Trans. Nonferrous Met. Soc. China 22(2012) 528-533

Effect of spark plasma sintering temperature on microstructure and

mechanical properties of melt-spun TiAl alloys

CHAI Li-hua1, CHEN Yu-yong2, ZHANG Lai-qi1, LIN Jun-pin1

1. State Key Laboratory for Advanced Metals and Materials,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 9 September 2011; accepted 28 December 2011

Abstract: A TiAl alloy from pulverized rapidly solidified ribbons with the composition of Ti-46Al-2Cr-4Nb-0.3Y (mole fraction, %) was processed by spark plasma sintering (SPS). The effects of sintering temperature on the microstructure and mechanical properties were studied. The results show that the microstructure and phase constitution vary with sintering temperature. Sintering the milled powders at 1200 °C produces fully dense compact. Higher sintering temperature does not improve the densification evidently. The dominant phases are γ and α2 in the bulk alloys sintered at 1200 °C. With higher sintering temperature, the fraction of α2 phase decreases and the microstructure changes from equiaxed near γ grain to near lamellar structure, together with a slight coarsening. The bulk alloy sintered at 1260 °C with refined and homogeneous near lamellar structure reveals the best overall mechanical properties. The compressional fracture stress and compression ratio are 2984 MPa and 41.5%, respectively, at room temperature. The tensile fracture stress and ductility are 527.5 MPa and 5.9%, respectively, at 800 °C.

Key words: TiAl alloy; rapid solidification; spark plasma sintering; microstructure; mechanical properties

1 Introduction

γ-based TiAl alloys are currently regarded as promising materials for high temperature aerospace and automotive industries due to their low density, high strength, good oxidation resistance and excellent creep resistance [1,2]. However, their practical applications are impeded because of poor ductility and toughness at room temperature.

Rapid solidification technique is a kind of method to improve the mechanical properties by refining and homogenizing the microstructure [3,4]. In particular, the melt-spinning method has been used in many kinds of materials. However, the melt-spun ribbons are very small in sizes, which cannot be used for structural applications.

The hot isostatic pressing (HIP) method was employed to consolidate the rapidly solidified ribbons and powders, and to produce homogeneous and dense bulk materials [5,6]. Extrusion was also applied to some ribbons after HIP treatment for better cohesion. The results showed that the initial boundaries of ribbons disappeared [5]. After HIP the rapidly solidified microstructure in the as-received powders could be transformed into a wide range of microstructures, from an equiaxed γ structure, a γ+α2 dual-phase structure to a fully lamellar structure, which were strongly dependent on the HIP temperature [6].

Spark plasma sintering (SPS) as one of the novel powder metallurgy techniques was also used to consolidate TiAl based alloys [7], with advantageous over conventional sintering techniques [8-10], such as a relatively low sintering temperature and a high sintering rate, which can effectively produce a dense and fine-grained material in a relatively short period of time. Moreover, SPS was expected to retain some characters of rapid solidification when sintering rapidly solidified ribbons or powders. But the consolidation of melt-spun ribbons by SPS method was rarely reported.

In this work, the SPS method was used to consolidate the pulverized melt-spun TiAl alloy ribbons. The transformation of the metastable microstructure of melt-spun ribbons during consolidation process and the relationships among the sintering temperature, microstructure, and mechanical properties of the bulk materials were studied.

2 Experimental

The rapidly solidified TiAl ribbons with nominal composition of Ti-46Al-2Cr-4Nb-0.3Y (mole fraction, %) were produced by melt spinning method under ejection pressure of 3×104 Pa and linear speed of copper wheel of 30 m/s. Alloy ribbons were obtained with a thickness of 30-40 μm and a width of 2-3 mm.

The rapidly solidified TiAl ribbons were pulverized by ball milling for 2 h, sintered and consolidated by spark plasma sintering (SPS) at 1200, 1260 and 1300 °C for 10 min under 50 MPa, respectively. The pulverized ribbons were filled into a graphite mold with two graphite punches pressed at both ends. The specimens were warmed at a heating rate of 100 °C/min under a vacuum of 2 Pa. After sintering, specimens were furnace-cooled to room temperature. Dense compacts of d20 mm×(6-7) mm were obtained.

