文章编号:1004-0609(2009)03-0464-05

溶质离子在铝合金微弧氧化陶瓷膜形成过程中的作用机理

杨 巍,蒋百灵,鲜林云,时惠英

(西安理工大学 材料科学与工程学院,西安 710048)

摘 要:利用交流脉冲微弧氧化电源在碳酸钠、硅酸钠和锡酸钠3种电解液中对LY12铝合金进行微弧氧化处理,通过SEM和XRD观察分析铝合金样品表面形貌和相组成的变化,研究各溶质离子对微弧氧化起弧现象及生长曲线的作用规律。结果表明:在3种电解液中进行微弧氧化处理时,在硅酸钠溶液中铝合金易于起弧,能够在短时间、低电压下获得高阻抗膜;而在锡酸钠溶液中铝合金不能形成高阻抗膜,未发生起弧现象;铝合金样品表面预先制备高阻抗膜有利于发生微弧氧化起弧现象;在碳酸钠和硅酸钠溶液中,微弧氧化陶瓷膜的后期生长曲线有着相似的变化规律,在锡酸钠溶液中样品表面产生电化学溶解,不能形成陶瓷膜;铝合金样品表面形成高阻抗膜是微弧氧化现象得以进行的必要条件。

关键词:LY12铝合金;微弧氧化;溶质离子;高阻抗膜

中图分类号:TG 174.2 文献标识码:A

Action mechanism of solute ions on forming process of

microarc oxidation coatings on aluminium alloy

YANG Wei, JIANG Bai-ling, XIAN Lin-yun, SHI Hui-ying

(School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: LY12 aluminium alloy was processed by microarc oxidation in Na2CO3, Na2SiO3 and Na2SnO3 solutions using AC electrical source. The effects of solute ions on the surface morphologies and phases of aluminium alloy samples were investigated by SEM and XRD, respectively. The effect rules of arc starting and growing curves were contrastively studied. The results show that in the above three electrolytes, arc starting can occur easily in Na2SiO3 solution, and high impedance coating can be prepared in short time at low voltage. Arc starting phenomenon cannot happen in Na2SnO3 solution. The phenomenon of arc starting will occur easily when high impedance coating occurs on the surface of aluminium alloy sample. Growing curves of ceramic coatings have similar rule during forming microarc oxidation coating in Na2CO3 and Na2SiO3 solutions. The sample is dissolved by galvano-chemistry in Na2SnO3 solution and the ceramic coating cannot be formed. The necessary condition of occurring microarc oxidation phenomenon is that high impedance coating must be formed on the surface of aluminium alloy.

Key words: LY12 aluminium alloy; microarc oxidation; solute ion; high impedance coating

微弧氧化处理是将铝、镁合金制品做阳极,不锈钢做阴极,置于脉冲电场环境的电解液中,使制品表面产生微弧放电而生成一层与基体以冶金方式结合的氧化铝或氧化镁陶瓷层,陶瓷质的氧化产物具有较好的抗磨损、耐腐蚀等优点,使微弧氧化技术在航空、航天、交通等领域获得较为广泛的应用[1?4]。目前,微弧氧化处理工艺研究工作多集中在微弧氧化设备开发、工艺参数确定、电解液成分对微弧氧化陶瓷层性能影响等方面,对溶质离子在微弧氧化过程中的作用尚未完全清楚[5?10]。大量试验结果表明,溶质离子种类对微弧氧化起弧时间、起弧电压以及陶瓷膜生长规律均有显著影响[11?14]。

本文作者所在的课题组根据微弧氧化陶瓷膜的生长机理将其过程分为初期成膜(起弧瞬间膜层)和后期生长两个不同阶段,在铝合金样品表面先获得高阻抗膜后再进行微弧氧化处理,为明确溶质离子在陶瓷膜形成过程中的作用提供理论依据。试验中选取性质相近的碳酸钠、硅酸钠和锡酸钠3种溶液为研究对象,通过草酸阳极氧化工艺在铝合金样品表面获得高阻抗膜,对比分析有无高阻抗膜铝合金在3种电解液中处理时起弧现象的差别以及生长曲线的变化规律,力求明确溶质离子在铝合金微弧氧化膜形成过程中的作用。

