文章编号:1004-0609(2014)11-2864-08

锐钛矿对氧化铝溶出性能的影响及其机理

李小斌1, 2,余顺文1, 2,董文波1, 2,陈永坤1, 2,齐天贵1, 2,周秋生1, 2,刘桂华1, 2,彭志宏1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 难冶有色金属资源高效利用国家工程实验室,长沙 410083)

摘 要:研究不同拜耳法溶出条件下锐钛矿对氧化铝溶出性能的影响,并研究不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响。结果表明:随着温度的升高、时间的延长和苛性碱浓度的增加,锐钛矿对氧化铝溶出性能的影响逐渐减小甚至消失;经水热处理的锐钛矿对氧化铝溶出性能的影响与水热处理的条件密切相关,温度越高、时间越长、铝酸钠溶液苛性碱浓度越高,其对氧化铝溶出性能的影响越小。经水热处理的锐钛矿的溶解性能实验和XRD分析结果表明:不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著差别的根源在于其溶解性能和结晶度存在差别。随着水热处理锐钛矿条件的不断强化,钛酸钠的结晶度逐渐提高,其在铝酸钠溶液中溶解形成钛酸根离子的浓度逐渐降低,对氧化铝溶出性能的影响也逐渐减小,甚至完全消失。

关键词:钛矿物;氧化铝;溶出性能;溶解性能

中图分类号:TF821 文献标志码:A

Effect and mechanism of anatase on digestion performance of alumina

LI Xiao-bin1, 2, YU Shun-wen1, 2, DONG Wen-bo1, 2, CHEN Yong-kun1, 2, QI Tian-gui1, 2,

ZHOU Qiu-sheng1, 2, LIU Gui-hua1, 2, PENG Zhi-hong1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. National Engineering Laboratory for Efficient Utilization of Refractory Non-ferrous Metals Resources, Central South University, Changsha 410083, China)

Abstract: The effect of anatase on the digestion performance of alumina was investigated under various Bayer digestion conditions as well as the effect of hydrothermal treated anatase under different conditions on the digestion performance of alumina. The results show that the effect of anatase on the digestion performance of alumina gradually decreases or even disappears with the increase of digestion temperature, time and caustic alkali concentration. The effect of hydrothermal treated anatase on the digestion performance of alumina is closely related to the conditions of hydrothermal treatment. The elevated temperature, prolonged time and high caustic alkali concentration are favorable to alleviate the influence. The results of dissolution performance test and XRD analysis indicate that the remarkable distinction of the effect of hydrothermal treated anatase under different conditions on the digestion performance of alumina is due to the difference of dissolution performance and crystallinity. As the conditions for anatase hydrothermal treatment are intensified, the crystallinity of sodium titanate increases and the concentration of dissolved titanate ions in the sodium aluminate solution decreases. Thus, the effect of hydrothermal treated anatase on the digestion performance of alumina gradually decreases or even disappears.

Key words: titanium-containing mineral; alumina; digestion performance; dissolution performance

