DOI:10.19476/j.ysxb.1004.0609.2017.07.12

石墨粒度及沥青粘结剂对铜-石墨电刷材料性能的影响

林雪杨,刘如铁,熊 翔,陈 洁

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:分别采用不同粒度鳞片石墨(鳞片石墨Ⅰ、Ⅱ、Ⅲ)和沥青石墨通过粉末冶金法对铜石墨电刷材料进行制备,采用XRD和SEM对其试验前后的物相和组织形貌进行分析,并运用XPS分析对偶件的表面成分。结果表明:随着石墨粒度的下降,铜石墨电刷材料的烧结密度、硬度和抵抗磨粒磨损的能力均有所下降,抵抗电弧烧蚀的能力则显著提高。沥青粘结剂能够促进铜和石墨的均匀分布,从而改善材料的物理力学性能和摩擦磨损性能。此外,产生于摩擦界面的CuO降低材料的导热导电能力并催化石墨氧化,从而加剧磨损。

关键词:石墨粒度;沥青粘结剂;摩擦;磨损;氧化

文章编号:1004-0609(2017)-07-1411-08 中图分类号:TF125;TH117.1 文献标志码:A

铜-石墨材料兼顾了铜基体良好的强度、硬度、导电导热性[1]以及石墨良好的高熔点、自润滑性、抗熔焊性和耐电弧烧蚀性等特点,因而被广泛地应用于滑动电接触部件中,如发动机的集电环、电枢和电刷等[2]。

在新型电机和发动机对电流密度和工作速度提出更高要求的条件下,铜石墨电刷材料现在面临着综合使用性能不足和寿命严重下降的严峻形势[3-6]。因此,为了满足日益苛刻的服役条件,基于载流摩擦磨损的新型铜-石墨材料的材料设计和磨损机理研究的开展变得异常迫切。目前,国内外研究人员主要从新组元的选用和不同工作参数下的磨损机制方面入手进行了研究工作。QIAN等[7]对新组元WS2的研究表明,WS2能够与石墨产生协同润滑作用,提高材料的磨损抗力。LI等[8]则选用石墨烯作为复合材料的新组元,研究表明石墨烯的加入对材料力学性能和摩擦性能有较大的提升。而ГЕРШМАН等[9]则对石墨改性化与不同电流密度下材料的磨损行为进行了研究,其结果表明含铌改性石墨的材料具有更优异的物理机械性能,同时材料与对偶的磨耗在较宽范围内对电流密度敏感。符蓉等[10]对不同制动条件下材料的磨损机制进行了研究,结果表明材料的磨损机制主要取决于材料的工作条件。虽然这些工作对影响铜-石墨材料载流摩擦磨损性能的因素做出了较为系统的研究,但是在材料设计中关于石墨粒度的选择上以及氧化磨损机制对性能的影响方面鲜有讨论。

本文作者以粉末冶金法制备的铜-石墨电刷材料作为研究对象,从不同粒度和类型的石墨与铜的烧结机制入手,分析石墨粒度与沥青粘结剂对烧结性能、显微组织以及载流磨损机制的影响,并对磨损过程中材料的氧化行为进行了探讨,以期为铜-石墨复合材料在滑动电接触方面的应用提供更多实验依据与理论基础。

1 实验

本实验使用的原料:电解铜粉,粒度25~38 μm,纯度≥99.0%;锡粉,粒度38~48 μm,纯度≥99.5%;二硫化钼粉,粒度≤44 μm,纯度≥98.5%;鳞片石墨粉,50号(石墨粒度(380±50) μm)、100号(石墨粒度(200±50) μm)和300号(石墨粒度(90±30) μm) 3种,按粒度由大到小依次记为鳞片石墨Ⅰ、Ⅱ、Ⅲ,纯度≥99.85%;含沥青鳞片石墨粉,沥青含量12.5%,粒度为100号(石墨粒度(200±50) μm)。

按照表1配方成分进行配制,试样A、B、C和D中石墨的实际含量均为28%,其中试样D中的沥青石墨以32%含量加入。将各组粉末分别置于V型混料机中干混2 h,并在200~300 MPa下模压成型,最后将压坯在氢气保护气氛下烧结。烧结温度880~910 ℃,保温时间90 min,水套冷却,试样尺寸6.75 mm×10 mm×4.5 mm。