1 实验

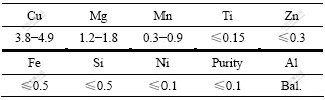

实验材料为LY12铝合金,其化学成分如表1所列。

表1 LY12铝合金的化学成分

Table 1 Chemical compositions of LY12 aluminium alloy (mass fraction, %)

样品尺寸为d 20 mm×5 mm。溶质离子选取0.1 mol/L的Na2CO3、Na2SiO3和Na2SnO3分别与去离子水配制微弧氧化电解液,阳极氧化电解液选取38 g/L的草酸溶液与去离子水配制而成[15]。微弧氧化和阳极氧化处理工艺均采用自行研制的65 kW微弧氧化装置。微弧氧化工艺采用恒流模式,电流密度5 A/dm2,频率400 Hz,占空比10,经8 min处理制备氧化膜,电解液温度控制在30 ℃左右;阳极氧化工艺采用恒压模式,电压100 V,频率30 Hz,占空比95,处理时间为10 min,溶液温度控制在21 ℃左右。

采用JSM?6700F型场发射扫描电子显微镜观察铝合金样品表面形貌,借助XRD?7000型X射线衍射仪分析样品表面的相组成,使用IM6e型电化学工作站测定分析铝合金样品微弧氧化初期成膜和预制备膜的阻抗值,该化学工作站采用传统的三电极体系,其中参比电极为饱和甘汞电极(SCE),铂电极(Pt)为辅助电极,研究电极为用环氧树脂封装的氧化膜试样,暴露面积约1 cm2,腐蚀介质为3.5%的NaCl水溶液,pH=7;测量参数:交流信号振幅5 mV,扫描速度0.1 mV/s,频率0.01~100 000 Hz,以恒电位方式扫描。

2 结果与讨论

2.1 溶质离子对铝合金微弧氧化陶瓷膜起弧时间和电压的影响

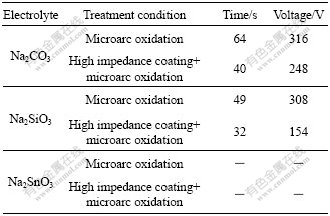

表2所列为不同表面状态铝合金在3种电解液中的起弧时间与起弧电压。由表2中数据并结合试验现象可知:在碳酸钠、硅酸钠溶液中进行微弧氧化处理,高阻抗膜铝合金微弧氧化起弧时间较无高阻抗膜铝合金明显缩短,起弧电压显著降低。碳酸钠溶液中,起弧时间由64 s缩减为40 s,起弧电压由316 V降低到248 V,硅酸钠溶液中,起弧时间由49 s缩减为32 s,起弧电压由308 V降低为154 V。在锡酸钠溶液中进行微弧氧化处理时,有无高阻抗膜铝合金均未发现弧光,不发生微弧氧化现象。可见,铝合金在3种电解液中进行微弧氧化处理时,硅酸钠溶液中最易发生起弧现象,而锡酸钠溶液不能对其进行微弧氧化处理;样品表面获取高阻抗膜有利于在短时间、低电压下发生起弧现象。

表2 铝合金在3种电解液中的起弧时间和起弧电压

Table 2 Time and voltage of arc starting on aluminium alloy in three electrolytes

