文章编号:1004-0609(2007)12-1973-08

Ti-6Al-4V合金超塑性变形中的组织演变及变形机制

赵文娟1,丁 桦1,曹富荣1,侯红亮2,李志强2

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 北京航空制造工程研究所,北京 100024)

摘 要:920℃、应变速率为1×10-3和2×10-4 s-1时,对不同初始晶粒尺寸(2.6、6.5和16.2 μm)的Ti-6Al-4V合金进行超塑性拉伸变形。采用光学显微镜、透射电镜观察变形后的显微组织。结果表明,初始晶粒尺寸的不同对超塑性变形中的组织演变及变形机制有着显著的影响。拉伸变形中晶粒明显粗化,变形诱发晶粒长大是超塑性变形组织的重要特征之一;随着变形程度的增大,应变诱发的晶粒长大显著增大,并且远大于静态长大的增幅。对于细晶粒材料(2.6和6.5 μm),位错运动协调的界面滑动是其变形的主要机制。而对于晶粒较粗的材料(16.2 μm),超塑变形机制是晶界滑动与晶内位错运动的共同作用。随着晶粒尺寸的增大,以晶界滑动为主的变形方式逐渐转向以晶内位错运动为主。

关键词:Ti-6Al-4V合金;超塑性变形;晶粒尺寸;晶粒长大;变形机制

中图分类号:TG 146.2 文献标识码:A

Microstructural evolution during superplastic deformation of Ti-6Al-4V alloy

ZHAO Wen-juan1, DING Hua1, CAO Fu-rong1, HOU Hong-liang 2, LI Zhi-qiang2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Beijing Aeronautical Manufacturing Technology Research Institute, Beijing 100024, China)

Abstract: Superplastic tensile tests were carried out for Ti-6Al-4V alloy using different initial grain sizes (2.6, 6.5 and 16.2 μm) at 920 ℃ with an initial strain rate of 1×10-3 and 2×10-4 s-1. To get an insight into the effect of grain size on microstructural evolution and superplastic deformation mechanisms, the microstructures of deformed alloy were investigated by using an optical microscope and transmission electron microscope. The results indicate that there is dramatic difference in the superplastic deformation mode of fine and coarse grained Ti-6Al-4V alloys. Grain growth is clearly observed, and strain inducing grain growth is one of the important microstructural characteristics during superplastic deformation. Moreover, grain growth induced by strain becomes dramatic with the increase of deformation, which is obviously larger than the static growth. For fine grained material, boundary sliding accommodated by dislocation motion is the main deformation mechanisms. For coarse grained material, superplastic deformation is accommodated by the mixture of grain boundary sliding and intragranular dislocation motions. It indicates a transition from boundary sliding to matrix deformation with the coarsening of grains.

Key words: Ti-6Al-4V alloy; superplastic deformation; grain size; grain growth; deformation mechanism

超塑性及超塑性变形行为,作为材料在外力作用下塑性变形行为的一种表征,反映了材料本身(如化学成分、显微组织等)及变形条件(如变形温度、变形速度、加热方式、外力大小等)和变形机制(如晶界滑动、扩散蠕变、再结晶等)诸多因素的综合作用,这些因素对许多材料加工工艺过程都有着重要的影响[1-3]。因此,随着航空、航天和精密仪表制造领域的发展,对超塑性技术的研究和应用日渐引起国际和国内相关领域的重视,使其成为现代成形领域中的一个很有发展前景的研究和应用分支。

通常,组织超塑性的实现要求材料具有微细的等轴晶粒组织(≤10 mm),并且希望材料的组织在超塑变形中保持细小、稳定。但已有的研究表明,超塑变形中材料的组织要发生变化[4],如动态再结晶、孔洞的发生与长大、晶粒长大等。而且,材料初始组织的不同也可能对超塑性变形中的组织演变或变形机制产生影响,然而这方面的研究尚不多见。因此,本文作者以超塑性合金Ti-6%Al-4%V(以下简称Ti-6Al-4V)为研究对象,观察初始晶粒尺寸不同时该合金超塑性拉伸过程中的组织演变,探索初始晶粒尺寸对超塑性变形中的组织演变以及变形机制的影响作用。

