文章编号:1004-0609(2008)04-0738-07

高电流密度TiB2/G阴极泄流式铝电解槽的电解实验

彭建平,冯乃祥,姜艳丽,王耀武,尤 晶

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:详述了泄流式TiB2/G阴极电解槽的制作与电解运行操作。在焦粒焙烧、干法启动后,保持1.54 A/cm2的高阳极电流密度进行140 h电解实验,平均电流效率为86.5%。实验过程中,TiB2/G层稳定而牢固,其腐蚀脱落速度为0.4 g/(h?m2),能很好地保护阴极基体。利用铝参比电极由瞬时断电技术测得泄流式电解槽的阳极过电压和阴极过电压,它们与对应的电流密度遵循塔菲尔方程关系,其阳极过电压与工业电解槽相当,而其阴极过电压比工业电解槽的高0.4 V左右。这可能是由于泄流式电解槽中不存在铝液波动,阴极表面附近的电解质分子比远高于工业电解槽阴极表面的电解质分子比。

关键词:铝电解;泄流式电解槽;石墨化阴极;TiB2涂层;过电压

中图分类号:TF 821;TF 801.3 文献标识码:A

Test of drained aluminum electrolysis cell with TiB2/G graphitized cathode at high current density

PENG Jian-ping, FENG Nai-xiang, JIANG Yan-li, WANG Yao-wu, YOU Jing

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The construction and testing of a drained cell with TiB2/G graphitized cathode were described. The coke-bed baking method and a dry start-up technology were adopted. During 140 h of electrolysis the drained cell performed steadily at an anodic current density of 1.54 A/cm2 with a current efficiency of 86.5%. After electrolysis it was found that the TiB2 coating layer shows a low wear rate of 0.4 g/(h?m2). Moreover, the overvoltage at different current densities is measured with an aluminum reference electrode by an interruption technique in the drained cell. The results can be depicted as a fairly straight line in a Tafel plot. The anodic overvoltage in the drained cell is close to the value in industrial cells, while the cathodic overvoltage in the drained cell is about 0.4 V higher than that in industrial cells at around 1 A/cm2, due to a stable molten Al layer and high molar NaF/AlF3 ratio of the bath close to the cathode.

Key words: aluminum electrolysis; drained cathode cell; graphitized cathode; TiB2 coating; overvoltage

TiB2/C惰性阴极泄流式电解槽是一种新型结构电解槽,由于泄流式电解槽的阴极表面只有一薄层的铝液,无铝液波动,因此泄流式电解槽可降低极距,使槽电压降低,从而可以达到降低能耗的目的。

国内外对铝电解槽使用TiB2层炭阴极进行过大量研究[1-12],国内学者也对泄流式阴极铝电解槽的物理场进行了大量的模拟与计算研究[13-17]。而在这些研究工作中规模最大的电解实验当属Comalco 铝业公司在92 kA的电解槽上进行的泄流式TiB2/C惰性阴极电解槽电解实验[18]。其中一台实验槽的阴极电流密度为0.97 A/cm2,极距降低至20 mm,150 d实验的吨铝电耗为12 800 kW?h。研究人员认为当提高阴极电流密度至1.2 A/cm2并保持热平衡不变时,电解槽的产量可增加50%。国内外研究人员一致认为Comalco的泄流式TiB2/C阴极电解槽在阴极材料和电解槽的结构设计上取得了重大的研究进展,并已经接近了工业化应用阶段。

2005年冯乃祥等[19]设计了另一种型式的泄流式TiB2/C阴极电解槽,并进行了实验。该槽电流强度为 1 350 A,阴极电流密度为1.2 A/cm2。其与Comalco泄流式电解槽的不同点在于,其阴极斜坡上生成的铝流向电解槽的一个侧面,而加料在另一侧,阴极钢棒从一个侧大面将电流导出。其优点在于电解过程中,由添加氧化铝而形成的沉淀堆积物不会对阴极表面形成的铝珠或铝液的泄流产生障碍,且阳极气体的逸出有利于氧化铝溶解。