我国铝土矿绝大多数为一水硬铝石型铝土矿,并且通常含有2%~4%的钛矿物,以锐钛矿、金红石和板钛矿形态存在[1]。在一水硬铝石型铝土矿拜耳法溶出过程中,钛矿物除了会使氧化铝的溶出率显著降低以外[2-5],还会与石灰的反应产物钛酸钙会在换热表面上形成结疤,严重影响换热效率,造成能耗和氧化铝生产成本增加[6-10]。关于钛矿物对铝土矿溶出过程的阻碍作用,研究者均认为是因为钛酸钠在铝矿物表面生成一层致密的保护膜,隔绝了它与溶液的接触[1, 5, 11-13]。采用拜耳法处理此类矿石时,为了消除钛矿物对铝矿物溶出严重的阻滞作用,目前工业上均采用添加石灰的办法[14-15]。虽然添加石灰可以消除钛矿物的不利影响,还具有降低碱耗、改善赤泥的沉降性能等优点,但同时带来诸如氧化铝损失增加、赤泥量增多、能耗升高和成本上升等一系列问题。为此,国内外对有关钛矿物对氧化铝生产的影响进行了大量研究,主要集中于钛矿物与拜耳法溶出体系中组分的相互作用[6, 16-17]、钛矿物对铝土矿溶出的影响及其作用机理[13, 18]和消除钛矿物危害的方法[14-15, 18]。由于一水硬铝石型铝土矿中除了一水硬铝石和钛矿物外,还存在大量的其他矿物,如硅矿物和铁矿物等,在拜耳法溶出过程中它们相互之间会发生复杂的化学反应,不利于揭示钛矿物对铝土矿溶出的影响作用及其作用机理。而目前,针对钛矿物对铝土矿溶出的影响作用的研究均以铝土矿为研究对象,基本停留在氧化铝厂生产经验的基础上,缺乏细致、深入的研究。此外,有研究表明[13],锐钛矿和钛酸钠均会严重影响氧化铝的溶出,而钛酸钠的组成与钛矿物在铝酸钠溶液中水热处理的条件密切相关,且不同水热条件下反应生成的钛酸钠对氧化铝溶出性能的影响程度目前还不清楚,也缺乏这方面的研究。

基于上述考虑,本文作者以Al2O3粉模拟一水硬铝石,系统地研究了不同拜耳法溶出条件下锐钛矿对氧化铝溶出性能的影响以及不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响,并结合经水热处理的锐钛矿的溶解性能分析和X射线衍射分析,阐明了不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著差别的原因。

1 实验

1.1 实验原料

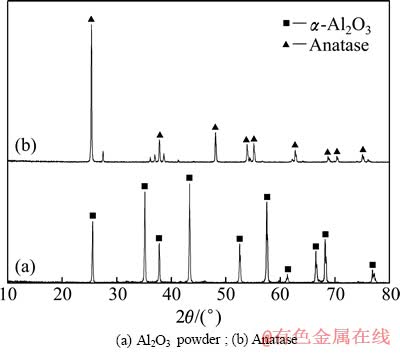

实验所用铝酸钠溶液由工业氢氧化铝与工业氢氧化钠配制而成;Al2O3粉为工业氢氧化铝在马弗炉中1200 ℃煅烧3 h所得;锐钛矿为分析纯粉末。Al2O3粉和锐钛矿的X射线衍射分析结果如图1所示。由图1可知,Al2O3粉为α-Al2O3,锐钛矿结晶非常完善。

图1 Al2O3粉和锐钛矿的XRD谱

Fig. 1 XRD patterns of Al2O3 powder and anatase

1.2 溶出实验

溶出实验在以熔盐为加热介质、自动控温的高压反应群釜(中南大学机械厂生产,控温精度±1 ℃)中进行。按配矿量称取Al2O3粉12 g(配料分子比αk为1.51)、锐钛矿或经水热处理的锐钛矿0.36 g(3%,以Al2O3粉质量计)和100 mL铝酸钠溶液加入高压釜钢弹中,放入钢球以加强搅拌,于已升温至预定温度的熔盐介质中搅拌反应并开始计时。当反应达到预定时间后,立即取出钢弹,放入冷水中强制冷却。溶出浆液经真空抽滤实现固液分离,滤液定容后采用滴定法分析其中的Al2O3含量,进而计算出Al2O3溶出率。

1.3 锐钛矿的水热处理

锐钛矿的水热处理实质就是锐钛矿与铝酸钠溶液在高温高压条件下发生水热反应,其过程与溶出实验类似。将2 g锐钛矿和100 mL铝酸钠溶液加入高压釜钢弹中进行反应,反应浆液固液分离后,将滤渣放入烘箱((100±5) ℃)中烘干备用,并利用X射线衍射仪(Rigaku TTR-Ⅲ型)进行分析。经水热处理的锐钛矿将用于溶出实验和溶解性能实验。