1 实验

材料选用商业2 mm标准冷轧Ti-6Al-4V板材。为获得不同晶粒尺寸的等轴晶粒组织,在920 ℃时进行再结晶退火,退火时间分别为1、12和48 h,获得相应的晶粒尺寸为2.6、6.5及16.2 μm(以下简称为1号、2号和3号材料)。

拉伸实验在AG 250KNE型电子拉伸实验机上进行,变形温度为920 ℃,采用恒定的拉伸速度1.8 mm/min和0.36 mm/min(分别相当于初始应变速率为 1×10-3 s-1和2×10-4 s-1),获得一定的变形量后立即水淬。拉伸试样的标距尺寸为:30 mm×15 mm×2 mm。

采用OLYMPUS GX51金相显微镜观察试样变形后的光学显微组织。为了清晰分辨Ti-6Al-4V合金中的α相和β相,采用两阶段浸蚀,对β相进行着色(β相为黑色)。第一阶段的浸蚀剂为3 mL HF+6 mL HNO3+100 mL H2O,第二阶段的为98 mL C2H2O4?2 H2O(20%,质量分数)+2 mL HF+1 g Fe(NO3)3。定量金相利用OLYCIATM M3 金相图像分析系统进行测定。采用TECNAI G20透射电镜(TEM)观察变形组织中的位错和晶界形貌。

2 结果与讨论

2.1 光学显微组织观察

图1所示为920 ℃两相区退火后的光学显微组织,由图可见,再结晶退火后获得了接近相等体积的两相,呈均匀等轴的晶粒形态,且随着保温时间的增加,晶粒明显长大。因此,热处理后得到3种晶粒尺寸的Ti-6Al-4V合金板材,其晶粒尺寸为2.6、6.5和16.2 μm(β相的体积分数分别为52.0%、52.4%和64.7%),分别记为1号、2号和3号试样。

图1 退火后的显微组织

Fig.1 Microstructures of specimens annealed for different times: (a) 1 h(specimen 1, 2.6 μm); (b) 12 h(specimen 2, 6.5 μm; (c) 48 h(specimen 3, 16.2 μm)

经920 ℃、初始应变速率为1×10-3 s-1的超塑性拉伸变形后,1号和2号材料的组织明显粗化,如图2所示。与图1相比,拉伸后的组织其晶粒仍保持等轴状,两相比例仍保持在50%左右,但其晶粒尺寸都明显增大。这表明Ti-6Al-4V合金的超塑拉伸变形中,晶粒长大为其变形过程中组织演化的显著特点之一。

图2 1号和2号试样变形后的显微组织

Fig.2 Microstructures of specimens 1 and 2 after superplastic deformation(920 ℃,1×10-3 s-1): (a) Specimen 1, ε=40%; (b) Specimen 1, ε=140%; (c) Specimen 2, ε=80%; (d) Specimen 2, ε=156%

2.2 晶粒长大

超塑性变形过程中的晶粒粗化现象已经逐渐被研究者们发现,并已经取得了一些研究成果。共析合金Zn-22%Al[5]和Al-33%Cu[6]、准单相合金Mg-8%Li[7]、Al-Zn-Mg[8]等一些材料在超塑变形过程中均出现了显著的晶粒长大,研究者们普遍认为这种晶粒粗化来自于变形过程中高温下的静态长大和变形引起的应变诱发长大。变形诱发晶粒长大是超塑性变形组织的重要特征之一。伴随着超塑性变形诱发晶粒长大实验现象研究的深入,研究者们针对细晶超塑性材料(≤10 μm),提出了几种变形诱发晶粒长大理论。如Clark等认为其原因是晶界滑动产生的过量空位;Wilkinson等认为滑动产生的晶格损伤被晶界迁移所协调;Sato、Hamilton等进一步发展了变形诱发晶粒长大的理论,提出了经验公式[5-6, 9]。Campenni等[10]提出超塑性晶粒长大为晶粒微观纯变形和静态长大之和的思想,并得到了相应的模型。曹富荣等[7]对Campenni的模型进行了修正,并通过Mg-8%Li准单相合金的实验数据得以验证。本研究采用该修正模型来计算、分析双相Ti-6Al-4V合金的超塑性晶粒长大现象。

