具制备方法如烧结、热等静压[7]和钎焊[8]等制备的工具材料多为大高径比,且工磨具胎体致密化程度较低,制约了其使用范围。为降低金刚石工磨具厚度和生产成本,提高胎体致密化程度,李文生等[9]和LI等[10]采用单轴模压+热压烧结法,以无Co及无WC的Fe-Cu基元素混合粉末为原材料,制备Fe-Cu基金刚石复合材料超薄切锯胎体。本文作者主要研究单轴冷压压力对胎体压坯组织和性能的影响,探讨不同冷压压力胎体压坯的致密化机理。

1 实验

1.1 试样制备

Fe-Cu基金刚石复合材料超薄切锯胎体成分如表1所列。其中Fe和Sn粉为水雾化粉,平均颗粒尺寸分别为53和37 μm,Cu和Ni粉为电解粉,平均颗粒尺寸为48 μm。

表1 Fe-Cu基金刚石复合材料超薄切锯胎体成分

Table 1 Composition of Fe-Cu-Based diamond composite ultra thin sawing matrixes

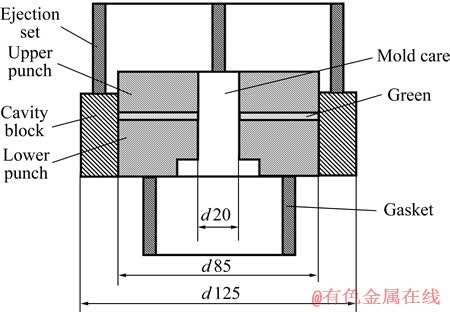

按表1成分称取粉末,在三维涡流混料机(TD-2)中混合1 h,金属混合粉中加入8.5%液体成型剂后重新混合0.5 h。混合粉装入冷压模具中,经均匀铺展压头表面后,在HT-1500KN压样机中单轴冷压成型,冷压加载速率为0.1 mm/min,压制力分别为149、168、187、205和224 MPa,保压时间2 min。冷压压坯脱模后在200 ℃惰性气氛中恒温5 min,以去除残余成型剂,最终制得平均厚度为0.29 mm的压坯试样。冷压模具装配简图如图1所示。

图1 冷压模具装配简图

Fig. 1 Schematic diagram of cold compaction mould (Unit: mm)

1.2 性能及结构分析

用精度0.1 mg分析天平称量冷压压坯,根据阿基米德原理测量压坯真实密度,理论密度的计算公式如下[11]

(1)

(1)

式中:fi、ri (i=1, 2, …, n)是各胎体组成元素的质量分数和理论密度,Fe、Cu、Ni和Sn元素的理论密度分别为7.86、8.96、8.908和7.265 g/cm3。

