Indirect 3D printed ceramic: A literature review

来源期刊:中南大学学报(英文版)2021年第4期

论文作者:张百成 蔡嘉伟 张茂航 温耀杰 曲选辉

文章页码:983 - 1002

Key words:indirect 3D printing; ceramic; binder jetting; stereolithography; fused deposition modeling

Abstract: Additive manufacturing (AM), also known as 3D-printing (3DP) technology, is an advanced manufacturing technology that has developed rapidly in the past 40 years. However, the ceramic material printing is still challenging because of the issue of cracking. Indirect 3D printing has been designed and drawn attention because of its high manufacturing speed and low cost. Indirect 3D printing separates the one-step forming process of direct 3D printing into binding and material sintering, avoiding the internal stress caused by rapid cooling, making it possible to realize the high-quality ceramic component with complex shape. This paper presents the research progress of leading indirect 3D printing technologies, including binder jetting (BJ), stereolithography (SLA), and fused deposition modeling (FDM). At present, the additive manufacturing of ceramic materials is mainly achieved through indirect 3D printing technology, and these materials include silicon nitride, hydroxyapatite functional ceramics, silicon carbide structural ceramics.

Cite this article as: CAI Jia-wei, ZHANG Bai-cheng, ZHANG Mao-hang, WEN Yao-jie, QU Xuan-hui. Indirect 3D printed ceramic: A literature review [J]. Journal of Central South University, 2021, 28(4): 983-1002. DOI: https://doi.org/ 10.1007/s11771-021-4674-1.

J. Cent. South Univ. (2021) 28: 983-1002

DOI: https://doi.org/10.1007/s11771-021-4674-1

CAI Jia-wei(蔡嘉伟)1, ZHANG Bai-cheng(张百成)1, 2, ZHANG Mao-hang(张茂航)1,WEN Yao-jie(温耀杰)1, QU Xuan-hui(曲选辉)1, 2

1. Beijing Advanced Innovation Center for Materials Genome Engineering, Advanced Material & Technology Institute, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Laboratory of Metallic Materials and Processing for Modern Transportation,Beijing 100083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Additive manufacturing (AM), also known as 3D-printing (3DP) technology, is an advanced manufacturing technology that has developed rapidly in the past 40 years. However, the ceramic material printing is still challenging because of the issue of cracking. Indirect 3D printing has been designed and drawn attention because of its high manufacturing speed and low cost. Indirect 3D printing separates the one-step forming process of direct 3D printing into binding and material sintering, avoiding the internal stress caused by rapid cooling, making it possible to realize the high-quality ceramic component with complex shape. This paper presents the research progress of leading indirect 3D printing technologies, including binder jetting (BJ), stereolithography (SLA), and fused deposition modeling (FDM). At present, the additive manufacturing of ceramic materials is mainly achieved through indirect 3D printing technology, and these materials include silicon nitride, hydroxyapatite functional ceramics, silicon carbide structural ceramics.

Key words: indirect 3D printing; ceramic; binder jetting; stereolithography; fused deposition modeling

Cite this article as: CAI Jia-wei, ZHANG Bai-cheng, ZHANG Mao-hang, WEN Yao-jie, QU Xuan-hui. Indirect 3D printed ceramic: A literature review [J]. Journal of Central South University, 2021, 28(4): 983-1002. DOI: https://doi.org/ 10.1007/s11771-021-4674-1.

1 Introduction

Ceramic materials have been used in various fields, including electronics, fuel cells, and biomedicine due to their excellent properties (such as electrical insulation, high thermal stability, high hardness, and biocompatibility) [1]. Traditional methods for preparing the ceramic materials include hot isostatic pressing (HIP), spark plasma sintering (SPS), powder metallurgy (PM), and mechanical alloying (MA), carbothermic and thermite reduction [2]. However, these forming technologies face the challenge of long processing time and high cost [3]. Besides, the extremely high hardness and brittleness of ceramic parts make them extremely difficult to be machined.

Additive manufacturing, also known as 3D printing, has been developed since the 1980s. 3D printing is a collection of advanced manufacturing technologies that digitally slice 3D CAD models into 2D cross-sections and fabricate parts in a layer-by-layer manner. In the process of preparing ceramic by additive manufacturing, high-energy beams such as lasers and electrons are usually used to melt the raw ceramic powder. However, severe internal stress caused by the rapid cooling during the melting of the high-energy beams greatly reduces the quality of the product.

The indirect 3D printing technology of ceramic materials provides entirely new possibilities to solve the problems mentioned above. And this paper aims to systematically investigate binder jetting, stereolithography, and fused deposition modeling in terms of technique overview, materials, mechanical properties, microstructure, etc. The materials of research include functional structural ceramic silicon nitride, bioceramic material hydroxyapatite functional ceramics, structural ceramic silicon carbide, etc. These technologies also require debinding and sintering the green body at higher temperatures to achieve densification, which will also be introduced.

The emergence of 3D-printing technology has made it possible to produce structural ceramics materials with highly complex geometric shapes and interconnected pores. Simultaneously, the use of 3D-printing technology based on light curing can alleviate defects caused by internal stress. The influence of binder and different powder states on printed parts will be discussed in detail.

2 Binder jetting and related ceramic materials

2.1 Technique overview

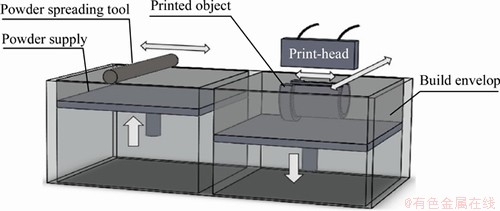

Binder jetting (BJ) was developed by SACHS et al in 1993 [4]. It is also known as the 3DP method. This technology involves inkjet nozzle, which sprays the binder on the plastic powder bed surface. The binder solidifies when contacting with air or light [5]. Thus, the binder constituent and process parameters are the two critical factors of this technology. After first layer solidification, the build platform descends, the following powder is spread on the first layer, and the process is repeated to complete the part. Figure 1 shows a schematic diagram of the 3DP process [6]. The green parts of silicon carbide ceramics [7] printed by 3DP are demonstrated in Figure 2.

The BJ method is initially designed to fabricate parts quickly from a wider range of materials, which is faster than other existing AM technologies, such as SLA, SLM. The BJ technology presents technical and economic advantages, allowing relatively low-cost manufacturing of complex geometries without thermal deformation [8]. Compared to SLM, SLA, or other traditional 3D printing methods, BJ avoids the enormous residual internal stress issue caused by rapid cooling rate from lasers or electron beams during the printing process.

Figure 1 Schematic diagram of 3DP process [6]

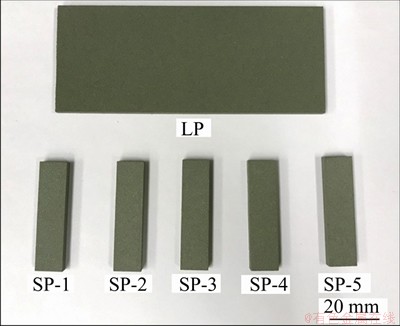

Figure 2 Green part of silicon carbide ceramics printed by 3DP [7]

2.2 BJ material overview

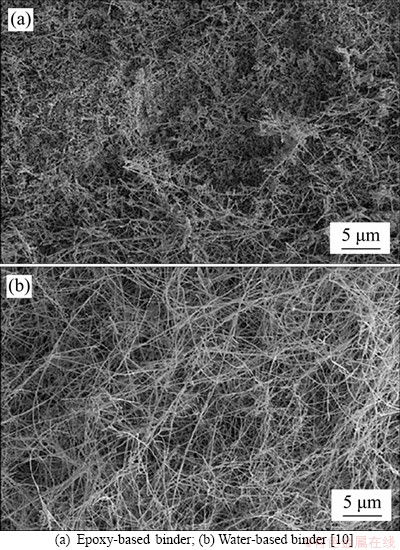

The binder jetting technique has been applied to commercial fields due to its tolerable flexibility in terms of materials and geometry. Silicon nitride (Si3N4) ceramics are widely used in different fields due to their excellent mechanical and thermal properties, such as jet engine structural components, brake system components. RABINSKIY et al [9] presented the research of binder jetting technology to fabricate porous silicon nitride ceramics. Two types of binders with polyurethane and modified starch are employed to fabricate silicon nitride components, as shown in Figure 3. The morphology of building silicon nitride is shown in Figure 4 [10]. The ceramic samples’ porosity using expoxy-based and water-based binders is about 60% and 70%, respectively. The advantage of this technology is to avoid the problem of powder dispersion in the slurry, so that it does not involve complicated material preparation processes.

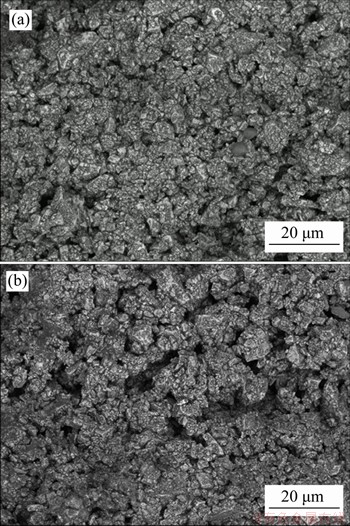

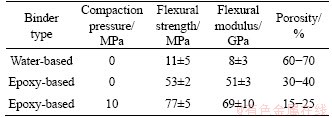

RABINSKIY et al [10] also presented a BJ silicon nitride building process using an epoxy-based binder and pressureless sintering method. The microstructure of fabricated components is shown in Figure 5. It can be seen that compaction can further promote the densification of the sample. The mechanical properties of sintered ceramics with various binders are shown in Table 1. It can be seen from the table that porosity substantially affects the mechanical properties of sintered ceramics. Therefore, the focus will tend to reduce the porosity of the sample to improve its density and mechanical properties in the subsequent research on structural ceramic materials.