对于退火过程中的静态晶粒长大[9-12],一般可表示为

指数q可以为2、3、4或5,该值取决于扩散的速率控制机制[9-12]。上述的值分别表示扩散经由粒子与基体的界面(q=2)、晶格(q=3)、晶界(q=4)或是位错管(q=5)来完成的。

对于超塑性变形诱发的晶粒长大,设晶粒换位是超塑性变形和晶粒长大的主要机制[10],4个晶粒为一组近邻,每次换位将产生0.55的真应变。连续多个这样的晶粒群便产生较大的应变。超塑性应变诱发的晶粒长大,如下式所示:

因此,超塑性变形中总的晶粒长大增量dD即为静态长大和变形诱发长大增量之和,可以表示为

进一步求解得到恒速度时的超塑性变形晶粒长大模型

参数 、q和K的含义与前面的相同,对双相合金

、q和K的含义与前面的相同,对双相合金 取为0.3[6]。

取为0.3[6]。

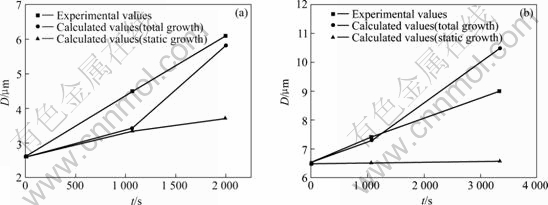

从式(5)可以看出,超塑性变形中的晶粒长大与变形温度、变形程度以及应变速率有着密切的关系。随着变形程度的增大,晶粒不断长大。随着应变速率的增大,晶粒粗化速度减慢。对于Ti-6Al-4V合金,根据文献[8,11]可知其静态晶粒长大指数q为5,即静态的晶粒粗化是由位错管扩散控制的。根据退火过程的静态晶粒长大数据计算可知K 为2.853×10-1 μm5/s。1号试样和2号试样的计算结果如图3所示。实测和式(5)计算的结果表明,模型的计算值与实测值较接近,可知该模型能够很好地描述、预测Ti-6Al-4V合金超塑性变形中的晶粒粗化。同时可以看出超塑性变形初期(ε=40%~42%),应变诱发的晶粒长大较小,随着变形程度的增大,应变诱发的晶粒长大显著增大,并且远大于静态长大的增幅。无论是实测的晶粒尺寸变化还是根据模型计算的,都证实了晶粒长大特别是应变诱发的晶粒长大是超塑性变形中的重要特征之一。另外,从图3中还可以看出,与1号试样相比,2号试样的静态晶粒长大并不明显。这是由于2号试样(6.5 μm)的初始晶粒尺寸较之1号试样(2.6 μm)的要大,相应的界面能要小一些,静态退火时晶粒长大的驱动力也相应小些。

图3 超塑性变形中晶粒尺寸的实测值、计算值与静态长大计算值

Fig.3 Experimental and calculated values of total grain growth, and calculated static grain growth during superplastic deformation(920℃,1×10-3 s-1): (a) Specimen 1; (b) Specimen 2

通常认为超塑性变形中的这种组织粗化是一种有害的现象,因晶粒尺寸的增大势必使超塑性流变应力增大,即硬化趋势的增强。然而,晶粒尺寸的增大同时也能抑制孔洞、微裂纹等的扩展,提高材料的抗颈缩能力。另一方面,随着晶粒粗化程度的加剧,可能会发生超塑变形机制的转变[6, 10],如从晶界滑动转向位错蠕变。可见,晶粒长大对超塑性变形有着双重的影响,对变形中晶粒粗化机制的探讨和预测就显得非常重要。式(5)是基于晶粒换位机制提出的超塑性晶粒长大模型,实验数据与模型预测数据的吻合说明该模型是可靠的。但是,对于双相Ti-6Al-4V合金来说,两相的变形能力不同,扩散系数相差很大,β相的扩散速度比α相的扩散速度大两个数量级,互相限制对方的长大,两相的体积分数比例势必对合金变形中晶粒尺寸的变化产生一定影响。因此,式(5)所示的晶粒长大模型还可以进行进一步的修正,加入与两相比例相关的影响因素。

