外加载荷对碳纳米管-银-石墨复合材料电磨损性能的影响

凤 仪, 张 敏, 徐 屹

(合肥工业大学 材料科学与工程学院, 合肥 230009)

摘 要: 研究了压力变化对碳纳米管-银-石墨复合材料纯机械磨损和电磨损性能的影响。 结果表明: 在纯机械磨损条件下, 随着压力的增加, 复合材料的磨损体积线性增加; 在电磨损条件下, 复合材料的磨损体积与压力成U型变化; 当压力过小时, 由于电气磨损量大以及电刷跳动产生的火花磨损, 导致复合材料的电磨损体积较大; 当压力过大时, 破坏了电刷和换向器之间形成的润滑膜, 产生严重的犁削和粘着磨损, 使复合材料的电磨损体积急剧增大; 复合材料的电磨损体积与电刷的极性有关, 正刷的磨损体积大于负刷的磨损体积; 随着压力的增大, 复合材料的摩擦系数也随之增大, 且在相同条件下, 电磨损时的摩擦系数大于纯机械磨损时的摩擦系数; 碳纳米管的加入可以提高复合材料的抗电磨损性能。

关键词: 碳纳米管-银-石墨复合材料; 机械磨损; 电摩擦磨损性能 中图分类号: TB331

文献标识码: A

Effect of pressure on electrical wear of CNTs-Ag-G composites

FENG Yi, ZHANG Min, XU Yi

(School of Materials Science and Engineering,Hefei University of Technology, Hefei 230009, China)

Abstract: The effect of pressure various on the mechanical and electrical wear properties of CNTs-Ag-G composites at 10A/cm2 were studied. The results show that the wear volume loss of composites increases with the increase of pressure under mechanical wear, but the wear volume loss of composites varies with the change of pressure by U shape under electrical wear. When the pressure becomes smaller, the electrical wear volume loss of composites becomes larger because of the additional electrical and spark wear. When the pressure is bigger, the electrical wear volume loss also becomes larger due to the discontinuous lubricating film, adhesion and ploughing. The wear volume loss of positive brush is more than that of negative brush. The friction coefficient of composites increases with the increase of pressure, and the friction coefficient of composites under electrical wear is greater than that under mechanical wear. Addition of CNTs-Ag-G can improve the electrical friction and wear properties of composites.

Key words: CNTs-Ag-G composite; mechanical wear; electrical friction and wear property

电接触是指两个组件因带电接触而产生的一种状态, 电接触材料是各类电器中的关键部件, 担负着传递电能、 电信号、 接触和分断电路等重要任务, 其性能的好坏直接关系到电机、 仪表、 电路的可靠性、 稳定性和使用寿命, 因此世界上工业发达国家都十分重视电接触材料的开发应用[1, 2]。 由于电接触材料在使用过程中, 除了受到机械力和摩擦力作用以外, 还有焦耳热、 电弧的灼烧以及因电流极性而产生的材料转移, 因此对电接触材料的性能要求较高, 通常要求其具有良好的导电和导热性、 低而稳定的接触电压降、 高的抗电磨损能力和较好的机械强度[3, 4]。 传统的银-石墨材料是典型的电接触材料, 广泛地用于制造电刷、 滑块和触点等, 它主要依靠银来改善材料的导电、 导热能力, 依靠石墨的减摩、 自润滑来提高材料的耐磨性。 但银含量的增加在改善导电、 导热性的同时, 导致材料耐磨性下降, 而石墨含量的增加在改善润滑、 耐磨性的同时削弱了材料的强度和导电性。 随各类电机、 仪表朝小型化、 轻质、 高速方向发展, 要求电接触材料的允许线速度大、 接触电压降低、 摩擦系数小、 磨损速率低、 载流能力大, 而银-石墨电接触材料在性能上已难以满足这些要求[5, 6]。 碳纳米管由于其具有强度高、 弹性模量大、 高温稳定、 减摩耐磨性优良等特性成为一种理想的复合材料增强体[7, 8]。 目前, 科技工作者对碳纳米管在复合材料中的应用进行了广泛研究[9, 10], 但对碳纳米管在金属基复合材料, 尤其在电接触材料中的应用还鲜见报道。 考虑电接触材料的实际工作状况, 为充分利用碳纳米管的优异的力学性能和减摩耐磨性能以改善复合材料的电磨损性能, 本文作者采用粉末冶金方法制备了碳纳米管-银-石墨复合材料, 研究了在不同压力下, 碳纳米管-银-石墨复合电接触材料的电磨损性能变化情况, 并对其机理进行了初步探讨。