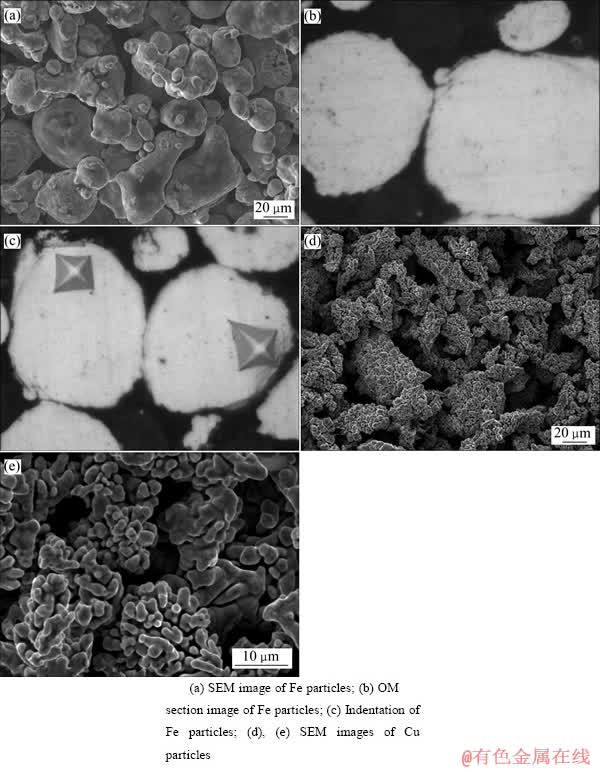

应用金相显微镜(MEF3A)和带能谱仪(EDX)的JSM-6700F场发射扫描电子显微镜观察分析冷压坯受压面、断面组织及粉末分布情况。利用数显显微硬度计(HVS-1000)测量组成胎体的松装单质粉末和压坯显微硬度,金刚石压头载荷为0.25 N。图2所示为Fe、Cu粉末形貌SEM像和Fe粉截面及硬度压痕光学照片。由图2可见,Fe粉形状不规则,Cu粉树枝状。

2 结果与讨论

2.1 压坯密度

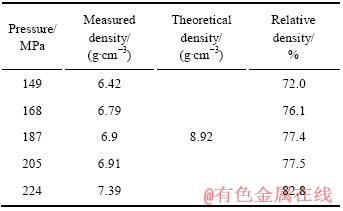

表2所列为Fe-Cu基金刚石复合材料超薄切锯胎体的冷压坯密度。在149~187 MPa和205~224 MPa范围内,胎体压坯相对密度随压力升高而增大的幅度较大,而在187~205 MPa范围内相对密度增大的幅度较小。

2.2 压坯组织结构

图3所示为不同冷压压力下的Fe-Cu基金刚石超薄切锯胎体压坯的受压面光学照片。由图3可看出,在149 MPa压力下,胎体压坯组织存在大量因打磨抛光试样产生的粉末脱落坑,孔隙主要存在于Cu粉中,Ni、Sn粉被Cu粉“包裹”,而Fe粉呈分散状态,如白色虚线所示;168 MPa压坯组织中的粉末脱落坑和孔隙较149 MPa的明显减少,Fe粉发生冷焊现象,如图3(d)白色实线所示;由图3(e)和(f)可知,187 MPa的压力下,压坯组织中的粉末脱落坑和孔隙较168 MPa压力下的增加;205 MPa的压力下,压坯组织中Fe粉重新分散,Sn粉被Fe粉包围,如图3(h)所示;224 MPa的压力下,压坯组织致密,更多Fe粉发生冷焊现象(见图3(i)和(j))。

图2 粉末形貌及压痕照片

Fig. 2 Powder morphologies and indentation images

表2 不同冷压压力下Fe-Cu基金刚石超薄切锯胎体压坯密度

Table 2 Green density and relative density of Fe-Cu-Based diamond ultra thin sawing matrixes at different cold pressures

