文章编号: 1004-0609(2006)05-0762-06

Ni-石墨固体自润滑材料的塑性变形

朱定一, 陈金栌, 林登宜

(福州大学 材料科学与工程学院, 福州 350002)

摘 要: 用熔炼法制备出具有较好塑性的Ni-石墨固体自润滑材料, 研究了球状石墨与片状石墨的变形组织与性能。 结果表明: Ni-石墨合金在室温三点弯曲实验中可压成近V字型而不发生脆性断裂; 经球化处理的铸态试样的延伸率为15.7%, 抗拉强度σb为259.5MPa。 在850℃进行锻打变形时, 压缩变形量达到75.8%, 可以加工成薄板材料; 变形后垂直于压缩方向的石墨呈高密度纤维状分布, 试样经变形后沿纤维方向的抗拉强度提高, 但韧性降低。 片状石墨在挤压变形过程中, 通过沿应力取向发生转动, 在弱结合面发生解理碎裂, 并通过解理面的相对滑动以及石墨片的彼此桥接形成长纤维状组织; 球状石墨在压扁的过程中, 沿子晶间的晶界发生破裂并逐渐被拉长。

关键词: Ni-石墨合金; 塑性变形; 纤维状组织; 延伸率 中图分类号: HT117.1

文献标识码: A

Plastic deformation of Ni-graphite solid self-lubricating material

ZHU Ding-yi, CHEN Jin-lu, LIN Deng-yi

(School of Materials Science and Engineering, Fuzhou University, Fuzhou 350002, China)

Abstract: The Ni-graphite solid self-lubricating material with good plasticity was prepared by melting method. An attempt was made to investigate the deformed microstructure and properties of spheroidal and flaky graphite. The results show that the Ni-graphite alloy presents nearly “V” shape in three-point bending test without brittle fracture at room-temperature, the elongation ratio of spheroidized as-cast specimen is 15.7% while the tensile strength σb is 259.5MPa. The ingot is hot-forged at 850℃ to sheet with thickness reduction of 75.8%. After deformation, the graphite perpendicular to compression direction forms a high density fiber morphology, and the tensile strength along fiber direction increases accompanied with the decreasing of ductility. During the extrusion forming process, the flaky graphite rotates along the stress orientation and cleavage fracture takes place in weak interface, then the relative slip among cleavage planes and bridging of graphite flake lead to the formation of long fiber-like microstructure. Intergranular crack generates and spheroidal graphite is stretched gradually during the bruising process.

Key words: Ni-graphite alloy; plastic deformation; fiber-like microstructure; elongation ratio

在含石墨的粉末冶金固体自润滑材料中, 由于石墨不易均匀分布, 金属粉末在制备过程中表面易形成氧化膜, 烧结后材料中存在一定数量的孔洞和存留在晶界处的氧化物膜等原因, 导致含石墨材料普遍存在较大脆性, 通常采用冲击韧性、 三点弯曲强度和压溃强度表征其力学性能[1-10]。 采用熔炼法制备的Ni-石墨合金、 Ni3Al-石墨合金、 Ni-Cu-石墨系合金、 Ni-Fe-石墨系合金具有石墨分布均匀、 组织致密的特点[11-14]。 在文献[11]中, 作者研究了熔炼法制备的Ni-石墨二元合金的摩擦学性能和导电性能, 这种材料具有高的冲击韧性, 比粉末冶金法制备的Ni合金-Ag-石墨的冲击韧性高28倍, 并且具有较小的摩擦因数。 能否将铸锭进一步轧制成板材或线材, 对于扩大工业应用范围, 制备具有自润滑性能的耐腐蚀导电滑动线材、 带材、 高温滑动减磨片、 高密度动态密封环件具有重要意义。 目前真正意义上能够进行锻造成型的铸铁较少[15], 有关含石墨材料的高温塑性加工的研究也鲜有报道。 本文作者研究了Ni-石墨合金承受大变形量以及变形的工艺条件和组织状态, 并对片状和球状石墨组织的变形作了初步研究。