2.3 变形机制

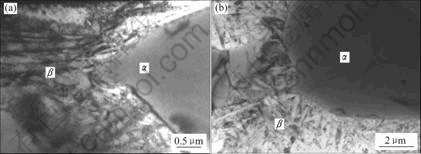

在920 ℃、初始应变速率为1×10-3 s-1时进行了上述3种Ti-6Al-4V合金的超塑性拉伸实验。由于拉伸一定变形量(ε)后立即快速水淬,所以β相均显现出共析转变后的组织,即“马氏体α′+β转”网篮组织。图4所示为1号试样(2.6 μm)拉伸后的透射电镜(TEM)组织。从图4(a)可见,α相与β相界面(相界)呈弧形并严重扭曲,这表明相界滑动是超塑性变形过程中的主要变形方式。α晶粒内部和α相与α相晶界附近均未发现位错,而且α相与α相晶界窄而平直,如图4(a)和4(c)所示。但是如图4(b)所示,位错从α相与β相相界发出,亦即α相与β相相界为位错源,说明相界/晶界的滑动是由相界/晶界面附近位错的滑移和攀移来协调的。因此,可以推断这些位错是由界面滑动所诱发的,同时这种界面滑动更容易发生在α相与β相相界处,而不是发生在α相与α相晶界处。另外,从图4(c)和4(d)还可以看到变形过程中β相挤入α相与α相晶界并沿着α晶界重新排列,α晶界出现了许多小的“凸起”,其结果使得同一相的晶群重新分布,从而增多了相界面。这表明Ti-6Al-4V合金的超塑性变形中β相易变形,滑动主要发生在α相与β相相界。

图4 1号试样拉伸后的TEM像

Fig.4 TEM images of deformed specimen 1(920 ℃,1×10-3 s-1): (a), (b), (c), (d) ε=40%

图5所示为2号试样拉伸后的TEM像。α相与β相相界发生扭曲变形(图5(a)),变形过程中β相沿晶界挤入α相与α相晶界并且α晶界出现“凸起”(图5(b))。2号试样的晶粒尺寸为6.5 μm,从图中可以看出其变形中的组织演变与1号试样类似。

图5 2号试样拉伸后的TEM像

Fig.5 TEM images of deformed specimen 2(920 ℃,1×10-3 s-1): (a) ε=42%; (b) ε=156%

图6所示为3号试样(16.2 μm)拉伸变形后的TEM组织。对于晶粒较粗大的3号试样,不但在α相与β相相界附近发现大量位错(图6(a)),而且在α相与α相晶界附近和α晶粒内部也发现了大量的位错(图6(b)),这明显不同于1号、2号试样。同时,在α晶粒内存在亚晶界,亚晶界附近有很多位错,如图6(c)所示。由此可以推断超塑性变形过程中位错运动的结果形成了由位错墙构成的亚晶界,亚晶界的形成表明晶粒较粗大的3号试样如果继续进行拉伸变形的话,将可能发生动态再结晶。

图6 3号试样拉伸后的TEM像

Fig.6 TEM images of deformed specimen 3(920 ℃,1×10-3 s-1): (a), (b), (c) ε=140%

从以上结果可以看出,在Ti-6Al-4V合金的超塑性变形过程中,由于初始晶粒尺寸的不同,合金的变形组织也有着显著的不同之处,初始晶粒尺寸对该合金的超塑性变形有着重要的影响。对于晶粒较细小的1号和2号试样,α相与β相相界圆弧化且严重扭曲,位错从相界发出,表明位错运动协调的界面滑动是细晶粒Ti-6Al-4V合金超塑性变形的主要变形机制。同时,除了界面附近的位错,在α晶粒内部几乎没有发现位错,这与Gifkins[1-2]的“芯部-表层”模型很相符。该模型将晶粒分为中心部分(芯部)和靠近晶界(表层)部分的两个区域。细晶粒变形时,“表层”行为是主要的。晶界滑动是由晶界位错在三角晶界处发生塞积而引起的,“表层”中的位错运动与“芯部”不存在相互作用关系,因此位错运动只限于晶界及其附近。另外,对于双相合金,由于两相的结构不同,变形能力也有差异,其中一相为“软相”(易变形),另一相为“硬相”(不易变形)。通常认为双相合金的超塑性变形有两种基本模式,即等应力模式和等应变模式[13-14]。本实验中,细晶粒材料在920 ℃超塑性变形温度下,β相易于变形且大部分的变形发生在β相中,其变形可认为是等应力模式的。对于晶粒较粗大的3号试样来说,变形过程中不仅在α相与β相相界附近有大量位错,而且在α晶粒内部也存在着大量的位错,表明除了晶界滑动以外,晶内的位错运动也占了很大一部分比例,因而此时的超塑性变形机制可以认为是晶界滑动与晶内位错运动的共同作用。由于3号试样的晶粒较粗(>10 μm),超塑性变形中,以界面滑动为主的界面变形行为逐渐转变为与普通塑性变形类似的以晶内位错运动为主的变形行为,这种转变的体现就是晶界与晶粒内同时存在大量位错。而且随着晶粒尺寸的增大,α晶粒内部也出现了大量位错(图6(b))及亚晶界,说明细晶材料中以β相变形为主的变形模式也逐渐转变为两相均参与的变形模式,因此可以认为3号试样的变形模式是等应力和等应变两种模式的混合。