1.4 溶解性能实验

将经水热处理的锐钛矿(0.3 g)和铝酸钠溶液(120 mL)加入到微量水热反应釜(Büchi eco075 型,瑞士生产)釜体中,密封后开启搅拌装置(搅拌速度400 r/min),并加热到预定温度,保温一定时间后取样。取样时通过带过滤器的取样系统在压力的作用下实现在线固液分离,过滤器为Swagelok SS-2F-05系列烧结式过滤器,公称孔尺寸为0.5μm。滤液即时加入过量盐酸,利用电感耦合等离子光谱仪(Intrepid II XSP)检测其中的铝含量和钛含量。溶液中钛酸根离子的浓度(以TiO2计)以Al2O3作为内标计算确定,铝酸钠溶液中的Na2Ok和Al2O3浓度采用滴定法测定。

2 结果与讨论

2.1 锐钛矿对氧化铝溶出性能的影响

有研究表明[13],钛矿物会阻滞一水软铝石和一水硬铝石型铝土矿的溶出,而对三水铝石型铝土矿的溶出几乎没有影响。此外,LOAN等[19]发现,钛矿物的形态也具有重要的影响,即锐钛矿影响氧化铝的溶出,而金红石的影响非常小。采用拜耳法处理一水硬铝石型铝土矿时,溶出的温度通常为250~280 ℃,溶出时间一般为30~90 min,循环母液的Na2Ok浓度一般为220~250 g/L。另外,在铝土矿的溶出过程中,铝酸钠溶液的组成也会发生改变。而目前关于钛矿物对铝土矿溶出影响作用的认识基本停留在氧化铝厂生产经验的基础上,缺乏系统研究。为此,本文作者以α-Al2O3粉模拟一水硬铝石,系统地研究了不同拜耳法溶出条件下锐钛矿对氧化铝溶出性能的影响。

2.1.1 温度的影响

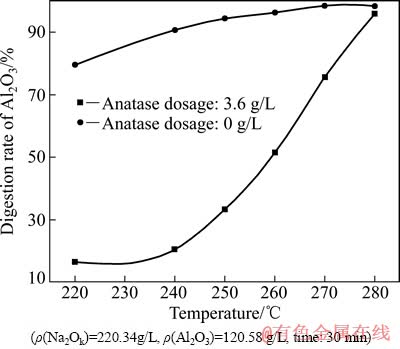

本实验中研究了不同温度下锐钛矿对氧化铝溶出性能的影响,其结果如图2所示。由图2可知:当不添加锐钛矿时,α-Al2O3的溶出性能良好,220 ℃时,溶出率已达到79.57%;280 ℃时,溶出率达到98.34%。

图2 温度对氧化铝溶出率的影响

Fig. 2 Effect of temperature on digestion rate of alumina

而当添加3%(以Al2O3粉质量计,下同)锐钛矿时,溶出温度较低时(<250 ℃),α-Al2O3的溶出性能受到非常明显的影响,250 ℃时溶出率仅为33.38%。但随着温度的升高,锐钛矿对α-Al2O3溶出性能的影响逐渐减小,甚至消失。这说明锐钛矿对氧化铝溶出的阻滞作用仅在于从动力学上降低氧化铝溶出的速率,随着溶出条件的强化,其对氧化铝溶出的阻滞作用将减小。有研究表明[1],当溶出温度高于300 ℃时,不论氧化铝水合物的矿物状态如何,大多数铝土矿的溶出过程都可以在几分钟之内完成,并得到接近于饱和的铝酸钠溶液,矿石类型的影响基本不再存在。