Figure 3 Sintered samples of silicon nitride fabricated by BJ [9]

Figure 4 Microstructure of ceramic samples obtained via binder jetting using different binders:

Figure 5 Microstructure of fabricated components obtained with using compaction (a) and without compaction (b) [10]

Table 1 Mechanical properties of sintered ceramics produced by using different binders with and without compaction during 3D printing

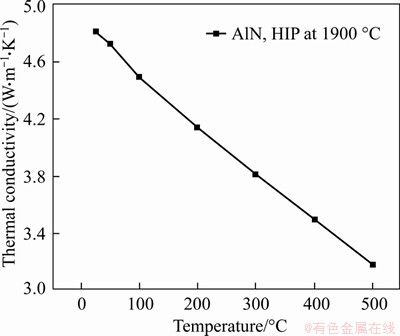

DIAZ-MORENO et al [11] reported the research of aluminum nitride (AlN) fabrication using binder jetting. The AlN density is increased from 1.13 to 1.96 g/cm3 by hot isostatic pressing (relative density is 60.1%). And it shows excellent performance with hardness H=(24.28±1.2) GPa and elastic modulus E=(251±5.0) GPa. Figure 6 shows the relationship between thermal conductivity and temperature. The thermal conductivity of BJ AlN component is similar to traditional fabrication of AlN such as thin film deposition [12]. In deed, the study has greatly shrinked the preparation time of aluminum nitride.

Figure 6 AlN thermal conductivity versus temperature [11]

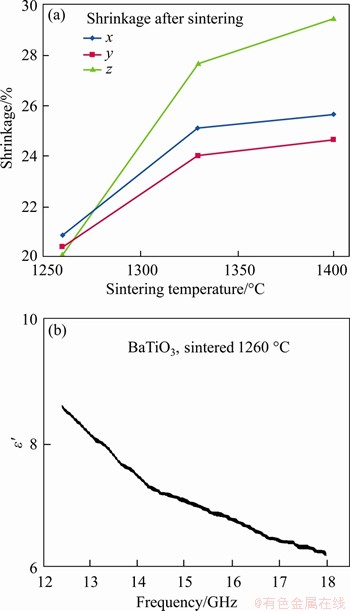

Barium titanate (BaTiO3) as perovskite ferroelectric ceramic, is drawn attention due to its excellent electrical properties [13]. The BJ fabrication of barium titanate specimens is ideal for dielectric because of its low losses and high permittivity [14, 15]. GAYTAN et al [16] studied the crystal structure, shrinkage, and dielectric constant of BaTiO3 prepared by BJ after sintering. Figure 7(a) shows the shrinkage of BaTiO3 in each orientation. Non-uniform size changes can be observed during sintering, for example, the reduction of axial dimensions, indicating that the selection of printing parameters and binders still needs to be improved. Figure 7(b) shows the dielectric constant of BaTiO3 in the frequency range of 12.4 to 18 GHz at room temperature. As the frequency increases from 12.4 to 18 GHz, the dielectric constant decreases from 8.62 to 6.23. And the application of multilayer ceramic capacitors requires a thin dielectric layer, which requires products prepared by BJ to avoid the presence of large particles and pores. In other words, further research of BJ fabrication of barium titanate should be focused on adjustment of binder, building parameters and powder processing to improve its performance, such as using smaller grains to increase the density of parts to increase the dielectric constant of BaTiO3 [17].

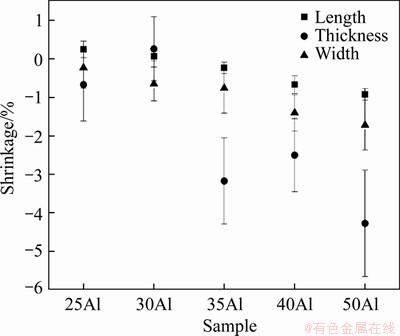

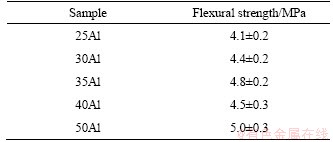

Alumina oxide as both structural ceramic and functional ceramic has been manufactured by binder jetting. A near-net shape fully ceramic part can be produced by BJ and following reactive bonded technology. In addition, this technology combines metal expansion and ceramic shrinkage, which makes it easier to control the shrinkage of the product. Figure 8 shows that as the amount of Al increases, the shrinkage rate decreases [18]. Flexural strength results of printed alumina are presented in Table 2. 25Al, 30Al, 35Al, 40Al and 50Al respectively represent 25%, 30%, 35%, 40% and 50% volume fractions of Al to Al2O3 (vol/vol). Comparing the flexural strength of 25Al and 50Al specimens, it can be observed that the maximum strength increased by more than 20% in the latter.

Figure 7 Shrinkage percentage in each direction versus temperature (a) and dielectric constant versus frequency (b) of BaTiO3 [16]

Figure 8 Linear shrinkage of sample length, width, and thickness after RBAO (Negative values indicate expansion) [18]

Table 2 Measured flexural strength of 5 samples with different Al content

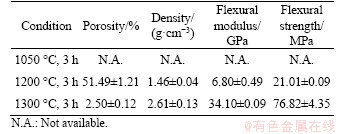

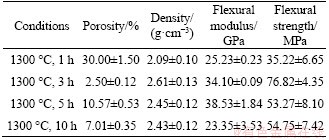

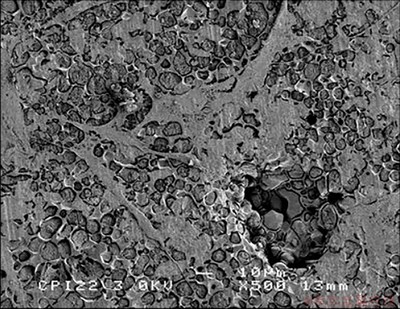

Biomedicine is an essential type of ceramic material that can be manufactured by BJ, including hydroxyapatite (Ca5(PO4)3(OH)), tricalcium phosphate (Ca3(PO4)2), silicon carbide (SiC). Since chemical composition of hydroxyapatite is similar to the main composition in bones, it shows excellent biocompatibility and has osteoconductivity. However, the mechanical properties of hydroxyapatite parts built by BJ are relatively low due to residual pores. The study uses the concept of liquid phase sintering to prepare bioactive composites of apatite-wollastonite (A-W) glass-ceramic/hydroxyapatite composites (HAAW) to improve the mechanical and bioactive properties of biological materials [19]. The effects of sintering duration and temperature on the porosity, density, and bending properties of 3DP HAAW composites are shown in Tables 3 and 4. The results show that the maximum flexural modulus (34.10 GPa) and strength (76.82 MPa) can be obtained under the products sintered at 1300 °C for 3 h. The biological activity test and the vitro toxicity study of the 3D printed HAAW composite material immersed in simulated body fluid (SBF) show non-toxic and good biologically active. The morphology of human osteoblasts on the 3DP-HAAW composite surface (1300 °C, 3 h) after six days of incubation is shown in Figure 9. It can be seen that the cells spread and adhere well on the surface of the 3DP-HAAW composite. Based on the test of its biological activity and toxicity, the 3DP-HAAW composite shows great potential as a bone substitute material.

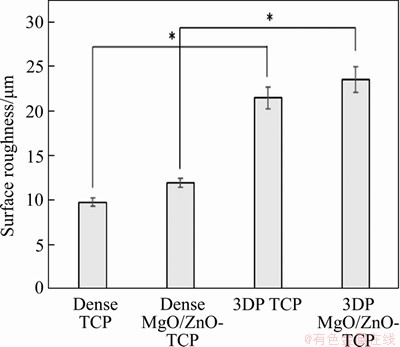

Calcium phosphate possesses both osseointegration and osteoconductive and is easy to form hydroxyapatite (HA) layers after implantation in the human body. Thus, porous tricalcium phosphate (TCP) made scaffold is used in the treatment of musculoskeletal diseases. It was reported that the doping of ZnO and MgO into TCP significantly increases the density and compressive strength of dense TCP [20]. KE et al [21] discussed the influence of MgO/ZnO on the properties of tricalcium phosphate scaffolds as biomaterial printed by binder jetting. A new type of 3D printed TCP and modified TCP scaffold with a porous surface and dense core design was prepared, with a designed pore size of 500 μm and a porosity of 18%, followed by sintering at 1250 °C for 2 h. The study showed that the adding of MgO and ZnO increased the surface area of TCP by 1.47 m2/g, increased the bulk density by 12.93%, and increased the compressive strength by 9.52 MPa. Figure 10 shows the surface roughness of dense TCP, dense modified TCP, 3DP TCP, and 3DP modified TCP. It can be seen that for 3D printed products, the modified TCP shows higher surface roughness. It was reported that the rough titanium alloy surface is more conducive to the proliferation of osteoblasts [22].

