DOI: 10.11817/j.ysxb.1004.0609.2020-37513

碳纤维表面超声振荡辅助电镀镍涂层工艺及其参数的影响规律

吕钊钊1,沙建军1,祖宇飞1,林冠璋1,代吉祥1,鲜玉强2,张 伟2,崔 鼎2,严从林2

(1. 大连理工大学 工业装备结构分析国家重点实验室,大连 116024;

2. 中国工程物理研究院 应用电子学研究所,绵阳 621900)

摘 要:碳纤维增强铝基复合材料具有诸多优良性能,在航空航天以及民用领域有广阔的应用前景。在碳纤维表面电镀镍涂层,可有效改善碳纤维与铝基体的润湿性,并抑制基体对纤维的损伤。镍涂层的质量与改善效果密切相关。通过预氧化处理并结合超声振荡辅助电镀的方法在纤维表面沉积镍涂层,解决碳纤维在电镀过程中因纤维束丝难以分散而出现的“黑心”问题。在此基础上,研究电镀工艺参数对涂层质量的影响规律,并对优化工艺参数后制备的镍涂层与碳纤维的结合强度进行评价。结果表明:使用添加剂可提高镍涂层与碳纤维之间的结合力,当电镀液pH值调整到3~4、电流密度大于0.3 A/dm2、电镀液温度控制在20~40 ℃时,所制备的镍涂层均匀致密。

关键词:碳纤维;铝基复合材料;电镀;镍涂层;微观结构

文章编号:1004-0609(2020)-03-0571-09 中图分类号:TG146 文献标志码:A

碳纤维增强铝基(Cf/Al)复合材料具有较高的比强度、比刚度、热导率,低的热膨胀系数以及不吸潮、耐腐蚀等一系列优良的性能,在航空航天及民用领域有着广阔的应用前景[1-5]。然而碳纤维与铝基体的润湿性较差,导致在Cf/Al复合材料制备过程中,铝熔体难以充分浸渗到碳纤维束中,使得纤维与基体界面结合较差,碳纤维难以起到应有的增强效果,尽管可以通过提高制备温度改善碳纤维与铝基体之间的浸润性,但是在高温条件下,碳纤维与铝熔体易发生界面化学反应并生成脆性物质Al4C3,界面反应不但破坏了碳纤维表面的原有结构,而且将严重影响复合材料的综合性能[6-8]。

为了改善碳纤维与铝熔体之间的润湿性并抑制界面反应,常用的方法有基体合金化和碳纤维表面涂覆等。其中基体合金化是通过在铝中添加合金元素来提高铝熔体的流动性,进而在一定程度上改善碳纤维与铝熔体之间的润湿性[9-11]。但加入的合金元素可能会与碳纤维发生反应,从而对碳纤维造成损伤[10-11]。与基体合金化相比,碳纤维表面涂覆处理是一种更为有效的方法,常见的碳纤维表面涂层材料有陶瓷涂层和金属涂层。WANG等[12-13]采用聚碳硅烷裂解方法在碳纤维表面制备了SiC涂层,并将其应用于Cf/Al复合材料中,发现SiC涂层能有效地提高碳纤维与铝熔体之间的润湿性,并显著抑制了界面反应。DAOUD等[14]通过熔体浸渗的方法制备了含Ni涂层的Cf/Al复合材料,微观组织结构分析表明,在制备过程中铝熔体可以充分浸渗到碳纤维束中,在碳纤维与铝基体的界面处未发现Al4C3反应物,这是由于镍与铝熔体有着很好的相容性,并且镍涂层可以有效抑制Al4C3的形成。尽管陶瓷涂层和金属涂层都能有效地改善碳纤维与铝熔体之间的润湿性并抑制界面反应,但陶瓷涂层较脆,在经受机械载荷或热冲击载荷时容易产生裂纹缺陷或发生脱落现象,因此金属涂层更适宜于Cf/Al复合材料的制备。

在碳纤维表面沉积金属涂层主要有电镀、化学镀等方法[15-17]。其中电镀法过程简单、速度快、成本低、效益高、适宜于工程化等优点,有望在工业化生产中得到应用[16]。然而,在涂层的电镀过程中,商业碳纤维的规格多为每束数千根甚至数万根,如此密集且细小的碳纤维在电镀液中很容易聚集,从而屏蔽电场,导致纤维束心部位难以沉积或涂层厚度远小于束丝外侧厚度,造成涂层涂覆不均匀,出现“黑心”问题[18-19]。