1 实验

采用粉末冶金法制备电接触材料, 银粉采用蚌埠金银制品厂生产的纯银粉(纯度为99.99%)。 碳纳米管购自深圳碳纳米管公司, 直径为30~50nm, 长度为0.5~500μm, 纯度大于95%, 比表面积为40~300m2/g, 石墨粉采用上海胶体化工厂生产的试剂石墨粉(纯度大于99.85%)。

由于碳纳米管的长径比大于1000, 易纠缠在一起, 在制备试样时很难将其与银粉混合均匀。 但通过对其进行研磨、 酸洗, 在H2SO4与HNO3摩尔比为3∶1的溶液里煮沸4h, 使纠缠在一起的碳纳米管分散开, 并在其表面酸蚀纹槽以增加粗糙度, 使其能与银粉更好地结合[11]。 将处理的碳纳米管干燥, 与30μm的银粉、 40μm的石墨粉混合、 研磨均匀, 采用冷压+烧结法制备复合材料, 初压压力为200MPa, 然后在氢气保护气氛下于700℃烧结, 保温1h, 随炉冷却到室温, 再进行复压, 复压压力为400MPa。 对制得的复合材料进行机械加工, 得到尺寸为24mm×20mm×8mm的复合材料试样块, 复合材料的成分为60%Ag, 5%CNTs和35%G(体积分数)。

电磨损实验按国家标准(GB12175-90)在自制的电磨损实验机上进行。 试样为环-块滑动, 对磨环为铜合金, 布氏硬度为105, 由3个相互绝缘的尺寸为d320mm×60mm的短路环组成, 环表面开有均匀轴向槽, 槽距为5.5mm, 槽宽为0.5mm, 槽深为2mm(见图1)。 试样在换向器上的位置如图2所示。 复合材料的摩擦系数可计算为

式中 nB为电刷数量; Fr为作用于界面的径向分力; ω为角速度; rc为短路换向器半径; P为实验电刷与短路换向器通电接触时, 拖动电机的负载功率; P0为实验电刷与短路换向器没有接触时(无摩擦)拖动电机的空载功率。 电刷的磨面形貌采用Olympus显微镜和S-570扫描电子显微镜观察。 电

图1 电磨损实验装置示意图

Fig.1 Schematic diagram of electrical wear equipment

图2 电刷在换向器上的位置

Fig.2 Position of brushes on commutator

磨损时通过电刷的电流密度为10A/cm2, 对磨环线速度为10m/s, 纯机械磨损时, 条件与电磨损相同, 只是不通入电流。

2 结果和讨论

图3所示为在电磨损条件下压力对复合材料磨损体积的影响。 由图中3可见, 在磨损初期, 复合材料磨损量显著增加, 随磨损时间的延长, 单位时间内的磨损增量略有下降。 从物理意义上说, 固体表面总是凹凸不平的, 电刷和换向器在磨损初期的相互接触都是局部的, 有效接触面积较小(见图4)。 但随着磨损的进行, 在外加载荷的作用下, 接触面积逐渐增大, 且随着磨损的进行, 由于物理吸附和化学吸附作用, 在电刷和换向器的表面形成一层润滑膜(见图5), 其组成为90%碳和10%水(见图6)。

图3 不同时间下外加载荷对碳纳米管-银-石墨复合材料磨损体积的影响

Fig.3 Effect of load on wear volume of CNTs-Ag-G composites at different time

图4 接触表面示意图

Fig.4 Schematic diagram of contact surface

图5 电磨损不同时间后磨环上形成的润滑膜微观组织

Fig.5 Microstructures of lubrication film between brush and commutator at electrical wear after different wear time

