DOI: 10.11817/j.issn.1672-7207.2016.02.034

煤矿锚喷作业区喷浆粉尘数值模拟与新型湿喷一体机研制

周刚1, 2, 3,张琦1, 2,程卫民1, 2,陈连军1, 2,冯开林4,聂文1, 2

(1. 山东科技大学 矿山灾害预防控制省部共建国家重点实验室培育基地,山东 青岛,266590;

2. 山东科技大学 矿业与安全工程学院,山东 青岛,266590;

3. 澳大利亚联邦科学与工业研究组织 能源研究分院,昆士兰 布里斯班,4069;

4. 山东科技大学 电气与自动化工程学院,山东 青岛,266590)

摘要:基于颗粒离散相模型采用FLUENT软件分别对干、湿喷时的喷浆粉尘运移规律和质量浓度进行数值模拟。根据呼吸带高度粉尘质量浓度模拟结果,提出“湿喷粉尘预防三区”的概念。研究结果表明:湿喷物料反弹射流较干喷对风流径向偏移的影响显著,加之湿喷粉尘粒径较大,所以其扩散较为均匀,沉降速度较快,整个巷道空间内的湿喷粉尘质量浓度比干喷时大为降低。在湿喷口后方16 m以外为最佳作业区域。为降低喷浆作业现场的粉尘质量浓度,改变目前湿喷机、搅拌机单独成体,运动、应用不方便的弊端,根据液压驱动原理研发集搅拌、喷射、行走三功能合一的湿喷一体机。相对于干喷而言,采用一体机湿喷作业后,作业现场的全尘、呼尘质量浓度和混凝土物料的回弹率大幅降低,并且提高了喷射混凝土大板的28 d抗压强度。

关键词:煤矿锚喷;粉尘质量浓度;数值模拟;湿喷一体机;降弹增强

中图分类号:TD714 文献标志码:A 文章编号:1672-7207(2016)02-0606-09

Numerical simulation on gunite dust of bolt-shotcrete operating area in coal mine and development of new wet spraying integral machine

ZHOU Gang1, 2, 3, ZHANG Qi1, 2, CHENG Weimin1, 2, CHEN Lianjun1, 2, FENG Kailin4, NIE Wen1, 2

(1. State Key Laboratory of Mining Disaster Prevention and Control Co-founded by Shandong Province and

Ministry of Science and Technology, Shandong University of Science and Technology, Qingdao 266590, China;

2. College of Mining and Safety Engineering, Shandong University of Science and Technology, Qingdao 266590, China;

3. Energy Flagship, Commonwealth Scientific and Industrial Research Organisation, Brisbane, QLD 4069, Australia;

4. College of Electrical and Automation Engineering, Shandong University of Science and Technology, Qingdao 266590, China)

Abstract: The numerical simulations on gunite dust of migration law and mass concentration during dry and wet spraying were conducted by FLUENT software based on dispersed phase model. According to the simulation results of dust mass concentration in the area of respiratory zone’s height, the concept of “preventive three zones of wet spraying dust” was proposed. The results show that the wet spraying materials’ rebound jet has much more influences on the air’s radial offset compared with that of dry spraying. Moreover, the dust particle size of wet spraying is large, so it has even diffusion and high settling velocity. The wet spraying dust concentration in the whole roadway is much smaller than that during dry spraying. The best operating area should be more than 16 m behind the wet spray gun. In order to decrease the dust concentration in the process of shotcrete and avoid the shortcomings i.e. wet spraying machine and mixer work as two separate bodies and their applications and movements are not convenient, the integral wet spraying machine with the functions of stirring, spraying and moving are designed according to the hydraulic driving principle. Compared with dry shotcrete, after applying the integral wet spraying machine, the mass concentration of whole and respirable dust and the rebound ratio of concrete materials in the working areas sharply decreases, moreover, and the compressive strength for the spraying concrete board of 28 d increases.

Key words: bolt-shotcrete in coal mine; dust mass concentration; numerical simulation; wet spraying integral machine; decreasing rebound and increasing strength