一些学者对Ti-6Al-4V合金的拉伸超塑性变形也进行了研究,但得到的结果与本实验不尽相同。Kim等[15]认为对于晶粒尺寸为3 μm和11 μm的Ti-6Al-4V合金(变形条件900 ℃,1×10-3 s-1)来说,其超塑变形机制均为位错运动协调的界面滑动,两者的区别在于前者的变形主要发生在β相,而后者的变形同时发生在β相与α相。Yang等[16]认为初始晶粒尺寸为5 μm的Ti-6Al-4V合金(变形条件为750 ℃、850 ℃,1×10-5 s-1、1×10-4 s-1),其超塑性变形主要发生在β相并且α相发生了动态再结晶。本实验中对1号(2.6 μm)和3号(16.2 μm)试样还进行了920 ℃、2×10-4 s-1时的超塑拉伸,变形后的TEM像如图7和图8所示。从中可以看出,此时的变形组织与1×10-3 s-1时的很类似。细晶粒材料(1号试样)变形过程中,α相与β相相界圆弧化并发生变形(图7(a)),β相沿晶界挤入α相与α相晶界(图7(b)),但晶界附近未发现位错,可认为此时1号样的变形机制为界面滑动,变形仍然主要发生在β相,与等应力变形模式相符。而较粗晶粒材料(3号试样)的变形组织形貌与图6很类似,α晶内出现大量位错(图8(a)),而且α晶内也发现了亚晶界(图8(b)),透射电镜观察时发现此种情况下3号试样中的位错密度增大、亚晶界增多。此时,3号试样的超塑变形机制也应为界面滑动与晶内位错运动的共同作用,但晶内位错运动所占的比例可能要大一些;α晶粒内大量亚晶界的出现也说明可能会发生动态再结晶。因此,920 ℃超塑拉伸时,应变速率从1×10-3 s-1变化到2×10-4 s-1,不同初始晶粒尺寸材料各自的变形组织演化基本没有太大的差异,说明本实验所分析得出的初始晶粒尺寸不同时的超塑性变形机制是可靠的。

图7 1号试样拉伸后的TEM像

Fig.7 TEM images of deformed specimen 1(920 ℃,2×10-4 s-1): (a), (b) ε=90%

图8 3号试样拉伸后的TEM像

Fig.8 TEM images of deformed specimen 3(920 ℃,2×10-4 s-1,ε=140%): (a) Dislocations in α grain; (b) Subgrains in α grain

3 结论

1) 光学显微组织观察发现,Ti-6Al-4V合金在超塑性变形中晶粒明显地粗化。采用基于超塑性晶粒长大为晶粒微观纯变形和静态长大之和的模型,对Ti-6Al-4V合金变形中的晶粒长大进行了计算,计算值与实测值较接近。计算结果表明:超塑性变形初期,应变诱发的晶粒长大的增幅较小,随着变形程度的增大,应变诱发的晶粒长大的增幅显著增大,并且远大于静态长大的增幅。

2) 初始晶粒尺寸对该合金的超塑性变形有着重要的影响。对于细晶粒材料(2.6和6.5 μm),位错运动协调的界面滑动是其变形的主要机制,且滑动更容易发生在α相与β相相界处,而不是发生在α相与α相晶界处,变形主要发生在β相(等应力模式)。

3) 较粗晶粒材料(16.2 μm),变形过程中不仅在α/β相界附近有大量位错,而且在α晶粒内部也存在着大量的位错,此时超塑性变形的机制是晶界滑动与晶内位错运动的共同作用(等应力与等应变速率模式的混合)。

REFERENCES

[1] 文九巴, 杨蕴林, 杨永顺, 陈拂晓, 张柯柯, 张耀宗. 超塑性应用技术[M]. 北京: 机械工业出版社, 2004: 10-14.