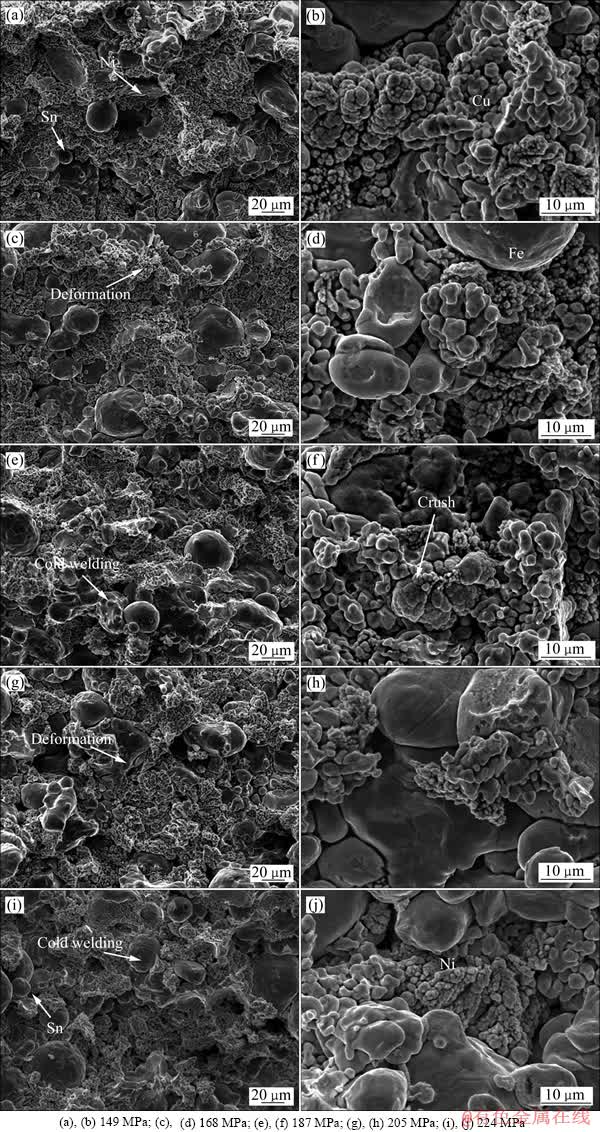

图4所示为不同压力冷压坯的断面形貌SEM像。由图4可见,组织中Cu粉、Fe粉变形较大,Ni粉、Sn粉基本无变化;149 MPa和168 MPa的压力下,压坯组织中的Cu粉发生大量变形,而Fe粉变形较小,Cu粉、Fe粉颗粒未发生冷焊;187 MPa和205 MPa的压力下,压坯中Cu粉发生压溃现象,Fe粉及Cu粉、Fe粉发生冷焊现象;与其他4种压坯相比,224 MPa的压力下,压坯组织中Cu粉变形较大、原形貌消失。

2.3 冷压致密化机理

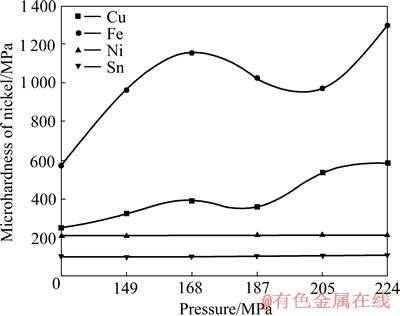

为研究不同压力压坯中各粉末的塑性变形和致密化,测试Cu、Ni、Fe、Sn单质松装粉末以及压坯的显微硬度,结果如图5所示。由图5可知,胎体压坯中Fe粉和Cu粉显微硬度均大于松装粉末显微硬度,而Ni粉和Sn粉显微硬度基本无变化。

图3 不同冷压压力Fe-Cu基金刚石超薄切锯胎体压坯受压面光学照片

Fig. 3 OM images of green compression faces of Fe-Cu-based diamond ultra thin sawing matrixes at different cold pressures

图4 不同冷压压力下Fe-Cu基金刚石超薄切锯胎体压坯断面的SEM像

Fig. 4 SEM images of section of Fe-Cu-based diamond ultra thin sawing matrixes at different cold pressures

图5 不同冷压压力下Fe-Cu基金刚石超薄切锯胎体压坯的显微硬度

Fig. 5 Microhardness of green of Fe-Cu-based diamond ultra thin sawing matrixes at different cold pressures

由粉末压制理论可知,粉末体的冷压致密化与粉末形貌、尺寸以及加工硬化性有关[12]。粉末的加工硬化性受其屈服强度制约,屈服强度越大则加工硬化性越差。由式(2)可知,屈服强度正比于显微硬度[13],因此,显微硬度可用于比较4种粉末的加工硬化性能。屈服强度与显微硬度的关系如下:

(2)

(2)