如果泄流式阴极电解槽在工业上能够实现,极距可从4.0 cm左右降低到2.0 cm左右。从热平衡的角度来看,此时电解槽有可能处于冷行程,为此必须补充电解槽的能量,其唯一办法就是要增加电流强度,即在电解槽阳极和阴极面积不变的情况下,增加电解槽的阳极和阴极电流密度。本研究就是在这样的背景和技术思想指导下进行的。

1 泄流式阴极电解槽的结构与安装

1.1 电解槽的结构

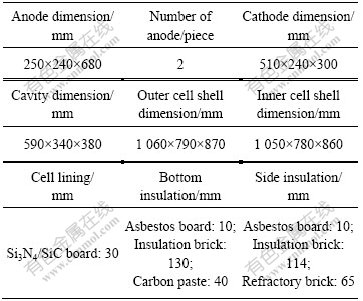

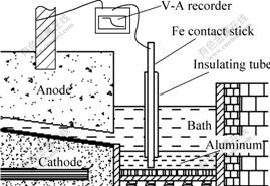

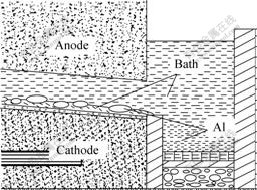

在本研究的电解实验中,电解槽的结构基本上与文献[19]的泄流式TiB2/C阴极电解槽的结构一样。其不同点在于:1) 在集铝沟一侧与阴极炭块的接触处,砌筑了一层厚度为2.0 cm的氮化硅结合碳化硅板(Si3N4/SiC board),达到集铝沟中的铝液与阴极炭块绝缘;2) 本次实验电解槽使用的TiB2/C阴极的基体采用石墨化阴极碳块;3) 电解槽的阳极及TiB2/C阴极的倾斜角为15?。该电解槽的结构如图1所示,电解槽的结构参数如表1所列。

图 1 泄流式电解槽的结构示意图

Fig.1 Schematic diagram of drained cell

1—Pin; 2—Anode; 3—Si3N4/SiC board; 4—Refractory brick; 5—Insulation brick; 6—Asbestos board; 7—Cell shell; 8—Paste; 9—Refractory concrete; 10—Collector bar; 11—Paste; 12—Si3N4/SiC board; 13—Aluminum; 14—Bath; 15—Graphited cathode; 16—TiB2/G coating

表 1 TiB2/G石墨化阴极泄流式电解槽的结构参数

Table 1 Structure parameters of drained cell with TiB2/G- coated graphited cathode

1.2 阴极的制作

本实验所用的泄流式阴极基体为石墨化电极材料。根据设计要求,先把该石墨化电极加工成510 mm×240 mm×300 mm的长方体,并在距离底面70 mm处钻2个直径为65 mm、深度为200 mm的洞,便于以后安装阴极钢棒,再将上表面切成倾斜角为15?。阴极基体加工后,在与电解质接触的阴极表面用电钻垂直钻

出直径为5 mm、深度为5 mm左右的孔,孔与孔之间的中心距离为7~8 mm。

在阴极表面所要涂覆的TiB2/G复合材料糊是由粒径0.075~0.106 μm的TiB2粉、0.075~0.106 μm的石墨粉和热固性树脂按一定的质量比配制。

在表面涂层时,首先将糊状物填充入阴极表面上的钻孔内,并压实,最后再在上面均匀涂抹并压实制成5 mm的厚度TiB2/G层。然后使其在150~180 ℃下固化,并与石墨化阴极碳块基体结合在一起。图2所示为本实验所用的TiB2/G石墨化阴极碳块的示意图。

图 2 泄流式TiB2/G石墨化阴极示意图

Fig.2 Drained graphitized cathode with TiB2/G coating

1.3 阳极的制作

本实验中TiB2/G泄流式阴极电解槽的阳极选用抚顺铝厂生产的预焙阳极炭块。阳极底部倾斜角被加工成15?,与电解槽阴极倾斜角一致。

1.4 阴极钢棒的安装

在次实验中,将粒径小于0.075 μm的TiB2粉与热固性树脂混合成糊后,置入事先已经加工好的阴极钢棒的棒孔中,然后将d 60 mm的两根阴极钢棒直立地插入孔中,再把阴极碳块放在地面的钢板上,之后将两根阴极钢棒作一极,钢板作一极,通入低电压、大电流的直流电进行电加热,缓慢升温到150~200 ℃,使阴极钢棒与阴极炭块之间的TiB2与热固性树脂的混合糊料固化。