我国煤矿巷道基本采用锚喷支护作为临时或永久支护,而喷射混凝土则是锚喷作业最重要的工序之一。由于我国煤矿井巷作业空间狭小,井下环境复杂,多年来锚喷作业一直采用较为落后的干喷和潮喷工艺,虽然其具有施工工艺简单的特点,但作业现场产尘的游离二氧化硅质量分数高达80%以上,最大粉尘质量质量浓度超过1 000 mg/m3,对矿工的身心健康危害极大[1-3]。因此,锚喷作业区作为煤矿井下重要的生产场所之一,其产尘量虽只占到矿井全部产尘量的15%左右,但尘肺病患病率却占到整个矿井的35%以上[4-6]。为此,2010-09,国家安全生产监督管理总局发布的“禁止井工煤矿使用的设备及工艺目录”(第三批)中,已经明确将干式混凝土喷射机列入淘汰产品[7]。因此,摸清喷浆粉尘的运移规律,并研发相应的成套湿喷装备对锚喷作业区粉尘防治具有十分重大的理论和现实意义。目前国内外主要通过数值模拟的方法对喷浆粉尘进行研究,但仅限于干喷时的产尘情况,尚未有学者对湿喷产尘的运移规律进行研究。再则,虽然湿式喷浆机在煤矿井下有所应用,但混凝土搅拌机和湿喷机均为单一设备,不仅体积庞大,移动不便,而且操作较为复杂,生产效率不高[8-9]。为此,本文作者对干、湿喷工艺产尘进行数值模拟,得到喷浆粉尘运移及其质量浓度分布规律,为粉尘预警提供依据。此外,根据液压传动理论研发煤矿新型湿喷一体机,通过现场应用大大降低喷浆作业的粉尘质量浓度,显著减少混凝土喷射物料回弹率,喷射混凝土的抗压强度也有效提高。

1 风流-粉尘流动数学模型

本文利用属于欧拉-拉格朗日法的离散相模型(DPM)构建风流-粉尘流动的数学模型,即用欧拉连续相法描述风流流场,采用Navier-Stokes方程进行计算,而用拉格朗日离散相法描述颗粒流动。

1.1 气体流动数学模型

将锚喷作业区的风流视为定常不可压缩流动,采用三维稳态不可压Navier-Stokes方程构建风流流动控制方程组,同时采用标准k-e 双方程模型表征其湍流特性,具体方程组如下[10-12]。

连续方程:

(1)

(1)

动量方程:

(2)

(2)

k方程:

(3)

(3)

ε方程:

(4)

(4)

其中:

(5)

(5)

(6)

(6)

xi和xj为坐标(i≠j),m;ui和uj为不同坐标点处的流体速度(i≠j),m/s;ρ为气体密度,kg/m3;p为湍流有效压力,Pa;μ为层流黏性系数,Pa·s;μt为湍流黏性系数,Pa·s;Gk为湍动能变化率受剪切力变化的影响系数,kg/(s3·m);k为湍动能,m2/s2;ε为湍动能耗散率,m2/s3; ,

, ,

, ,

, 和

和 为常数,分别取1.43,1.91,0.09,1.20和1.00。

为常数,分别取1.43,1.91,0.09,1.20和1.00。

1.2 粉尘流动数学模型

采用DPM模型求解喷浆粉尘运动,仅需考虑阻力和重力,而忽略其他较小作用力,粉尘颗粒受力平衡方程为[13]

(7)

(7)

式中: 为单位质量的粉尘颗粒阻力;u为风流速度,m/s;vp为粉尘颗粒的速度,m/s;ρp为粉尘颗粒的密度,kg/m3;g为重力加速度,m/s2。

为单位质量的粉尘颗粒阻力;u为风流速度,m/s;vp为粉尘颗粒的速度,m/s;ρp为粉尘颗粒的密度,kg/m3;g为重力加速度,m/s2。

(8)

(8)

式中:CD为阻力系数; dp为粉尘颗粒的直径,m。

因风流瞬时速度可用平均速度与脉动速度之和来表示,即:

(9)

(9)

则粉尘颗粒轨迹控制方程为

(10)

(10)

式中:τp为颗粒松弛时间,s。

对于k-ε模型,设当地湍流是各向同性的,作为小旋涡脉动速度的一个样本可表示为

(11)

(11)

式中:ζ为服从正态分布的随机数。

流场中细小粉尘的积分时间可近似等同于风流的拉格朗日积分时间,即

(12)

(12)

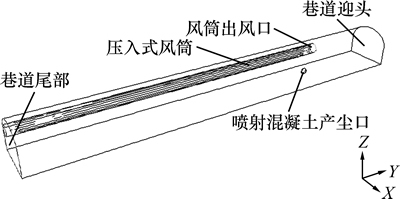

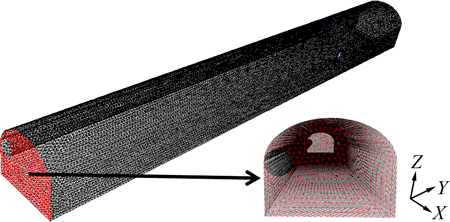

2 数值模拟几何模型

忽略工作人员和湿喷机对产尘的影响,对锚喷工作面的计算区域进行以下适当的简化:将巷道视为三心拱,巷道长×宽×高为40.0 m×4.5 m×3.5 m,压风筒直径为0.6 m,长度为33.0 m,风筒出风口到迎头距离为7.0 m,喷射混凝土产尘口位于风筒出风口上风侧4.0 m处。而且,将巷道顶板、底板、壁面简化为平面边界。采用FLUENT自带的前处理软件GAMBIT建立针对上述作业场景的几何模型,并进行网格划分。本模型的网格取Interval size为0.2的整体六面体网格。锚喷工作面数值模拟几何模型及网格划分结果分别如图1和图2所示。