显而易见,采用纤维束丝中有“黑心”的碳纤维制备铝基复合材料,将会发生纤维束内部浸渗铝基体不足,影响纤维与基体界面结合质量,进而影响复合材料综合性能。

因此,本文针对碳纤维涂覆过程中的“黑心”问题,采用碳纤维表面预氧化处理的方法改变纤维表面结构,并结合超声辅助电镀的方法在碳纤维表面涂覆了镍涂层。在此基础上,进一步研究了电镀工艺参数(添加剂、镀液pH值、电流密度、镀液温度)对镍涂层的微观结构及结合强度的影响规律。

1 实验

1.1 实验材料

实验所采用的碳纤维(Cf)为日本东丽公司生产的T300 型聚丙烯腈基碳纤维,每束含3000根单丝,单丝直径约为7 μm,纤维密度为1.76 g/cm3,拉伸强度为3.53 GPa,拉伸模量为230 GPa。采用Watts电镀液在Cf表面电镀镍(Ni)涂层,经过大量的实验对比分析,对电镀液的成分进行了优选,优选后电镀液的主要成分包括:硫酸镍(NiSO4·6H2O,123 g/L)、硼酸(H3BO3,30 g/L)、氯化镍 (NiCl2·6H2O,32 g/L)、十二烷基硫酸钠(CH3(CH2)11OSO3Na,0.12 g/L)。其中NiSO4·6H2O作为镍源,H3BO3作为pH缓冲剂,NiCl2·6H2O和CH3(CH2)11OSO3Na作为添加剂来提高涂层质量。

1.2 实验方法

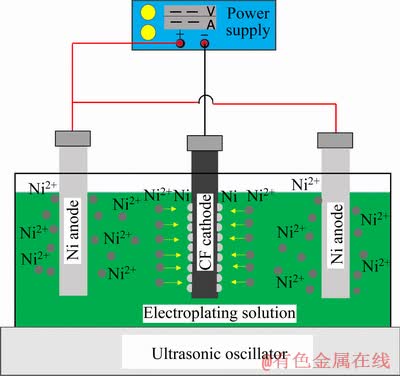

商业Cf表面通常存在上浆剂,其主要组成为有机化合物,上浆剂的存在会严重影响Cf在电镀液中的导电性,致使电流传输效率低,因此在电镀之前,需要对碳纤维进行除胶处理:首先将Cf放入丙酮中浸泡24 h,然后清洗干燥,再放入马弗炉中在400 ℃大气环境中预氧化处理30 min。将预氧化处理的Cf束放入电镀液中,与电源阴极相接;将两块Ni极板置于电镀槽两端与Cf束平行,并与电源阳极相接,如图1所示。在电镀过程中,通过超声振荡易于使Cf均匀分散于电镀液中,在通入恒定电流的作用下,可以使镍离子沉积到Cf表面。为了研究电镀工艺参数对Ni涂层微观结构的影响规律,采用扫描电镜(SEM, QUANTA 450)和X射线衍射仪(XRD-6000)对各工艺条件下获得的Ni涂层微观结构及相成分进行了分析表征,通过热冲击实验对Ni涂层与Cf之间的结合性能进行了评估。

图1 碳纤维表面电镀镍涂层装置示意图

Fig. 1 Schematic diagram of experimental setup used for electroplating of Ni coating on surface of carbon fibers

2 结果与分析

2.1 碳纤维表面预氧化处理及镍涂层沉积

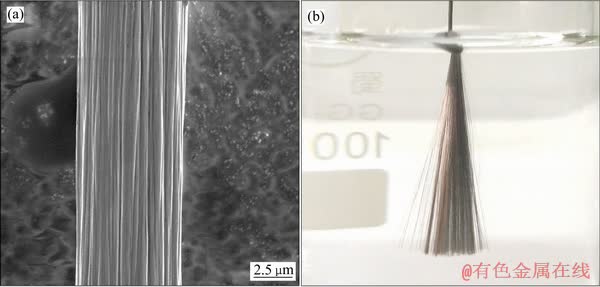

图2(a)所示为大气环境下400 ℃预氧化处理30 min后的碳纤维表面微观形貌。预氧化处理后的碳纤维表面粗糙,沿轴向分布着沟壑状条纹。在之前的研究中[20]发现,未经预氧化处理的碳纤维表面光滑,无明显的沟壑状条纹,且Cf在电镀液中很难分散。这是由于未经处理的Cf表面有一层上浆剂,上浆剂的存在使得Cf表面呈现化学惰性和憎液性,同时Cf平滑的表面也不利于与涂层的结合。图2(b)所示为Cf表面电镀Ni涂层后的宏观照片,从图2(b)可以看出,Cf束丝在去离子水中能够均匀分散,Cf被完整的沉积上了银白色光亮的Ni涂层,在Cf束丝内部,没有发现未被涂覆的纤维。可见,采用预氧化处理结合超声振荡可有效解决碳纤维束在电镀过程中易出现的“黑心”问题。