2 电解槽焙烧、启动与电解

2.1 电解槽的焙烧与启动

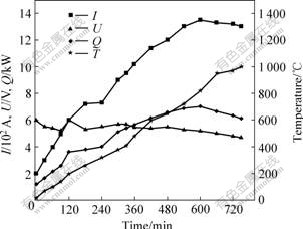

本研究中电解槽焙烧方法与文献[19]一样,但在选用的焦粒的尺寸上有差别,本实验泄流式TiB2/G复合材料阴极电解槽焙烧采用粒径为2~4 mm的粗粒冶金焦粉焙烧,其目的是为了增加焦粒的电阻,即提高焙烧时的电功率和升温速度。焙烧时电压、电流、功率以及和升温曲线如图3所示。

图 3 焙烧阶段能量输入与温度上升曲线

Fig.3 Energy input curves and temperature curve during baking

待电解槽两极之间的焙烧温度达到1 000 ℃左右后,焙烧结束断电,然后将阳极升降装置与阳极挂接,利用阳极升降装置缓慢提高阳极,用这种方法提高槽电压并提高电解槽的电流强度,使槽内物料逐渐熔 化,并使电解质温度升到980 ℃左右,电解质水平达到25~30 cm,保持这个温度5~6 h,捞出电解槽内炭渣后,逐渐降低槽电压,使电解槽进入正常生产条件下的电解温度。

2.2 正常电解时的技术条件与工艺操作

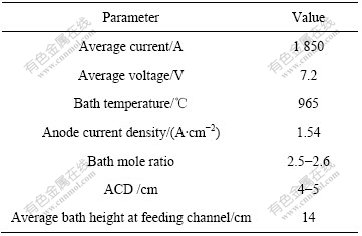

电解槽按上述方法启动转入正常电解阶段,正常电解时电解槽的工艺技术条件如表2所列。

表 2 正常电解时的工艺技术条件

Table 2 Process parameters in normal operation

电解过程中,原料氧化铝从聚铝沟对面的加工面加入,每隔30 min加入1次,每次按照法拉第定律的理论量的86%(电流效率)加入,而出铝是借助一个铁制的焊有铁棒的杯型容器从聚铝沟中取出。

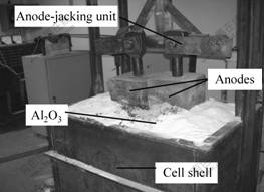

在电解过程中,需经常调整电解槽的温度、槽电压和槽电流,使其稳定在给定的值。调整方法是依靠阳极的升降装置对极距的增减,并配合供电系统的电压和电流调整来实现。图4所示为电解实验用的电解槽。

图 4 1 850 A实验电解槽

Fig. 4 Drained cathode cell

3 结果与讨论

本实验在高电流密度下进行,以便考查泄流式电解槽运行的稳定性、电流效率、TiB2/G层的抗腐蚀能力,测量和研究阳极过电压和阴极过电压,为泄流式电解槽的设计提供参考数据。由于是实验槽,需要较高的槽电压来维持电解槽的热平衡,故此参数不作为大型泄流式槽设计参考。

3.1 电解槽的电流效率

对本实验来说,电解时间自电解质水平达到 20 cm开始、到电解槽转入正常生产至停槽为止,一共进行了140 h,要较为准确地计算本电解实验的电流效率是困难的。这是因为,本实验采用焦粒焙烧,干法启动并转入正常的电解,这几个过程实际上是连续进行的,很难判断是什么时间熔化的电解质达到足够的量并将阳极和阴极之间的焦粒漂离出去,也很难判断电解是从什么时候开始。与上次电解实验[19]相比,本电解实验中槽电压和电流以及温度等参数更加稳定。如果以电解槽电解质的水平达到20 cm时作为电解的起始时间,并根据槽内铝量和这一阶段的正常出铝量(在出铝计算电流效率期间保持聚铝沟中的铝水平不变),可算得本实验电解槽在电解期间的电流效率为86.5%。