表1 试验成分配比

Table 1 Components of composites

图1 电摩擦磨损试验机简图与换向器

Fig. 1 Friction and wear testing system in energized state (a) and commutator (b)

载流摩擦磨损试验是在自制的电摩擦磨损试验机上进行,载流摩擦磨损机构和对偶件换向器如图1所示。其中换向片为紫铜,对偶件的直径为29.52 mm。试验在30 A的恒流条件下进行,电流密度为98.8 A/cm2,换向器转动速度为1000 r/min(线速度为1.55 m/s),负荷为10 N,每隔30 min换向器的旋转方向更迭一次,共进行32 h试验,试验完成后测算记录试样的质量损失并计算磨损率。磨损率(RW)根据公式(1)进行计算:

RW=V/(FL) (1)

式中:V=△m/ρ为磨损体积;△m为试样的质量损失;ρ为试样的密度;F为摩擦作用力;L为滑动距离;磨损率RW的单位为m3/(N·m)。

采用NavoNanoSEM230型附带能谱仪的扫描电子显微镜观察试样试验前后的表面组织形貌;采用SIMENS型X射线衍射仪对试验前后的试样进行物相分析;采用ESCALAB 250Xi型X射线光电子能谱仪对试验后换向器的摩擦表面膜进行分析;采用排水法对试样的密度和开孔率进行测算;采用210HR-150型碳刷硬度计对试样硬度进行测量。

2 结果与分析

2.1 材料性能

表2所列为4种试样的压坯密度、烧结密度、体积收缩率、开孔率及硬度。由表2可见,含粘结剂的试样A、B和C在烧结后的体积发生了膨胀,且膨胀程度随石墨粒度减小而增大;同时,随着石墨粒度的降低,试样的烧结密度和硬度逐渐下降,开孔率呈上升的趋势。而含粘结剂的试样D在烧结后则发生收缩,而其烧结密度和硬度均有明显的提高,开孔率则明显下降。

表2 不同试样的性能

Table 2 Performance of different samples

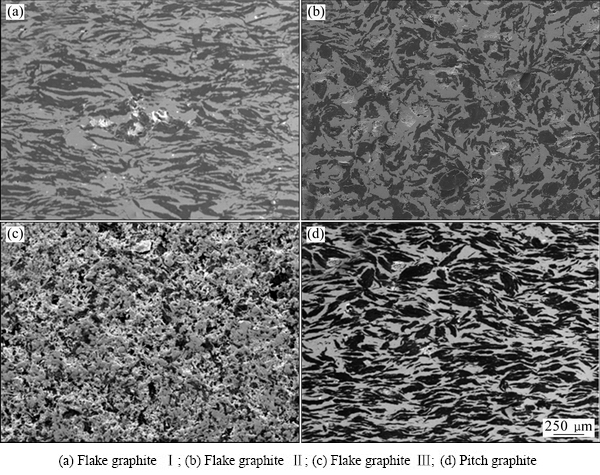

图2所示为由4种不同石墨组成试样的组织形貌。由图2可见,在试样A(见图2(a))的局部区域存在着集中的孔洞,石墨与铜各自存在偏聚区。而试样B(见图2(b))中的孔洞则相对分散,石墨与铜各自偏聚区减少。当粒度降为300号时(见图2(c)),铜基体被石墨严重割裂,孔洞数量急剧增加。显而易见,随着石墨粒度的降低,铜和石墨的接触界面增加。同时,在界面处存在着较大的孔洞,并且孔洞数量随着石墨粒度的减小而增加。而在含粘结剂的试样D(见图2(d))中,铜与石墨分布更加均匀,且其孔洞数量明显减少、孔洞尺寸明显变小。