Table 3 Effects of sintering temperature on porosity, density, and flexural properties of 3DP HAAW composites

Table 4 Effects of duration on porosity, density, and flexural properties of 3DP HAAW composites

Figure 9 Morphology of human osteoblasts on 3DP-HAAW composite surface (1300 °C, 3 h) after 6 d incubation [19]

Figure 10 Surface roughness of dense TCP, dense MgO/ZnO-TCP, 3DP TCP and 3DP MgO/ZnO-TCP [22]

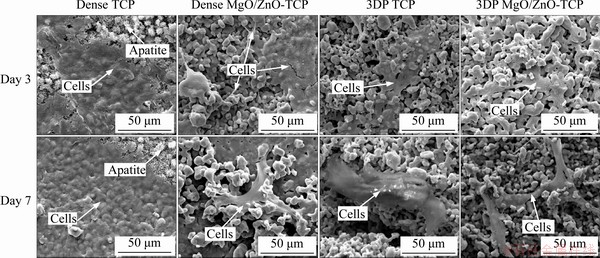

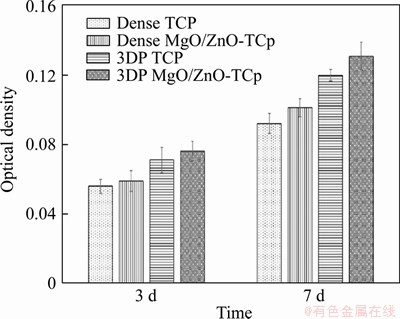

Figure 11 shows the microstructures of dense TCP, dense MgO/ZnO-TCP, 3DP TCP, and 3DP MgO/ZnO-TCP on the 3rd and 7th day of cell culture. The dense TCP not only forms apatite but also shows stretched cell formation on the surface. However, the dense modified TCP, 3DP TCP, and 3DP modified TCP only shows stretched cell formation on the surface. During cell culture, 3D printed scaffolds have much higher cell viability than dense scaffolds. Simultaneously, MgO and ZnO further enhanced the cell viability of the dense and 3D printed scaffolds, especially on the case at 7th day, as shown in Figure 12. It can be seen that the doping of MgO and ZnO significantly enhances the growth of osteoblasts, which means that it has enormous potential in the fields of bone repair and regeneration.

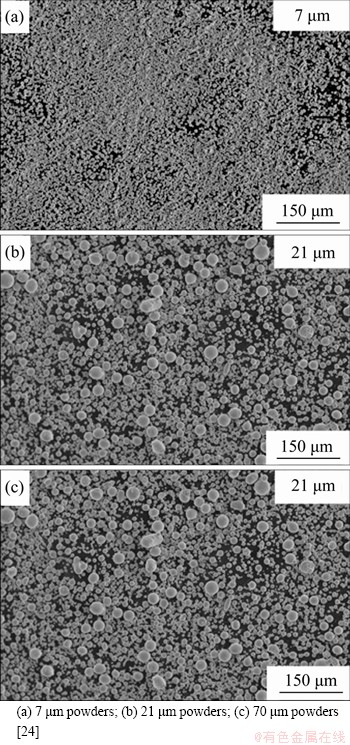

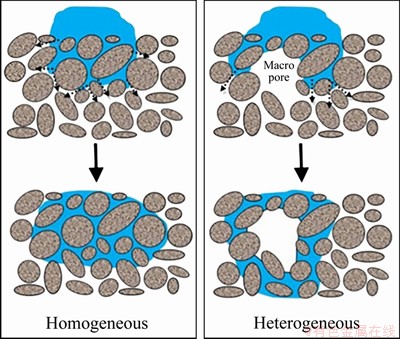

Another critical factor affecting BJ is the powder particle size distribution. Generally, the powder size for binder jetting is in the range of 20-200 μm [23]; the mixing unimodal powders of different sizes can significantly improve body density of BJ printed component. Figure 13 shows the morphology of powders with different particle sizes from small to large. The fine powder is easier to agglomerate in the binder, whereas coarse powder has better flowability [24]. The fine powder has a high specific surface area, which makes them highly reactive and easy to form irregular agglomerates in the powder bed, resulting in the formation of many large pores. The presence of large pores increases the penetration time of droplets, as shown in Figure 14 [25]. However, adding a certain proportion of fine powder into the coarse powder can reduce the pore diameter between the particles, thus improving the anisotropy and promoting the the product’s density. Meanwhile, the minimum layer thickness and resolution depend on the maximum particle size [26]. Thus, it is necessary to adjust the particle size distribution in the raw material.

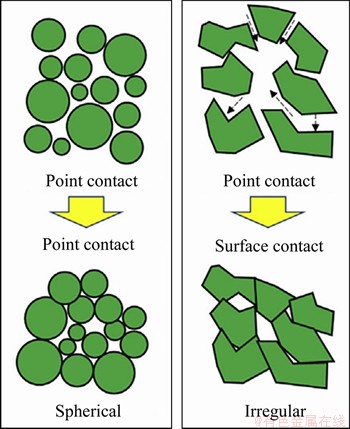

DU et al [7] developed bimodal raw powder material and prepared silicon carbide ceramics through the binder jetting technology. Mixing powders of different sizes can increase the bulk density of the powder bed, thereby increasing the density of printed parts. The fine particles fill the voids between coarse particles by this technique. Research results show that the green density of parts made from the optimal bimodal powder is about 5% higher than that of the unimodal powder. The literature introduced a silicon carbide fiber-reinforced silicon carbide (SiCf/SiC) composite material prepared by binder jetting, followed by polymer infiltration and pyrolysis [27]. Both spherical and irregularly shaped SiC powders are used to prepare SiCf/SiC mixtures for binder jetting. Compared with spherical powder, irregular powders present a relatively higher density. This is because point contact becomes surface contact after spreading irregular powders (see Figure 15). It indicates that the shape of the powder also significantly influences flowability, particles’ interactions, and porosity.

Figure 11 Microstructures of dense TCP, dense MgO/ZnO-TCP, 3DP TCP, and 3DP MgO/ZnO-TCP on the 3rd and 7th day of cell culture showing osteoblast adhesion [22]

Figure 12 MTT assay of dense TCP, dense MgO/ZnO-TCP, 3DP TCP, and 3DP MgO/ZnO-TCP on the 3rd and 7th day of cell culture [22]

Figure 13 Micrographs of gas-atomized powders:

Figure 14 Schematic diagram illustrates the proposed penetration behaviour of different droplets in homogeneously and heterogeneously distributed powder beds [25]

Figure 15 Mechanism of packing density of spherical and irregular ceramic powders after powder spreading [27]

3 Stereolithography and related ceramic materials

3.1 Technique overview

The SLA process, also known as stereolithography or photocuring process, was invented by Charles HULL in 1984. In 1986, the United States 3D Systems launched the world’s first stereolithography apparatus (SLA) [28]. Stereolithography (SLA) is a 3D printing technique that uses photopolymerization to create objects layer by layer. SLA can be categorized into two classes: scanning-based stereolithography and projection-based stereolithography, as shown in Figure 16 [29]. The laser source only exposes a thin resin layer with a specific thickness from above in both methods. After curing, the building platform moves down to spread a new layer of resin on top of the previously cured layer.

Figure 16 Schematic design of two basic approaches for stereolithographic systems:

SLA is one of rapid prototyping technologies with the characteristics of high maturity. So far, SLA is the only light-curing 3D printing technology that can print large-size parts. With the development of SLA technology, various available materials can be processed by SLA process. Nowadays, SLA has been widely developed and used in many fields because of its manufacture capability of high-quality surface parts, such as dense/porous ceramic parts, molds with complex structure parts, sensors, bone supports and dental components. The main challenge of the SLA technology is that a higher volume fraction of ceramic particles is conducive to reducing volume shrinkage and higher density (thus improving mechanical strength) during the preparation process. On the other hand, a lower volume of ceramic particles can reduce viscosity and avoid solid phase separation; therefore, trade-offs need to be made. Another essential issue that must be considered is the important influence of light scattering caused by the ceramic particles’ addition. Therefore, the critical technology of stereolithography is to select the appropriate resin to match with the corresponding material.

3.2 SLA material overview

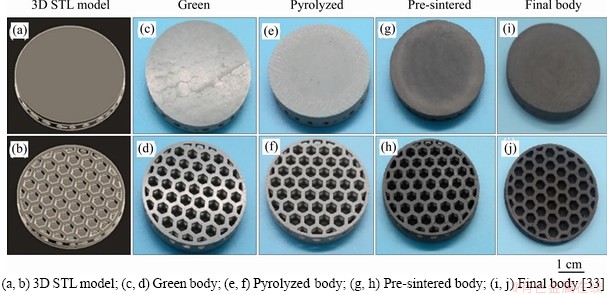

Stereolithography can be applied to both structural and functional ceramics fabrication. Ceramic stereolithography using an ultraviolet-curable system consisted of polymerized ceramic particles suspended in a photopolymer [5]. Silicon carbide (SiC) ceramic has achieved a wide range of commercial applications due to its excellent mechanical and thermal properties. And it has different applications in the aerospace, nuclear energy, and transportation fields [30]. CHEN et al [31] prepared the SiC ceramic precursor with high photosensitivity and ceramic yield by stereolithography. This study shows that stereolithography is beneficial for preparing complex ceramic parts. The comparative studies show that the best solid loading of SiC for stereolithography is 40 vol% [30, 32]. DING et al [33] fabricated a lightweight SiC optical mirror via stereolithography 3D printing combined with pyrolysis. The photo of the SiC optical mirror is shown in Figure 17. It can be seen from Figure 17 that the SLA 3D printed parts show high intensive accuracy. And it is also found that pyrolysis does not damage the appearance of the mirror.