图6 表面润滑膜的光电子能谱

Fig.6 XPS patterns of surface lubricating film

这层润滑膜的形成, 使电刷和换向器之间的接触由金属-金属型转变成金属-润滑膜-金属型接触, 从而降低了磨损速率。

图7所示为磨损时间为30h, 压力对复合电接触材料纯机械磨损和电流为10A/cm2时的电磨损体积的影响。 由图7可见, 在同一压力条件下, 复合电接触材料的电磨损体积约为纯机械磨损的10~15倍左右。 电接触材料的电磨损实际上取决于机械、 电气和化学等多种因素共同作用的结果, 一般由以下3种磨损组成: 1)不通电的纯机械磨损; 2)纯电气磨损; 3)电气和机械相互作用导致的磨损增量。 当电接触材料在换向器上运动时, 如果通入电流, 由于实际接触面积较小, 约为整个接触面积的10-3~10-2[4], 电流仅集中在电接触材料表面很小的实际接触区域内(a-斑点), 产生收缩电阻Rc(见图8)[12], 其计算式如下:

式中 ρ为接触材料的电阻系数; r为接触点的半径。 由于接触元件是两种不同材料, 假设其电阻系数分别为ρ1和ρ2, 则式(2)可变为:

当接触点的数目n>1时, 真正的接触面积之和A=nπr2, 此时

图7 外加载荷对碳纳米管-银-石墨复合材料机械和电磨损体积的影响

Fig.7 Effect of load on mechanical and electrical wear volume of CNTs-Ag-G composites

图8 收缩电阻示意图

Fig.8 Schematic diagram of contraction for electrical current

由于通过a-斑点的实际电流密度远大于表观电流密度, 收缩电阻的存在使得电接触材料局部发热, 电接触材料表面温度升高, 并使其表面产生氧化, 结合强度减小, 容易脱落而造成异常磨损, 从而导致电接触材料的电磨损体积远大于纯机械磨损体积。

从图7中还可发现, 对纯机械磨损而言, 随压力的增大, 复合材料的电磨损体积逐渐增大。 对电磨损而言, 当压力比较小时, 复合电接触材料的电磨损体积较大; 并随着压力的增大, 复合电接触材料的电磨损体积逐渐减小, 当压力为150~200kPa时, 复合材料的电磨损体积最小; 继续增加压力, 复合材料的电磨损体积开始增大, 压力与电磨损体积成U型关系。 电磨损时磨损量的计算公式为[13]

ΔV=ΔVm+ΔVE+ΔVF(5)

式中 ΔV、 ΔVm、 ΔVE和ΔVF分别为总磨损量、 机械磨损量、 电气磨损量和火花磨损量。 假设接触为基本稳定的, 则实际接触面积A和外加压力的关系为[4]

式中 p和 分别为总压力和每个接触点面积的平均压力; H为电刷硬度, ξ为常数。 当压力较小时, 虽然机械磨损量较小, 但是由于接触面积较小, 因此通过每个接触点的电流较大, 电气磨损量较大, 且由于压力小, 电刷容易产生跳动, 使电刷在运行时产生火花, 导致电磨损量急剧增大。 随压力增加, 虽然机械磨损量略有增加, 由式(4)和(6)可知, 由于电刷和换向器的实际接触区域面积的增大, 使通过每个接触点的电流密度下降, 收缩电阻减小, 电气磨损量减小, 且接触稳定, 不产生火花, 因此此时电刷的磨损主要为机械磨损和电气磨损, 因而总磨损量下降。 当压力过大时, 会破坏在电刷和换向器之间形成的润滑膜, 导致金属-金属接触, 在压力和电流的作用下, 产生严重的犁削和粘着磨损(见图9), 使接触不稳定, 导致电磨损量急剧增大。

分别为总压力和每个接触点面积的平均压力; H为电刷硬度, ξ为常数。 当压力较小时, 虽然机械磨损量较小, 但是由于接触面积较小, 因此通过每个接触点的电流较大, 电气磨损量较大, 且由于压力小, 电刷容易产生跳动, 使电刷在运行时产生火花, 导致电磨损量急剧增大。 随压力增加, 虽然机械磨损量略有增加, 由式(4)和(6)可知, 由于电刷和换向器的实际接触区域面积的增大, 使通过每个接触点的电流密度下降, 收缩电阻减小, 电气磨损量减小, 且接触稳定, 不产生火花, 因此此时电刷的磨损主要为机械磨损和电气磨损, 因而总磨损量下降。 当压力过大时, 会破坏在电刷和换向器之间形成的润滑膜, 导致金属-金属接触, 在压力和电流的作用下, 产生严重的犁削和粘着磨损(见图9), 使接触不稳定, 导致电磨损量急剧增大。