图1 锚喷工作面数值模拟几何模型

Fig. 1 Geometric model of numerical simulation of bolt-shotcrete operating area

图2 锚喷工作面几何模型网格图

Fig. 2 Meshing map of geometric model of bolt-shotcrete operating area

3 干喷、湿喷粉尘模拟对比分析

设定入口为风筒出风口,边界类型为VELOCITY_INLET,出口为巷道尾部,边界类型为OUTFLOW,压入式风筒出风速度为16.7 m/s。粉尘粒度分布符合Rosin-Rammler准则,产尘速率为0.02 kg/s。应用FLUENT进行数值模拟时,采用离散求解器,湍流模型为k-ε,风流压力-速度耦合运用SIMPLEC方法进行处理,离散格式利用有限体积法[14-15]。

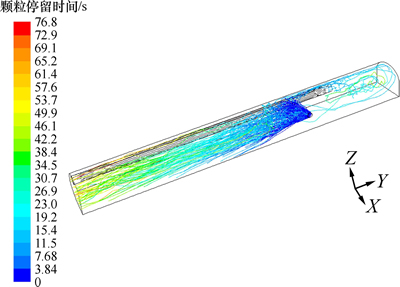

3.1 粉尘运移轨迹

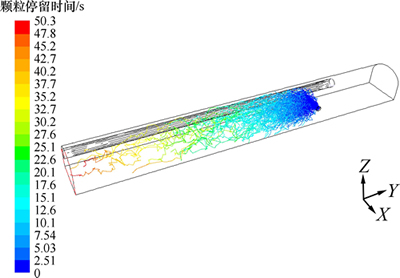

干喷和湿喷作业的喷浆产尘运移轨迹图分别如图3和图4所示。

由图3和图4可以看出:干喷粉尘扩散不充分,粉尘近乎为轴向流动,少数粉尘由于受迎头附近涡流区的影响发生逆向流动;而湿喷粉尘沿轴向和径向扩散充分,沉降较快。产生上述现象的主要原因是干喷作业时物料的反弹射流不足以引起风流产生较大的径向流动,且干喷粉尘的粒径较小、质量较轻,多呈现漂浮状态,这使得大量干喷粉尘难以沉降,直至巷道出口处仍有干喷粉尘流动。然而湿喷作业时,回弹的物料引起部分风流沿径向发生了偏移,致使粉尘扩散和沉降较快,也无逆向流动,锚喷作业区的工作环境大为改善。