图2 不同石墨组成试样的表面形貌

Fig. 2 Surface morphologies of samples with different graphite

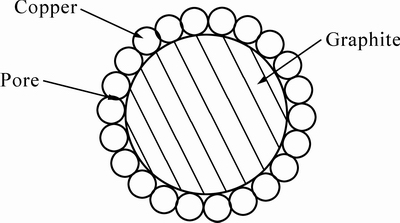

图3所示为铜与石墨简单堆积的截面图。其中,将石墨与铜颗粒以球形近似,并忽略接触过程中的弹性和塑性变形。对于不同粒度石墨组成的试样而言,铜与石墨的堆积情况是不同的[11]。由图3可知,当石墨总量一定时,随着石墨粒度的减小,每个石墨颗粒与铜之间的孔洞数目减小,但是由于总的石墨颗粒数量会增加,铜与石墨相邻的几率会大大的提高,从而体系总孔洞数也将大大的提高。而铜与石墨为不互溶体系,在910 ℃下,烧结只发生在铜与铜之间,因此,除了靠近这个区域的孔洞会产生收缩外,其他地方不会形成烧结颈。因此,随着石墨粒度的减小,石墨因弥散分布而阻碍铜原子间扩散的作用越发明显,从而削弱了材料的物理力学性能。并且由于石墨与铜的比重相差大,在混料的过程中,铜与石墨往往无法实现均匀的混合,因此,在图2(a)、(b)和(c)中可以明显观察到局部的石墨聚集区。而对于添加沥青石墨的试样D(见图2(d))而言,粘结剂能给铜和石墨提供足够的粘结力,在混料过程中改善了石墨与铜的均匀分布。

图3 石墨-铜堆积截面

Fig. 3 Section of accumulation of copper and graphite particles

在烧结初期,温度上升引起的压坯内部应变能的释放,将导致压坯体积膨胀[12]。由于不含粘结剂的试样A、B和C的压坯密度较高,且在烧结过程中因铜颗粒之间形成烧结颈所产生的收缩效应无法完全抵消膨胀效应,所以最终造成体积发生膨胀,这是其密度、硬度较低以及开孔率较高的主要原因。而对于含有粘结剂的试样D而言,由于其本身的压坯密度较低,且在烧结初期,粘结剂的焦化以及挥发分的排出在材料内部留下了大量的空隙,从而铜与铜形成烧结颈并且能进一步收缩的体积将大大地增加,这导致烧结产生的收缩效应将大于膨胀效应。另外,试样D中石墨与铜的均匀分布减小了铜原子扩散所需的总路程,烧结致密化的过程能更快地完成,因此,试样D表现出相对更高的密度、硬度和较低的开孔率。

2.2 载流摩擦磨损性能

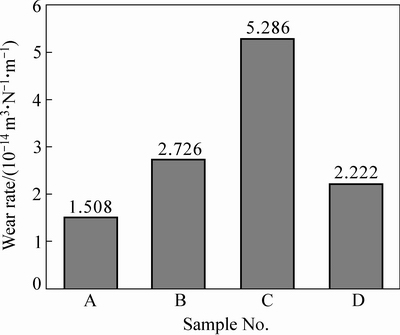

图4所示为不同试样的磨损率。由图4可知,随着石墨粒度的降低,试样的磨损率上升,当石墨粒度降为300号时,试样C的磨损明显加剧。而在相同石墨粒度下,含沥青粘结剂试样D的磨损比不含沥青粘结剂试样B的低22.7%。

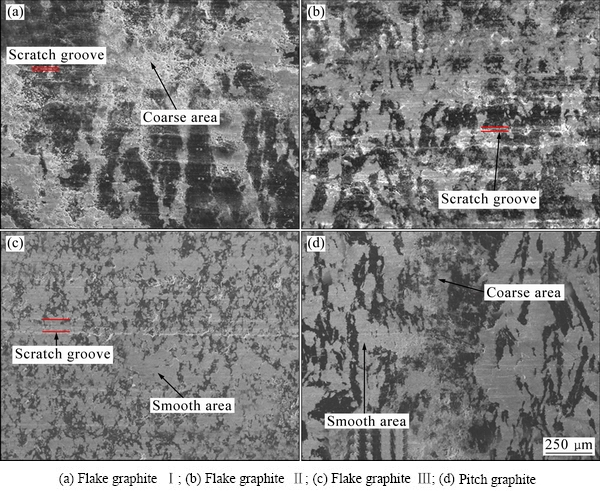

图5所示为不同试样的摩擦表面。由图5可以发现,随着石墨粒度的降低,试样摩擦表面的犁沟变得稀疏,而其宽度逐渐变宽,同时,铜基体的形貌特征由粗糙向平滑转变。而添加沥青石墨的试样表面的犁沟较细,且其中大部分铜基体是以平滑状态分布于材料中。