3.2 TiB2/G阴极的寿命

在铝电解过程中,铝液和电解质熔体不断地对阴极腐蚀。阴极表面的TiB2的腐蚀为化学腐蚀,被铝液和电解质熔体腐蚀的TiB2可进入到阴极生成的铝液中,因此分析电解槽铝液中的钛含量可推算出阴极表面TiB2/G层的腐蚀速度。在本实验中,借助于光谱分析得到电解4 h后铝液中的钛含量为0.006 3%,结合2.15 kg的出铝量可计算出电解过程中钛的消耗速度,推算出TiB2/G层单位面积的腐蚀速度为0.4 g/(h?m2),此值比前次[19]采用的振动成型固化TiB2/G涂层的腐蚀速度(1.0 g/(h?m2))小。这表明采用先表面粗糙化再涂层的方法能获得牢固的TiB2/G复合材料层,可以很好地保护阴极基体。

3.3 阴极过电压和阳极过电压

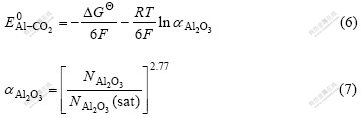

对于一个新型的TiB2/G泄流式阴极电解槽,测量和研究其在电解过程中的过电压是非常有意义的,尽管在实验室TiB2/G阴极的电解槽上有过研究,但本研究中这种接近半工业实验规模的1 850 A的TiB2/G泄流式电解槽并不是完全与实验室电解槽相同。它的阳极过电压和阴极过电压的测定需借助于一个铝参比电极和利用瞬时断电的技术来实现[20]。图5所示为阳极过电压的测量原理图。

图 5 阳极过电压的测量示意图

Fig.5 Schematic diagram of measuring anodic overvoltage

由图5可见,参比电极由d16 mm、长1.2 m的铁棒,外套一个d 25 mm的不锈钢管组成,不锈钢管与铁棒之间用石棉绳缠绕。测量阳极过电压时,该参比电极与函数记录仪的一个电压信号端连接,函数记录仪电压信号输入的另一接线端则通过导线与阳极连接。测量电解槽的阴极过电压时,函数记录仪信号输入端的另一端与电解槽阴极钢棒连接。由于在研究泄流式TiB2/G阴极电解槽中,其电解电流主要从阳极通过电解质熔体直接进入TiB2/G阴极表面,而从集铝沟中流入到阴极的电流很小,因此可视集铝沟中的阴极电流密度为0 A/m2。此时可以将外部缠绕石棉绳与电解质熔体绝缘而插入集铝沟铝液中的铁棒看成是一个铝参比电极。在电解进行的过程中,当函数记录仪的信号输入端按测量阴极过电压方式连接时,函数记录仪上记录的电压V等于集铝沟铝液中参比电极到阴极表面电解质熔体电阻欧姆电压降Vb、阴极电压降Vc、参比电极与阴极表面上铝之间的原电池电势 以及阴极上的过电压

以及阴极上的过电压 之和,即:

之和,即:

当瞬时断电时,则式(1)中的Vb和Vc等于0 V,则:

而在式(1)和式(2)中,Al—Al之间的电池电势 等于0 V,因此,瞬时断电后,从参比电极和阴极钢棒之间测得的电压

等于0 V,因此,瞬时断电后,从参比电极和阴极钢棒之间测得的电压 即为TiB2/G泄流式槽的阴极过电压

即为TiB2/G泄流式槽的阴极过电压 ,即:

,即:

铝电解槽上的阴极过电压是在电解过程中,由阴极表面的NaF的富集所引起的,是浓差极化过电压。因此当铝电解槽瞬时停电后,其阴极表面的高浓度的NaF会逐渐向电解质熔体中扩散,最后与电解质熔体中的NaF具有相同的浓度,此时的阴极过电压为0 V。