式中: 为屈服强度;HV为维氏硬度。

为屈服强度;HV为维氏硬度。

粉末体的冷压致密化主要包括两个阶段,粉末重排和变形,并贯穿于冷压的整个过程。而液体成型剂的存在减小了粉间摩擦力,促进了颗粒重排并使其快速进入变形阶段[13]。随着冷压压力的增大,压坯中Cu和Fe粉颗粒变形逐渐增加,粉末结合及排布方式均发生变化。当压力达到149 MPa时,由于树枝状Cu粉较Fe粉颗粒的摩擦力大且加工硬化性好,Cu粉优先发生大量塑性变形[14-15],显微硬度增大,如图5所示;由于较低压力下,Cu、Fe粉末间摩擦力较小,易发生相对滑动,使粉末难于发生粘着(冷焊)(见图4(a)和 (b)),导致试样在打磨抛光过程中压坯粉末发生大量脱落(见图3(a)和(b))。当压力增大到168 MPa时,Cu粉的大量塑性变形使其重叠、粉末尺寸增大,进而提高了粉末间的摩擦力。且Cu、Fe粉变形量增加、显微硬度增大,增强粉末结合,减少脱落坑(见图3(c)和 (d))。由图3(e)、(f)和图5可知,与168 MPa压力相比,187 MPa压力下压坯组织中Fe粉显微硬度减小,脱落坑增加;这主要是因为单轴模压实验为连续升压,而胎体粉末塑性变形主要发生在保压阶段,又由于Fe粉变形性较Cu粉的差,使得在187 MPa下Cu粉的变形比Fe粉的变形快。Cu和Fe粉相对滑动,降低了粉末结合力同时Fe粉发生冷焊现象,从而抑制Fe粉变形、显微硬度减小。由图3(g)、(h)和图4(g)、(h)可知,205 MPa压力下胎体组织中Cu粉的变形量较187 MPa压力下Cu粉的变形量大,且显微硬度明显增大,而Fe粉的变形量变化较小(见图5)。其原因如下:一方面,高压下的易变形Cu粉发生大量塑性变形使其显微硬度增大;另一方面,Cu粉大量变形加速Fe粉运动、冷焊增大了粉末尺寸和粉间摩擦力,增大粉末进一步加工硬化的阻力,抑制胎体致密化,使密度增大较少(见表2)。当压力达到224 MPa时,由于较大压力使Cu、Fe粉克服因冷焊造成的致密化阻力而产生大量塑性变形,从而促进胎体致密化,更多Fe粉发生冷焊,粉末脱落坑明显减少(见图3(i)和4(i))。

胎体中Ni和Sn粉含量较少,其含量仅为Cu的、Fe粉的1/20~1/5,且与Cu和Fe具有相似的粉末形貌,在压制过程中,随Cu和Fe粉的运动而运动,因此,Ni和Sn粉的有效承载压力尺寸较小,使其与Cu、Fe粉摩擦力较小,这就阻碍了Ni和Sn粉在压制过程中的变形。又由于Sn粉尺寸较小,在较高压力下被Fe粉“包裹”起来,进一步抑制了粉末的变形,所以,Ni和Sn粉对胎体压坯冷压致密化的影响很小。

3 结论

1) 149~168 MPa压坯组织中Cu、Fe粉间摩擦力较小,Cu变形速率比Fe粉的快,粉末结合较弱,Fe粉发生冷焊现象,粉末显微硬度和压坯密度均增大。

2) 在187~205 MPa压力下,Fe粉冷焊造成粉间摩擦力增大,导致变形和显微硬度减小,阻碍压坯致密化;在205~224 MPa压力下,高压力克服了摩擦阻力,促使胎体粉末变形和致密化,压坯组织中的Fe粉将相似形貌的Sn粉“包裹”起来。

3) 压坯中Ni、Sn粉末的含量较少,Sn粉尺寸较小,均抑制粉末变形,使其对冷压致密化的影响很小。

REFERANCES

[1] 苏宏华. 新型金属结合剂金刚石工具技术的基础研究[D]. 南京: 南京航空航天大学, 2007: 3-5.

SU Hong-hua. Fundamental research of new metal based matrix diamond tool technology[D]. Nanjing: University of Aeronautics & Astronautics, 2007: 3-5.

[2] LIAO Y S, LUO S Y. Effects of matrix characteristics on diamond compositions[J]. Journal of materials science, 1993, 28: 1245-1251.

[3] 董洪峰, 路 阳, 李文生, 张 杰. 粉末冶金Fe基孕镶金刚石刀头的热处理强化[J]. 粉末冶金技术, 2012, 30(4): 288-292.

DONG Hong-feng, LU Yang, LI Wen-sheng, ZHANG Jie. Heat treatment strengthening of P/M Fe-based impregnated diamond segment[J]. Powder Metallurgy Technology, 2012, 30(4): 288-292.