对比各试样试验前后的表面形貌,试样A在试验前后的主要变化是铜基体形貌更加粗糙。图6(a)所示为是试样A(见图5(a))中的粗糙区域(Coarse area),可以发现,该区域存在着大小不一的液滴状颗粒,并且许多颗粒已附着在石墨表面上。图6(b)所示为该区域的能谱,可以发现氧的明显存在。因此,推断这些区域是在电弧的高温作用下,局部区域瞬间形成熔池后,铜液凝固所形成,而这些区域即为电弧烧蚀区;试样B除了在摩擦表面出现电弧烧蚀区外,其变化还体现在摩擦面上铜相的扩大和石墨相的缩小;而试样C在摩擦前后的主要变化则是以铜相扩大和石墨相缩小为主,且伴随着摩擦面上大量的孔洞消失。摩擦面上铜相和石墨相的变化,是因为在摩擦过程中表层的材料剥落形成磨屑,构成磨粒磨损。其中,材料内部石墨被挤出,并以润滑层的形式存在[13-14];由于铜基体较软,在剪切应力的作用下,铜凸点能铺展摩擦面而形成铜相扩大的形貌。对于含有粘结剂的试样D而言,其试验前后的变化与试样B相似,也是以出现电弧烧蚀区及铜相和石墨相的变化为主。

图4 不同石墨组成试样的磨损率

Fig. 4 Wear rate of samples with different graphites

图5 不同石墨组成试样的摩擦表面

Fig. 5 Friction surfaces of samples with different graphites

图6 电弧烧蚀区域的形貌与能谱分析

Fig. 6 Morphology of ace ablation area (a) and EDS analysis (b)

比较试样A、B和C的摩擦面形貌,并结合上述分析可以知道,随着石墨粒度的减小,摩擦面上电弧烧蚀特性逐渐减轻而磨粒磨损特性则逐渐明显。同时,结合相应的磨损结果(见图4)可以推断,磨粒磨损对材料磨损率的直接影响要高于电弧烧蚀对磨损率的直接影响。

此外,电流对磨损率的间接影响也是不可忽略的。在载流摩擦过程中,摩擦表面电流传递的缩流效应、隧道效应更强,从而部分接触点的温度会达到赤热程度。此时,被离化的正离子束将由换向器表面流向试样。当换向器表面与试样间的电压越高,离子的速度则越快,对试样的冲击作用将越大,从而试样接触表层材质更疏松。电流传递时,电子从试样逸出,加速了碳微粒从试样上脱落的速度,使磨损增大[15-17]。

就铜与石墨组元而言,由于石墨熔点远高于铜的熔点,所以石墨本身的抗电弧烧蚀能力要远优于铜的。对于低碳电刷材料而言,细粒度石墨在材料中分布相对更加弥散,从而提升材料的抗电弧烧蚀的能力。但是,由于其材料本身较低的物理力学性能,加之电弧烧蚀对铜的影响,使整体材料的力学性能弱化更加明显,材料抗磨粒磨损性能会大大的降低,从而加剧了材料的磨损;相反,粗石墨在抗电弧烧蚀性能上相对较差,但是整体材料的力学性能受电弧烧蚀带来的弱化作用相对较小,因而其磨损也较低;而粘结剂的引入改善了材料中铜与石墨的均匀性,提高材料物理力学性能,较未添加粘结剂的同粒度石墨而言,相对改善了其抵抗磨损的能力。

2.3 载流条件下的氧化行为

一般而言,固相化学反应所需的高活化能是以热能和机械能的形式供给,即晶格畸变和摩擦热能够提高材料与周围气态或液态介质的反应几率。所以,摩擦化学反应能改变表面范围内的强度,从而改变滑动特性,并有助于生成氧化层[18]。不同石墨粒度下的材料开孔率不同,这不仅影响了材料的密度和硬度等性能,而且也为气体扩散提供了通道。此外,摩擦表面及亚表面在周期性摩擦应力的作用下产生了许多裂纹等缺陷。因此,氧分子会借助这些缺陷或通道渗入材料基体内部,在摩擦过程中对材料产生深层氧化。

图7 试样C试验前后的XRD谱

Fig. 7 XRD patterns of sample C

图8 试样C在试验后剖面的SEM像与能谱分析

Fig. 8 SEM image of profile of sample C after test (a) and EDS analysis of zones A (b) and B (c)