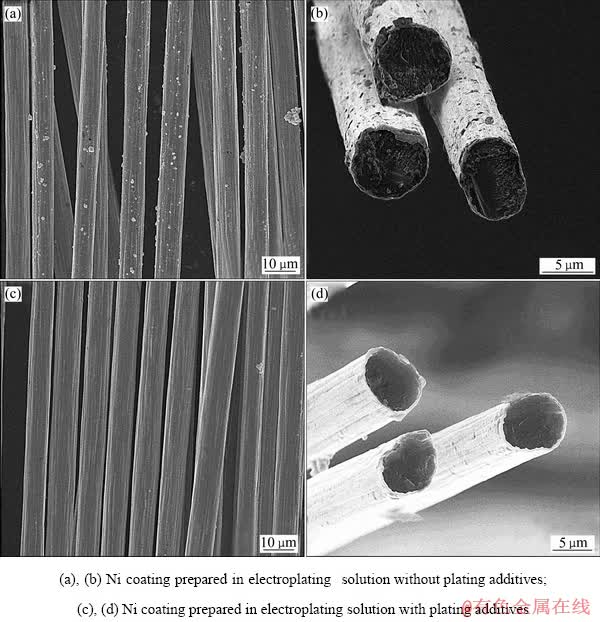

2.2 添加剂对镍涂层微观结构的影响

为了研究添加剂对Ni涂层微观结构的影响,在两种不同成分的镀液环境下(有添加剂和无添加剂)沉积了Ni涂层。电镀工艺参数如下:电镀时间5 min;电流密度0.4 A/dm2;pH值4;温度25 ℃。图3(a)和(b)所示为不含添加剂时电镀Ni涂层的微观形貌,从图3(a)和(b)可以看出,Cf表面被Ni涂层完整地包裹着,未观察到明显的裸露碳纤维,但Ni涂层的表面粗糙不平,且表面粘附有较大的Ni颗粒。这是因为在没有添加剂的镀液中,涂层表面易析出氢气,氢气的析出降低了该区域的电流效率,减少了Ni2+的还原,在没有氢气析出的区域Ni2+还原正常,首先会在碳纤维表面形成凹凸不平区域,凸的区域比凹的区域活性高,Ni也易于在此处沉积,随着电镀的进行,最终形成较大的Ni颗粒,使得涂层粗糙不平。图3(c)和(d)所示为含添加剂时电镀Ni涂层的微观形貌。通过对比可以看出,加入添加剂后Ni涂层表面变得光滑平整,未出现较大的Ni颗粒。添加剂中CH3(CH2)11OSO3Na是一种阴离子型的表面活性剂,这种表面活性剂具有很强的亲水性,在电镀的过程能够吸附在阴极表面,减少电极与电镀液之间的界面张力,使得氢气不易在涂层表面析出。

图2 预氧化处理碳纤维表面SEM像及镍涂覆后纤维束在去离子水中的宏观形貌

Fig. 2 Surface SEM image for carbon fibers after pre-oxidation(a) and morphology of Ni-coated fiber bundles immersed in distilled water(b)

图3 两种不同成分镀液制备的镍涂层SEM像

Fig. 3 SEM images of Ni coatings prepared in two kinds of electroplating solutions

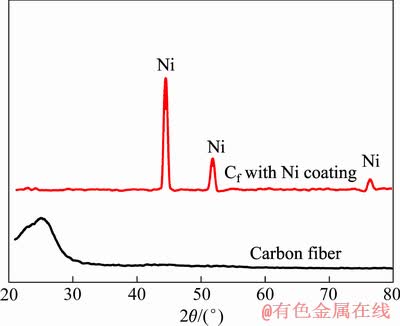

图4所示为碳纤维在电镀Ni涂层前后的XRD谱。从图4中可以看出,在未经涂覆的Cf中检测出了宽化的C峰。在电镀Ni涂层后,XRD检测出了一组Ni的衍射峰,并未检测到其他物质,这说明该涂层的主要成分为单质Ni,另外,Ni的衍射峰峰形尖锐,说明Ni的结晶度较高。在电镀后,XRD谱中并未检测到碳的宽化峰,这可能一方面因为Ni涂层完整的包覆在Cf表面,削弱了检测信号;另一方面,由于Ni的衍射峰结晶度较高,衍射峰强信号远高于碳的宽化峰,因此在XRD检测中难以被检测识别。

