文章编号:1004-0609(2008)10-1831-08

稀土Y对 ZK60合金板材退火组织与性能的影响

王 斌,易丹青,吴春萍,罗文海,方西亚,刘会群

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:将ZK60合金及ZK60(0.9Y)合金热轧板材在300~400 ℃下进行了不同时间退火,观察其组织及性能演变规律。结果表明:经30 min退火后,合金均出现再结晶组织,稀土Y的添加导致ZK60合金再结晶晶粒尺寸细小,300~400 ℃退火后晶粒长大幅度较小,400 ℃退火120 min后晶粒尺寸为20 μm,σb为226.9 MPa,经计算,Y元素的加入提高了ZK60合金再结晶晶界迁移激活能,其激活能由42.66 kJ/mol增加至56.34 kJ/mol,并建立了合金的再结晶晶粒长大模型。

关键词:ZK60合金;钇;退火;晶粒长大

中图分类号:TG 113 文献标识码: A

Effect of yttrium on microstructure and properties of ZK60 sheet in annealing states

WANG Bin, YI Dan-qing, WU Chun-ping, LUO Wen-hai, FANG Xi-ya, LIU Hui-qun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: ZK60 and ZK60(0.9Y)alloys were hot rolled and then annealed for various times. The evolution of microstructure and properties of the alloy were investigated. The results show that all alloys after annealing for 30 min have recrystallized structure. But the grain of ZK60(0.9Y)alloy is more fine and the growth amplitude of annealed grain is less than that of ZK60 alloys after annealing at 300-400 ℃. The grain size is 20 μm and σb is 226.9 MPa when ZK60(0.9Y) alloy after annealing for 120 min at 400 ℃. The calculation result shows that the activation energy of grain boundary migration of ZK60 alloy recrystallization is increased from 42.66 kJ/mol to 56.34 kJ/mol because of the addition of yttrium element. In addition, the growth model of recrystallized grain was established.

Key words: ZK60 alloy; yttrium; annealing; grain grow

ZK60(名义成分Mg-4.9Zn-0.7Zr)镁合金属于高强变形镁合金,由于其具有较高的强度、良好的工艺塑性及可热处理强化等优点使其成为高强韧变形镁合金的研究热点之一[1-2]。

变形镁合金板材在退火过程可能发生再结晶,再结晶温度取决于合金成分、压下量、始轧温度和终轧温度等[3]。如果要获得最佳的常温综合力学性能,则需严格的控制退火工艺,退火温度过高或时间过长,都容易导致镁合金晶粒长大,从而降低镁合金的力学性能。余琨等[4]研究了Mg-Al-Zn系合金板材轧后退火工艺对材料再结晶行为和显微组织的影响,发现热轧合金板材在573 K温度退火1 h后发生完全再结晶,生成细小均匀的等轴晶,板材强度略有下降,但伸长率大幅提高。詹美燕等[5]研究了AZ31镁合金轧制薄板经200~400 ℃退火5~240 min后的组织性能演变。结果表明,合金轧制板材在250 ℃退火10 min组织出现明显的静态再结晶组织。文献[6-7]对Mg-Al-Zn系镁合金挤压过程中的动态再结晶行为进行了分析。

以上研究主要涉及Mg-Al-Zn系镁合金的在高温下的再结晶规律,对低塑性的Mg-Zn-Zr系镁合金板材的退火过程中的组织及性能变化涉及较少。张继东等[8]研究了Y对Mg-Zn-Zr系镁合金组织及强度的影响,结果发现添加0.9%(质量分数)的Y对Mg-Zn-Zr系合金铸态组织有明显的晶粒细化作用。马庆波等[9]研究了锑和混合稀土对AZ31镁合金在不同温度下的热压缩流变应力和动态再结晶的影响,结果表明:AZ31镁合金分别加入1%RE和Sb后,有效促进了热变形过程中的动态再结晶。本文作者前期研究发现,Mg-Zn-Zr系镁合金添加稀土Y和Nd后,板材热轧后出现大量细小弥散的再结晶晶粒[10]。

因此,本文作者在ZK60镁合金中添加微量稀土元素Y,制备出热轧板材,研究稀土元素Y、退火温度及时间等对合金退火后组织与性能的影响,目的在于优化退火工艺,使合金产生大量细小的等轴晶,以进一步提高合金的塑性,这对于变形镁合金板材的后续加工成型有着特别重要的意义。