WEN Jiu-ba, YANG Run-lin, YANG Yong-shun, et al. Application technology of superplasticity[M]. Beijing: Chinese Machine Industry Press, 2004: 10-14.

[2] 陈浦泉. 组织超塑性[M]. 哈尔滨: 哈尔滨工业大学出版社, 1988: 15-35.

CHEN Pu-quan. Morphologic superplasticity[M]. Harbin: Harbin University Press, 1988: 15-35.

[3] 丁 桦, 张凯峰. 材料超塑性研究的现状与发展[J]. 中国有色金属学报, 2004, 14(7): 1059-1067.

DING Hua, ZHANG Kai-feng. Current status and developments in superplastic studies of materials[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1059-1067.

[4] Ridley N. Microstructures of superplastic materials[J]. Mater Sci Tech, 1990, 6 (11): 1145-1156.

[5] Senkov O N, Myshlyyaev M M. Grain growth in a superplastic Zn-22%Al alloy[J]. Acta Metall, 1986, 34: 97-106.

[6] Sato E, Kuribayashi K. Superplasticity and deformation induced grain growth[J]. ISIJ International, 1993, 33: 825-832.

[7] 曹富荣, 雷 方, 崔建忠, 温景林. 超塑变形晶粒长大模型的修正与实验验证[J]. 金属学报, 1999, 35(7): 770-772.

CAO Fu-rong, LEI Fang, CUI Jian-zhong, WEN Jing-lin. Modification of a deformation induced grain growth model of superplasticity and its experimental verification[J]. Acta Metall Sinica, 1999, 35(7): 770-772.

[8] Zelin M. Grain growth during superplastic deformation[J]. Interface Science, 2002, 10: 37-42.

[9] Richter S, Hamilton C H. Deformation enhanced grain growth in a two phase titanium alloy[J]. Mater Sci Forum, 1993, 113/115: 195-200.

[10] Campenni V D, Càceres C H. Strain enhanced grain growth at large strains in a superplastic Zn-Al alloy[J]. Scripta Metall, 1987, 22: 359-364.

[11] 崔建忠, 吴庆龄, 马龙翔. 晶粒长大对超塑性的影响[J]. 东北工学院学报, 1988, 54(1): 6-10.

CUI Jian-zhong, WU Qing-ling, MA Long-xiang. Effect of grain growth on superplasticity[J]. Journal of Northeast University of Technology, 1988, 54(1): 6-10.

[12] Johnson C H, Richter S K, Hamilton C H, Hoyt J J. Static grain growth in a microduplex Ti-6Al-4V alloy[J]. Acta Mater, 1998, 47: 23-29.

[13] Leader J R, Neal D F, Hammond C. The effect of alloying additions on the superplastic properties of Ti-6pct Al-4pct V[J]. Metall Trans A, 1986, 17: 93-106.

[14] Meier M L, Lesuer D R, Mukherjee A K. α Grain size and β volume fraction aspects of the superplasticity of Ti-6Al-4V[J]. Mater Sci Eng A, 1991, 136: 71-78.

[15] Kim J S, Kim J H, Lee Y T, Park C G, Lee C S. Microstructural analysis on boundary sliding and its accommodation mode during superplastic deformation of Ti-6Al-4V alloy[J]. Mater Sci Eng A, 1999, 263: 272-280.

[16] Yang H S, Gurewitz G, Mukherjee A K. Mechanical behavior and microstructural evolution during superplastic deformation of Ti-6Al-4V[J]. Mater Trans, JIM, 1991, 32: 465-472.

基金项目:国家安全重大基础研究项目

收稿日期:2007-04-25;修订日期:2007-09-20

通讯作者:赵文娟,博士研究生;电话:024-83687746;传真:024-23906316;E-mail:zhaowenjuan80102@163.com

(编辑 陈爱华)