图4 碳纤维表面电镀镍涂层前后的XRD谱

Fig. 4 XRD patterns for carbon fibers with and without Ni coatings

2.3 电镀工艺参数对涂层微观形貌的影响

在电镀过程中,电镀工艺参数将显著影响涂层的微观形貌及其结合。在前期的研究中,已通过对比实验分析,对电镀液成分进行了优化,在此基础上,针对电镀工艺参数(电镀液pH值、电流密度和镀液温度)对涂层质量的影响规律进行了研究。

2.3.1 pH值对涂层的影响

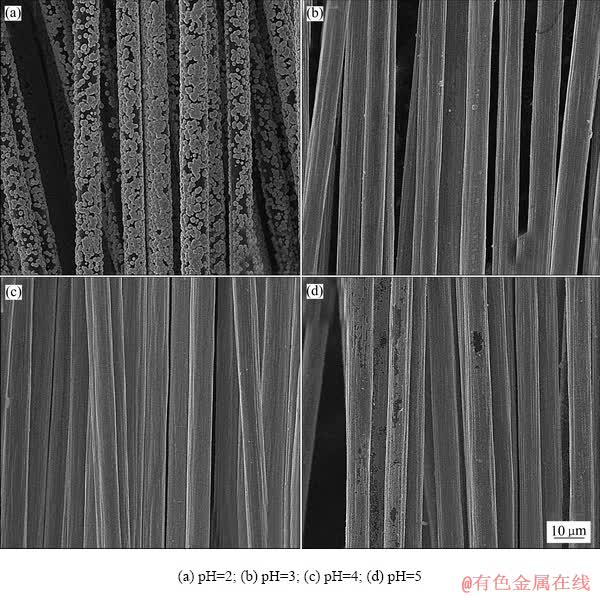

为了研究pH值对Ni涂层微观结构影响,在不同pH值(pH=2~5)条件下制备了Ni涂层,其他电镀工艺参数如下:电流密度0.4 A/dm2,电镀时间5 min,温度25 ℃。图5所示为不同pH值条件下电镀Ni涂层的微观形貌。从图5(a)中可以看出,当pH=2时,Cf表面的涂层由球状Ni颗粒聚集而成,这些颗粒没有完全的包覆在Cf表面。当pH值升高到3和4时,由图5(b)和(c)可以看出,纤维表面的Ni涂层光滑细腻,均匀完整,与碳纤维紧密的包覆在一起。当pH=5时,尽管纤维表面大部分被均匀连续的涂覆上了Ni涂层,但是仍有一些碳纤维的表面裸露在外,如图5(d)所示。由此可以发现pH值过高或者过低均不利于Ni涂层的沉积。当电镀液pH值过低时(pH=2),电镀液中H+浓度过高,在碳纤维周围(阴极附近)的H+将直接得到电子,并伴随有大量的H2析出,H2析出时消耗了大量的电子,使得阴极电流效率降低;另一方面,析出的H2会形成气泡,在涂层与电镀液之间形成气体屏障,阻碍Ni的沉积,致使Cf表面的Ni涂层不致密。反之,当pH值过高时(pH=5),随着电镀过程的进行,阴极附近的H+消耗过快,相对地OH-的浓度进一步增加,OH-会与Ni2+生成Ni(OH)2胶体,使得电极周围Ni2+浓度减少,降低了碳纤维表面Ni的沉积速率。

2.3.2 电流密度对涂层的影响

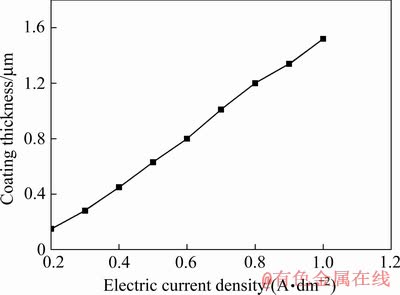

为了研究电流密度对Ni涂层微观结构的影响,在不同电流密度条件下(0.2~1.0 A/dm2)制备了镍涂层,并对镍涂层厚度进行了测量。其他工艺参数如下:电镀时间5 min,pH值为4,温度25 ℃。图6所示为Ni涂层厚度与电流密度的关系曲线。从图中可以看出涂层厚度与电流密度几乎呈线性变化关系。根据法拉第定律,涂层厚度的计算式如下[21]:

(1)

(1)

式中: 为涂层的厚度,mm;JK为电流密度,A/dm2;

为涂层的厚度,mm;JK为电流密度,A/dm2; 为电流效率,%;t为电镀时间,h;E为涂层金属化学当量,g/(A·h);

为电流效率,%;t为电镀时间,h;E为涂层金属化学当量,g/(A·h); 为涂层金属密度,g/cm3。

为涂层金属密度,g/cm3。

其中电镀时间,涂层金属化学当量,涂层金属密度均为定值,因此可以发现随着电流密度增加,电流效率几乎保持恒定,表明在该电镀过程中,发生的其他副反应较少,对电流利用率较高[16]。

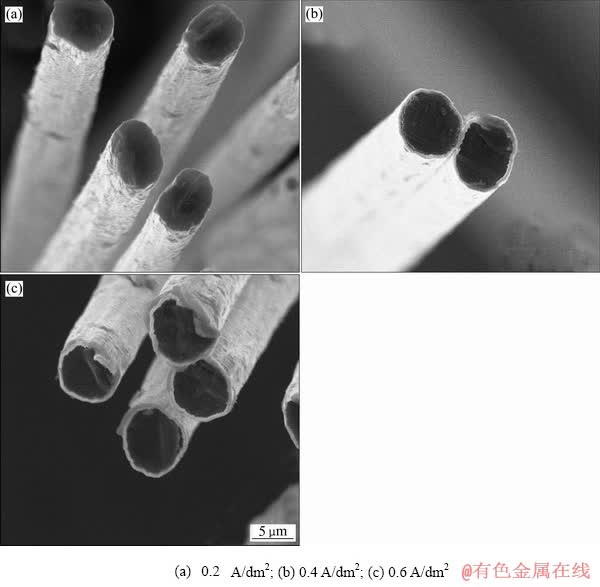

图7所示为不同电流密度条件下获得Ni涂层的微观形貌。通过图7(a)观察发现,当电流密度为0.2 A/dm2时,Cf周围包裹着一层薄薄的Ni涂层,由于电流密度较低时,Ni2+得电子速率较慢,导致晶核成形速率低下,金属镍较难在Cf表面沉积,致使获得的涂层较薄。当电流密度增大到0.4 A/dm2时,Cf周围包裹一层均匀完整的Ni涂层,如图7(b)所示,而且Ni涂层与Cf之间结合紧密,Ni涂层厚度约为0.45 μm。当进一步增大电流密度到0.6 A/dm2时,Ni涂层厚度为0.80 μm,Ni涂层包覆依然均匀完整。

图5 不同pH条件下电镀镍涂层的微观形貌

Fig. 5 Surface morphologies of Ni coating electroplated under different pH values