1 实验

选用纯Mg、纯Zn、Mg-27.5Zr和Mg-37Y中间合金为原料。合金熔炼在井式坩埚炉中进行,熔炼温度720 ℃,采用熔剂保护,铸锭尺寸为300 mm×250 mm×33 mm。合金成分分别为Mg-4.9Zn-0.7Zr(合金1)和Mg-4.9Zn-0.9Y-0.7Zr(合金2)。试样在400 ℃保温18 h进行均匀化处理,热轧温度400 ℃,平均道次压下量12%,最终压下量95%。采用CSS-44100电子万能实验机上进行力学性能测试,采用PolyvarmetH2-UMA金相显微镜上进行组织观察,侵蚀剂为4%的硝酸+酒精溶液。采用HBS-3000布氏硬度计进行硬度测量,实验条件为:圆形钢压头,直径为2.5 mm,负荷2 450 N,加载时间为30 s,每个样品测量3个数据,取平均值。采用用Sirion200场发射扫描电镜观察第二相颗粒形貌。室温拉伸实验在INSTRON8032万能材料实验机上进行,拉伸速率为2 mm/min。板材经机加工制成标准片状式样,式样标距尺寸为50 mm×10 mm×2 mm。

2 实验结果

2.1 退火温度对合金组织的影响

图1所示为合金轧制态及300、350和400 ℃温度下分别退火30 min后的金相显微组织照片。由图可见,合金1和2经30 min退火后均已基本完成了再结晶组织转变,晶粒呈等轴状。合金1经300 ℃退火后晶粒较为细小,但晶粒大小不均匀。随着退火温度升高至350和400 ℃时,再结晶组织较粗大,晶粒尺寸不均匀现象较严重,晶界较平直(见图1(b)、(c)、(d))。添加了稀土Y的合金2经300 ℃下退火退火后,再结晶晶粒尺寸较合金1细小,沿轧制方向仍存在少量变形组织痕迹,再结晶晶粒尺寸较均匀,晶界弯曲。随着退火温度的升高至350和400 ℃时,合金2再结晶晶粒尺寸长大不明显(见图1(b′)、(c′)、(d′))。

图1 合金1和2轧制后在不同退火温度下退火30 min的显微组织

Fig.1 Microstructures of alloys 1 and 2 after annealing for 30 min at various temperatures

Alloy 1: (a) As-rolled; (b) Annealed at 300 ℃; (c) Annealed at 350 ℃; (d) Annealed at 400 ℃

Alloy 2: (a′) As-rolled; (b′) Annealed at 300 ℃; (c′) Annealed at 350 ℃; (d′) Annealed at 400 ℃

2.2 退火工艺参数对合金硬度与组织的影响

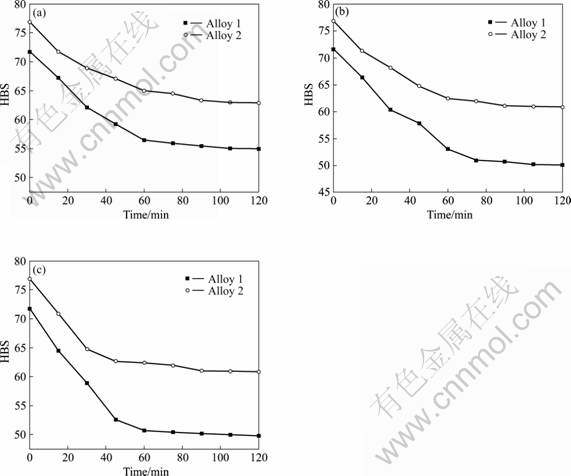

图2所示为合金1和2板材分别在300、350和400 ℃下硬度值随时间变化的规律。由图可见,合金1在退火前期硬度值下降很快,随后硬度下降趋势逐渐变缓;合金2在300 ℃退火时,硬度值呈现平稳下降趋势,在350 ℃退火时,前期硬度值下降趋势增快,在400 ℃退火时,硬度值下降趋势与合金1相似。

图2 合金1和2板材在不同温度下硬度与时间的关系

Fig.2 Relationships between hardness and time at various temperatures of alloys 1 and 2: (a) At 300 ℃; (b) At 350 ℃; (c) At 400 ℃

表1所列为合金1和2在不同退火状态下平均再结晶晶粒尺寸。该数据表明随着退火时间的延长,合金晶粒均有不同程度的长大。合金1经300、350和400 ℃退火120 min后,再结晶晶粒尺寸约为19、23和30 μm;在400 ℃退火时晶粒长大相当明显,且尺寸不均匀(见图3(a)~(d))。合金2经300、350和400 ℃退火120 min后,平均晶粒尺寸约为11、14和20 μm,晶粒长大幅度较小;在300和350 ℃退火时,晶粒长大幅度都在30%左右;在400 ℃退火时,晶粒快速长大,但总体仍保持了细小均匀的组织,晶界也保持弯曲状(见图3(a′)~(d′))。