The densities of the sintered samples were tested by Archimedes method. The hardness was measured with a microhardness tester. X-ray diffraction (XRD) analysis was conducted using Cu Kα radiation to examine the phase constitutions. Microstructural observation was carried out by scanning electron microscopy using back scattering electron (BSE) imaging and energy dispersive spectroscopy (EDS).

The compressive tests for cylindrical samples with a gauge size of d3 mm×4.5 mm, and the tensile tests for samples with the gauge section size of 8.0 mm×1.5 mm×1.2 mm with a fillet radius for reducing stress concentration were performed on an Instron machine at a strain rate of 5×10-4 s-1 at room temperature and 800 °C, respectively.

3 Results and discussion

3.1 Characterization of melt-spun ribbons and pulverized powders

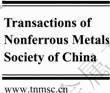

Figure 1 shows the X-ray diffraction (XRD) patterns of melt-spun ribbons and pulverized powders. The melt-spun ribbons are mainly composed of γ phase and a minor fraction of α2 phase. The intensity of α2 phase peaks shown in the XRD pattern is very low. Whereas, in the case of ball milled powders, (201)α2 peak of the α2 phase can be clearly seen, as shown in Fig. 1(b), which indicates that during ball milling, partly metastable γ phase have transformed to α2 phase.

Figure 2(a) shows the microstructure of rapidly solidified ribbons. The microstructure is characterized by equiaxed grains and lamellar structure with the average lamellar colony size of 3-7 μm. Selected area electron diffraction (SAED) pattern (Fig. 2(b)) indicates that the matrix is γ phase, and the lamellar structure mainly consists of γ lamina.

Fig. 1 XRD patterns of melt-spun ribbons (a) and ball milled powders (b)

The surface morphology of pulverized rapidly solidified TiAl based alloy ribbons is shown in Fig. 2(c). After ball milling for 2 h, the melt-spun ribbons are crashed to round-shaped particles with particle size less than 75 μm. The magnified image of particles is shown in Fig. 2(d). It is clear that the particles are heavily deformed, with quite rough surfaces.

3.2 Microstructure and mechanical properties of sintered samples

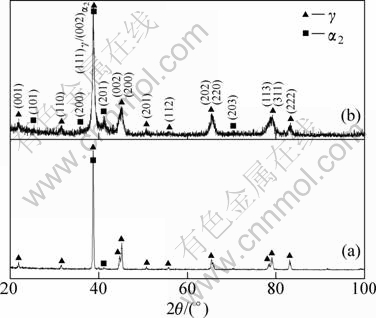

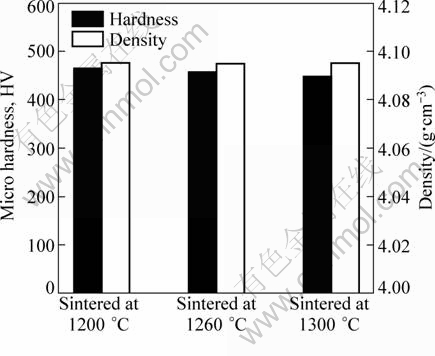

Figure 3 shows the effects of sintering temperature on the density and hardness of the sintered specimens. It is clear that the sintering temperature has a minor impact on the density and hardness as the temperature is higher than 1200 °C, which indicates that the milled powders sintered at 1200 °C can produce fully dense compact. Increasing the sintering temperature does not further improve the densification; however, the microstructure and phase constitutions vary with sintering temperature. The XRD patterns of the bulk alloy sintered at different temperatures presented in Fig. 4 indicate that the sintered specimens are dominated by γ phase with a minor amount of α2 phase, which are similar to those of the ball milled powders. The absence of β/B2 phase shown in conventionally cast alloy indicates that the sintered alloys have less segregation, because enrichment of β stabilized elements Nb or Cr is often observed in β phase [11]. With increasing sintering temperature, the volume fraction of α2 phase decreases slightly. Compared with the ball milled powders, the peaks of (002) and (200), (113) and (311) crystal planes in γ phase are well separated, which indicates that a larger lattice distortion is shown in the sintered alloys.