同理,当用函数记录仪记录阳极与参比电极之间的电压V时,则:

如果采用瞬时断电技术测量阳极过电压ηa,则在瞬时断电后Va=0 V和Vb=0 V,此时式(4)可化为:

式中 氧化铝的理论分解电压 可按下式计 算[20]:

可按下式计 算[20]:

在本电解实验中,电解温度为965 ℃,即1 238 K,Al2O3的 =-688.5 kJ/mol;此时氧化铝在电解质熔体中的浓度

=-688.5 kJ/mol;此时氧化铝在电解质熔体中的浓度 为4%,饱和浓度

为4%,饱和浓度 为10%。根据式(6)、(7)计算求得

为10%。根据式(6)、(7)计算求得 =1.23 V。

=1.23 V。

在本电解实验中,按上述阳极过电压和阴极过电压的测量方法测量了在965 ℃的电解温度下,不同的阴极和阳极电流密度时的泄流式TiB2/G阴极电解槽的阳极过电压和阴极过电压,其测量结果如图6所示。

图 6 阳极过电压与阴极过电压的塔菲尔曲线

Fig.6 Tafel plots of anodic overvoltage(a) and cathodic overvoltage(b)

由图6的测量结果可以看出,无论是阳极过电压还是阴极过电压,它们都与对应的电极电流密度Ia和Ic遵循塔菲尔方程式的关系:

另从图6(a)所示的测量结果可以看出,在泄流式TiB2/G阴极电解槽中的阳极尽管是倾斜的,但阳极过电压大小与普通槽的阳极过电压没有什么差别。电解后观察阳极低掌面仍然是平滑的,与水平面之间的斜度在电解过程中并没有发生改变,这说明在TiB2/G泄流式阴极电解槽的电解过程中,其阳极的电流密度基本上均匀。

但是由图6(b)可以看出,对于泄流式TiB2/G阴极电解槽的阴极过电压而言,其值高达0.4~0.5 V,远远大于目前工业电解槽的阴极过电压(0.1 V左右)[20]。在目前的工业电解槽中阴极表面的铝液是波动的,从而使浓度极化引起的铝液表面附近电解质熔体中的高浓度NaF能以较快的速度传质到电解质熔体中。由于在TiB2/G泄流式阴极的表面只存在铝液滞流流动,而没有波动,因此在TiB2/G泄流式阴极电解槽中,TiB2/G阴极表面的电解质分子比要远高于目前工业电解槽中的阴极表面的电解质分子比。这可能是造成高阴极过电压的根本原因。为了证实这种结论,在电解停槽后,从TiB2/G阴极表面取电解质试样进行化学分析,其分子比在3.0以上。这样的电解质非常坚硬,熔点较高。在刨炉的过程中还发现石墨化阴极表面的TiB2/G层与石墨化阴极基体牢牢地结合在一起,而其TiB2/G阴极表面并非是一层铝液层,而是一个坚硬的电解质层,电解生成的铝通常以较大的铝珠形式存在于此阴极表面坚硬的固体电解质之上,如图7所示。这表明,在泄流式TiB2/G阴极铝电解槽经过一段电解时期后,阴极表面上所生成的铝并没有像预测的那样完全在阴极表面形成薄的铝液层顺着阴极斜坡而流下。

图 7 阴极表面的铝与电解质

Fig.7 Bath and Al on cathode surface

4 结论

1) 本研究进行1.54 A/cm2的高电流密度的泄流式TiB2/G石墨化阴极电解槽的电解实验,连续电解140 h,电解过程稳定,平均电流效率为86.5%。

2)采用表面粗糙化后再涂层的方法获得的泄流式阴极TiB2/G层,该涂层具有较高的寿命,受电解质熔体和铝液腐蚀而脱落的速度小,能有效地保护阴极基体。

3) 泄流式电解槽的阳极过电压和阴极过电压与对应的电极电流密度遵循塔菲尔方程式关系。其阳极过电压与工业电解槽相当,而阴极过电压比工业电解槽的高0.4 V左右。这可能是由于泄流式电解槽中不存在铝液波动,阴极表面附近的电解质分子比远高于工业电解槽阴极表面的电解质分子比。

REFERENCES

[1] DIONNE M, ESPERANCE G L, MIRCHI A. Microscopic characterization of a TiB2-carbon material composite: raw materials and composite characterization[J]. Metallurgical and Materials Transactions A, 2001, 32(10): 2649-2656.