图6 涂层厚度与电流密度的关系曲线

Fig. 6 Relationship between coating thickness and electric current density

2.3.3 镀液温度对涂层的影响

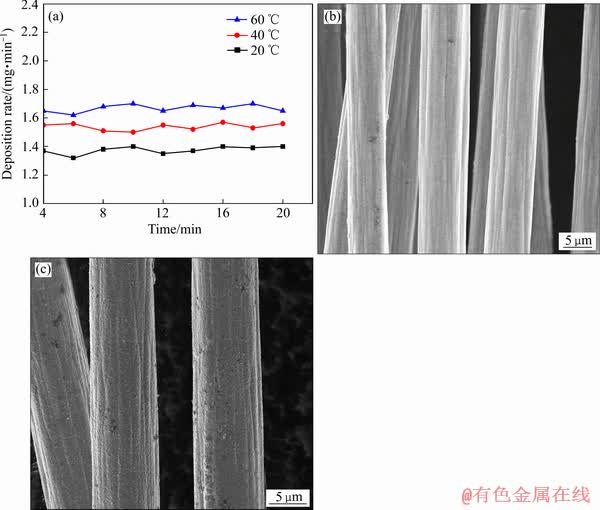

为了研究镀液温度对Ni涂层微观结构及沉积速率的影响,首先选取同等质量的Cf,在不同温度条件下(20~60 ℃)制备了Ni涂层,并通过碳纤维的增重评价了镍涂层的沉积速率。其他电镀工艺参数为:电流密度0.4 A/dm2,pH值为4,电镀时间为5 min。图8(a)所示为不同温度条件下的Ni涂层沉积速率。当镀液温度为20、40、60 ℃时,Ni涂层的平均沉积速率分别为1.38、1.54和1.67 mg/min。随着镀液温度的升高,Ni涂层的沉积速率也在不断增大。温度的升高会加快镀液中离子的流动,从而降低浓度极化带来的影响,增加电流效率。同时随着温度的升高,镀液的导电能力和离子均匀化程度也能得到一定的提升,从而加快了涂层的沉积速率。对比镀液温度为20和60 ℃时的涂层微观形貌可以看出,当温度较低时(20 ℃),涂层表面光滑且均匀致密(见图8(b))。当温度升高到60 ℃时,虽然可以获得均匀完整的Ni涂层,但涂层与20 ℃时相比较为疏松(见图8(c))。这是由于过高的温度会导致镍盐发生水解现象,生成的氢氧化镍胶体吸附在涂层表面,滞留氢气造成涂层疏松。

图7 不同电流密度条件下沉积的镍涂层SEM像

Fig. 7 SEM images of Ni coatings under different electric current density

图8 不同温度条件下获得的镍涂层的沉积速率及微观形貌

Fig. 8 Deposition rate of Ni coating at different temperatures(a), surface morphology for Ni coated at 20 ℃(b) and surface morphology for Ni coated at 60 ℃(c)

2.4 Ni涂层与碳纤维的界面结合质量

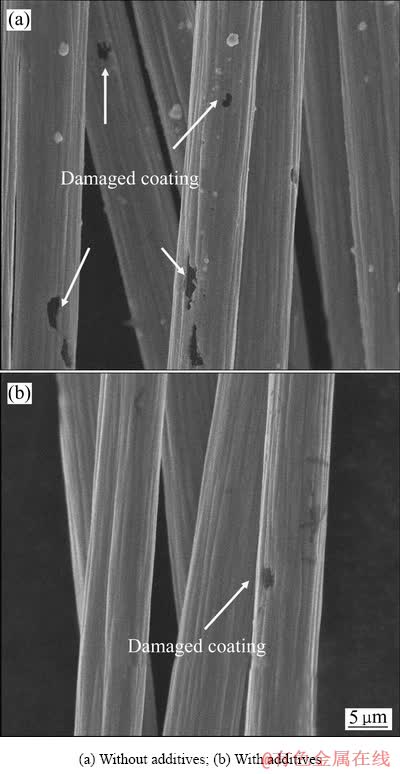

采用热冲击法对Ni涂层与碳纤维的界面结合力进行了评价。Ni涂层为采用优化后的工艺参数制备的,具体电镀工艺参数:pH值为4,电流密度为0.4 A/dm2,电镀时间为5 min;温度为25 ℃,添加剂为NiCl2·6H2O和CH3(CH2)11OSO3Na。并选取了不含添加剂所制备的镍涂层(其余工艺参数相同)作为热冲击实验的对比样品。首先将具有涂层的Cf置于沸水中加热20 min,然后迅速取出放入冰水混合物中浸泡5 min。经过6次反复循环,然后观察其表面微观形貌,通过涂层的剥离程度来分析涂层与纤维表面的结合力[16]。图9(a)所示为不含添加剂情况下涂层在经历热冲击实验后的微观形貌,碳纤维表面可发现涂层多处剥落现象。对热冲击前后涂层的质量进行了测量,发现热冲击导致的质量损失率可达10.4%。图9(b)所示为含添加剂时镍涂层在经历了6次热冲击循环后的表面微观形貌。从图9(b)清晰可见,涂层依然表面光滑且质地均匀,热冲击前后涂层的微观形貌未发生明显变化,在纤维表面出现较少涂层剥落的痕迹。对比涂层质量变化,热冲击试验后涂层质量损失率约为2.2%。说明在此优化的制备工艺下,Ni涂层与碳纤维的结合力较高,涂层质量好。如前文所述,当不含添加剂时,由于电镀过程中表面析出H2并滞留在纤维表面,影响涂层沉积,使涂层变的松散,降低涂层与纤维之间的结合力。当含有添加剂时,这一现象将被CH3(CH2)11OSO3Na所抑制。另外,添加剂中的NiCl2·6H2O在电镀液中能够电离出Cl-,Cl-能够抑制Ni2O3的形成,一旦有Ni2O3形成将会吸附在Ni涂层上,增加涂层的内应力,将降低涂层与纤维之间的结合力。

图9 热冲击实验后碳纤维表面涂层的微观形貌

Fig. 9 Surface morphologies of Ni coating after thermal shock test (Ni coatings prepared in electroplating solutions)