图3 干喷粉尘运移轨迹图

Fig. 3 Dust migration path of dry shotcrete

图4 湿喷粉尘运移轨迹图

Fig. 4 Dust migration path of wet shotcrete

3.2 呼吸带高度粉尘质量浓度

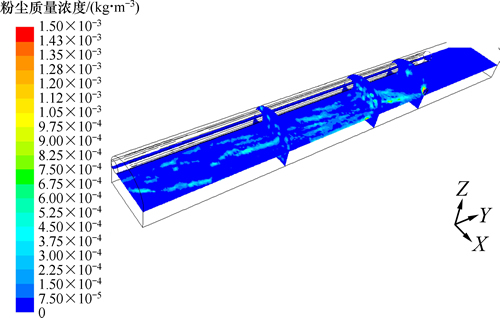

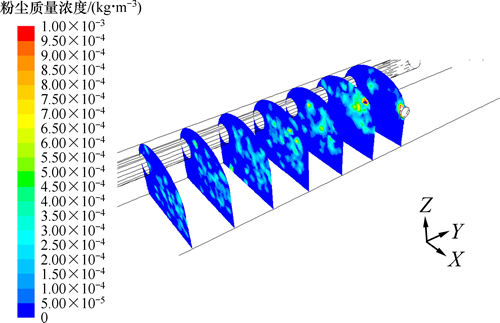

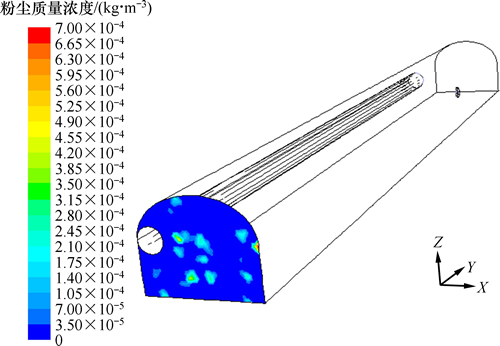

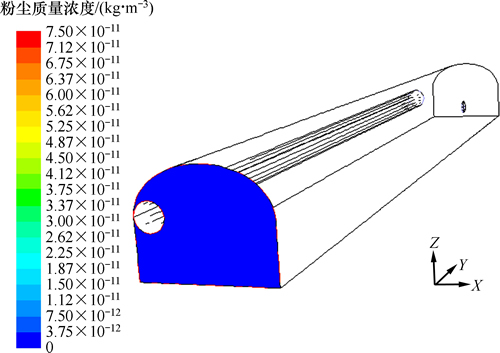

干喷和湿喷作业的呼吸带高度粉尘质量浓度分布情况如图5和图6所示。

由图5和图6可知:在呼吸带高度范围内,干喷时,粉尘质量浓度明显较高,喷枪附近及其风流下风侧的粉尘平均质量浓度分别达750 mg/m3和400 mg/m3左右,而相应位置处,湿喷粉尘的平均质量浓度却只有20 mg/m3和15 mg/m3,比干喷时的粉尘质量浓度大大降低。而且湿喷作业时,粉尘沿整条巷道扩散、沉降明显,以湿喷口后方6 m和16 m为界(图6中的2个横截面),粉尘质量浓度变化明显,湿喷口后方0~6 m是高质量浓度粉尘区,湿喷口后方6~16 m是低质量浓度粉尘区,湿喷后方16 m之后,粉尘质量浓度维持在3 mg/m3以下。

图5 干喷作业呼吸带高度粉尘质量浓度分布图

Fig. 5 Dust mass concentration distribution at breathing zone height of dry shotcrete

图6 湿喷作业呼吸带高度粉尘质量浓度分布图

Fig. 6 Dust mass concentration distribution at breathing zone height of wet shotcrete

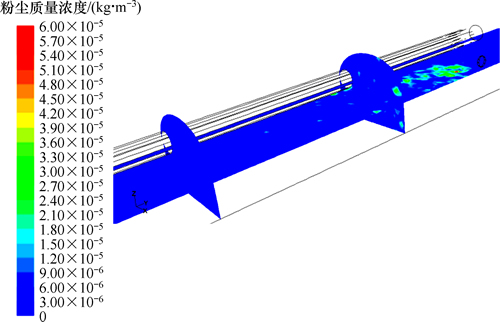

3.3 喷浆口后方粉尘质量浓度沿程变化

干喷和湿喷作业的喷浆口后方粉尘质量浓度沿程变化如图7和图8所示。

从图7和图8可以看出:干喷作业时,粉尘弥散于整个巷道空间内,粉尘质量浓度沿整条巷道的变化程度较小;但湿喷作业时,粉尘质量浓度沿程变化明显,以喷浆口后方6 m处的横截面为界,湿喷粉尘质量浓度已经降到12 mg/m3以下,而且分布范围有限,但干喷粉尘在此界面之后的平均质量浓度仍高达350 mg/m3,而且几乎覆盖了整个巷道端面。

图7 干喷口后方粉尘质量浓度沿程变化

Fig. 7 Dust mass concentration variation along behind dry spray gun

图8 湿喷口后方粉尘质量浓度沿程变化

Fig. 8 Dust mass concentration variation along way behind wet spray gun

3.4 巷道出口粉尘质量浓度

干喷和湿喷作业的巷道出口粉尘质量浓度分布情况分别如图9和图10所示。

从图9和图10可以看出:巷道出口位于喷浆口后方33 m处,湿喷粉尘在出口处的质量浓度几乎为0 mg/m3;但干喷粉尘虽然经过30多米的扩散、沉降,但出口处的局部粉尘质量浓度仍然高达210 mg/m3,严重污染了锚喷作业区的工作环境。

图9 干喷巷道出口粉尘质量浓度分布图

Fig. 9 Dust mass concentration distribution in tunnel exit of dry shotcrete

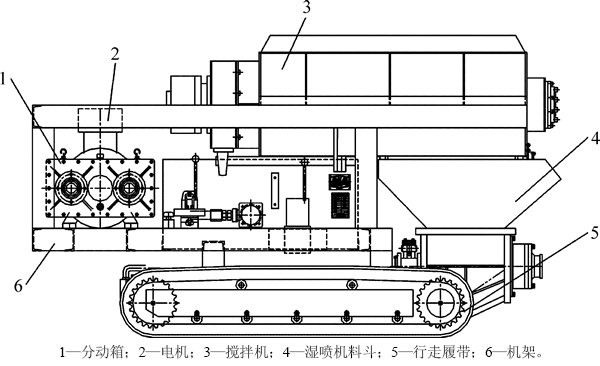

4 新型高效湿喷一体机研发

由上述的数值模拟可知:湿喷工艺比干喷工艺粉尘质量浓度大大减小,为此,研发新型湿喷机并应用于煤矿喷浆作业区具有重要的现实意义。

图10 湿喷巷道出口粉尘质量浓度分布图

Fig. 10 Dust mass concentration distribution in tunnel exit of wet shotcrete operating

4.1 新型湿喷机研发理念

鉴于目前湿喷机、搅拌机单独成体,运动、应用不方便的弊端[16-18],新研发的湿喷机为集成搅拌、喷射、行走三功能的一体机。即新研发的湿喷机应具有以下功能:搅拌,由液压马达驱动的双卧轴强制搅拌;倒料,由液压缸驱动打开搅拌桶放料口将混凝土倒入湿喷料斗;湿喷,由液压缸驱动的泵送式湿喷机构;行走,由液压马达驱动的履带底盘。