2.1.2 时间的影响

从理论上讲,在适当的温度下,只要有足够长的溶出时间,氧化铝就会完全溶出。为了进一步证实锐钛矿对α-Al2O3溶出性能的影响仅在于从动力学上降低氧化铝溶出的速率,而并不会使溶出反应完全停止,在此,研究了不同时间条件下锐钛矿对氧化铝溶出性能的影响,结果如图3所示。由图3可知,在不添加锐钛矿的情况下,250 ℃溶出15 min时,氧化铝的溶出率已达到90.16%,说明α-Al2O3在250 ℃时能够迅速溶出。而当添加锐钛矿时,在较短的溶出时间内(<30 min),锐钛矿对溶出的影响非常显著。同样地,随着时间的延长,锐钛矿对α-Al2O3溶出性能的影响逐渐减小,甚至接近消失。

图3 时间对氧化铝溶出率的影响

Fig. 3 Effect of time on digestion rate of alumina

2.1.3 苛性碱浓度的影响

强化溶出条件除了提高溶出温度外,还可以增加铝酸钠溶液的苛性碱浓度。为此,本实验中研究了不同苛性碱浓度下锐钛矿对氧化铝溶出性能的影响,结果如图4所示。由图4可知,随着苛性碱浓度的增加,氧化铝的溶出率显著增加,即锐钛矿对α-Al2O3溶出性能的影响逐渐减小,甚至消失。这进一步证实了锐钛矿对α-Al2O3溶出性能的影响仅在于从动力学上降低氧化铝溶出的速率。王少娜等[20]研究发现,当用高浓度的氢氧化钠溶液(50%~70%)处理一水硬铝石型铝土矿时,无需添加石灰即可达到较高的溶出率(>90%),这与本研究结果是一致的。

图4 苛性碱浓度对氧化铝溶出率的影响

Fig. 4 Effect of caustic alkali concentration on digestion rate of alumina

2.2 经水热处理的锐钛矿对氧化铝溶出性能的影响

锐钛矿与铝酸钠溶液在一定的水热条件下反应生成钛酸钠,其形态与反应温度和溶液组成有关,有研究[21-22]曾报道了钛酸钠存在NaHTiO3、Na2Ti3O7、NaxH2-xTi3O7·nH2O、Na2O·3TiO2·2H2O、Na2O·TiO2等多种形式的分子式。同时也有研究[13]报道锐钛矿和钛酸钠均会严重影响一水软铝石的溶出,但是不同水热条件下反应生成的钛酸钠对氧化铝溶出性能的影响程度目前还不清楚,缺乏这方面的研究。基于此,本文作者系统研究了不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响。为了便于比较,溶出实验的条件均保持一致,即在250 ℃溶出30 min,铝酸钠溶液的成分为ρ(Na2Ok):220.34 g/L,ρ(Al2O3):120.58 g/L。由前面的研究可知,在此条件下添加3%未经水热处理的锐钛矿时,α-Al2O3的溶出性能受到显著的影响,其溶出率仅为33.38%。

图5~7所示分别为经不同温度、不同时间和不同苛性碱浓度铝酸钠溶液水热处理的锐钛矿对氧化铝溶出性能的影响。由图5~7可知,不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著的差别,且随着水热处理温度的提高、时间的延长和铝酸钠溶液苛性碱浓度增加,经水热处理的锐钛矿对氧化铝溶出的影响逐渐减小,甚至消失。当温度提高到280 ℃或时间延长到180 min或铝酸钠溶液苛性碱浓度增加到280 g/L,经水热处理的锐钛矿对氧化铝溶出的影响几乎消失。

图5 经不同温度水热处理的锐钛矿对氧化铝溶出率的影响

Fig. 5 Effect of hydrothermal treated anatase with different temperatures on digestion rate of alumina

图6 经不同时间水热处理的锐钛矿对氧化铝溶出率的影响

Fig. 6 Effect of hydrothermal treated anatase with different times on digestion rate of alumina