Fig. 2 Microstructures of Ti-46Al-2Cr-4Nb-0.3Y ribbons: (a) TEM bright-field micrograph showing equiaxed grain and lamellar structure; (b) SAED pattern taken from equiaxed grain; (c), (d) SEM images showing surface morphology of pulverized rapidly solidified ribbons

Fig. 3 Density and microhardness of bulk alloys sintered at various temperatures

The microstructures of the sintered alloy are shown in Fig. 5. It is noted that the sintered specimens arenearly fully dense with no evident pores, which is consistent with the results of the measured density. The alloy sintered at 1200 °C exhibits the refined and uniform near gamma structure (NG) which is comprised of equiaxed γ phase with an average grain size of 4-6 μm and dispersive irregular α2 phase with light grey contrast (shown in Fig. 5(a)). The Y-rich phase as white particles dispersing in the matrix is also observed. However, the original particle boundaries owing to insufficient diffusion during sintering are also visible. The phase locating at particle boundaries is determined as α2 phase which has the same contrast to the intracrystalline α2 phase. The non-uniform microstructure may be detrimental to the mechanical properties of the alloy.

Fig. 4 XRD patterns of samples spark sintered at various temperatures: (a) 1200 °C; (b) 1260 °C; (c) 1300 °C

Longer time or higher temperature of sintering is needed to eliminate this inhomogeneity. When the sintering temperature is up to 1260 °C, the interfaces of these particles disappear, and a near lamellar structure (NL) containing lamellar structure and a small amount of α2 phase at grain boundaries is formed. The average lamellar colony size is about 13 μm. The lamellar structure of the specimens sintered at a higher temperature (1300 °C) shows slight grain growth and a coarse microstructure. The approximate lamellar colony size is 16-30 μm.

Fig. 5 SEM images of samples spark sintered at different temperatures: (a), (b) 1200 °C; (c), (d) 1260 °C; (e), (f) 1300 °C

The microstructure variation of pulverized melt- spun ribbon powders can be reconciled with that of the referenced TiAl based alloy powders during SPS sintering. An equiaxed microstructure is formed at a lower temperature, and the microstructure is transformed to duplex structure, near lamellar structure and fully lamellar structure when increasing sintering temperature [12]. When the samples are sintered at 1200 °C, a small amount of α2 phase with various orientations will form in the matrix of equiaxed γ phase and the existing lamellar structure in the melt-spun ribbon disappears. The decomposition of the lamellar structure may experience two processes: partial decomposition during ball milling and final transformation during the sintering process. According to the XRD results of melt-spun ribbon, powder and sintered alloy, partial α2 phase forms in the course of prior powder consolidation as well. The sintering temperature of 1260 °C is located at the upper and middle part of (α+γ) phase field. During heating, most of the primary γ phases transform to α phase. A near lamellar structure is formed during cooling. It is noted that Y-rich phase which is dissolved in the rapidly solidified ribbons precipitates during sintering process, but the particles size is still very small, less than 0.6 μm. Increasing the sintering temperature further close to the α phase transverse temperature, more volume fraction of α phase presents. So, when the alloys are sintered at 1300 °C, more lamellar structure is formed, and some of the lamellar structure with different orientations is overlapped. By comparing with the conventionally cast alloy, the sintered alloys do not show any obvious element segregations. The β phase stabilized elements Cr and Nb distribute uniformly in the alloy, so no β phase segregation is observed in the sintered alloys. The rare earth-rich particles in melt-spun ribbons show a little growth during sintering, but still distribute uniformly compared with those in conventionally cast alloys.