图9 电磨损条件下复合材料的磨面形貌

Fig.9 Morphologies of wore surface for composite under electrical wear(p=30kPa)

图10 电刷的极性对电刷磨损体积的影响

Fig.10 Effect of polarity on wear volume of brush at different load(t=30h)

图10所示为不同压力下正刷磨损量与负刷磨损量的对比。 由图10可看出, 正刷的磨损量要大于负刷的磨损量。 电流从电刷流入到换向器再经换向器由另一电刷流出, 电流流入的电刷为正刷, 流出的电刷为负刷。 通电磨损时, 换向器上吸附的水膜在电流的作用下发生离解:

H2O=H++OH-(7)

在电刷的正极侧时, 电流由电刷流向换向器, 从阴极游离出氢, 阳极游离出氧, 而这种氧很活泼, 会与电刷中的碳或金属发生氧化反应, 使得表面变得粗糙, 且削弱其结合力, 导致磨损加剧, 从而使得阳极电刷的磨损量要大于阴极电刷的磨损量。

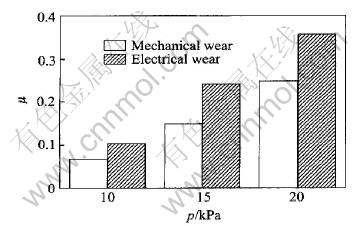

摩擦系数是电刷正常运行必须考虑的一个重要因素, 一般要求电刷在运行过程中摩擦系数适中而平稳, 因为摩擦系数波动导致电刷接触不稳定, 引起电刷振动发出噪音, 且摩擦系数越大, 摩擦损耗也越大。 图11所示为压力为200kPa时, 在电磨损和纯机械磨损条件下, 电刷的摩擦系数与磨损时间的关系。 由图11可见, 在磨损刚开始时, 材料的摩擦系数都比较大, 且随着磨损的进行, 摩擦系数逐渐变小, 最后稳定在一个比较小的数值上。 分析其变化的原因, 是由于在磨损初期, 电刷和换向器是直接接触, 随着磨损的继续, 在换向器和电刷的表面形成一层润滑膜(见图5), 使电刷和换向器之间的接触由金属-金属型转变成金属-润滑膜-金属型, 从而降低了电刷和换向器之间的摩擦系数。 由图11还可发现, 复合材料在电磨损时的摩擦系数大于在纯机械磨损时的摩擦系数。 通电磨损时, 由于有效接触面积较小, 电流通过时产生收缩, 形成收缩电阻, 导致温度升高, 破坏了润滑膜的均匀性和完整性, 导致摩擦系数逐渐增大[14]。 图12所示为在机械磨损和电磨损条件下, 压力对复合材料摩擦系数的影响。 由图12可看见, 随压力的增大, 在机械磨损和电磨损条件下, 复合材料的摩擦系数逐渐增大, 且电磨损时的摩擦系数高于纯机械磨损的摩擦系数。 这是由于在式(6)中, 实际接触面积的增长慢于载荷的增长, 导致单位面积上载荷加大。 另一方面, 当外加载荷较大时, 会破坏电刷和换向器之间润滑膜的完整性(见图5和8), 导致电刷表面粗糙度的增大和摩擦系数的增加。

表1所列为电流强度为10A/cm2、 压力为200kPa、 磨损时间为30h时, 碳纳米管对复合材料电磨损性能的影响。 从表1中可看出, 用碳纳米管部

图11 磨损时间对纯机械磨损和电磨损时复合材料摩擦系数的影响

Fig.11 Effect of wear time on friction coefficient of composites at mechanical and electrical wear(p=20kPa)

图12 机械磨损和电磨损时压力对复合材料摩擦因数的影响

Fig.12 Effect of load on friction coefficient of composites at mechanical and electrical wear