2.3 经水热处理的锐钛矿的溶解性能

图7 经不同苛性碱浓度铝酸钠溶液水热处理的锐钛矿对氧化铝溶出率的影响

Fig. 7 Effect of hydrothermal treated anatase with different caustic alkali concentrations on digestion rate of alumina

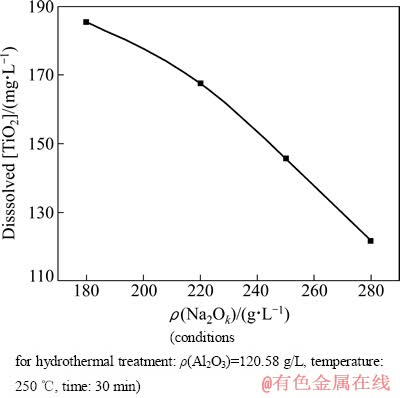

为了揭示不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著差别的原因,实验中测定了不同条件下经水热处理的锐钛矿在铝酸钠溶液中溶解形成钛酸根离子的浓度(以TiO2计),其结果如图8~10所示。为了便于比较,溶解性能实验的条件均保持一致,即在250 ℃溶解30 min后取样,铝酸钠溶液的成分为ρ(Na2Ok):220.34 g/L,ρ(Al2O3):120.58 g/L。由图8~10可知:未经水热处理的锐钛矿在铝酸钠溶液中溶解形成钛酸根离子的浓度最高,为256.83 mg/L。且随着水热处理的温度提高、时间延长和铝酸钠溶液苛性碱浓度增加,经水热处理的锐钛矿在铝酸钠溶液中的溶解性能显著变差。当水热处理的温度提高到280 ℃或时间延长到180 min或苛性碱浓度增加到280 g/L,经水热处理的锐钛矿在铝酸钠溶液中溶解形成钛酸根离子的浓度仅有未经水热处理的锐钛矿的一半左右。

图8 经不同温度水热处理的锐钛矿的溶解性能

Fig. 8 Dissolution performance of hydrothermal treated anatase with different temperatures

图9 经不同时间水热处理的锐钛矿的溶解性能

Fig. 9 Dissolution performance of hydrothermal treated anatase for different times

图10 经不同苛性碱浓度铝酸钠溶液水热处理的锐钛矿的溶解性能

Fig. 10 Dissolution performance of hydrothermal treated anatase with different caustic alkali concentrations

由此可见,经水热处理的锐钛矿对氧化铝溶出性能的影响与其在铝酸钠溶液中的溶解性能存在高度的相关性,即经水热处理的锐钛矿在铝酸钠溶液中的溶解性能越差,其对氧化铝溶出性能的影响越小。由此也不难看出,只要设法降低锐钛矿在铝酸钠溶液中的溶解性能(如添加石灰和形成难溶的钛酸钙),就能消除其对氧化铝溶出性能的影响。

铝土矿中的钛矿物一般呈弥散分布状态,并且与铝矿物相互包裹,所以钛矿物与铝酸钠溶液反应产生的钛酸钠会包裹在铝矿物表面,进而阻碍铝矿物的溶出。而在本文的实验中,锐钛矿或经水热处理的锐钛矿与氧化铝在铝酸钠溶液中各自分散存在,因此,钛酸钠要在铝矿物表面形成包裹,必然要经历溶解-再结晶的过程,即铝酸钠溶液中的钛酸根离子是形成膜的“桥梁”。随着水热处理锐钛矿条件的不断强化,其在铝酸钠溶液中的溶解性能显著变差,于是形成膜的“桥梁”被破坏或部分破坏,其对氧化铝溶出性能的影响也会逐渐减小,甚至完全消失。总之,不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著差别的根源在于其溶解性能的差别。

采用高浓度的氢氧化钠溶液水热处理TiO2粉末是一种合成钛酸盐纳米管的有效方法,并且得到了广泛的研究[23]。KUKOVECZ等[24]提出了钛酸盐纳米管形成的溶解-再结晶机理,即TiO2与氢氧化钠溶液反应形成的钛酸钠,经过溶解后再结晶形成钛酸盐纳米管,这与本文作者的结论是一致的。