Figure 17 Photographs of lightweight SiC ceramic optical mirror:

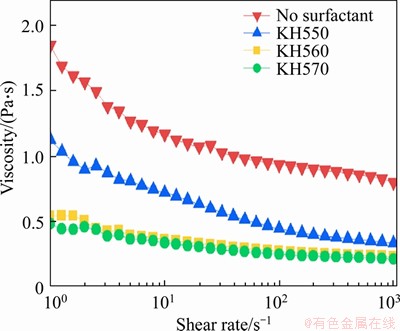

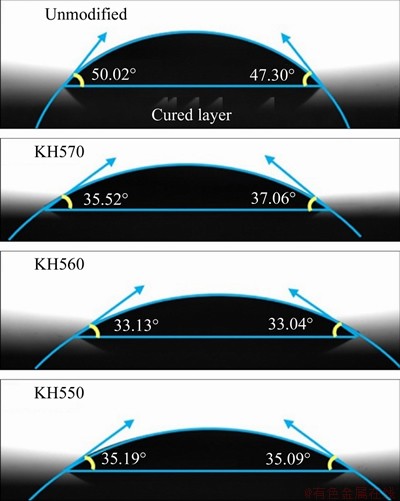

Silicon nitride (Si3N4), as a new biological/ thermal conductive ceramic, is widely used in electron devices and implants. LIU et al [34] studied the formation mechanism of stereolithography Si3N4 slurry with a silane coupling agent as a modifier and dispersant. Figure 18 shows the rheological properties of silicon nitride with different coupling agents. It can be seen that all slurries exhibit shear thinning behavior. The contact angle of the three coupling agent modified Si3N4 slurries on the cured layer is shown in Figure 19. The wetting angles of all modified Si3N4 slurries are significantly reduced, revealing that the silane coupling agent can significantly reduce the slurry’s surface tension. The research reveals that KH550, KH 560 and KH 570 couple with hydrophobic groups to the surface of Si3N4, which will be helpful for future research. In conclusion, this literature clarifies the corresponding formation mechanism of KH560 modified Si3N4 slurries for the first time.

Figure 18 Rheological properties of silicon nitride with different coupling agents [34]

Figure 19 Wetting angles of modified Si3N4 slurries with coupling agents on cured layer [34]

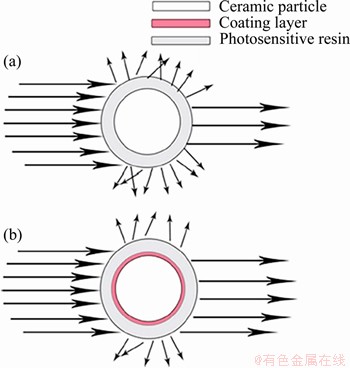

Zirconium oxide (ZrO2) is another structural ceramic with excellent mechanical property, low thermal conductivity, and good biocompatibility [35]. FU et al [36] prepared zirconia with different laser power through SLA. The research results show that the process parameters have a significant influence on the dimensional accuracy of the parts, but the improvement of mechanical properties mainly depends on the cracks and density controlling during the debinding process. LI et al [37] studied the curing properties of paraffin coating modified ZrO2 based on stereolithography. Due to the large refractive index difference between photosensitive resin and ceramic, strong light scattering and a small refractive index can be obtained using paraffin coating modified ZrO2. Figure 20 shows the scattering diagram of paraffin-free and paraffin-containing coated ZrO2 particles. The report also stated that the curing depth of paraffin-coated ZrO2 increased by 13.2% and 16.8% after the curing time of 10 s and 20 s, respectively [37]. In deed, paraffin coating of ZrO2 can reduce light scattering.

Figure 20 Scattering diagram of ZrO2 particles without (a) and with (b) paraffin coating [37]

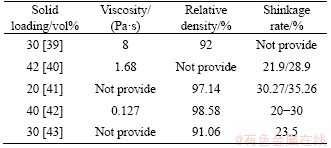

The effect of surface modification on the dispersion of nano-zirconia particles has also been studied [38]. Disperbyk (BYK), oleic acid (OA), and coupling agent KH560 showed a better dispersion performance with optimized load compared to paraquat CC 42 NS (CC) and stearic acid (SA). The SLA processed ZrO2 slurry with the solid loading of less than 50 vol% shows a low density, high shrinkage (>20%), as summarized in Table 5 [35].

In order to further increase the solid loading of the ZrO2 slurries, ZHANG et al [35] systematically studied the effect of dispersant type, concentration, and solid loading on its dispersion and rheological behaviour. The research finally obtained a photosensitive ZrO2 suspension with a low viscosity of 1.65 Pa·s and high solid loading of 55 vol% at 200 s-1 shear rate when 2 wt% KOS110 is selected as dispersant. However, the cracks and deformation of ZrO2 fabricated by SLA still cannot be avoided after sintering. LIU et al [44] used zirconia as the second phase to increase the fracture toughness of Al2O3 ceramics. The study indicated that hardness, the density, and fracture toughness of the ZrO2-Al2O3 were 14.1 GPa, 3.75 g/cm3, and 4.05 MPa·m1/2 when sintered at the maximum sintering temperature of 1500 °C for a retention time of 60 min. WU et al [45] studied effects of sintering mechanism on mechanical properties of Al2O3-ZrO2 composites prepared by SLA. The fracture toughness of printed samples is 5.2 MPa·m1/2, and the density can reach 4.27 g/cm3.

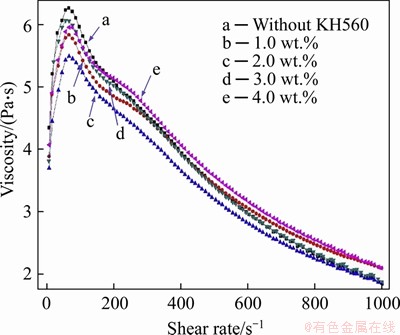

Table 5 Information on photosensitive ZrO2 suspensions for stereolithography and sintered parts

Another typical biomaterial available for SLA is β-TCP, which is considered ideal hard tissue for implantation. ZHOU et al [46] fabricated spinal β-TCP for tissue repair applications via SLA method. Figure 21 presents the rheological properties of the ceramic slurries with different content of coupling agents. It can be seen that when the addition amount of KH560 is 2.0 wt%, the viscosity reaches the minimum. The porosity and density of β-TCP ceramics prepared by different solid loading slurries are shown in Figure 22(a). The density of ceramics increases as the solid loading in the slurry increases while the porosity of the ceramic is reduced. Figure 22(b) shows the horizontal and vertical shrinkage rates of β-TCP ceramics prepared by different solid loading slurries. When the solid loading of the slurry is 48 wt%, the shrinkage is the smallest. In conclusion, the study results showed that when the addition amount of KH560 and the solid loading of the slurry were 2.0 wt% and 48 wt%, the corresponding slurry used for subsequent SLA possesses remarkable homogeneity and fluidity.

Figure 21 Rheological properties of ceramic slurries with different content of coupling agents [46]

Figure 22 Density and porosity (a) and vertical and horizontal shrinkage rates (b) of β-TCP ceramics prepared by different solid loading slurries [46]

3.3 Digital light processing (DLP)

Digital light processing (DLP) is one of SLA technology based on lithographies. It is based on the digital micromirror component DMD developed by Texas Instruments in the United States to complete the visual digital information display technology. The basic principle of DLP 3D printing technology is that the digital light source is projected on the surface of the liquid photosensitive resin until all resin material was cured and shaped.

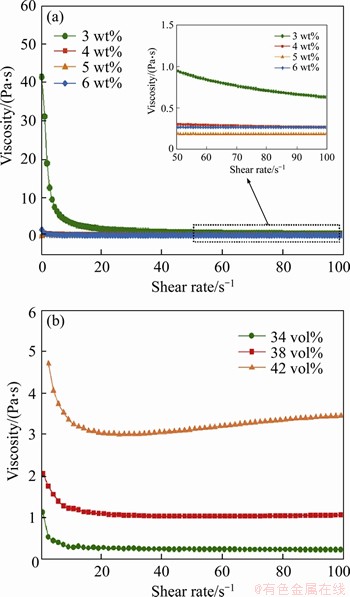

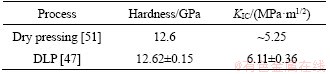

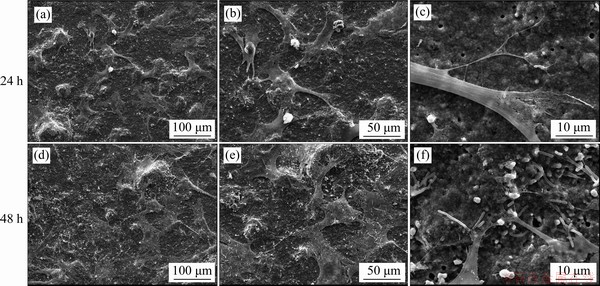

Customized zirconium dioxide (ZrO2) teeth have attracted wide attention in the dental field. CHEN et al [47] presented the ZrO2 ceramic teeth fabrication through DLP method based on photosensitive resin. The solid loading plays a vital role in the performance of the green body manufacture process. The sintered body with higher solid loading can lead to a lower shrinkage rate and a higher relative density. Figure 23 shows the effect of different solid loading and dispersion concentration on slurry viscosity. The lowest viscosity of the slurry can be obtained by 5 wt% of dispersant concentration, as shown in Figure 23(a). When the solid loading increased from 34 vol% to 42 vol%, the viscosity of the slurry increased from 0.25 Pa·s to 3.01 Pa·s under the shear rate of 30 s-1, as shown in Figure 23(b). Thus, the ZrO2 slurry with a solid loading of 42 vol% is selected for subsequent research. When the samples are prepared with 42 vol% solid loading slurry under sintering temperature of 1500 °C for 3 h, the relative density of the obtained dense ZrO2 ceramic is (98.02±0.32)% with a fracture toughness of (6.11±0.36) MPa·m1/2, and a Vickers hardness of (12.62±0.15) GPa, as shown in Table 6. And the research was carried in vitro biological experiments on rat bone marrow mesenchymal stem cells of 3D printing samples. The morphology of cell adhesion to the 3D printed sample is shown in Figure 24. It can be seen that the 3D printed ZrO2 surface of the cell has been fully expanded after two days.