由图7中试样C在试验前后的XRD结果可知,试验后,试样中的Cu含量减少,并且有明显的Cu2O产生。这是由于在大气中,Cu存在如下氧化反应:185~200 ℃时,2Cu+1/2O2=2Cu2O;350 ℃以上时,Cu2O+1/2O2=2CuO。图8所示为试样C试验后的剖面SEM像以及能谱分析。如图8(a)所示,在白色区域部分存在两种衬度,其中衬度较亮的区域被低衬度相所包围。对比图8(b)、(c)可以知道,暗衬相中的氧含量明显高于亮衬相。结合XRD分析,能够推断出亮衬区域为Cu,暗衬区域为Cu2O。同时,在图8(a)中可以发现,Cu2O分布在Cu基体周围的现象,尤其在孔洞以及铜与石墨交界处更加明显,这表明在摩擦过程中,不仅在试样表面会形成氧化膜,而且氧分子还可以通过材料的孔隙或铜与石墨之间的孔隙通道渗入材料的基体,对材料内部产生深层氧化[19]。

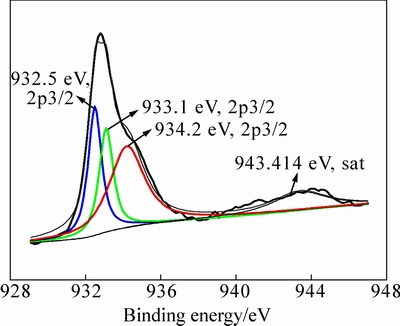

图9所示为换向器摩擦表面膜的Cu2p谱。由图9可以发现,在图中具有明显的震激伴峰(结合能位于943.414 eV附近),判定Cu2p结合能在934.2 eV的为Cu2+。结合XRD分析,可以推测Cu2p结合能位于932.5eV和933.1 eV的峰为Cu+和Cu。因此,可以判断在摩擦过程中除了产生Cu2O还生成了CuO。基体中大量的Cu2O为CuO的生成提供了条件,摩擦过程中的局部“闪点”高温,可以促进CuO的生成。而Cu2O和CuO的存在使电阻率提高,导致在工作过程中大量热量产生,降低了试样在服役条件下的稳定性和使用寿命。同时,在电弧的局部高温作用下,CuO作为催化剂能促进石墨的氧化,从而加快试样的磨损速度[20-22]。同时,随着石墨粒度的降低,相界面和孔洞的数目的提高将造成更多的散射面积,减弱自由电子与声子的传热能力,降低材料的热导率[23-24]。在这种情况下,由于散热不均造成的石墨氧化现象将更加严重,从而使由细粒度石墨组成的试样C的磨损加剧。

图9 换向器摩擦表面膜的Cu2p谱

Fig. 9 Cu2p spectra of friction surface film on commutator

3 结论

1) 随着石墨粒度的下降,铜石墨复合材料的开孔率上升,烧结密度、收缩率及硬度下降,载流摩擦过程中的磨损增加、电弧烧蚀逐渐减轻而磨粒磨损更加明显。

2) 沥青粘结剂能给石墨与铜提供粘结力,改善石墨与铜的均匀分布,促进烧结的致密化,提高材料物理力学性能,进而改善载流摩擦磨损性能。

3) 在摩擦过程中,氧分子可以通过材料孔隙或铜与石墨之间的孔隙通道渗入材料的基体,对材料内部产生深层氧化;摩擦过程中生成的Cu2O和CuO使电阻率提高,降低了试样在服役条件下的稳定性和使用寿命。

REFERENCES

[1] 王常川, 王日初, 彭超群, 冯 艳, 韦小凤. 金属基固体自润滑复合材料的研究进展[J]. 中国有色金属学报, 2012, 22(7): 1945-1955.

WANG Chang-chuan, WANG Ri-chu, PENG Chao-qun, FENG Yan, WEI Xiao-feng. Research progress of metallic solid self-lubricating composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1945-1955.

[2] 汪礼敏. 铜及铜合金粉末与制品[M]. 长沙: 中南大学出版社, 2010: 112-113.

WANG Li-ming. Copper and powders and products of copper alloy[M]. Changsha: Central South University Press, 2010: 112-113.

[3] ZHENG R G, ZHANG X X. Wear behavior of Cu-based composite under different electrical currents[J]. Advanced Materials Research, 2013, 750/752: 701-704.

[4] 董 霖. 载流摩擦磨损机理研究[D]. 重庆: 西南交通大学, 2008: 3-4.