3 结论

1) 采用预氧化处理改变了碳纤维的表面活性,并结合超声振荡辅助电镀的方法在Cf表面成功的制备了Ni涂层,预氧化处理和超声振荡有利于Cf束丝在电镀液中的分散,可以使碳纤维与电镀液充分接触,有效的解决了Cf在电镀过程中出现的“黑心”问题,实现了Cf表面Ni涂层高质量的沉积。

2) 研究了电镀工艺参数对Ni涂层微观形貌及沉积规律的影响,结果表明:过高或过低的pH值都不利于Ni涂层的沉积,最佳pH值应维持在3~4之间;电流密度小于0.3 A/dm2时,金属Ni很难在Cf表面沉积,增大电流密度可以获得均匀完整且不同厚度的Ni涂层;镀液温度越高,Ni涂层的沉积速率也将越大,但温度过高时,会造成涂层表面疏松,最佳温度应在20~40 ℃之间。

3) 通过热冲击实验研究了添加剂对Ni涂层与Cf结合力的影响,发现不含添加剂的电镀液获得的Ni涂层表面粗糙,镍颗粒粗大,热冲击试验后Ni涂层的质量损失率达到10.4%。而使用添加剂时电镀的Ni涂层表面光滑平整,热冲击试验后Ni涂层的质量损失率仅为2.2%。

REFERENCES

[1] RAWAL S. Metal-matrix composites for space applications[J]. JOM, 2001, 53(4): 14-17.

[2] KACZMAR J W, PIETRZAK K, WLOSINSKI W. The production and application of metal matrix composite materials[J]. Journal of Materials Processing Technology, 2000, 106(1/3): 58-67.

[3] QU X H, ZHANG L, WU M, REN S B. Review of metal matrix composites with high thermal conductivity for thermal management applications[J]. Progress in Natural Science: Materials International, 2011, 21(3): 189-197.

[4] 孙德伟, 张广玉, 张其馨, 武高辉. 石墨纤维增强铝基复合材料在空间遥感器镜筒结构中的应用[J]. 光学精密工程, 2009, 17(2): 368-374.

SUN De-wei, ZHANG Guang-yu, ZHANG Qi-xin, WU Gao-hui. Application of graphite fiber reinforced aluminum matrix composite to body tube structure in space remote sensor[J]. Optics and Precision Engineering, 2009, 17(2): 368-374.

[5] 李寅雪. 纤维增强铝基复合材料在输电导线中的应用[J]. 华北电力技术, 2010(8): 29-32.

LI Yin-xue. Application of fiber-reinforced aluminum matrix composites in conductor[J]. North China Electric Power, 2010(8): 29-32.

[6] 胡银生, 余 欢, 王振军, 徐志锋, 董敬涛. 织物结构对2.5D-Cf/Al 复合材料微观组织与力学性能的影响[J]. 中国有色金属学报, 2018, 28(12): 2512-2522.

HU Yin-sheng. YU Huan, WANG Zhen-jun, XU Zhi-feng, DONG Jing-tao. Effect of woven fabric structure on microstructure and mechanical properties of 2.5D-Cf/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2512-2522.

[7] DENG C F, ZHANG X X, WANG D Z. Chemical stability of carbon nanotubes in the 2024Al matrix[J]. Materials Letters, 2007, 61(3): 904-907.

[8] WANG X, JIANG D M, WU G H, LI B, LI P Z. Effect of Mg content on the mechanical properties and microstructure of Grf/Al composite[J]. Materials Science and Engineering A, 2008, 497(1/2): 31-36.

[9] MATSUNAGA T, MATSUDA K, HATAYAMA T, SHINOZAKI K, YOSHIDA M. Fabrication of continuous carbon fiber-reinforced aluminum-magnesium alloy composite wires using ultrasonic infiltration method[J]. Composites: Part A, 2007, 38(8): 1902-1911.

[10] CHENG H M, ZHOU B L. Effect of silicon additions on characteristics of carbon fiber reinforced aluminum composites during thermal exposure[J]. Journal of Materials Research, 1996, 11(5): 1284-1292.

[11] SOBCZAK N, SOBCZAK J, SEAL S, MORGIEL J. TEM examination of the effect of titanium on the Al/C interface structure [J]. Materials Chemistry and Physics, 2003, 81(2/3): 319-322.

[12] WANG Y Q, ZHOU B L. Behaviour of coatings on reinforcements in some metal matrix composites[J]. Composites Part A, 1996, 27(12): 1139-1145.