2.2 溶质离子对铝合金微弧氧化陶瓷膜后期生长过程的影响

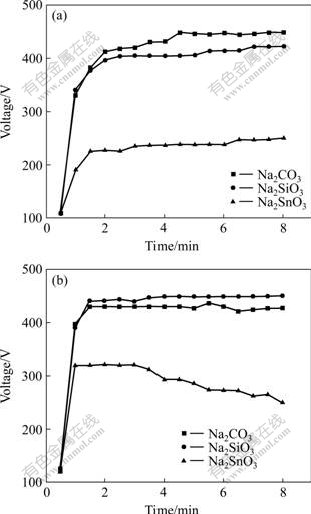

图1所示为铝合金在3种电解液中进行微弧氧化处理时电压随时间的变化曲线。由图1(a)可知,无高阻抗膜铝合金在碳酸钠与硅酸钠溶液中微弧氧化处理1.5 min,两者的电压—时间曲线吻合较好,1.5 min后,碳酸钠和硅酸钠溶液中微弧氧化电压均可稳定在400 V左右,实现对初期成膜电击穿,陶瓷层不断生长增厚;锡酸钠溶液中电压—时间变化曲线虽有微弧氧化陶瓷膜的生长曲线变化趋势,但其稳定电压很低,难以实现对膜层的击穿放电,不能形成陶瓷层。由图1(b)知,在碳酸钠和硅酸钠溶液中,高阻抗膜铝合金微弧氧化生长曲线同样相差不大,但在锡酸钠溶液中,高阻抗膜铝合金的生长曲线在后期出现明显的下降趋势,表明在该溶液中样品表面产生溶解,同样难以成膜。

图1 不同表面状态铝合金微弧氧化电压随时间的变化曲线

Fig.1 Variation of voltage with time in microarc oxidation process on aluminium alloy without high impedance coating(a) and with high impedance coating(b)

2.3 溶质离子对铝合金微弧氧化陶瓷膜表面相组成的影响

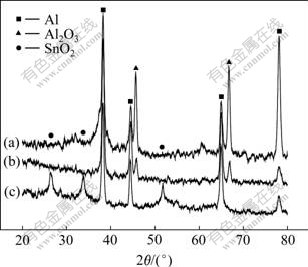

在不同溶质离子组成的电解液中对铝合金样品经8 min处理所得膜层的X射线衍射分析结果如图2所示。由图2可知,碳酸钠和硅酸钠溶液中,样品表面获得了以Al2O3为主相的陶瓷膜,并未发现溶质离子参与形成的相;锡酸钠电解液中,样品表面为SnO2的沉积膜,并未发现Al2O3相。可见,铝合金在锡酸钠溶液中未发生微弧氧化现象,样品表面无陶瓷质产物形成。

图2 3种电解液中铝合金微弧氧化8 min所得膜层的XRD谱

Fig.2 XRD patterns of coatings treated by microarc oxidation for 8 min in three electrolytes: (a) Na2CO3; (b) Na2SiO3; (c) Na2SnO3

2.4 讨论

通过上述分析可知,溶质离子种类对铝合金微弧氧化起弧时间和电压、后期生长曲线以及表面相组成均有显著影响。其原因在于,微弧氧化过程中电解液和阴、阳极串联形成回路,溶质离子将起到传递电荷的作用,其中阴离子向阳极(铝合金)移动,在阳极区附近形成该离子的富集区而显负电性,并与外电路高电位相连的铝合金样品形成109 V/cm的强电场[16],氧化过程中阴离子将依据放电特性不同而有选择地跃出富集区进入强电场,其中OH?离子较含氧酸根优先放电,铝、氧等原子发生激烈化合作用形成陶瓷膜。同时,含氧酸根因吸附与溶解特性不同而影响陶瓷膜的形成过程,其方式主要表现在两个方面:一是影响初期成膜的阻抗值,二是对微弧氧化后期陶瓷膜生长稳定电压的影响。

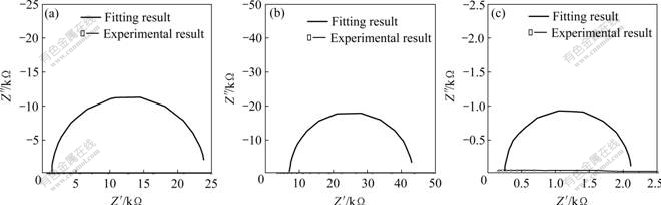

由于各溶质离子中阴离子特性不同所表现出的不同物理化学性质(如吸附特性和溶解特性),导致初期成膜的交流阻抗值不同,如图3所示。

图3 3种电解液中铝合金高阻抗膜的阻抗复数平面图

Fig.3 Complex impedance plane figures of high impedance coatings formed in three electrolytes on aluminium alloy: (a) Na2CO3; (b) Na2SiO3; (c) Na2SnO3