表1 合金1和2不同退火制度下的平均晶粒尺寸

Table 1 Average grain size of alloys 1 and 2 after annealing

图3 合金1和2 在400 ℃退火时的组织演变

Fig.3 Microstructure evolutions of alloys 1 and 2 after annealing at 400 ℃: (a), (b), (c), (d) Alloy 1 for 30, 60, 90 and 120 min; (a′), (b′), (c′), (d′) Alloy 2 for 30, 60, 90 and 120 min

2.3 合金退火后的力学性能

表2所列为合金1和2板材退火后的力学性能(试样均沿轧制方向取样)。合金1和2经退火处理后抗拉强度、屈服强度相对热轧态有所下降,伸长率提高;随着退火时间的延长,合金强度、伸长率均下降,其中合金1下降幅度较为显著,这主要跟再结晶晶粒尺寸的迅速长大有关[11]。合金2在300 ℃温度下退火30 min后抗拉强度仍保持在300 MPa左右; 350 ℃温度退火60 min后,抗拉强度在280 MPa左右,伸长率均超过了20%,400 ℃温度退火120 min后,合金2力学性能明显下降,抗拉强度在220 MPa左右。

表2 合金1和2板材退火后的力学性能

Table 2 Mechanical properties of alloys 1 and 2 after annealing

2.4 合金再结晶晶粒的长大模型

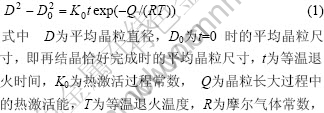

文献[3-12]将再结晶晶粒长大的动力学过程用下式描述:

8.314 J/(mol·K)。由式(1)两边取对数得:

将表1中合金1和2的D与t的数值代入式(2),得

D2与t的关系如图4(a)和(b)所示。由图可见,两合金的D2与t均符合线性关系,得不同退火温度下D2—t直线的斜率m=( D2-D02)/t。将m代如入式(2)得:

ln m=ln K0-Q/(RT) (3)

图4 合金再结晶退火晶粒尺寸与退火时间关系

Fig.4 Relationship between grain size and annealing time of alloys after recrystallization annealing: (a) Alloy 1; (b) Alloy 2; (c) ln m—1/T curves of alloys 1 and 2

经线性回归,计算得出不同直线的斜率为合金lnm与1/T关系图如图4(c)所示,其斜率为Q/R,对斜率值进行线性回归,计算热激活能Q1 = 42.66 kJ/mol,Q2 = 56.34 kJ/mol。

将Q值代入式(3)中,计算出常数K0值。合金1的K0值为206 901.89,合金2的K0值为790 167.32,将Q、K0及各退火状态下的数据代入式(1)得D0值,则合金1和2再结晶晶粒长大动力学模型可分别表 示为:

对于合金1

3 分析与讨论

3.1 Y元素对再结晶晶粒尺寸的影响

大变形量轧制+再结晶退火是变形镁合金获得细晶组织的一条重要途径。文献[12-13]指出:再结晶尺寸D与晶粒长大速率G和再结晶晶核形核率 用如下关系表示:

用如下关系表示: 所有能使G/

所有能使G/ 值发生变化的因素(如变形程度、退火温度、退火时间等)都可能引起再结晶晶粒尺寸的变化。本实验中,添加Y元素的合金2中存在大量Mg3Zn6Y相[14],该相在轧制过程中破碎成细小颗粒,在基体中弥散分布(如图5(b)),其能谱分析如图5(e),从其原子比及相关文献推测其应为Mg3Zn6Y相。该相与镁基体结合较好[15],因此轧制过程中位错难以穿过,在变形量较大时,Mg3Zn6Y相粒子周围的基体产生不均匀变形,周围出现大量的位错环和胞状组织,胞壁附近位错密度高,单胞内部位错密度较低(图5(d))。该相粒子能有效阻碍位错运动,导致位错增殖,这对提高合金强度有着重要的作用。同时,弥散分布的Mg3Zn6Y相粒子可提供了更多可形核位置,从而导致再结晶晶粒的细化。