DONG Lin. Study on the mechanism of friction and wear with electric current[D]. Chongqing: Southwest Jiaotong University, 2008: 3-4.

[5] 黎凯强, 向雄志, 白晓军, 梁宝盈, 龚文亚. 不同粒度和石墨含量对铜-镀铜石墨复合材料性能的影响[J]. 金属功能材料, 2016, 23(1): 47-50.

LI Kai-qiang, XIANG Xiong-zhi, BAI Xiao-jun, LIANG Bao-ying, GONG Wen-ya. Effects of particle size and copper-coated graphite content on properties of the Cu/copper-coated graphite composite[J]. Metallic Functional Materials, 2016, 23(1): 47-50.

[6] 王观民, 张永振, 杜三明, 刘维民. 不同气氛环境中钢/铜摩擦副的高速干滑动摩擦磨损特性研究[J]. 摩擦学学报, 2007, 27(4): 346-351.

WANG Guan-min, ZHANG Yong-zhen, DU San-ming, LIU Wei-min. Study on tribological behavior of steel brass couples in different atmosphere under high speed and dry sliding[J]. Tribology, 2007, 27(4): 346-351.

[7] QIAN Gang, FENG Yi, CHEN Yang-ming, MO Fei, WANG Yu-qing, LIU Wen-hong. Effect of WS2 addition on electrical sliding wear behaviors of Cu-graphite-WS2 composites[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1986-1994.

[8] LI Jing-fu, ZHANG Lei, XIAO Jin-kun, ZHOU Ke-chao. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 3354-3362.

[9] ГЕРШМАН И С, 胥金荣. 改性石墨-铜复合材料的特性研究[J]. 国外机车车辆工艺, 2015(1): 20-23.

ГЕРШМАН И С, XU Jin-rong. The study on characteristics of modified graphite and copper composite[J]. Foreign Locomotive & Rolling Stock Technology, 2015(1): 20-23.

[10] 符 蓉, 王嘉阳, 高 飞, 韩晓明. 惯性制动条件对铜-石墨材料摩擦性能及第三体的影响[J]. 润滑与密封, 2014, 39(11): 31-35.

FU Rong, WANG Jia-yang, GAO Fei, HAN Xiao-ming. Effects of inertia brake conditions on friction properties and the third bodies of copper-graphite materials[J]. Lubrication Engineering, 2014, 39(11): 31-35.

[11] COBLE R L. Initial sintering of alumina and hematite[J]. Journal of the American Ceramic Society, 1958, 41: 55-62.

[12] 阮建明, 黄培云. 粉末冶金原理[M]. 北京: 机械工业出版社, 2012: 304-307.

RUAN Jian-ming, HUANG Pei-yun. Powder metallury principle[M]. Beijing: China Machine Press, 2012: 304-307.

[13] 浩宏奇, 丁华东, 李雅文, 金志浩. 石墨含量对铜基材料摩擦磨损性能的影响[J]. 中国有色金属学报, 1997, 17(3): 120-123.

HAO Hong-qi, DING Hua-dong, LI Ya-wen, JIN Zhi-hao. Effect of graphite content on friction and wear properties of copper base material[J]. The Chinese Journal of Nonferrous Metals, 1997, 17(3): 120-123.

[14] 高 强, 吴渝英, 张国定, 洪 锓, 肖学明. 碳纤维对铜-石墨复合材料性能的影响[J]. 中国有色金属学报, 2000, 20(S1): 97-101.

GAO Qiang, WU Yu-ying, ZHANG Guo-ding, HONG Qin, XIAO Xue-ming. Effect of carbon fiber on property of copper-graphite composite materials[J]. The Chinese Journal of Nonferrous Metals, 2000, 20(S1): 97-101.

[15] 李雪飞, 上官宝, 张永振. 石墨粒度对C/Cu复合材料载流摩擦磨损性能的影响[J]. 热加工工艺, 2011, 40(24): 115-117.

LI Xue-fei, SHANGGUAN Bao, ZHANG Yong-zhen. Effects of graphite particle size on friction and wear properties of C/Cu composite[J]. Hot Working Technology, 2011, 40(24):115-117.

[16] 彭秀英. 对电刷磨损机制的探讨[J]. 润滑与密封, 1990(5): 48-51.

PENG Xiu-ying. Inquiring into the wear mechanisms of brush[J]. Lubrication Engineering, 1990(5): 48-51.