Figure 23 Effect of shear rate on viscosity of zirconium dioxide slurry with different dispersant concentrations (solid loading: 30 vol%) (a) and different solid loadings (dispersant concentration: 5 wt%) (b) [47]

Table 6 Comparison of mechanical properties of ZrO2 ceramics prepared by dry pressing and DLP

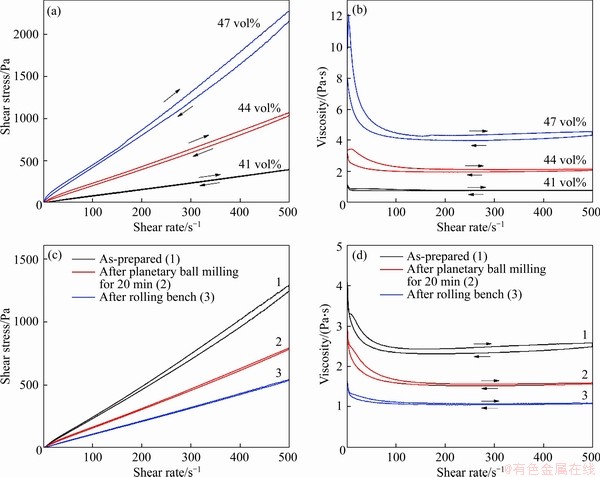

ZrO2 ceramics fabricated by DLP can provide an ideal biocompatible environment for mesenchymal stem cells. BORLAF et al [48] used a two-step process to prepare ZrO2 UV-curable slurries for DLP. Firstly, the surface modification of ZrO2 particles is completed by adding dispersants. Secondly, it is need to disperse the modified powder in the acrylate mixture. Figure 25 shows the rheology of ZrO2 UV-curable slurries with different solid loading and rheology of the 44 vol% ZrO2 UV-curable slurry after processing in different ways. Based on the rheological properties of these slurries, 44 vol% solid loading slurries were finally selected. For the 44 vol% solid loading slurries, all slurries exhibit shear-thinning behaviour. It can be seen that these two steps reduce viscosity and thixotropy, improving the rheology of the slurries (closer to Newtonian fluid behaviour). In conclusion, the two-step method further increases the solid loading of ZrO2 slurries to 44 vol%. And the flexural strength of the DLP printed part is 741 MPa. Based on the above research, it has fully illustrated the great potential of 3D printed ZrO2 in the biomaterial field.

Solid oxide fuel cell (SOFC) is one of third-generation fuel cells. It is an all-solid-state device that directly converts chemical energy stored in fuel and oxidant into electrical energy efficiently and environmentally friendly. XING et al [49] prepared a dense 8 mol% yttria-stabilized zirconia (8YSZ) ceramic, a key material of SOFC, through DLP. In this research, a fully dense ceramic was obtained by sintering at 1450 °C, and the conductivity of sintered 8YSZ ceramic can reach 2.18×10-2 S/cm at 800 °C, which is acceptable in practical applications. VARGHESE et al [50] proposed a low-cost 3D printing technology based on DLP as a potential manufacturing technology for preparing ceramics such as alumina, 3-YSZ, and 8-YSZ. The study shows that a higher ceramic loading can make the object denser at a fixed sintering temperature. The maximum solid loading of the resin is about 60%. Above the solid loading, the adhesion force of the extra ceramic powder to the sintered object is not strong. And this meets the requirements for stereolithography described earlier. The solid loading in the slurry should be in the range of 50 vol%-65 vol%.

Figure 24 SEM microstructures cells adhesion [47]

Figure 25 Rheology (a) and viscosity (b) curves of ZrO2 UV curable slurries with different solid loading, and rheology (c) and viscosity (d) curves of as-prepared 44 vol% ZrO2 UV-curable slurry, after planetary ball milling for 20 min and after 24 h on a rolling bench [48]

4 Fused deposition modeling and related ceramic materials

4.1 Technique overview

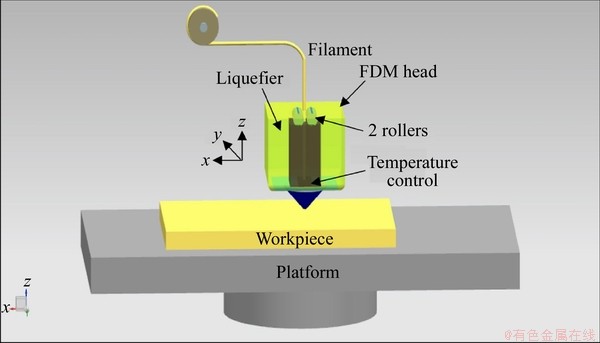

The fused deposition modeling (FDM) is the most frequently used 3D printing method. It was first developed by CRUMP and applied for a patent in 1989 [3]. Fused deposition modeling (FDM) is based on the extrusion process, where materials are selectively distributed through nozzles or holes [52]. In the FDM manufacturing process, the printing nozzle’s filamentous material is melted at a temperature slightly higher than the melting point of the printing material. Then the material is deposited layer by layer like squeezing toothpaste on the printer hotbed. The process of FDM is shown in Figure 26 [5]. The relatively low cost of FDM equipment has attracted widespread interest [53]. Fused deposition modeling technology can be applied to many types of materials, such as ceramics.

Figure 26 Schematic diagram of FDM method [5]

Compared with the binder jetting and stereolithography technology mentioned above, FDM successfully balanced the process cost and product stability due to the lack of solvent in the preparation.

4.2 FDM material overview

In FDM, the characteristics of low binder viscosity and high mechanical strength are required in raw material filaments. The low viscosity of the binder prevents the reflux of the molten material, and the high-strength filament prevents it from being twisted during the manufacturing process [5]. Nowadays, filament materials are customized according to different properties to meet their chemical, physical and mechanical requirements in various fields.

AGARWALA et al [54] firstly prepared Si3N4 and Al2O3 ceramic materials using FDM in 1996. The density of these sintered parts printed by FDM for the first time is not uniform, in the range of 75%-90%, but it is characterized by the fact that there is no delamination of parts, as seen in Figure 27.

Figure 27 (a) Filaments filled with Si3N4 for FDM processing and ceramic parts fabricated from them; (b) SEM image of cross-section of a green part showing no delamination between adjacent FDM-produced lines and layers [54]

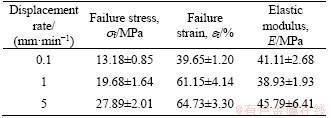

RANGARAJAN et al [55] studied rheology, powder processing, and feedstock’s mechanical properties of Si3N4 ceramics. It was reported that FDM filaments which meet the requirements were successfully prepared, processed from GS44 Si3N4 powder. The elastic modulus, failure stress and strain of RU955 (55 vol% GS44 Si3N4 in RU9 binder) can be seen in Table 7. IYER et al [56] continued to study the microstructure and mechanical properties of Si3N4 fabricated by FDM. The research results showed that the processes of extrusion, vectorization, and delamination would influence the anisotropy and inhomogeneity of FDM parts. It was observed that only a small amount of shrinkage (1%) occurred when the binder was removed, while most of the shrinkage (16%-18%) occurred during the sintering process.

Table 7 Failure stress, failure strain, and elastic modulus for RU955 in compression

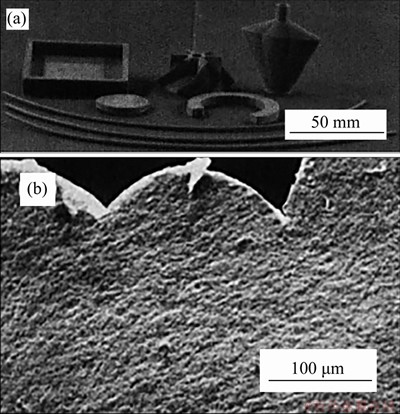

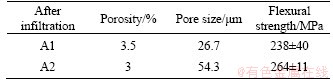

Another application of ceramics manufactured by FDM is in the field of bio-medicine and implants, such as hydroxyapatite (HA) and metallic oxides (e.g., Al2O3, MgO). WU et al [57] prepared PVA/ PLA/HA bioactive nanocomposites for FDM. Polyvinyl alcohol/hydroxyapatite (PVA/HA) can be used for cartilage repair because of its excellent mechanical properties and osteoconductivity. However, there are PVA foaming problems caused by nanofillers (such as HA) during the extrusion process. To solve this problem, the study simultaneously introduced HA and PLA into the PVA matrix. And it was proved that treated HA was separated from the PVA matrix, which helps to avoid foaming of PVA. The research of ARNESANO et al [58] focused on 3D printing of glass-modified alumina via FDM. Figure 28 shows the picture of samples manufactured by FDM during different manufacturing processes and after testing. It can be seen that the penetration of glass dramatically improves the mechanical strength of alumina. And Table 8 shows the porosity, pore size, and 3-point bending strength of A1 and A2 after the glass was immersed at 1120 °C for 40 min. Wherein A2 has a higher solid load than A1. Compared with each other, a higher solid loading means better mechanical properties to a certain extent.