1 实验

1.1 材料制备

用纯度为99%的工业电解Ni、 上海胶体化工厂生产的纯石墨粉(石墨粉的纯度为 99.8%, 平均粒度30μm)按质量分数配制Ni-3.5%C合金。 采用真空中频感应加热熔炼, 合金的熔炼制备方法见文献[11, 13]。 材料分为未球化处理与球化处理两种, 球化处理的方法是在液态合金浇铸前, 加入0.75%的稀土镁球化剂, 经0.8~1.5min反应后浇铸, 球化剂的成分见文献[13]。 铸型尺寸为120mm×60mm×20mm。

1.2 组织与性能测试

拉伸试样均为板型试样, 铸态拉伸试样的标距段尺寸为40mm×10mm×2.5mm, 热锻打变形后的薄板拉伸试样的标距段尺寸为25mm×3mm×1.4mm; 三点弯曲试样尺寸为60mm×10mm×6mm, 两端支点间距为40mm; 高温变形试样的原始尺寸为30mm×10mm×6mm, 实验采用锻打变形方式, 在箱式空气炉中加热, 变形温度分为800、 850和900℃, 经多次锻打完成变形, 每次锻打变形前的保温时间为15min, 锻打变形后的薄板拉伸试样均经过同一加热温度的退火处理。 将变形后的试样经金相抛光及10%的硝酸酒精腐蚀处理后, 用XL30 ESEM型扫描电镜和MM-6宽视场显微镜分析石墨的形变组织。

2 结果与分析

2.1 室温拉伸性能

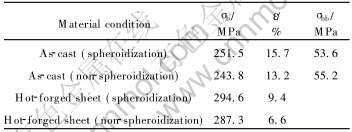

表1所列为Ni-3.5%C合金的力学性能。 分为球化处理和未球化处理2种。 在室温拉伸条件下, 铸态Ni-3.5%C合金具有较高的延伸率, ε达到13.2%, 经球化处理的试样其延伸率略有提高, 达到了工业用结构材料对塑性的基本要求。 铸态板形拉伸试样拉伸断裂后的外观形貌有显著的凹凸变形痕迹, 表明试样在变形过程中经历了较大滑移变形, 变形均匀分配在试样承力区的各个部位, 随后在没有明显颈缩情况下断裂。 这种表面均匀凹凸区域是变形过程中金属基体中的位错在某些石墨界面前沿受阻塞积而发生变形区转移的结果。 图1所示为三点弯曲试样变形后的外观形貌。 Ni-3.5%C合金在室温下经三点弯曲变形, 可压成近V字型而不发生脆性断裂, 裂纹在试样底部最大拉应力处形成并随变形量的增加而缓慢扩展, 而普通含石墨的粉末冶金材料以及含石墨的铸铁合金通常呈脆性断裂。 但同时可以看到, Ni-3.5%C合金由于含有面密度约22.4%的石墨[9], 在室温下仍然难以承受较大的变形量。

表1 Ni-3.5%C合金的力学性能

Table 1 Mechanical properties of Ni-3.5%C alloy

图1 三点弯曲试样变形形貌

Fig.1 Deformed morphology of three-point

bending specimen (Non-spheroidization)

2.2 高温塑性变形

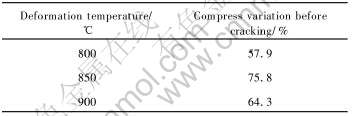

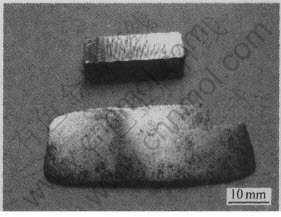

表2所列为Ni-3.5%C合金在锻打条件下变形温度对形变裂纹出现前压缩率的影响。 结果表明, 在850℃锻打时, 试样表面出现裂纹前的变形量较大, 可将6.2mm厚的试样锻打成1.5mm厚的板材, 压缩变形量达到75.8%。 而在800℃或900℃变形时, 试样表面宏观裂纹出现前的变形量相对较小, 分别为57.9%和64.3%。 这是因为温度低时, 容易在石墨与金属的界面处因过高密度的位错塞积而产生裂纹, 而温度太高时则合金表面的氧化加重, 一旦在材料表面产生裂纹, 则将使裂纹尖端脆化而导致塑性变形能力降低。 图2所示为Ni-3.5%C合金(经球化处理)在850℃高温变形前后的宏观形貌。