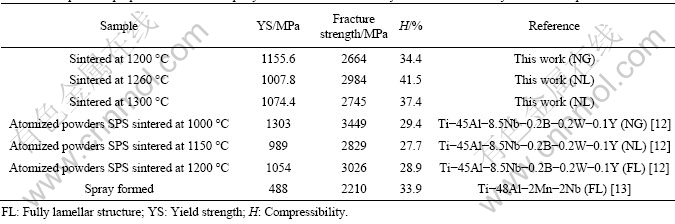

The compressive properties at room temperature and tensile properties at 800 °C of sintered rapidly solidified TiAl based alloys at different SPS temperatures and the other TiAl based alloys are shown in Table 1 and Table 2, respectively. The sintered alloys in this work show higher compressive properties at room temperature, the highest yield strength is 1155.6 MPa in the alloy sintered at 1200 °C with near gamma structure and the highest fracture strength is 2984 MPa in the alloy sintered at 1260 °C with near lamellar structure. The homogeneous and refined microstructure reduces the anisotropy, improves the compression ratio as high as 41.5%. The coarse lamellar colony of 50-200 μm, and the high porosity in the spray formed Ti-48Al-2Mn-2Nb alloy with lower cooling rate result in the bad deformability [13]. Compared with the high Nb added Ti-45Al-8.5Nb-0.2B-0.2W-0.1Y alloy by SPS using atomic powders, the alloys in this work show lower strength but better compressive ratio. The two alloys with the same microstructure show comparable grain size, but higher SPS temperature is needed in this project.

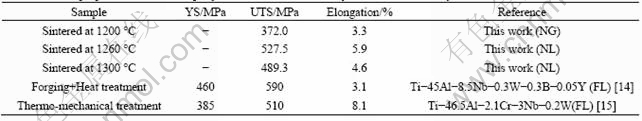

The alloys sintered at 1260 °C shows the best tensile properties at 800 °C, the fracture strength is 527.5 MPa and the elongation is 5.9 %. The reason for the good mechanical properties is that the microstructure in this alloy is homogeneous and refined. Compared with the Ti-45Al-8.5Nb-0.3W-0.3B-0.05Y cast alloy after forging and heat treatment, the sintered alloys in this work show better ductility but lower fracture strength. On the contrary, compared with the Ti-46.5Al-2.1Cr- 3Nb-0.2W alloy after thermo-mechanical treatment, lower elongation but a little higher fracture strength is shown. So, additional heat treatment is still needed to get more homogeneous fully lamellar structure in sintered rapidly solidified TiAl based alloys. In conclusion, the microstructure of the sintered alloys shows no obvious growth and good thermal stability compared with the melt spun ribbons. The good balanced mechanical properties can be got through controlling the SPS parameters.

Table 1 Compressive properties of sintered rapidly solidified TiAl based alloys and referenced alloys at room temperature

Table 2 Tensile properties of sintered rapidly solidified TiAl based alloys and referenced alloys at 800 °C

4 Conclusions

1) The melt-spun TiAl based ribbons were pulverized into fine powders by ball milling. After milling for 2 h, the average particle size is less than 75 μm, and some α2 phases precipitate from the γ matrix.

2) The alloy sintered above 1200 ?C can get fully dense compact, and the hardness does not change too much with increasing sintering temperature. The dominant phases are γ and α2 in the bulk alloys, which is similar to alloy ribbons.

3) The microstructure of alloy ribbons is composed of lamellar and equiaxed γ phase. After sintering the microstructure is changed from near gamma structure to near lamellar structure with increasing sintering temperature. The alloys sintered at 1200 °C and 1300 °C show inhomogeneous or coarse microstructure, which is detrimental to their mechanical properties; however, the alloy sintered at 1260 °C with homogeneous microstructure and average lamellar colony size of 13 μm shows the best overall mechanical properties.

References

[1] KIM Y W. Ordered intermetallic alloys, part III: Gamma titanium aluminides [J]. JOM, 1994, 46: 30-39.

[2] LIU C T, WRIGHT J L, DEEVI S C. Microstructures and properties of a hot-extruded TiAl containing no Cr [J]. Materials Science and Engineering A, 2002, 329-331: 416-423.

[3] FRAZIER W E, CHEN S J. The melt spinning of gamma titanium Aluminides [J]. JOM, 1992, 44: 52-55.

[4] TSUKAMOTO S, UMEZAWA O. Metastable alloy phase formation from undercooled steel and Ti-Al melts [J]. Materials Science and Engineering A, 1997, 223: 99-113.