表1 碳纳米管对复合材料电磨损性能的影响

Table 1 Effect of CNTs on electrical wear properties of composites

分代替石墨对复合材料的摩擦系数影响不大, 但使相同条件下复合材料的磨损体积损失下降约16%。 这是由于在银-石墨材料中, 随石墨含量的增加, 材料强度迅速下降, 与石墨相比, 碳纳米管具有较高的强度和弹性模量, 适量碳纳米管的加入, 不仅没有降低基体银的强度, 反而提高了材料的强度[15]; 另一方面, 与石墨相比, 碳纳米管具有较高的导电和导热性能, 用碳纳米管代替石墨, 可以改善复合材料在电摩擦磨损过程中的热效应[16]。

REFERENCES

[1]Mansori M E, Paulmier D, Ginsztler J, et al. Lubrication mechanisms of a sliding contact by simultaneous action of electric current and magnetic field[J]. Wear, 1999, 225-229: 1011-1016.

[2]Zhao H, Barber G C, Liu J. Friction and wear in high speed sliding with and without electrical current[J]. Wear, 2001, 249: 409-414.

[3]Lu C T, Bryant M D. Thermoelastic evolution of contact area and mound temperatures in carbon graphite electrical brushes[J]. Wear, 1994, 174: 137-146.

[4]Rapoport L, Parkansky N, Lapsker I. Effect of trans-verse current injection on the tribological properties of WC cemented carbide[J]. Wear, 2001, 249: 1-5.

[5]Keil A, Merl W A, Vinaricky E. Elektrische Knotakte Und Ihre Werkstoffe[M]. Springer: Verlag, 1984.

[6]He H D, Manory R. A novel electrical contact material with improved self-lubrication for railway current collectors[J]. Wear, 2001, 249: 626-636.

[7]Thostenson E T, Ren Z, Chou T W. Advances in the science and technology of carbon nanotubes and their composites: a review[J]. Composites Science and Technology, 2001, 61: 1899-1912.

[8]Andrews R, Weisenberger M C. Carbon nanotube polymer composites[J]. Current Opinion in Solid State and Materials Science, 2004, 8: 31-37.

[9]Ning J W, Zhang J J. Fabrication and mechanical properties of SiO2 matrix composites reinforced by carbon nanotube[J]. Materials Science and Engineering, 2003, A357: 392-396.

[10]Erik T T, Chunyu L, Tsu W C. Nanocomposites in context[J]. Composites Science and Technology, 2005, 65: 491-516.

[11]Feng Y, Yuan H L. Electroless plating of carbon nanotube with silver[J]. Journal of Materials Science, 2004, 39: 3241-3243.

[12]刘先曙. 电接触材料的应用[M]. 北京: 国防工业出版社, 1979.

LIU Xian-shu. Application of Electrical Contact Materials[M]. Beijing: Defense Industry Press, 1979.

[13]Senouci A, Frene J, Zaidi H. Wear mechanism in graphite-copper electrical sliding contact[J]. Wear, 1999, 225-229: 949-953.

[14]Feng Y, Zhang M. Effect of the electric current on the friction and wear properties of the CNT-Ag-G composites[J]. Carbon, 2005, 43: 2685-2692.

[15]凤仪, 袁海龙, 张敏. 碳纳米管-银基复合材料力学性能研究[J]. 材料热处理学报, 2005, 24(2): 23-26.

FENG Yi, YUAN Hai-long, ZHANG Min. Processing and mechanical properties of carbon nanotubes-silver composites[J]. Transactions of Materials and Heat Treatment, 2005, 24(2): 23-26.

[16]凤仪, 袁海龙, 张敏. 碳纳米管-银复合材料制备工艺和电导率[J]. 中国有色金属学报, 2004, 14(9): 1451-1455.

FENG Yi, YUAN Hai-long, ZHANG Min. Processing and electrical conductivity of carbon nanotubes-silver composites[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1451-1455.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50271021); 安徽省自然科学基金资助项目(03044601); 日本NSGF基金资助项目

收稿日期: 2005-04-25; 修订日期: 2005-06-13

作者简介: 凤 仪(1964-), 男, 教授, 博士

通讯作者: 凤 仪, 电话: 0551-3423150; E-mail: fy123@mail.hf.ah.cn