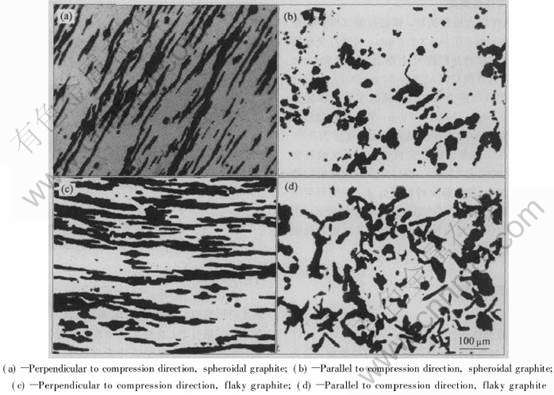

实验结果表明, Ni-3.5%C合金的热锻打温度在850℃比较合适。 图3所示为一组Ni-3.5%C合金经热锻打变形后的石墨组织形貌。 其中图3(a)、 (b)所示为在变形后的薄板上(经球化处理)切取一块试样, 分别在垂直于压缩方向和平行于压缩方向上所观察到的组织; 图3(c)、 (d)所示为未经球化处理的变形试样分别在垂直于压缩方向和平行于压缩方向上所观察到组织。 可以看到, 经过较大的压缩变形后, 在垂直于压缩方向上, 无论是球状石墨还是片状石墨均呈高密度纤维状平行排布, 石墨片伸长并变窄, 许多石墨经挤压变形后桥接在一起, 纤维状石墨平均间距约为20μm, 在该面上石墨面密度增大。 在平行于压缩方向上, 球状石墨呈破碎不规则状, 尺寸越大越易破碎, 而尺寸小的球状石墨相对容易保持原有的形态, 在该平面上, 石墨的间距增大, 石墨面密度有所减小; 在平行于压缩方向上, 片状石墨自身的宽度有所增大, 形貌则基本保持了原有的状态。

表2 变形温度与压缩变形量

Table 2 Deformation temperature and

corresponding compress variation (spheroidization)

图2 850℃高温压缩变形试样形貌

Fig.2 Deformed morphology of hot-compression

specimen at 850℃(Spheroidization)

图3 Ni-3.5%C合金经850℃高温变形后的微观组织

Fig.3 Microstructures of Ni-3.5%C alloy after hot deformation at 850℃

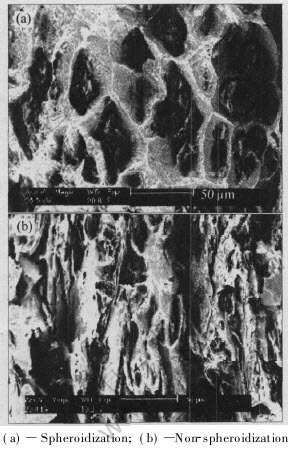

图4所示为经锻打变形后薄板试样的拉伸断口形貌, 其中图4(a)所示为经过球化处理的试样断口, 图4(b)所示为未经球化处理的试样断口。 从表1可知, 经热锻打变形后, Ni-3.5%C合金的抗拉强度得到提高而延伸率降低, 从拉伸试样断口形貌可以看到, 球状石墨的断口呈菱形杯口状, 金属基体连续没有明显的分层现象, 塑性变形能力相对较高; 而片状石墨的断口沿压缩面呈明显的分层状, 金属基体被严重割裂, 导致延伸率有所降低。