[4] 谭松成, 杨 洋. 热压金刚石钻头铁基胎体机械性能研究[J]. 金刚石与磨料磨具工程, 2009, 170(2): 625-629.

TAN Song-cheng, YANG Yang. Study of mechanical performance of iron-based matrix for hot-pressed diamond bit[J]. Diamond & Abrasives Engineering, 2009, 170(2): 625-629.

[5] DAI Q L, LUO X P, XU X P, WANG Y C. Effects of rare earth and sintering temperature on the transverse rupture strength of Fe-based diamond composites[J]. Journal of Materials Processing Technology, 2002, 129: 427-430.

[6] 张小军, 徐西鹏. 新型高强度超薄金刚石锯片: 中国, ZL 200720009141.5[P]. 2008-11-05.

ZHANG Xiao-jun, XU Xi-peng. A new ultra thin diamond sawing with high strength: China, ZL 200720009141.5[P]. 2008-11-0 5.

[7] 刘谷成, 姜荣超, 雷 雨. 热等静压(HIP)技术在超硬工具制造中的应用[J]. 金刚石与磨料磨具工程, 2007, 4: 38-40.

LIU Gu-cheng, JIANG Rong-chao, LEI Yu. Application of hot isostatic pressing in superhard tools manufacture[J]. Diamond & Abrasives Engineering, 2007, 4: 38-40.

[8] 郭晓琴. 金刚石磨具钎焊工艺研究[J]. 金刚石与磨料磨具工程, 2007, 3: 40-42.

GUO Xiao-qin. Study on welding technol ogy for diamond tools[J]. Diamond & Abrasives Engineering, 2007, 3: 40-42.

[9] 李文生, 王智平, 路 阳, 肖荣振, 朱昌盛, 冯 力, 李国全, 袁柯祥, 徐建林, 苏义祥. 铜铁基粉末烧结金刚石复合材料及其制备方法: 中国, ZL 200910021464. X[P]. 2012-02-22.

LI Wen-sheng, WANG Zhi-ping, LU Yang, XIAO Rong-zhen, ZHU Chang-sheng, FENG Li, LI Guo-quan, YUAN Ke-xiang, XU Jian-lin, SU Yi-xiang. Preparation of powder sintering Cu-Fe-based diamond composites: China, ZL 200910021464. X [P]. 2012-02-22.

[10] LI Wen-sheng, ZHANG Jie, WANG Shun-cai, DONG Hong-feng. Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix[J]. Rare Metals, 2012, 30(1): 81-87.

[11] ZHU Y Z, YIN Z M, XIANG Z D and ZHE Z. Cold densification behavior of multiple alloy powder containing Fe-Cr and Fe-Mo hard particles[J]. Powder Metallurgy, 2008, 51(2): 143-149.

[12] 王盘鑫. 粉末冶金学[M]. 北京: 冶金工业出版社, 2006: 117-163.

WANG Pan-xin. Powder metallury[M]. Beijing: Metallurgy industry Press, 2006: 117-163.

[13] MORENO M F,  OLIVER C J R. Densification of Al powder and Al-Cu matrix composite (reinforced with 15% Saffli short fibres) during axial cold compaction[J]. Powder Technology, 2011, 206: 297-305.

OLIVER C J R. Densification of Al powder and Al-Cu matrix composite (reinforced with 15% Saffli short fibres) during axial cold compaction[J]. Powder Technology, 2011, 206: 297-305.

[14] POQUILLON D, LEMAITRE J, BACO-CARLES V, TAIHADES P, LACAZE J. Cold compaction of iron powders-relations between powder morphology and mechanical properties (Part Ⅰ): Powder preparation and compaction[J]. Powder Technology, 2002, 126: 65-74.

[15] JAMES P J. Particle deformation during cold isostatic pressing of metal powders[J]. Powder Metallurgy, 1977, 4: 199-204.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51165021);甘肃省杰出青年基金资助项目(1111RJDA013);甘肃省高校科研基本业务费(01-0506)

收稿日期:2012-09-03;修订日期:2012-12-06

通信作者:李文生,教授,博士;电话:0931-2976640;E-mail: Wensheng-li@sohu.com