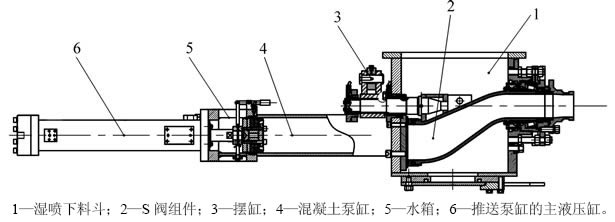

新型湿喷一体机的主要部件示意图如图11所示。

4.2 新型湿喷一体机各组成系统设计

4.2.1 电气控制系统

湿喷机组动力来源为37 kW矿用防爆电机,电源660 V/1 140 V均适用,由矿用电磁启动器控制。湿喷机组不包含其他电气元件。

4.2.2 动力系统

湿喷机组由电机驱动的两路柱塞泵提供动力,为开式液压系统,拥有液位、液温、吸油、高压过滤、散热等功能。主定量柱塞泵的额定排量为63 mL/r,额定工作压力为18 MPa,主泵提供的流量进入湿喷机主阀块、驱动湿喷主油缸及摆缸。副定量柱塞泵的额定排量为63 mL/r,额定工作压力为10 MPa,流量供给搅拌多路阀、驱动搅拌马达、放料油缸和行走马达。

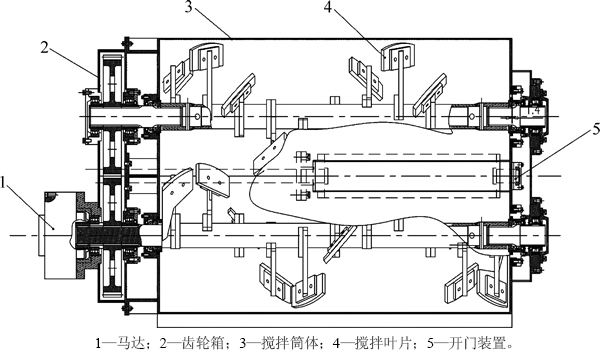

4.2.3 搅拌系统

搅拌系统由搅拌筒、搅拌轴、搅拌叶片等组成,如图12所示。搅拌叶片通过托板固定在搅拌臂上,并与搅拌轴成一体,形成2组螺旋,方向相反,搅拌臂与搅拌筒内壁间隙可微量调整。其中,搅拌机理如下:电机带动液压柱塞泵,使液压马达带动带齿轮的搅拌轴进行旋转,同时另一搅拌轴在齿轮的带动下旋转,通过搅拌轴上的叶片搅拌物料。由于螺旋升角的作用,搅拌叶片工作时使筒内的物料由一侧推向另一侧,又由另一侧推向原处的循环动作,使物料得到充分的搅拌。混凝土搅拌好之后,通过多路阀控制搅拌筒放料缸翻转,把搅拌好的混凝土倒入湿喷系统的料斗中。

图11 新型湿喷一体机主要部件示意图

Fig. 11 Schematic diagram of main components of new wet spraying integral machine

图12 混凝土搅拌装置示意图

Fig. 12 Schematic diagram of concrete stirring device

4.2.4 泵送系统

混凝土传输泵(双活塞泵)由2个并列放置的泵缸组成,如图13所示。当泵浆混凝土流入1个泵缸时,被强大的液压动力从另一个泵缸中压出,通过S阀组件送至混凝土软管。泵缸的冲程速率可通过液压泵上的手柄手动调节。S阀液压系统采用2个液压柱塞摆缸使其在2个泵缸之间进行切换。

4.2.5 行走底盘系统

湿喷机组行走底盘采用履带式,由2个带刹车制动柱塞马达的驱动减速机构成,马达由2个手动换向阀分别控制,可完成前进、后退、单边转向及滑移转向等功能。

4.2.6 速凝剂添加系统

速凝剂由气动马达驱动的软管泵输送,通过节流阀控制气动马达改变添加流量。速凝剂通过雾化器进入压缩空气气路后在喷枪处与混凝土混合,然后被喷出。该过程可产生可靠的黏附力,并使喷浆混凝土在预定位置快速凝固。