[17] 万 成, 李继文, 王 展, 马窦琴, 张会杰, 魏世忠, 张国赏, 徐流杰. W-30Cu电接触材料直流电接触行为[J]. 中国有色金属学报, 2016, 26(1): 126-136.

WAN Cheng, LI Ji-wen, WANG Zhan, MA Dou-qin, ZHANG Hui-jie, WEI Shi-zhong, ZHANG Guo-shang, XU Liu-jie. Electrical contact behavior of W-30Cu contact material under direct current condition[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 126-136.

[18] 凯尔 A, 默尔 W A, 维纳里库 E. 电接触和电接触材料[M]. 赵华人, 陈昌图, 陶国森, 译. 北京: 机械工业出版社, 1993: 153-155.

KEIL A, MERL W A, VINARICKY E. Electrical contact and electrical contact materials[M]. ZHAO Hua-ren, CHEN Chang-tu, TAO Guo-sen, transl. Beijing: China Machine Press, 1993: 153-155.

[19] 郭忠全. 高性能铜基电接触复合材料的研制及强化机理研究[D]. 济南: 山东大学, 2011: 114-115.

GUO Zhong-quan. The production and reinforcement of high-performace copper-based electrical contact composite[D]. Jinan: Shandong University, 2011: 114-115.

[20] MCCARROLL B, MCKEE D W. Reactivity of graphite surfaces with atoms and molecules of hydrogen, oxygen and nitrogen[J]. Carbon, 1971, 10(3): 301-311.

[21] SAVAGE D E, LAGALLY M G, SCHRADER M E. Electron spectroscopy analysis of contact surfaces in the wear of carbon brushes against copper commutators[J]. Applications of Surface Science, 1981, 7(1/2): 142-155.

[22] SAKAI Y, NINOMIYA S, HIRAOKA K. XPS depth analysis of CuO by electrospray droplet impact[J]. Surface & Interface Analysis, 2012, 44(8): 938-941.

[23] 堵永国, 龙雁, 张家春. 电接触材料的热导率[J]. 电工合金, 1996, 2(1): 15-21.

DU Yong-guo, LONG Yan, ZHANG Jia-chun. Thermal conductivity of electric contact material[J]. Electric Engineering Alloy, 1996, 2(1): 15-21.

[24] DENG C H, CHEN G Z, QI-LU G E. Effect of graphite content and granularity on mechanical and tribological properties of bronze alloyed powder composite[J]. Journal of Iron & Steel Research International, 2005, 12(1): 54-57.

Effects of graphite granularity and pitch binder on properties of copper-graphite brush

LIN Xue-yang, LIU Ru-tie, XIONG Xiang, CHEN Jie

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Copper-graphite brushes were fabricated through powder metallurgy method by flake graphite with different sizes (graphiteⅠ, Ⅱ, Ⅲ) and pitch binder. The original phase components and structure morphologies were compared with the worn sample by using X-ray diffraction and scanning electron microscopy, respectively. The surface components of counterparts were studied by X-ray photoelectron spectroscopy. The results indicate that physical properties and the ability to resist the abrasive wear will be worse with the graphite granularity decreasing. However, the arc ablation will be enhanced. Uniform distribution of copper and graphite can be achieved by adding pitch binder, which improves the physical and mechanical properties and friction and wear properties. Furthermore, copper oxide generated from friction interface will reduce the thermal and electrical conductivity and catalyze graphite oxidation, which exacerbates the wear performance.

Key words: graphite granularity; pitch binder; friction; wear; oxidation

Foundation item: Project supported by State Key Laboratory of Powder Metallurgy, China; Project(2015DFR50580) supported by International S&T Cooperation Program of China; Project(51505503) supported by the National Natural Science Foundation of China

Received date: 2016-06-28; Accepted date: 2016-11-18

Corresponding author: LIU Ru-tie; Tel: +86-731-88876566; E-mail: llrrtt@csu.edu.cn

(编辑 李艳红)

基金项目:粉末冶金国家重点实验室自主课题资助;科技部国家国际合作项目(2015DFR50580);国家自然科学基金资助项目(51505503)

收稿日期:2016-06-28;修订日期:2016-11-18

通信作者:刘如铁,副教授,博士;电话:0731-88876566;E-mail:llrrtt@csu.edu.cn