Figure 28 Picture of mechanical test sample after:

Table 8 Comparison of porosity, pore size and 3 point flexural strength between A1 and A2 after glass infiltration at 1120 °C for 40 min

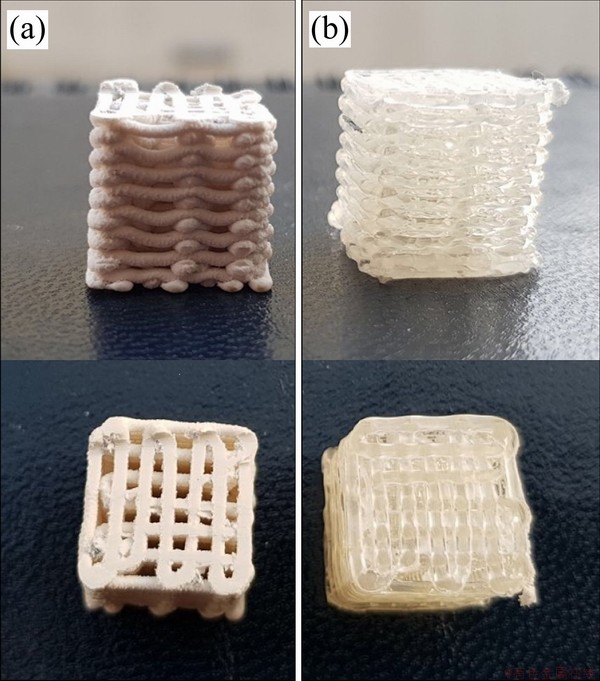

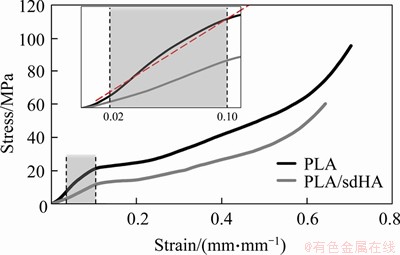

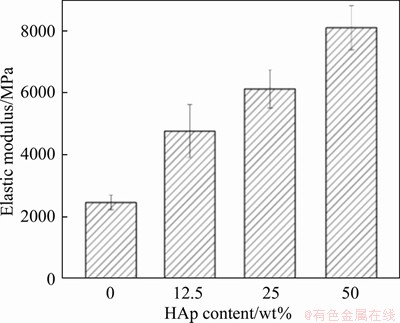

ESPOSITO et al [59] prepared PLA/HA porous scaffolds for bone tissue engineering by FDM method. In the raw material for PLA/HA porous scaffold, the loading of HA is as high as 50%. The 3D printed PLA/HA and pure PLA are shown in Figure 29. The PLA/HA (55.5%) porous scaffolds show higher porosity compared to pure PLA (39.0%). The compression curves of the PLA/HA porous scaffold and pure PLA are shown in Figure 30. It can be seen that pure PLA has higher stiffness due to low porosity. In short, the role of HA is not to act as a reinforcing phase in PLA matrix but to promote the formation of pores, thereby increasing the available surface area of the scaffold. DUBINENKO et al [60] also prepared PLA/HA scaffolds via FDM. When the HA content in the composite reaches 50%, the maximum elastic modulus of the 3D printed product is (8111±714) MPa, as shown in Figure 31.

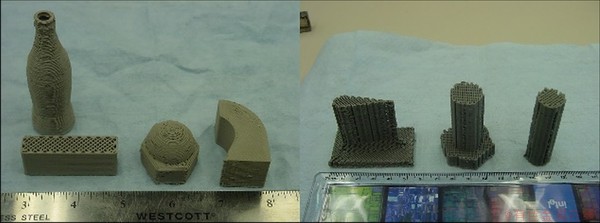

ONAGORUWA et al [61] prepared ceramics and composites of different systems, including mullite, fused silica, and titanium dioxide through the FDM process. Among them, mullite feedstock includes 47.93 vol% of mullite, 6.85 vol% of alumina, and 0.69 vol% of magnesia. The fused silicon oxide feedstock contains approximately 53 vol% of fused silica and 3 vol% of magnesia. The feedstock of titanium dioxide contains about 51 vol% of titanium dioxide powder and 4 vol% of magnesia. And all feedstocks have the mature binder system, which is composed of 44% PE, 13.9% elastomer, 8.7% plasticizer, 7.8% thickener, and 15.6% wax. PE is the base polymer and the backbone of the filament. Elastomer ensures flexibility, while plasticizer ensures filament formability. Thickener enables tackiness while wax reduces viscosity. Figure 32 shows the mullite parts manufactured by FDM.

Figure 29 Pictures of 3D printed PLA/HA and pure PLA [59]

Figure 30 Compression curves of PLA/HA porous scaffold and pure PLA [59]

Figure 31 Elastic modulus of obtained materials [60]

To improve the mechanical strength and density of ceramic parts, ONAGORUWA et al [61] completed the binder removal and sintering in two steps. In the first step, all the binders are eliminated under various heating rates to prevent the the sample from cracking. In the second step, ceramic parts are sintered and densified. The results show that the linear shrinkage for the FDM parts is 10%-12% for mullite parts. In summary, the literature discussed the quality improvement of parts from the feedstock, fabrication of parts, and post-process parameters of the ceramic part.

Figure 32 Mullite parts manufactured by FDM [61]

5 Conclusions and perspectives

Indirect 3D printing is one of the crucial rapid prototyping technologies and has attracted wide interest in materials processing, medical treatment, culture, and art industries in recent years. In this review, three main 3D printing technologies based on light curing, BJ, SLA, and FDM, are presented.

1) Binder jetting has been used in silicon nitride, aluminum nitride structure, and functional ceramics and bioceramic materials such as hydroxyapatite because of its fast-molding speed and low cost of molding materials. The influence of the morphology and particle size of the powder on the BJ method can significantly influence the printed component density and mechanical properties. Due to the working principle of powder bonding, the surface of the final product is not smooth enough, and the resolution is not high. Therefore, it is imperative to find suitable binders matching different powder systems.

2) Stereolithography has also been widely developed and used in the field of functional and structural ceramics because the SLA can manufacture high-quality surface parts with micron-level resolution. Digital light processing, as a variant of SLA, is also introduced in this paper. Both technologies involve light-induced polymerization. And the rheological properties of the slurry are an essential factor affecting SLA printing products. And a compromise must be made in the solid loading of the slurry to simultaneously ensure the resolution and mechanical strength of the printed product. Another fundamental issue that must be considered is the substantial influence of light scattering caused by ceramic particles’ addition. This problem can be alleviated by surface modification of the ceramic material.

3) The primary technique for controlling the surface characteristics of the FDM pattern is to adjust various parameters of the process, such as air gap, layer thickness. The materials that can be used as filaments are limited, which narrows the application range of FDM. And due to the demand for high-quality products such as surface finish, high mechanical properties, further research is needed to optimize process parameters and the development of new materials for the FDM process is required.

4) Different manufacture techniques of the same material will also have a great impact on its properties. For example, the porosity and flexural strength of hydroxyapatite are 2.5% and 76.82 MPa for BJ, while these values are 3% and 264 MPa for FDM. And the solid loading of the zirconia material in the dental field prepared by the two similar methods of SLA and DLP is completely different, which is 55 vol% for SLA and 44 vol% for DLP.

This paper reviews recent research progress in the field of indirect 3D printing from the perspective of technique overview, materials, pros, and cons. It can be seen that the indirect 3D printing technology greatly improves the manufacturing speed while reducing costs. Since these technologies all involve using binders, high porosity is often the characteristic of these technologies when preparing ceramic materials. On the one hand, high porosity would usually deteriorate the mechanical properties of parts. Future work should focus on finding binders suitable for specific materials, and the interaction between powder and binder should also be extensively researched. For BJ, the penetration of the binder into the powder should be further improved to increase the strength of the printed part. For SLA, the higher solid loading of the slurry often means better mechanical properties of the printed part, and the future should focus on the research on the rheology and dispersion of the slurry. For FDM, since the filament used for printing can be customized, it can be used to develop composite materials which meet different performance requirements.

Contributors

ZHANG Bai-cheng and QU Xuan-hui provided the concept and edited the draft of manuscript. CAI Jia-wei conducted the literature review and wrote the first draft of the manuscript. ZHANG Mao-hang and WEN Yao-jie edited the draft of manuscript.

Conflict of interest

QU Xuan-hui, ZHANG Bai-cheng, CAI Jia-wei, ZHANG Mao-hang and WEN Yao-jie declare that they have no conflict of interest.

References

[1] LEE J H, KIM J H, HWANG K T, HWANG H J, HAN K S. Digital inkjet printing in three dimensions with multiple ceramic compositions [J]. Journal of the European Ceramic Society, 2020, 41(2): 1490-1497. DOI: 10.1016/ j.jeurceramsoc.2020.09.044.

[2] ARAMIAN A, RAZAVI S M J, SADEGHIAN Z, BERTO F. A review of additive manufacturing of cermets [J]. Additive Manufacturing, 2020, 33: 101130. DOI: 10.1016/ j.addma.2020.101130.

[3] CHEN Zhang-weu, LI Zi-yong, LI Jun-jie, LIU Cheng-bo, LAO Chang-shi, FU Yue-long, LIU Chang-yong, LI Yang, WANG Pei, HE Yi. 3D printing of ceramics: A review [J]. Journal of the European Ceramic Society, 2019, 39(4): 661-687. DOI:10.1016/j.jeurceramsoc.2018.11.013.

[4] SACHS E M, HAGGERTY J S, CIMA M J, WILLIAMS P A. Three-dimensional printing techniques: US, 5204055A [P]. 1993-04-20.

[5] HWA L C, RAJOO S, NOOR A M, AHMAD N, UDAY M B. Recent advances in 3D printing of porous ceramics: A review [J]. Current Opinion in Solid State and Materials Science, 2017, 21(6): 323-347. DOI: 10.1016/j.cossms.2017.08.002.

[6] ZIAEE M, CRANE N B. Binder jetting: A review of process, materials, and methods [J]. Additive Manufacturing, 2019, 28: 781-801. DOI: 10.1016/j.addma.2019.05.031.

[7] DU W, SINGH M, SINGH D. Binder jetting additive manufacturing of silicon carbide ceramics: Development of bimodal powder feedstocks by modeling and experimental methods [J]. Ceramics International, 2020, 46(12): 19701-19707. DOI: 10.1016/j.ceramint.2020.04.098.

[8] LEARY M. Design for additive manufacturing [M]. Berlin: Springer, 2020. DOI: 10.1016/b978-0-12-816721-2.00013-0.