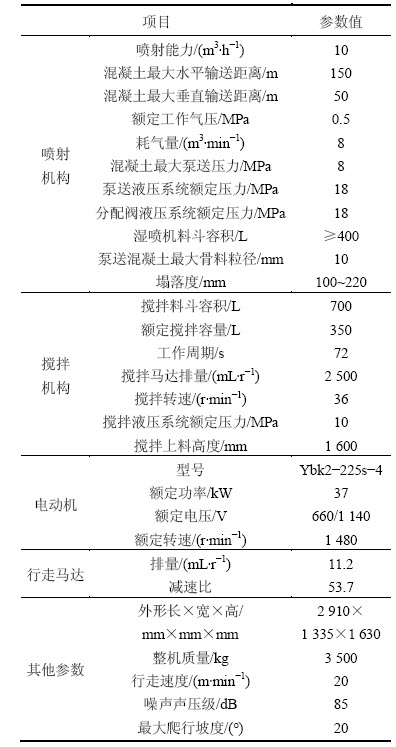

4.3 新型湿喷一体机主要技术参数

主要技术参数如表1所示。

图13 湿喷机泵送系统

Fig. 13 Pumping system of new wet spraying integral machine

表1 新型湿喷一体机主要技术参数

Table 1 Main technical parameters of new wet spraying integral machine

5 现场应用

将湿喷一体机在兖矿集团东滩煤矿南翼皮带巷掘进一区工作面进行了现场应用,干、湿喷均采用标号为32.5的水泥和型号为WT-1的无碱液体速凝剂。相比干喷工艺而言,采用湿喷工艺后,作业区的粉尘质量浓度大幅度降低,而且回弹率和喷射混凝土的抗压强度均得以明显改善。

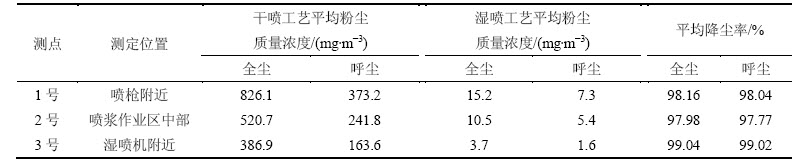

5.1 粉尘质量浓度测定

根据GB 50086—2001“锚杆喷射混凝土支护技术规范”的规定,分别对干、湿喷工艺喷浆现场粉尘质量浓度进行测定。测定方式为滤膜称量法,当喷浆作业正常且粉尘质量浓度相对稳定后进行粉尘采样,测得粉尘质量浓度如表2所示。

由表2可知:当采用喷浆一体机进行湿喷作业时,人员主要作业地点的粉尘质量浓度大为降低,人员主要作业地点的全尘、呼尘平均质量浓度分别由577.90 mg/m3和259.53 mg/m3降至9.80 mg/m3和4.77 mg/m3,平均降尘率高达98.40%和98.28%。

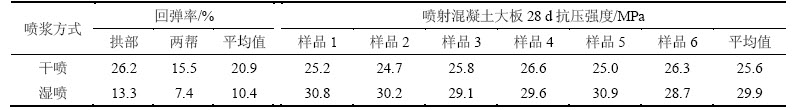

5.2 回弹率及喷射混凝土抗压强度测定

将塑料布铺在巷道底板上,首先对拱部进行喷浆,喷射0.5 m3混凝土,喷浆结束后将回弹的物料进行收集后称量、计算,得到拱部回弹率;再对两帮进行喷浆,方法同喷射拱部。此外,采用电子万能试验机对干喷、湿喷喷射混凝土大板的抗压强度进行测定。干、湿喷工艺回弹率及喷射混凝土抗压强度测试结果如表3所示。

由表3可知:采用湿喷工艺后,混凝土的平均回弹率由20.9%降至10.4%,但喷射混凝土大板的28 d抗压强度平均值则由25.6 MPa增至29.9 MPa。

综上所述可知:采用湿喷工艺后,不仅从根本上降低了作业现场粉尘质量浓度,实现了清洁生产。而且混凝土的回弹率大为降低,喷射混凝土的抗压强度有效增加,在保证工程质量的同时,降低了生产成本,实现了可观的经济效益。

表2 干、湿喷工艺产尘质量浓度对比

Table 2 Dust mass concentration contrast between dry and wet shotcrete process

表3 干、湿喷工艺回弹率及喷射混凝土抗压强度测试

Table 3 Test results on rebound ratio and compressive strength of concrete between dry and wet shotcrete process

6 结论

1) 受风流和湿喷混凝土反弹射流的共同作用,湿喷口附近出现了喷射状的粉尘流,导致风流发生了径向的偏移;而干喷混凝土的物料反弹射流未发生此类现象。湿喷混凝土粉尘粒径较大,扩散较为均匀,沉降速度较快;然而,干喷混凝土粉尘由于质轻,易漂浮,多发生轴向流动,沉降速度较慢。

2) 整个巷道空间内的湿喷粉尘质量浓度比干喷时大为降低。呼吸带高度范围内干、湿喷的平均粉尘质量浓度分别为400 mg/m3和12 mg/m3;喷浆口后方6 m之后湿喷粉尘质量浓度迅速降低到15 mg/m3以下,但此界面之后的干喷粉尘质量浓度依然高达350 mg/m3;位于喷浆口后方33 m巷道出口处的湿喷粉尘质量浓度几乎为0 mg/m3,但干喷的局部粉尘质量浓度仍然高达210 mg/m3,严重污染了锚喷作业区的工作环境。