值发生变化的因素(如变形程度、退火温度、退火时间等)都可能引起再结晶晶粒尺寸的变化。本实验中,添加Y元素的合金2中存在大量Mg3Zn6Y相[14],该相在轧制过程中破碎成细小颗粒,在基体中弥散分布(如图5(b)),其能谱分析如图5(e),从其原子比及相关文献推测其应为Mg3Zn6Y相。该相与镁基体结合较好[15],因此轧制过程中位错难以穿过,在变形量较大时,Mg3Zn6Y相粒子周围的基体产生不均匀变形,周围出现大量的位错环和胞状组织,胞壁附近位错密度高,单胞内部位错密度较低(图5(d))。该相粒子能有效阻碍位错运动,导致位错增殖,这对提高合金强度有着重要的作用。同时,弥散分布的Mg3Zn6Y相粒子可提供了更多可形核位置,从而导致再结晶晶粒的细化。

图5 合金1和2热轧后的位错组态和能谱分析

Fig.5 Dislocation configuration and EDS of alloys 1 and 2 after hot rolling: (a), (c) Alloy 1; (b), (d) Alloy 2; (e) EDS pattern of Mg3Zn6Y in alloy 2

3.2 Y元素对再结晶晶粒长大的影响

再结晶晶粒的长大是一个晶界迁移的过程。大量第二相颗粒的存在,无疑会阻碍晶界的运动。第二相颗粒对晶界的阻碍运动可表现为齐纳(Zener)阻力pz[16]: ,其中φ为第二相体积分数,γ为单位面积晶界能,r为圆球状第二相颗粒半径,齐纳阻力的大小与第二相颗粒的体积分数成正比,与粒子直径成反比。合金2经过轧制后,Mg3Zn6Y相被破碎成细小颗粒,并在基体中弥散分布,它对晶界起钉扎作用,其不仅阻碍了再结晶晶粒的长大,而且该相颗粒良好的热稳定性,在高温下不发生粗化现象,因此在退火过程中,能有效阻止合金2再结晶晶粒尺寸的长大。

,其中φ为第二相体积分数,γ为单位面积晶界能,r为圆球状第二相颗粒半径,齐纳阻力的大小与第二相颗粒的体积分数成正比,与粒子直径成反比。合金2经过轧制后,Mg3Zn6Y相被破碎成细小颗粒,并在基体中弥散分布,它对晶界起钉扎作用,其不仅阻碍了再结晶晶粒的长大,而且该相颗粒良好的热稳定性,在高温下不发生粗化现象,因此在退火过程中,能有效阻止合金2再结晶晶粒尺寸的长大。

3.3 Y元素对合金退火后力学性能的影响

对比两种合金退火后的力学性能可知,添加Y的合金2力学性能总体优于合金1,Y元素对合金退火后力学性能的影响主要体现在两个方面:1) Mg3Zn6Y颗粒由于其较高的硬度、良好的热稳定性以及与基体较低的界面结合能,即使在较高温度下也不发生粗化,能成为有效的增强颗粒,保持良好的钉扎作用[17];2) Y元素的加入使得合金退火再结晶组织显著细化,根据Hall-Petch关系[13],使合金退火后能保持较高强度;同时细小的再结晶组织能使各个微观局部的变形以及应力的分布更为均匀,从而有效地降低应力集中的程度,使合金2获得较高的塑性。

4 结论

1) ZK60和ZK60(0.9Y)合金在300~400 ℃温度退火后,硬度和强度性能均缓慢下降,400 ℃温度退火120 min后,ZK60(0.9Y)合金抗拉强度为226.9 MPa。

2) ZK60(0.9Y)合金退火板材的再结晶晶粒尺寸比ZK60合金的细小,且在300~400 ℃退火不同时间后晶粒长大幅度也较小。在400 ℃退火120 min后其晶粒尺寸为20 μm左右,σb为226.9 MPa。

3) Y元素的加入提高了合金再结晶晶粒长大热激活能,ZK60和ZK60(0.9Y)合金激活能分别为Q1 = 42.66 kJ/mol,Q2 = 56.34 kJ/mol。建立了合金再结晶晶粒长大模型。

REFERENCES

[1] DECKER R F. The renaissance in magnesium[J]. Advanced Mater & Proc, 1998, 157(9): 31-35.

[2] FROES F H, AGHION E, ELIEZER D. The science technology and applications of magnesium[J]. Advanced Performance Materials, 1998, 5 (3): 201-212.

[3] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 23-30.

CHEN Zhen-hua. Wrought magnesium alloys[M]. Beijing: Chemical Industry Press, 2005: 23-30.

[4] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zhen-qin. Research development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[5] 詹美燕, 李元元, 陈维平, 陈宛德. AZ31镁合金轧制板材在退火处理中的组织性能演变[J]. 金属热处理, 2007, 32(7): 8-11.