结合溶质离子对微弧氧化起弧现象的影响可知,硅酸钠溶液中,铝合金表面能够在处理49 s时获得阻抗为36.005 kΩ的高阻抗膜层,为后期陶瓷膜击穿放电提供了保证;碳酸钠溶液中也可形成铝合金高阻抗膜,其阻抗为11.080 kΩ,而锡酸钠在水溶液中由于水解形成xSnO2·yH2O,在样品表面难以形成高阻抗膜,处理1 min时所得膜层的阻抗仅为1.868 kΩ。由此可知,铝合金微弧氧化初期成膜阻抗越高,越易发生微弧放电现象。但通过试验发现,有高阻抗膜铝合金在能够发生微弧氧化起弧现象的电解液中起到了缩短起弧时间、降低起弧电压的作用;而对电解液自身不能发生微弧氧化起弧现象的未起作用。由此可得,微弧氧化起弧现象的发生依赖于样品表面高阻抗膜的形成,但溶质离子自身的特性同样制约着铝合金在电解液中的起弧。

铝合金样品在电场作用下,发生击穿和冷凝的循环过程,陶瓷膜生长增厚。试验发现,样品表面无论有无高阻抗膜,在碳酸钠和硅酸钠溶液中微弧氧化陶瓷膜的生长曲线相近,均能够在1.5 min后达到400 V左右的稳定值;在锡酸钠溶液中,不具备微弧氧化陶瓷膜高压击穿的生长曲线特征,电压稳定值仅在250 V左右,且样品表面发生电化学溶解(见图4),其中,无高阻抗膜铝合金经8 min处理后,样品表面凹凸不平,出现大量腐蚀坑,高阻抗膜铝合金表面则出现大的腐蚀裂纹,溶解作用更加明显。其原因在于微弧氧化过程是一个离子放电过程,OH?离子较试验中的3种含氧酸根优先放电而为铝、氧原子的化合提供条件,使所得陶瓷层仅为Al2O3相,但同时阳极区附近因OH?离子放电而呈酸性,对氧化膜起到了溶解作用,试验中CO32?和SiO32?离子可与H+离子结合而抑制其溶解,使陶瓷膜不断生长增厚,SnO32?离子因发生水解作用形成SnO2而不能大量结合H+离子,样品表面因溶解作用而不能形成高阻抗膜,击穿放电过程难以发生。可见,在样品表面能够形成高阻抗膜的溶质离子,陶瓷膜后期生长才可顺利进行,且击穿电压随氧化时间有着相似的变化规律,溶质离子对其影响甚小,但在铝合金样品表面不能形成高阻抗膜的溶质离子,即使表面具备高阻抗膜,因其自身特性导致微弧氧化陶瓷层同样难以形成。

图4 不同表面状态铝合金在锡酸钠溶液中所得膜层的表面形貌

Fig.4 Surface morphologies of coatings formed in Na2SnO3 solution on aluminium alloy: (a) Without high impedance coating; (b) With high impedance coating

3 结论

1) 3种电解液中,微弧氧化起弧时间和起弧电压不同,其中,硅酸钠溶液易于起弧,能够在短时间、低电压下获得高阻抗值膜层,锡酸钠溶液中不能发生起弧现象;在能够发生起弧现象的电解液中,陶瓷膜后期生长曲线有相似的变化规律,不能发生起弧现象的电解液中,铝合金表面产生电化学溶解。

2) 在碳酸钠和硅酸钠溶液中微弧氧化膜层表面为Al2O3相,在锡酸钠溶液中仅在样品表面获得SnO2相,无陶瓷质产物形成。

3) 铝合金表面形成高阻抗膜是微弧氧化现象得以发生的必要条件,但溶质离子的自身特性同样制约着陶瓷膜的形成过程。

REFERENCES

[1] 蒋百灵, 白力静, 蒋永峰. LY12铝合金表面氧化铝陶瓷层的生长过程[J]. 中国有色金属学报, 2001, 11(2): 186?189.

JIANG Bai-ling, BAI Li-jing, JIANG Yong-feng. Growth of alumina ceramic coatings on the surface of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 186?189.

[2] XUE W B, SHI X L, HUA M, LI Y L. Preparation of anti-corrosion films by microarc oxidation on an Al-Si alloy[J]. Applied Surface Science, 2007, 253: 6118?6124.

[3] WRITZ G P, BOWN S D, KRIVEN W M. Ceramic coatings by anodic spark deposition[J]. Materials and Manufacturing Processes, 1991, 6(1): 87?115.