[9] RABINSKIY L, RIPETSKY A, SITNIKOV S, SOLYAEV Y, KAHRAMANOV R. Fabrication of porous silicon nitride ceramics using binder jetting technology [J]. IOP Conference Series: Materials Science and Engineering, 2016, 140: 012023. DOI: 10.1088/1757-899x/140/1/012023.

[10] RABINSKIY L N, SITNIKOV S A, POGODIN V A, RIPETSKIY A A, SOLYAEV Y O. Binder jetting of Si3N4 ceramics with different porosity [J]. Solid State Phenomena, 2017, 269: 37-50 DOI: 10.4028/www.scientific.net/SSP. 269.37.

[11] DíAZ-MORENO C A, LIN Y, HURTADO-MACíAS A, ESPALIN D, TERRAZAS C A, MURR L E, WICKER R B. Binder jetting additive manufacturing of aluminum nitride components [J]. Ceramics International, 2019, 45(11): 13620-13627. DOI: 10.1016/j.ceramint.2019.03.187.

[12] CHEN Hong, ZHANG Ji-fa, CUI Jing-biao, FANG Rong-chuan. Deposition of diamond film on aluminum nitride ceramics and the study of their thermal conductance [J]. Chinese Physics Letters, 1996, 13(8): 625. DOI: 10.1088/0256-307X/13/8/018/.

[13] BUSCAGLIA V, RANDALL C A. Size and scaling effects in barium titanate. An overview [J]. Journal of the European Ceramic Society, 2020, 40(11): 3744-3758. DOI: 10.1016/j.jeurceramsoc.2020.01.021.

[14] GAYTAN S M, CADENA M A, KARIM H, DELFIN D, LIN Y, ESPALIN D, MACDONALD E, WICKER R B. Fabrication of barium titanate by binder jetting additive manufacturing technology [J]. Ceramics International, 2015, 41(5): 6610-6619. DOI: 10.1016/j.ceramint.2015.01.108.

[15] BUSCAGLIA V, VIVIANI M, BUSCAGLIA M T, NANNI P, MITOSERIU L, TESTINO A, STYTSENKO E, DAGLISH M, ZHAO Z, NYGREN M. Nanostructured barium titanate ceramics [J]. Powder Technology, 2004, 148(1): 24-27. DOI: 10.1016/j.powtec.2004.09.016.

[16] GAYTAN S M, CADENA M, ALDAZ M, HERDERICK E, MEDINA F, WICKER R, KECK W. Characterization of ceramic components fabricated using binder jetting additive manufacturing technology [J]. Ceramics International, 2016, 42(9): 10559-10564. DOI: 10.1016/j.ceramint.2016.03.079.

[17] CHEN Ren-zheng, CUI Ai-li, WANG Xiao-hui, LI Long-tu. Barium titanate coated with magnesium titanate via fused salt method and its dielectric property [J]. Materials Science and Engineering B, 2003, 99(1-3): 302-305. DOI: 10.1016/S0921-5107(02)00557-3.

[18] SOLIS D M, SILVA A V, VOLPATO N, BERTI L F. Reaction-bonding of aluminum oxide processed by binder jetting [J]. Journal of Manufacturing Processes, 2019, 41: 267-272. DOI: 10.1016/j.jmapro.2019.04.008.

[19] SUWANPRATEEB J, SANNGAM R, SUVANNAPRUK W, PANYATHANMAPORN T. Mechanical and in vitro performance of apatite-wollastonite glass ceramic reinforced hydroxyapatite composite fabricated by 3D-printing [J]. J Mater Sci Mater Med, 2009, 20(6): 1281-1289. DOI: 10.1007/s10856-009-3697-1.

[20] BANDYOPADHYAY A, BERNARD S, XUE W, BOSE S. Calcium phosphate-based resorbable ceramics: Influence of MgO, ZnO, and SiO2 dopants [J]. Journal of the American Ceramic Society, 2006, 89(9): 2675-2688. DOI: 10.1111/j.1551-2916.2006.01207.x.

[21] KE D, BOSE S. Effects of pore distribution and chemistry on physical, mechanical, and biological properties of tricalcium phosphate scaffolds by binder-jet 3D printing [J]. Additive Manufacturing, 2018, 22: 111-117. DOI: 10.1016/j.addma. 2018.04.020.

[22] MARINUCCI L, BALLONI S, BECCHETTI E, BELCASTRO S, GUERRA M, CALVITTI M, LULL C, CALVI E M, LOCCI P. Effect of titanium surface roughness on human osteoblast proliferation and gene expression in vitro [J]. International Journal of Oral & Maxillofacial Implants, 2006, 21(5): 719-725.

[23] SUWANPRATEEB J, SANNGAM R, PANYATHANMAPORN T. Influence of raw powder preparation routes on properties of hydroxyapatite fabricated by 3D printing technique [J]. Materials Science and Engineering C, 2010, 30(4): 610-617. DOI: 10.1016/j.msec. 2010.02.014.

[24] UTELA B, STORTI D, ANDERSON R, GANTER M. A review of process development steps for new material systems in three dimensional printing (3DP) [J]. Journal of Manufacturing Processes, 2008, 10(2): 96-104. DOI: 10.1016/j.jmapro.2009.03.002.

[25] ZHOU Z, BUCHANAN F, MITCHELL C, DUNNE N J M S, C E. Printability of calcium phosphate: Calcium sulfate powders for the application of tissue engineered bone scaffolds using the 3D printing technique [J]. Materials Science and Engineering C, 2014, 38: 1-10. DOI: 10.1016/j.msec.2014.01.027.

[26] LV Xin-yuan, YE Fang, CHENG Lai-fei, FAN Shang-wu, LIU Yong-sheng. Binder jetting of ceramics: Powders, binders, printing parameters, equipment, and post-treatment [J]. Ceramics International, 2019, 45(10): 12609-12624. DOI: 10.1016/j.ceramint.2019.04.012.

[27] POLOZOV I, RAZUMOV N, MASAYLO D, SILIN A, LEBEDEVA Y, POPOVICH A. Fabrication of silicon carbide fiber-reinforced silicon carbide matrix composites using binder jetting additive manufacturing from irregularly-shaped and spherical powders [J]. Materials, 2020, 13(7): 1766. DOI: 10.3390/ma13071766.

[28] OVERMEYER L, NEUMEISTER A, KLING R. Direct precision manufacturing of three-dimensional components using organically modified ceramics [J]. CIRP Annals, 2011, 60(1): 267-270. DOI: 10.1016/j.cirp.2011.03.067.

[29] ZAKERI S, VIPPOLA M, LEVANEN E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography [J]. Additive Manufacturing, 2020, 35: 101177. DOI: 10.1016/j.addma.2020.101177.

[30] HE R, DING G, ZHANG K, LI Y, FANG D. Fabrication of SiC ceramic architectures using stereolithography combined with precursor infiltration and pyrolysis [J]. Ceramics International, 2019, 45(11): 14006-14014. DOI: 10.1016/ j.ceramint.2019.04.100.

[31] CHEN Jiang-shan, WANG Yuan-jie, PEI Xue-liang, BAO Chong-hao, HUANG Zheng-ren, HE Liu, HUANG Qing. Preparation and stereolithography of SiC ceramic precursor with high photosensitivity and ceramic yield [J]. Ceramics International, 2020, 46(9): 13066-13072. DOI: 10.1016/ j.ceramint.2020.02.077.

[32] LV Xin-yuan, YE Fang, CHENG Lai-fei, FAN Shang-wu, LIU Yong-sheng. Fabrication of SiC whisker-reinforced SiC ceramic matrix composites based on 3D printing and chemical vapor infiltration technology [J]. Journal of the European Ceramic Society, 2019, 39(11): 3380-3386. DOI: 10.1016/ j.jeurceramsoc.2019.04.043.

[33] DING Guo-jiao, HE Ru-jie, ZHANG Ke-qing, ZHOU Ni-ping, XU Hao. Stereolithography 3D printing of SiC ceramic with potential for lightweight optical mirror [J]. Ceramics International, 2020, 46(11): 18785-18790. DOI: 10.1016/ j.ceramint.2020.04.196.

[34] LIU Yao, CHENG Li-jin, LI Hao, LI Qing, SHI Yuan, LIU Fei, WU Qiu-mei, LIU Shao-jun. Formation mechanism of stereolithography of Si3N4 slurry using silane coupling agent as modifier and dispersant [J]. Ceramics International, 2020, 46(10): 14583-14590. DOI: 10.1016/j.ceramint.2020.02.258.

[35] ZHANG Ke-qiang, HE Ru-jie, XIE Chen, WANG Gang, DING Guo-qiao, WANG Min, SONG Wei-dong, FANG Dai-ning. Photosensitive ZrO2 suspensions for stereolithography [J]. Ceramics International, 2019, 45(9): 12189-12195. DOI: 10.1016/j.ceramint.2019.03.123.

[36] FU Xiang-song, ZOU Bin, XING Hong-yu, LI Lei, LI Yi-shang, WANG Xin-feng. Effect of printing strategies on forming accuracy and mechanical properties of ZrO2 parts fabricated by SLA technology [J]. Ceramics International, 2019, 45(14): 17630-17637. DOI: 10.1016/j.ceramint.2019. 05.328.

[37] LI Yan-hui, CHEN Yong, WANG Ming-lang, LI Lian, WU Hai-dong, HE Fu-po, WU Shang-hua. The cure performance of modified ZrO2 coated by paraffin via projection based stereolithography [J]. Ceramics International, 2019, 45(3): 4084-4088. DOI: 10.1016/j.ceramint.2018.10.003.

[38] SUN J, BINNER J, BAI J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography [J]. Journal of the European Ceramic Society, 2019, 39(4): 1660-1667. DOI: 10.1016/ j.jeurceramsoc.2018.10.024.