3) 根据湿喷粉尘沿呼吸带高度的质量浓度分布规律,提出了“湿喷粉尘预防三区”的概念,即以湿喷口后方6 m和16 m为分界线,将湿喷作业区域分为“湿喷粉尘警戒区”、“湿喷粉尘预警区”和“湿喷粉尘安全区”。对于搅拌、上料等工种的矿工来说,湿喷口后方16 m以外的区域为最佳作业区域。

4) 根据液压驱动原理,研发了由电气控制系统、动力系统、上料系统、搅拌系统、泵送系统、速凝剂添加系统、行走底盘系等7大系统构成的集搅拌、喷射与行走三功能合一的新型湿喷一体机。该新型湿喷机搅拌系统上料高度可达1 600 mm、额定搅拌容量为350 L、双卧轴强制搅拌转速为36 r/min;湿喷系统混凝土最大泵送压力为8 MPa、混凝土最大水平和垂直输送距离分别为150 m和50 m、机料斗容积≥400 L、喷射能力为10 m3/h;一体机行走速度为20 m/min、最大爬坡坡度达20°。

5) 采用一体机湿喷作业后,相比较干喷而言,人员主要作业地点的全尘、呼尘平均质量浓度分别由干喷时的577.90 mg/m3和259.53 mg/m3降至9.80 mg/m3和4.77 mg/m3;混凝土物料的平均回弹率由20.9%降至10.4%,喷射混凝土大板的28 d抗压强度平均值则由25.6 MPa增至29.9 MPa。

参考文献:

[1] 聂文. 综掘工作面气载粉尘运移规律及抑制技术研究[D]. 青岛: 山东科技大学矿业与安全工程学院, 2013: 1-3.

NIE Wen. Research on the airborne dust migration rule and inhibition technology in mechanized excavation face[D]. Qingdao: Shandong University of Science and Technology. College of Mining and Safety Engineering, 2013: 1-3.

[2] 程卫民, 聂文, 周刚, 等. 煤矿高压喷雾雾化粒度的降尘性能研究[J]. 中国矿业大学学报, 2011, 40(2): 185-189.

CHENG Weimin, NIE Wen, ZHOU Gang, et al. Study of dust suppression by atomized water from high pressure sprays in mines[J]. Journal of China University of Mining & Technology, 2011, 40(2): 185-189.

[3] 王绪友. 岩巷锚喷作业粉尘防治技术与效果分析[J]. 矿业安全与环保, 2012, 39(2): 50-51.

WANG Xuyou. Dust prevention and control technology and effect analysis of rock drift shotcreting[J]. Mining Safety & Environmental Protection, 2012, 39(2): 50-51.

[4] 中华人民共和国国家卫生和计划生育委员会. 职业与放射卫生信息查询[EB/OL]. [2014-07-19]. http://www.nhfpc.gov.cn/ jkj/ zyfsws/list.shtml.

The National Health and Family Planning Commission of the People's Republic of China. Professional and radiological health information inquiry [EB/OL]. [2014-07-19]. http://www. nhfpc.gov.cn/jkj/zyfsws/list.shtml.

[5] 程卫民, 刘伟, 聂文, 等. 煤矿采掘工作面粉尘防治技术及其发展趋势[J]. 山东科技大学学报, 2010, 29(4): 77-81.

CHENG Weimin, LIU Wei, NIE Wen, et al. The prevention and control technology of dusts in heading and winning faces and its development tendency[J]. Journal of Shandong University of Science and Technology, 2010, 29(4): 77-81.

[6] 周刚, 程卫民, 陈连军. 矿井粉尘控制关键理论及其技术工艺的研究与实践[M]. 北京: 煤炭工业出版社, 2011: 1-2.

ZHOU Gang, CHENG Weimin, CHEN Lianjun. Research and practice on the key theory and technology of coal mine dust control[M]. Beijing: China Coal Industry Publishing House, 2011: 1-2.

[7] 国家安全生产监管管理总局, 国家煤矿安全监察局. 关于发布禁止井工煤矿使用的设备及工艺目录(第三批)的通知[EB/OL]. [2011-01-27]. http://www.chinasafety.gov.cn/ newpage/Contents/Channel_6289/2011/0130/122432/content_122432.htm.

State Administration of Work Safety, State Administration of Coal Mine Safety. Directory of prohibited equipment and technology used in the underground coal mines (the third batch) [EB/OL]. [2011-01-27]. http://www.chinasafety.gov.cn/ newpage/Contents/Channel_6289/2011/0130/122432/content_122432.htm.

[8] 陈杰, 荆升国, 李鉴, 等. PS6I矿用混合型湿喷机组的设计及性能分析[J]. 煤炭科学技术, 2014, 42(3): 81-84.

CHEN Jie, JING Shengguo, LI Jian, et al. Design and performances analysis on PS6I wet concrete shooter machine in coal mine[J]. Coal Science and Technology, 2014, 42(3): 81-84.