[13] WANG Y Q, ZHOU B L. Effect of a fiber coating on the fabrication of fiber reinforced metal-matrix composites[J]. Journal of Materials Processing Technology, 1998, 73(1/3): 78-81.

[14] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration[J]. Materials Science and Engineering A, 2005, 391(1/2): 114-120.

[15] XUE Y L, CHEN W G, ZHAO Q, FU Y Q. Electroless carbon fibers: A new route for improving mechanical property and wettability of composites[J]. Surface & Coatings Technology, 2019, 358: 409-415.

[16] HUA Z S, LIU Y H, YAO G C, WANG L, MA J, LIANG L S. Preparation and characterization of nickel-coated carbon fibers by electroplating[J]. Journal of Materials Engineering and Performance, 2012, 21(3): 324-330.

[17] LIU L, TANG Y P, ZHAO H J, ZHU J H, HU W B. Fabrication and properties of short carbon fibers reinforced copper matrix composites[J]. Journal of Materials Science, 2008, 43(3): 974-979.

[18] 刘双进, 崔春翔, 戚玉敏, 董天顺. 碳纤维表面电镀铜工艺的研究[J]. 材料科学与工艺, 2008, 16(6): 840-842.

LIU Shuang-jin, CUI Chun-xiang, QI Yu-min, DONG Tian-shun. Surface treating technology of carbon fibers[J]. Materials Science & Technology, 2008, 16(6): 840-842.

[19] LU G H, LI X T, JIANG H C. Electrical and shielding properties of ABS resin filled with nickel-coated carbon fibers[J]. Composites Science and Technology, 1996, 56(2): 193-200.

[20] 吕钊钊, 祖宇飞, 沙建军, 鲜玉强, 张 伟, 崔 鼎, 严从林. 含Cu界面层碳纤维增强铝基复合材料制备工艺及其力学性能研究[J]. 金属学报,2019, 55(3): 317-324.

Lü Zhao-zhao, ZU Yu-fei, SHA Jian-jun, XIAN Yu-qiang, ZHANG Wei, CUI Ding, YAN Cong-lin. Fabrication and mechanical properties of carbon fiber-reinforced aluminum matrix composites with Cu interphase[J]. Acta Metallurgica Sinica, 2019, 55(3): 317-324.

[21] YANG H, KANG S W. Improvement of thickness uniformity in nickel electroforming for the LIGA process[J]. International Journal of Machine Tools & Manufacture, 2000, 40(7): 1065-1072.

Influences of electroplating parameters on deposition of Ni coatings on carbon fibers by electroplating technique assisted with ultrasonic vibration

Lü Zhao-zhao1, SHA Jian-jun1, ZU Yu-fei1, LIN Guan-zhang1, DAI Ji-xiang1, XIAN Yu-qiang2, ZHANG Wei2, CUI Ding2, YAN Cong-lin2

(1. State Key Laboratory of Structural Analyses for Industrial Equipment, Dalian University of Technology, Dalian 116024, China;

2. Institute of Applied electronics, China Academy of Engineering Physics, Mianyang 621900, China)

Abstract: Carbon fiber reinforced aluminum matrix composite (Cf/Al-based composite) is a typical structure material used for widely applications. To overcome the poor wetting ability and the chemical reaction between Cf and aluminum, it is necessary to electroplate Ni coatings on the surface of Cf. In this study, Cf were pre-oxidized and an electroplating technique assisted with the ultra-sonic vibration were used to deposit Ni coating on the Cf. The results show that such electroplating technique could effectively deposit a homogeneous Ni coating on the Cf without the ‘black core’ phenomenon. Moreover, the influences of electroplating parameters on the microstructure of nickel coatings were investigated systematically. The interfacial bonding strength between Ni coatings and Cf was evaluated by the thermal shock method. The results indicate that the interfacial bonding strength is significantly improved. In addition, the suitable electroplating parameters are identified in terms of the microstructures of Ni coatings.

Key words: carbon fiber; aluminum matrix composite; electroplating technique; nickel coating; microstructure

Foundation item: Project(U1630129) supported by the Joint Funds of the National Natural Science Foundation of China

Received date: 2019-03-13; Accepted date: 2019-10-08

Corresponding author: SHA Jian-jun; Tel: +86-411-84709004; E-mail: jjsha@dlut.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金委员会与中国工程物理研究院联合基金项目(U1630129)

收稿日期:2019-03-13;修订日期:2019-10-08

通信作者:沙建军,教授,博士;电话:0411-84709004;E-mail:jjsha@dlut.edu.cn