图4 锻打变形后薄板试样的拉伸断口形貌

Fig.4 Tensile fracture morphologies of hot rolled plate

2.3 变形组织分析

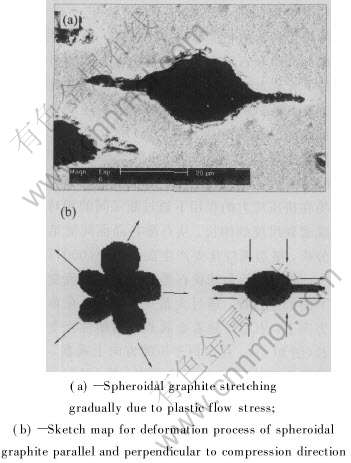

石墨本身是不可变形的脆性相, 但具有面心立方结构的金属基体镍具有良好的塑性变形能力。 从图3(c)的片状石墨纤维状组织可以看到, 在高温锻打变形过程中, 片状石墨随Ni基体在高温下通过塑性流变发生沿应力取向转动, 逐渐使片的平面与应力方向垂直。 当受力较大时, 石墨片很容易发生破断, 破断的石墨有利于其自身取向的调整。 由Ni-C相图可知[16], 在共晶温度1316℃以下加热, Ni-C合金不发生相的转变, 仅基体镍的固溶度有较小变化, 因此这种纤维状石墨组织的形成与共析钢热轧带状组织的形成原理不同[17], 它不是在反复的溶解与析出的相变过程中形成的, 而主要是宏观取向的调整和石墨内部破裂后沿断层间的相对滑动。 图5所示为石墨经压缩变形后内部的微观组织形貌。 其中图5(a)所示为球状石墨在挤压应力作用下内部组织的裂纹形貌; 图5(b)所示为片状石墨在挤压应力作用下内部组织的裂纹形貌。 可以看到, 石墨在变形过程中均发生了明显的碎裂, 碎裂的石墨在挤压应力的作用下通过断层间的相对滑动而造成宏观尺度的伸长。 从石墨各晶面间的结合键强度分析, 破裂面应优先产生在石墨的(0001)弱结合面上。 图6所示为球状石墨在基体塑性流变应力作用下的形变过程。 通过大量观察发现, 在垂直于压缩方向上, 石墨球随着金属基体的塑性流变被逐渐拉长(图6(a)), 在平行于压缩方向上观察, 石墨球沿子晶界破裂形成花瓣状形态(图6(b)), 石墨球内部发生了明显碎裂, 表面的碎裂程度比球的中心区域严重(图5(a))。 实验表明石墨在应力作用下的伸长均是通过断层间的相对滑动而实现的。 随着变形量的增大, 球状石墨在垂直于压缩方向上的形状已变得毫无规则。

图5 石墨经压缩变形后内部组织的裂纹形貌

Fig.5 Crack configurations of graphite after compression deformation

图6 球状石墨在塑性流变应力作用下的形变过程

Fig.6 Deformation process of spheroidal

graphite due to plastic flow stress

3 结论

1) 熔炼法制备的Ni-3.5%C合金具有较好的塑性变形能力, 室温三点弯曲实验中均可压成近V字型而不发生脆性断裂, 延伸率达到了工业用结构材料的要求。 经球化处理的合金塑性有所改善。

2) Ni-3.5%C合金在850℃经反复热锻打变形后, 可以轧制成薄板材料, 压缩变形量达到75.8%。 变形后的薄板材料经退火处理后, 沿纤维方向的抗拉强度有所提高, 韧性则降低。

3) 片状石墨在挤压变形过程中通过沿应力取向的转动、 石墨内部断面间的相对滑动以及石墨片之间的相互桥接形成纤维状组织; 球状石墨在受到挤压变形时, 沿子晶间的晶界发生了破裂, 并随着金属基体的塑性流变及破断晶面间的相对滑动逐渐伸长。

REFERENCES

[1]欧阳锦林, 牛淑琴, 阮虎生, 等. 镍合金基自润滑复合材料的研究[J]. 摩擦学学报, 1993, 13(1): 33-47.

OUYANG Jin-lin, NIU Shu-qin, RUAN Hu-sheng, et al. Study on nickel alloy self-lubrication composite[J]. Tribology, 1993, 13(1): 33-47.

[2]牛淑琴, 朱家珮, 欧阳锦林. 几种高温自润滑复合材料的研制与性能研究[J]. 摩擦学学报, 1995, 15(4): 324-332.

NIU Shu-qin, ZHU Jia-pei, OUYANG Jin-lin. Study on the development and properties of several new type high self-lubrication composites[J]. Tribology, 1995, 15(4): 324-332.

[3]LU Jin-jun, YANG Sheng-rong, WANG Jing-bo, et al. Mechanical and tribological properties of Ni-based alloy/CeF3/graphite high temperature self-lubrication composites[J]. Wear, 2001, 249(12): 1070-1076.

[4]Ted Guo M L, Tsao C Y A. Tribological behavior of self-lubrication aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method[J]. Composites Science and Technology, 2000, 60(1): 65-74.

[5]尹延国, 郑治祥, 马少波, 等. 温度对铜基自润滑材料减摩耐磨特性的影响[J]. 中国有色金属学报, 2004, 14(11): 1856-1861.

YIN Yan-guo, ZHENG Zhi-xiang, MA Shao-bo, et al. Influence of temperature on friction and wear properties of Cu-matrix/graphite self-lubricating composite materials[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1856-1861.