[5] HUANG S C, SIEMERS P A. Characterization of the high-temperature phase fields near stoichiometric γ-TiAl [J]. Metallurgical and Materials Transactions A, 1989, 20: 1899-1906.

[6] ZHANG G, BLENKINSOP P A, WISE M L H. Hot-isostatic-pressing/microstructure/property relationships in a powder metallurgy gamma TiAl alloy [C]//BLENKINSOP P A, EVANS W J, FLOWER H M. Proceedings of the 8th World Conference on Titanium. Birmingham, United Kingdom: Institute of Materials, 1996: 542-549.

[7] COURET A, MOL?NAT G, GALY J, THOMAS M. Microstructures and mechanical properties of TiAl alloys consolidated by spark plasma sintering [J]. Intermetallics, 2008, 16: 1134-1141.

[8] ORR? R, LICHERI R, LOCCI A M, CINCOTTI A, CAO G. Consolidation/synthesis of materials by electric current activated/assisted sintering [J]. Materials Science and Engineering R, 2009, 63: 127-287.

[9] MUNIR Z A, ANSELMI-TAMBURINI U, OHYANAGI M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method [J]. Journal of Materials Science, 2006, 41: 763-777.

[10] EUGENE A O, SASTRY K, LUDO F. Consolidation enhancement in spark-plasma sintering: Impact of high heating rates [J]. Journal of Applied Physics, 2007, 102: 114913.

[11] CHEN G L, XU X J, TENG Z K, WANG Y L, LIN J P. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale [J]. Intermetallics, 2007, 15: 625-631.

[12] LU X, HE B, ZHANG B, ZHANG L, QU X H, GUO Z X. Microstructure and mechanical properties of a spark plasma sintered Ti-45Al-8.5Nb-0.2W-0.2B-0.1Y alloy [J]. Intermetallics, 2009, 17: 840-846.

[13] CHEN W Z, XIE H, QIAN K W, GU H C. Microstructure evaluation during plastic deformation in a centrifugal spray deposition (CSD) Ti-48Al-2Mn-2Nb alloy [J]. Materials Science and Engineering A, 1997, 234-236: 245-248.

[14] YAN Y Q, ZHOU L, WANG W S, ZHANG Y N. 8.5Nb–TiAl alloy with fine grains [J]. Journal of Alloys and Compounds, 2003, 361: 241-246.

[15] KIM Y W. Effects of microstructure on the deformation and fracture of γ-TiAl alloys [J]. Materials Science and Engineering A, 1995, 192-193: 519-533.

烧结温度对快速凝固TiAl合金组织及力学性能的影响

柴丽华1,陈玉勇2,张来启1,林均品1

1. 北京科技大学 新金属材料国家重点实验室,北京 100083;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:将快速凝固Ti-46Al-2Cr-4Nb-0.3Y(摩尔分数,%)合金薄带破碎成粉末,然后通过等离子烧结(SPS)制备成块体。研究烧结温度对烧结块体的组织和力学性能的影响。在1200 ℃烧结时得到完全致密的块体。进一步升高烧结温度对合金密度的影响不大,但是对烧结块体的显微组织及相结构有显著影响。烧结块体主要由γ和α2相组成,随着烧结温度的升高,α2相的体积分数降低,块体合金由近γ组织演变为近层片组织,且组织逐渐粗化,但是长大不明显。1260 °C烧结得到的块体组织细小、均匀,没有明显微偏析,具有良好的综合力学性能,室温压缩断裂强度和压缩率分别为2984 MPa和41.5%,高温(800 °C)拉伸断裂强度和伸长率分别为527.5 MPa和5.9%。

关键词:TiAl合金;快速凝固;等离子烧结;显微组织;力学性能

(Edited by YANG Hua)

Foundation item: Project (2011CB605500) supported by the National Basic Research Program of China; Project (FRF-MP-10-005B) supported by the Fundamental Research Funds for the Central Universities, China; Project (50674037) supported by the National Natural Science Foundation of China

Corresponding author: ZHANG Lai-qi; Tel: +86-10-62334925; E-mail: zhanglq@skl.ustb.edu.cn

DOI: 10.1016/S1003-6326(11)61209-0