[9] 任广信, 贾国平, 杨晋, 等. 湿喷工艺在大巷掘进初期的研究与应用[J]. 煤炭与化工, 2013, 36(5): 23-24.

REN Guangxin, JIA Guoping, YANG Jin, et al. Research and application of wet spraying technology in the early alleys tunneling[J]. Coal and Chemical Industry, 2013, 36(5): 23-24.

[10] 刘毅, 蒋仲安, 蔡卫, 等. 综采工作面粉尘运动规律的数值模拟[J]. 北京科技大学学报, 2007, 29(4): 351-353.

LIU Yi, JIANG Zhongan, CAI Wei, et al. Numerical simulation of the dust movement rule in fully-mechanized coal faces[J]. Journal of University of Science and Technology Beijing, 2007, 29(4): 351-353.

[11] 谢中强. 锚喷支护巷道喷浆作业粉尘分布规律的数值模拟[J]. 煤矿开采, 2012, 17(3): 96-99.

XIE Zhongqiang. Numerical simulation of ash distribution rule in grouting operation of anchored-grouting supporting[J]. Coal mining Technology, 2012, 17(3): 96-99.

[12] 邱天德, 赵宏伟. 湿喷机多相流数值模拟分析与试验应用[J]. 建井技术, 2011, 32(5): 26-29.

QIU Tiande, ZHAO Hongwei. Numerical simulation analysis and experiment application of wet spraying machinery multiphase flow[J]. Mine Construction Technology, 2011, 32(5): 26-29.

[13] 蒋仲安, 姜兰, 陈举师. 露天矿潜孔打钻粉尘浓度分布规律数值模拟[J]. 深圳大学学报(理工版), 2013, 30(3): 313-318.

JIANG Zhongan, JIANG Lan, CHEN Jushi. Numerical simulation of dust concentration distribution regularities of down-the-hole drilling in open-pit mine[J]. Journal of Shenzhen University (Science and Engineering), 2013, 30(3): 313-318.

[14] 王晓珍, 蒋仲安, 王善文, 等. 煤巷掘进过程中粉尘浓度分布规律的数值模拟[J]. 煤炭学报, 2007, 32(4): 386-390.

WANG Xiaozhen, JIANG Zhongan, WANG Shanwen, et al. Numerical simulation of distribution regularities of dust concentration during the ventilation process of coal roadway driving[J]. Journal of China Coal Society, 2007, 32(4): 386-390.

[15] 秦跃平, 姜振军, 张苗苗, 等. 综掘面粉尘运移规律模拟及实测对比[J]. 辽宁工程技术大学学报(自然科学版), 2014, 33(3): 289-293.

QIN Yueping, JIANG Zhenjun, ZHANG Miaomiao, et al. Comparison of simulation and measurement on dust migration regularity in fully mechanized workface[J]. Journal of Liaoning Technical University(Natural Science), 2014, 33(3): 289-293.

[16] 牛文章. 锚喷巷道湿式喷浆工艺的应用[J]. 现代矿业, 2013(5): 136-138.

NIU Wenzhang. Application of wet shotcrete technology on shotcreting roadway[J]. Modern Mining, 2013(5): 136-138.

[17] 马利, 许鹏. 岩巷掘进快速湿式喷射混凝土支护技术[J]. 煤炭科学技术, 2013, 41(4): 5-7.

MA Li, XU Peng. Rapid wet shotcreting support technology of mine rock roadway[J]. Coal Science and Technology, 2013, 41(4): 5-7.

[18] 赵文彬, 谭允祯, 商岩冬, 等. 矿用喷射混凝土外加剂机理分析[J]. 煤炭学报, 2009, 34(4): 526-530.

ZHAO Wenbin, TAN Yunzhen, SHANG Yandong, et al. Mechanism analysis of shotcrete concrete additive used in coal mine[J]. Journal of China Coal Society, 2009, 34(4): 526-530.

(编辑 杨幼平)

收稿日期:2015-02-21;修回日期:2015-04-24

基金项目(Foundation item):国家自然科学基金资助项目(U1261205,51474139,51404147);山东科技大学杰出青年科技人才支持计划项目(2014JQJH106);中国博士后科学基金面上资助项目(2015M570602);山东煤炭安全高效开采技术与装备协同创新中心项目(2013);2014年度青岛市黄岛区科技资助项目(2014-1-30) (Projects (U1261205, 51474139, 51404147) supported by the National Natural Science Foundation of China; Project (2014JQJH106) supported by the SDUST Research Fund; Project (2015M570602) supported by the China Postdoctoral Science Foundation; Project (2013) supported by the Joint Innovative Center for Safe and Effective Mining Technology and Equipment of Coal Resources of Shandong Province; Project (2014-1-30) supported by the Qingdao City Huangdao District Technology Fund)

通信作者:聂文,博士,讲师,从事煤矿通风与防尘方面研究;E-mail:skdniewen@163.com