[4] ZHANG R F, SHAN D Y, CHEN R S, HAN E H. Effects of electric parameters on properties of anodic coatings formed on magnesium alloys[J]. Materials Chemistry and Physics, 2008, 107: 356?363.

[5] VERDIER S, BOINET M, MAXIMOVITCH S, DALARD F. Formation, structure and composition of anodic films on AM60 magnesium alloy obtained by DC plasma anodizing[J]. Corrosion Science, 2005, 47: 1430?1444.

[6] 骆海贺, 蔡启舟, 魏伯康, 余 博, 何 剑, 李定骏. 添加剂浓度对微弧氧化陶瓷层结构及耐蚀性的影响[J]. 中国有色金属学报, 2008, 18(6): 1082?1088.

LUO Hai-he, CAI Qi-zhou, WEI Bo-kang, YU Bo, HE Jian, LI Ding-jun. Effects of additive concentration on microstructure and corrosion resistance of ceramic coatings formed by micro-arc oxidation on AZ91D Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1082?1088.

[7] GUO H F, AN M Z, XU S, HUO H B. Formation of oxygen bubbles and its influence on current efficiency in micro-arc oxidation process of AZ91D magnesium alloy[J]. Thin Solid Films, 2005, 485: 53?58.

[8] 蒋百灵, 吴国建, 张淑芬. 镁合金微弧氧化陶瓷层生长过程及微观结构的研究[J]. 材料热处理学报, 2002, 23(1): 5?7.

JIANG Bai-ling, WU Guo-jian, ZHANG Shu-fen. The research on micromechanism and growth procedure of ceramic coating formed by microarc oxidation on magnesium alloys[J]. Transactions of Materials and Heat Treatment, 2002, 23(1): 5?7.

[9] 张荣发, 曲铁平, 巢强花, 聂新兵, 王 为. 环保型电解质对镁合金氧化膜性能的影响[J]. 中国有色金属学报, 2008, 18(6): 1027?1031.

ZHANG Rong-fa, QU Tie-ping, CHAO Qiang-hua, NIE Xin-bing, WANG Wei. Effects of environmentally friendly electrolytes on properties of anodic coatings formed on magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1027?1031.

[10] GUO H F, AN M Z. Effect of surfactants on surface morphology of ceramic coatings fabricated on magnesium alloys by micro-arc oxidation[J]. Thin Solid Films, 2006, 500: 186?189.

[11] LIANG J, GUO B, TIAN J, LIU H W, ZHOU J F, LIU W M, XU T. Effects of NaAlO2 on structure and corrosion resistance of microarc oxidation coatings formed on AM60B magnesium alloy in phosphate—KOH electrolyte[J]. Surface and Coatings Technology, 2005, 199: 121?126.

[12] ZHENG H Y, WANG Y K, LI B S, HAN G R. The effects of Na2WO4 concentration on the properties of microarc oxidation coatings on aluminum alloy[J]. Materials Letters, 2005, 59: 139?142.

[13] XIN S G, SONG L X, ZHAO R G, HU X F. Properties of aluminium oxide coating on aluminium alloy produced by micro-arc oxidation[J]. Surface & Coatings Technology, 2005, 199: 184?188.

[14] WANG Y H, WANG J, ZHANG J B, ZHANG Z. Effects of spark discharge on the anodic coatings on magnesium alloy[J]. Materials Letters, 2006, 60: 474?478.

[15] 朱祖芳. 铝合金阳极氧化与表面处理技术[M]. 北京: 化学工业出版社, 2004: 79?81.

ZHUN Zu-fang. Anodic oxidation on aluminium alloy and surface treatment technology[M]. Beijing: Chemical Industry Press, 2004: 79?81.

[16] 杨德钧, 沈卓身. 金属腐蚀学[M]. 北京: 冶金工业出版社, 2003: 48?50.

YANG De-jun, SHEN Zhuo-shen. Metal corrosion science[M]. Beijing: Metallurgical Industry Press, 2003: 48?50.

基金项目:镁合金微弧电泳成套装备与工艺技术研究开发资助项目(2006BAE04B05-1)

收稿日期:2008-07-03;修订日期:2008-11-20

通讯作者:蒋百灵,教授;电话:029-82312617;E-mail: jbl@xaut.edu.cn

(编辑 李向群)