[39] FAES M, VLEUGELS J, VOGELER F, FERRARIS E. Extrusion-based additive manufacturing of ZrO2 using photoinitiated polymerization [J]. CIRP Journal of Manufacturing Science and Technology, 2016, 14: 28-34. DOI: 10.1016/j.cirpj.2016.05.002.

[40] SUN J, BINNER J, BAI J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography [J]. Journal of the European Ceramic Society, 2019, 39(4): 1660-1667. DOI: 10.1016/ j.jeurceramsoc.2018.10.024.

[41] HE Rong-xuan, LIU Wei, WU Zi-wei, AN Di, HUANG Mei-peng, WU Hai-dong, JIANG Qiang-guo, JI Xuan-rong, WU Shang-hua, XIE Zhi-peng. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method [J]. Ceramics International, 2018, 44(3): 3412-3416. DOI: 10.1016/j.ceramint.2017.11.135.

[42] LIAN Qin, SUI Wen-quan, WU Xiang-quan, YANG Fei, YANG Shao-peng. Additive manufacturing of ZrO2 ceramic dental bridges by stereolithography [J]. Rapid Prototyping Journal, 2018, 24(1): 114-119. DOI: 10.1108/RPJ-09-2016-0144.

[43] JIANG C P, HSU H J, LEE S Y. Development of mask-less projection slurry stereolithography for the fabrication of zirconia dental coping [J]. International Journal of Precision Engineering and Manufacturing,2014, 15(11): 2413-2419. DOI: 10.1007/s12541-014-0608-2.

[44] LIU Xiao-yan, ZOU Bin, XING Hong-yu, HUANG Chuan-zhen. The preparation of ZrO2-Al2O3 composite ceramic by SLA-3D printing and sintering processing [J]. Ceramics International, 2020, 46(1): 937-944. DOI: 10.1016/j.ceramint. 2019.09.054.

[45] WU Zi-wei, LIU Wei, WU Hai-dong, HUANG Rong-ji, HE Rong-xuan, JIANG Qiang-guo, CHEN Yan, JI Xuan-rong, TIAN Zhuo, WU Shang-hua. Research into the mechanical properties, sintering mechanism and microstructure evolution of Al2O3-ZrO2 composites fabricated by a stereolithography-based 3D printing method [J]. Materials Chemistry and Physics, 2018, 207: 1-10. DOI: 10.1016/j.matchemphys. 2017.12.021.

[46] ZHOU Tian-yuan, ZHANG Le, YAO Qing, MA Yue-long, HOU Chen, SUN Bing-heng, SHAO Cen, GAO Pan, CHEN Hao. SLA 3D printing of high quality spine shaped β-TCP bioceramics for the hard tissue repair applications [J]. Ceramics International, 2020, 46(6): 7609-7614. DOI: 10.1016/j.ceramint.2019.11.261.

[47] CHEN Fen, ZHU Hao, WU Jia-min, CHEN Shuang, CHENG Li-jin, SHI Yu-sheng, MO Yuan-chang, LU Chen-hui, XIAO Jun. Preparation and biological evaluation of ZrO2 all-ceramic teeth by DLP technology [J]. Ceramics International, 2020, 46(8): 11268-11274. DOI:10.1016/j.ceramint.2020.01.152.

[48] BORLAF M, SERRA-CAPDEVILA A, COLOMINAS C, GRAULE T. Development of UV-curable ZrO2 slurries for additive manufacturing (LCM-DLP) technology [J]. Journal of the European Ceramic Society, 2019, 39(13): 3797-3803. DOI: 10.1016/j.jeurceramsoc.2019.05.023.

[49] XING Bo-hang, CAO Chuan-ru, ZHAO Wei-ming, SHEN Min-hao, WANG Cao, ZHAO Zhe. Dense 8 mol% yttria-stabilized zirconia electrolyte by DLP stereolithography [J]. Journal of the European Ceramic Society, 2020, 40(4): 1418-1423. DOI: 10.1016/j.jeurceramsoc.2019.09.045.

[50] VARGHESE G, MORAL M, CASTRO-GARCIA M, LOPEZ-LOPEZ J J, MARíN-RUEDA J R, YAGUE-ALCARAZ V, HERNANDEZ-AFONSO L, RUIZ-MORALES J C, CANALES-VáZQUEZ J. Fabrication and characterisation of ceramics via low-cost DLP 3D printing [J]. Boletín de la Sociedad Espanola de Cerámica y Vidrio, 2018, 57(1): 9-18. DOI: 10.1016/j.bsecv.2017.09.004.

[51] ZHANG Fan, LI Liang-feng, WANG En-ze. Effect of micro-alumina content on mechanical properties of Al2O3/3Y-TZP composites [J]. Ceramics International, 2015, 41(9): 12417-12425. DOI: 10.1016/j.ceramint.2015.06.081.

[52] WANG Shu-heng, MA Yong-bin, DENG Zi-chen, ZHANG Sen, CAI Jia-xin. Effects of fused deposition modeling process parameters on tensile, dynamic mechanical properties of 3D printed polylactic acid materials [J]. Polymer Testing, 2020, 86. DOI: 1016/j.polymertesting.2020.106483.

[53] MELOCCHI A, UBOLDI M, MARONI A, FOPPOLI A, PALUGAN L, ZEMA L, GAZZANIGA A. 3D printing by fused deposition modeling of single- and multi-compartment hollow systems for oral delivery―A review [J]. International Journal of Pharmaceutics, 2020, 579: 119155. DOI: 10.1016/j.ijpharm.2020.11915.

[54] AGARWALA M, WEEREN R V, BANDYOPADHYAY A, WHALEN P, SAFARI A, DANFORTH S. Fused deposition of ceramics and metals: An overview [C]// International Solid Freeform Fabrication Symposium. Austin, TX, USA, 1996: 385-392.

[55] RANGARAJAN S, QI G, VENKATARAMAN N, SAFARI A, DANFORTH S. Powder processing, rheology, and mechanical properties of feedstock for fused deposition of Si3N4 ceramics [J] Journal of the American Ceramic Society. 2000, 83(7): 1663-1669. DOI: 10.1111/j.1151-2916.2000. tb01446.x.

[56] IYER S, MCINTOSH J, BANDYOPADHYAY A, LANGRANA N, SAFARI A, DANFORTH S C, CLANCY R B, GASDASKA C, WHALEN P J. Microstructural characterization and mechanical properties of Si3N4 Formed by fused deposition of ceramics [J]. International Journal of Applied Ceramic Technology, 2008, 5(2): 127-137. DOI: 10.1111/j.1744-7402.2008.02193.x.

[57] WU Jin-tian, CHEN Ning, BAI Feng, WANG Qi. Preparation of poly(vinyl alcohol)/poly(lactic acid)/hydroxyapatite bioactive nanocomposites for fused deposition modeling [J]. Polymer Composites, 2018, 39(S1): E508-E518. DOI: 10.1002/pc.24642.

[58] ARNESANO A, KUNJALUKKAL PADMANABHAN S, NOTARANGELO A, MONTAGNA F, LICCIULLI A. Fused deposition modeling shaping of glass infiltrated alumina for dental restoration [J]. Ceramics International, 2020, 46(2): 2206-2212. DOI: 10.1016/j.ceramint.2019.09.205.

[59] ESPOSITO CORCIONE C, GERVASO F, SCALERA F, PADMANABHAN S K, MADAGHIELE M, MONTAGNA F, SANNINO A, LICCIULLI A, MAFFEZZOLI A. Highly loaded hydroxyapatite microsphere/PLA porous scaffolds obtained by fused deposition modelling [J]. Ceramics International, 2019, 45(2): 2803-2810. DOI: 10.1016/ j.ceramint.2018.07.297.

[60] DUBINENKO G E, ZINOVIEV A L, BOLBASOV E N, NOVIKOV V T, TVERDOKHLEBOV S I. Preparation of poly(L-lactic acid)/hydroxyapatite composite scaffolds by fused deposit modeling 3D printing [J]. Materials Today: Proceedings, 2020, 22: 228-234. DOI: 10.1016/j.matpr. 2019.08.092.

[61] ONAGORUWA S, BOSE S, BANDYOPADHYAY A. Fused deposition of ceramics (FDC) and composites [C]// International Solid Freeform Fabrication Symposium. Texas, USA, 2001. DOI: 10.26153/tsw/3267.

(Edited by HE Yun-bin)

中文导读

间接3D陶瓷打印技术:文献综述

摘要:增材制造(AM),也称为3D打印(3DP)技术,是一种在过去40年中发展迅速的先进制造技术。然而,由于开裂的问题,陶瓷材料的打印仍然具有挑战性。间接3D打印由于其快制造速度和低成本而受到关注。间接3D打印将直接3D打印的一步成型过程分为粘结和材料烧结,避免了由于快速冷却而导致的内应力,从而可以实现形状复杂的高质量陶瓷组件的制备。本文介绍了先进的间接3D打印技术的研究进展,包括黏结剂喷射(BJ),立体光刻(SLA)和熔融沉积建模(FDM)。目前,陶瓷材料的增材制造主要是通过间接3D打印技术实现的,这些材料包括氮化硅,羟基磷灰石功能陶瓷,碳化硅结构陶瓷。

关键词:间接3D打印;陶瓷;黏合剂喷射;立体光刻;熔融沉积建模

Foundation item: Project(51901020) supported by the National Natural Science Foundation of China; Project(2019JZZY010327) supported by Shandong Key Research and Development Plan, China; Project(201942074001) supported by Aeronautical Science Foundation of China; Project(FRF-IP-20-05 ) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2021-01-08; Accepted date: 2021-04-08

Corresponding author: ZHANG Bai-cheng, PhD, Professor; E-mail: zhangbc@ustb.edu.cn; ORCID: https://orcid.org/0000-0001-6406-6226