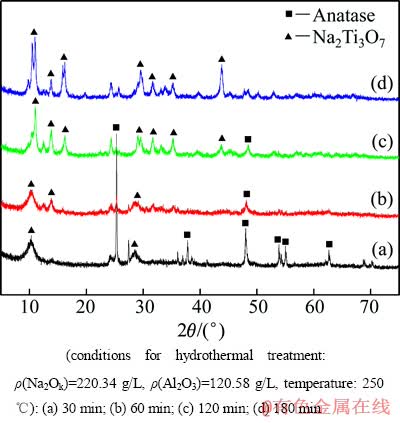

2.4 经水热处理的锐钛矿的XRD分析

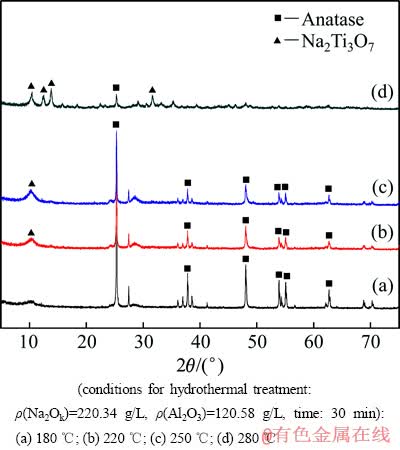

图11 经不同温度水热处理的锐钛矿的XRD谱

Fig. 11 XRD patterns of hydrothermal treated anatase at different temperatures

图12 经不同时间水热处理的锐钛矿的XRD谱

Fig. 12 XRD patterns of hydrothermal treated anatase for different times

图13 经不同苛性碱浓度铝酸钠溶液水热处理后锐钛矿的XRD谱

Fig. 13 XRD patterns of hydrothermal treated anatase with different caustic alkali concentrations

为了明确不同条件下经水热处理的锐钛矿的物相组成,进而从本质上弄清不同条件下经水热处理的锐钛矿在铝酸钠溶液中的溶解性能存在显著差别的原因,对其进行了X射线衍射分析,结果如图11~13所示。由图11~13可知,锐钛矿经水热处理后生成钛酸钠,其化学式为Na2Ti3O7,经水热处理的锐钛矿是锐钛矿与钛酸钠的混合物。随着水热处理的温度提高、时间的延长或铝酸钠溶液苛性碱浓度的增加,锐钛矿的特征峰逐渐消失,Na2Ti3O7的特征峰逐渐增强,并且结晶逐渐完善,结晶度提高。有研究表明,在水热合成钛酸钠纳米管时,温度和时间是影响钛酸钠纳米管结晶度的重要因素[25-26],这与本文作者的结论也是一致的。

晶体的溶解性能一般会受其结晶度的影响,结合溶解性能实验可以得出结论:随着水热处理锐钛矿条件的不断强化,钛酸钠的结晶度逐渐提高,其在铝酸钠溶液中溶解形成钛酸根离子的浓度逐渐降低,形成膜的“桥梁”被破坏或部分破坏,其对氧化铝溶出性能的影响也逐渐减小,甚至完全消失。

3 结论

1) 锐钛矿对氧化铝溶出的阻滞作用仅在于从动力学上降低氧化铝溶出的速率,随着溶出温度的升高、时间的延长和苛性碱浓度的增加,锐钛矿对氧化铝溶出的阻滞作用逐渐减小,甚至消失。

2)经水热处理的锐钛矿对氧化铝溶出性能的影响程度与水热处理的条件密切相关,水热处理的温度越高、时间越长、铝酸钠溶液苛性碱浓度越高,其对氧化铝溶出性能的影响越小,甚至消失。

3) 不同条件下经水热处理的锐钛矿对氧化铝溶出性能的影响存在显著差别的根源在于其溶解性能和结晶度的差别。随着水热处理锐钛矿条件的强化,钛酸钠的结晶度提高,其在铝酸钠溶液中溶解形成钛酸根离子的浓度降低, 对氧化铝溶出性能的影响也逐渐减小,甚至完全消失。

REFERENCES

[1] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993: 61-63.