ZHAN Mei-yan, LI Yuan-yuan, CHEN Wei-ping, CHEN Wan-de. Evolution of microstructure and mechanical properties of AZ31 magnesium alloy rolled sheets during annealing[J]. Heat Treatment of Metals, 2007, 32(7): 8-11.

[6] 曲家惠, 李四军, 张正贵, 王 福, 左 良. 挤出和退火工艺对AZ31镁合金组织和织构的影响[J]. 中国有色金属学报, 2007, 13(7): 434-440.

QU Jia-hui, LI Si-jun, ZhANG Zheng-gui, WANG Fu, ZUO Liang. Effect of extrusion and annealing technology on microstructure and texture of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 13(7): 434-440.

[7] KIM W J, CHUNG S W, CHUNG C S, KUM D. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures[J]. Acta Mater, 2001, 49(16): 3337-3341.

[8] 张继东, 李亚国, 张少卿, 刘海林. 钇对MB25镁合金组织及强度的影响[J]. 中国稀土学报, 1989, 15(7): 89-94.

ZHANG Ji- dong, LI Ya-guo, ZHANG Shao-qin, LI Hai-ling. Y on microstructure and properties of MB25 magnesium alloys[J]. Journal of the Chinese Rare Earth Society 1989, 15(7): 89-94.

[9] 马庆波, 刘胜新, 李庆奎, 刘 俊, 李双喜. 锑和混合稀土对AZ31镁合金高温变形行为的影响[J]. 机械工程材料, 2007, 21(4): 23-25.

MA Qing-bo, LIU Sheng-xin, LI Qing-kui, LIU Jun, LI Shuang-xi. Effect of antimony and rare earth on hot deformation behavior of AZ31 magnesium alloy[J]. Materials for Mechanical Engineering, 2007, 21(4): 23-25.

[10] 王 斌, 易丹青, 方西亚, 周玲伶, 罗文海. 稀土元素Y和Nd对Mg-Zn-Zr系合金组织和性能的影响[J]. 金属热处理, 2005, 47(7): 9-11.

WANG Bin, YI Dan-qing, FANG Xi-ya, ZHOU Ling-ling, LUO Wen-hai. Influence of Y and Nd on microstructure and properties of Mg-Zn-Zr alloys[J]. Heat Treatment of Metals, 2005, 47(7): 9-11.

[11] BAE D H, KIM S H, KIM D H, KIM W T. Deformation behavior of Mg-Zn-Y alloys reinforced by icosahedral quasicrystalline particles[J]. Acta Materialia, 2002, 50(9): 2343-2356.

[12] 唐仁正. 物理冶金基础[M]. 北京: 冶金工业出版社, 1997: 79-88.

TANG Ren-zheng. Physical metallurgy foundation[M]. Beijing: Metallurgy Industry Publishing Company, 1997: 79-88.

[13] 郭 强, 严红革, 陈振华, 张 辉. AZ31镁合金高温热压缩变形特性[J]. 中国有色金属学报, 2005, 15 (6): 900-904.

GUO Qiang, YAN Hong-ge, CHENG Zhen-hua, ZHANG Hui. Hot compression deformation behavior of AZ31 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 900-904.

[14] 罗文海. Y元素对Mg-Zn-Zr合金微观组织与力学性能的影响[D]. 长沙: 中南大学, 2006: 55-64.

LUO Wen-hai. The effects of Y element addition on microstructure and mechanical properties in Mg-4.9Zn-0.7Zr alloy[D]. Changsha: Central South University, 2006: 55-64.

[15] BAE D H, KIM D H, KIM W T, KIM, D H. High strength Mg-Zn-Y alloy containing quasicrystalline particles[J]. Materials Transactions, 2001, 42(10): 2144-2147.

[16] 毛为民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 2-95.

MAO Wei-ming, ZAO Xin-bin. The recrystallization and grain growth of metal[M]. Beijing: Metallurgy Industry Publishing Company, 1994: 2-95.

[17] BAE D H, LEE M H, KIM K T, KIM W T. Application of quasicrystalline particles as a strengthening phase in Mg-Zn-Y alloys[J]. Journal of Alloys and Compounds, 2002, 342: 445-450.

基金项目:湖南省科技攻关计划资助项目(04GK1008-2);教育部有色金属重点实验室基金资助项目

收稿日期:2008-02-18;修订日期:2008-06-10

通讯作者:易丹青,教授,博士;电话:0731-8830263;E-mail: danqing@mail.csu.edu.cn

(编辑 何学锋)