[6]高强, 吴渝英, 张国定, 等. 碳纤微对铜-石墨复合材料性能的影响[J]. 中国有色金属学报, 2000, 10(S1): 97-101.

GAO Qiang, WU Yu-ying, ZHANG Guo-ding, et al. Effect of carbon fiber on property of copper-graphite composite materials[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): 97-101.

[7]李溪滨, 刘如铁, 杨慧敏. 铝铅石墨固体自润滑复合材料的性能[J]. 中国有色金属学报, 2003, 13(2): 465-468.

LI Xi-Bin, LIU Ru-tie, YANG Hui-min. Properties of solid self-lubricating Al-Pb-graphite composites[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 465-468.

[8]Moustafa S F, El-Badry S A, Sanad A M, et al. Friction and wear of copper-graphite composites made with Cu-coated and uncoated graphite powders[J]. Wear, 2002, 253: 699-710.

[9]丁华东, 李雅文, 浩宏奇, 等. 铜石墨材料抗弯强度与孔隙的关系[J]. 中国有色金属学报, 1996, 6(4): 123-126.

DING Hua-dong, LI Ya-wen, HAO Hong-qi, et al. Grey equation between bending strength and porosity of copper-graphite composite[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(4): 123-126.

[10]王静波, 吕晋军, 宁莉萍, 等. 锡青铜基自润滑材料的摩擦学特性研究[J]. 摩擦学学报, 2001, 21(2): 110-113.

WANG Jing-bo, LI Jin-jun, NING Li-ping, et al. Study on the tribological behavior of bronze-matrix self-lubricating composites[J]. Tribology, 2001, 21(2): 110-113.

[11] 朱定一, 关翔锋, 陈丽娟, 等. 镍-石墨高温自润滑材料的熔炼制备及组织性能[J]. 中国有色金属学报, 2004, 14(5): 707-712.

ZHU Ding-yi, GUAN Xiang-feng, CHEN Li-juan, et al. Preparation and structure property of high-temperature self-lubricating Ni-graphite alloy by melting method[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 707-712.

[12]朱定一, 关翔锋, 陈丽娟, 等. 新型Ni3Al-石墨高温固体自润滑材料的制备及其性能[J]. 中国有色金属学报, 2004, 14(4): 528-533.

ZHU Ding-yi, GUAN Xiang-feng, CHEN Li-juan, et al. Preparation and properties of high-temperature self-lubricating Ni3Al-graphite alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 528-533.

[13]朱定一, 陈丽娟. 新型Ni-Cu-C合金中石墨的球化处理及其性能[J]. 中国有色金属学报, 2004, 14(11): 1817-1821.

ZHU Ding-yi, CHEN Li-juan. The spheroidization of graphite and properties of new Ni-Cu-C alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1817-1821.

[14]陈丽娟, 朱定一, 汤伟, 等. 镍-铁-石墨-硅自润滑材料及其性能[J]. 中国有色金属学报, 2004, 14(12): 2108-2113.

CHEN Li-juan, ZHU Ding-yi, TANG Wei, et al. Ni-Fe-C-Si self-lubricating material its properties[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2108-2113.

[15]郝石坚. 现代铸铁学[M]. 北京: 冶金工业出版社, 2004. 153-180.

HAO Shi-jian. Modern Cast Iron [M]. Beijing: Metallurgical Industry Press, 2004. 153-180.

[16]虞觉奇, 易文质, 陈邦迪, 等. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1987. 249.

YU Jue-qi, YI Wen-zhi, CHEN Bang-di, et al. Binary Alloy Phase-Diagrams[M]. Shanghai: Shanghai Science and Technology Press, 1987. 249.

[17]胡赓祥, 钱苗根. 金属学[M]. 上海: 上海科学技术出版社, 1980. 344-345.

HU Geng-xiang, QIAN Miao-gen. Metallurgy[M]. Shanghai: Shanghai Science and Technology Press, 1980. 344-345.

基金项目: 国家自然科学基金资助项目(50471007); 福建省教育厅科技发展资助项目(K02005)

收稿日期: 2005-07-19; 修订日期: 2006-02-28

通讯作者: 朱定一, 教授; 电话: 0591-87893540; E-mail: zdy7081@163.com

(编辑陈爱华)