YANG Zhong-yu. The technology of alumina production[M]. Beijing: The Metallurgical Industry Press, 1993: 61-63.

[2] PAWLEK F, KHEIRI M J, KAMMEL R. The leaching behavior of bauxite during mechanochemical treatment[C]//Light Metals. Warrendale, Pennsylvania: TMS, 1992: 91-95.

[3] PRAKASH S, HORVATH Z. Behavior of titanium minerals in the titanium-rich Indian bauxite during its digestion by Bayer's process[J]. Technical University of Heavy Industry B, 1979, 34(1): 43-63.

[4] AUTHIER-MARTIN M, FORTE G, OSTAP S, SEE J. The mineralogy of bauxite for producing smelter-grade alumina[J]. JOM, 2001, 53(12): 36-40.

[5] 陈万坤, 彭关才. 一水硬铝石型铝土矿的强化溶出技术[M]. 北京: 冶金工业出版社, 1997: 103-108.

CHEN Wang-kun, PENG Guan-cai. Intensified digestion technology for diasporic bauxite[M]. Beijing: Metallurgical Industry Press, 1997: 103-108.

[6] LI Xiao-bin, ZHOU Qiu-sheng, WANG Hao-yu, PENG Zhi-hong, LIU Gui-hua. Hydrothermal formation and conversion of calcium titanate species in the system Na2O-Al2O3-CaO-TiO2-H2O[J]. Hydrometallurgy, 2010, 104(2): 156-161.

[7] YIN Zhong-lin, GU Song-qing. The influence of lime addition amount on scaling rate in preheating process of diasporic bauxite slurry[C]. Light Metals, Warrendale, Pennsylvania: TMS, 2001: 139-142.

[8] 尹中林, 顾松青. 石灰添加方式对一水硬铝石型铝土矿浆预热过程结疤的影响[J]. 中国有色金属学报, 2001, 11(5): 910-914.

YIN Zhong-lin, GU Song-qing. Influence of lime adding method on scaling process in Bayer preheating process of diasporic bauxite slurry[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 910-914.

[9] 尹中林, 顾松青, 毕诗文. 双流法预热条件下铝土矿浆中杂质矿物的反应行为[J]. 中国有色金属学报, 2005, 15(2): 310-315.

YIN Zhong-lin, GU Song-qing, BI Shi-wen. Reaction behavior of impurity minerals in bauxite slurry in preheating process condition of two stream process of diasporic bauxite in China[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 310-315.

[10] 尹中林,毕诗文,顾松青. 铝土矿中含钛矿物在矿浆预热过程中反应动力学研究[J]. 矿冶工程, 2005, 7(4): 54-57.

YIN Zhong-lin, BI Shi-wen, GU Song-qing. Study of reaction kinetics of Ti-containing minerals in preheating process of bauxite slurry[J]. Mining and Metallurgy Engineering, 2005, 7(4): 54-57.

[11] LI Xiao-bin, YU Shun-wen, LIU Nan, CHEN Yong-kun, QI Tian-gui, ZHOU Qiu-sheng, LIU Gui-hua, PENG Zhi-hong. Dissolution behavior of sodium titanate in sodium aluminate solutions at elevated temperatures [J]. Hydrometallurgy, 2014, 147: 73-78.

[12] CHESTER R, JONES F, LOAN M, OLIVEIRA A, RICHMOND W R. The dissolution behaviour of titanium oxide phases in synthetic Bayer liquors at 90 ℃[J]. Hydrometallurgy, 2009, 96(3): 215-222.

[13] DUDEK K, JONES F, RADOMIROVIC T, SIMITH P. The effect of anatase, rutile and sodium titanate on the dissolution of boehmite and gibbsite at 90 ℃[J]. International Journal of Mineral Processing, 2009, 93(2): 135-140.

[14] WHITTINGTON B I. The chemistry of CaO and Ca(OH)2 relating to the Bayer process[J]. Hydrometallurgy, 1996, 43(1): 13-35.

[15] WHITTINGTON B I, CARDILE C M. The chemistry of tricalcium aluminate hexahydrate relating to the Bayer industry[J]. International Journal of Mineral Processing, 1996, 48(1): 21-38.

[16] BI Shi-wen, LI Dian-feng, YANG Yi-hong. The study on the reaction of rutile in Bayer liquor[C]//Light Metals. Warrendale, Pennsylvania: TMS, 1996: 43-48.

[17] LI Xiao-bin, FU Wei-an, ZHOU Qiu-sheng, LIU Gui-hua, PENG Zhi-hong. Reaction behavior and mechanism of anatase in digestion process of diasporic bauxite[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 142-146.

[18] GU Song-qing, YIN Zhong-lin, ZHOU Hui-fang. Behaviour of some additives in Bayer digestion process of diasporic bauxite[C]//Light Metals. Warrendale, Pennsylvania: TMS, 1992: 27-33.

[19] LOAN M, LOUGHLIN B, HAINES J, CROKER D. In situ time-resolved synchrotron diffraction studies of high temperature Bayer digestion[C]//Alumina Quality Workshop. Perth, Australia, 2005: 117-122.

[20] 王少娜,郑诗礼,张懿. 亚熔盐溶出一水硬铝石型铝土矿过程中赤泥的铝硅行为[J]. 过程工程学报, 2007, 7(5): 967-972.

WANG Shao-na, ZHENG Shi-li, ZHANG Yi. Behavior of Al and Si in red mud from leaching process of diaspore bauxite with NaOH sub-molten salt[J]. The Chinese Journal of Process Engineering, 2007, 7(5): 967-972.

[21] LIU H, WACLAWIK E R, ZHENG Z, YANG D , KE X , ZHU H, FROST R L. TEM investigation and FBB model explanation to the phase relationships between titanates and titanium dioxides[J]. The Journal of Physical Chemistry C, 2010, 114(26): 11430-11434.

[22] KIATKITTIPONG K, YE C H, SCOTT J, AMAL R. Understanding hydrothermal titanate nanoribbon formation[J]. Crystal Growth and Design, 2010, 10(8): 3618-3625.

[23] WONG C L, TAN Y N, MOHAMED A R. A review on the formation of titania nanotube photocatalysts by hydrothermal treatment[J]. Journal of Environmental Management, 2011, 92(7): 1669-1680.

[24] KUKOVECZ A, HODOS M, HORVATH E, RADNOCZI G, KONYA Z, KIRICSI I. Oriented crystal growth model explains the formation of titania nanotubes[J]. The Journal of Physical Chemistry B, 2005, 109(38): 17781-17783.

[25] THORNE A, KRUTH A, TUNSTALL D P, IRVINE J T S, ZHOU W. Formation, structure and stability of titanate nanotubes and their photon conductivity[J]. The Journal of Physical Chemistry B, 2005, 109(38): 5439-5444.

[26] LAN Y, GAO X P, ZHU H Y,ZHENG Z F, YAN T Y, WU F, RINGER S P, SONG D Y. Titanate nanotubes and nanorods prepared from rutile powder[J]. Advanced Functional Materials, 2005, 15(8): 1310-1318.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51374239)

收稿日期:2014-03-20;修订日期:2014-10-09

通信作者:齐天贵,讲师,博士;电话:0731-88830453;E-mail:qitiangui@csu.edu.cn