[2] IBRAHIEM M O, FOOSN?S T, ?YE H A. Stability of TiB2-C composite coatings[C]//GALLOWAY T J. Light Metals. San Antonio: TMS, 2006: 691-696.

[3] PAWLEK R P. Aluminium wettable cathodes: An update[C]// PETERSON R D. Light Metals. Warrendale: TMS, 2000: 449-454.

[4] MCCLUNG M, BROWNING J, CARTE S, LIGHTLE C, LOVE R O, ZERKLE R. Plant experience with an experimental titanium diboride cell[C]//TABEREAUX A T. Light Metals. Warrendale: TMS, 2004: 399-404.

[5] KENIRY J. The economics if inert anodes and wettable cathodes for aluminum reduction cells[J]. JOM, 2001, 53(5): 43-47.

[6] LI Jie, L? Xiao-jun, LI Qing-yu, LAI Yan-qing, YANG Jian-hong. Electrical resistivity of TiB2/C composite cathode coating for aluminum electrolysis[J]. Journal of Central South University of Technology, 2006, 13(3): 209-213.

[7] LI Qing-yu, LAI Yan-qing, LI Jie, YANG Jian-hong, FANG Jing, CHEN Zhu. The effect of sodium-containing additives on the sodium-penetration resistance of TiB2/C composite cathode in aluminum electrolysis[C]//KVAND H. Light Metals. San Francisco: TMS, 2005: 789-791.

[8] LAI Yan-qing, LI Qing-yu, YANG Jian-hong, LI Jie. Ambient temperature cured TiB2 cathode coating for aluminum electrolysis[J]. Transaction of Nonferrous Metals Society of China, 2003, 13(3): 704-707.

[9] 冯乃祥. 冰晶石熔体和金属Na在铝电解阴极碳块中的共同渗透[J]. 金属学报, 1999, 35(6): 611-617.

FENG Nai-xiang. Penetration of cryolite melt and sodium into cathode carbon blocks during electrolysis[J]. Journal of Metals, 1999, 35(6): 611-617.

[10] 冯乃祥, 姜东涛. 铝电解槽TiB2/C阴极材料的研究[J]. 炭素技术, 1992, 10(6) : 23-27.

FENG Nai-xiang, JIANG Dong-tao, Investigation of TiB2/C composite cathode for aluminium cell[J]. Carbon Techniques, 1992, 10(6): 23-27.

[11] FENG Nai-xiang, KVANDE H. Penetration of sodium and molten bath into high pressure baked cathode block[J]. Aluminum, 1997, 73(4): 836-839.

[12] 段学良, 冯乃祥, 吴建国, 戚喜全, 彭建平, 苏世杰. TiB2/C复合材料阴极在电解过程中的膨胀和对钠的渗透性研究[J]. 材料与冶金学报, 2004, 3(1): 30-34.

DUAN Xue-liang, FENG Nai-xiang, WU Jian-guo, QI Xi-quan, PENG Jian-ping, SU Shi-jie. Study on expansibility of TiB2-C compound and Na penetration in electrolyzation[J]. Journal of Materials and Metallurgy, 2004, 3(1): 30-34.

[13] LI X P, LI J, LAI Y Q, ZHAO H Q, LIU Y X. Freeze profile and heat balance calculation of the 160 kA drained cell[J]. Acta Metallurgica Sinica, 2004, 17(2): 215-220.

[14] LI Xiang-peng, LI Jie, LAI Yan-qing, ZHAO Heng-qin, LIU Ye-xiang. Mathematical simulation of gas induced bath flow in drained aluminum reduction cell[J]. Transaction of Nonferrous Metals Society of China, 2004, 14(6): 1222-1226.

[15] ZHOU Ping, WANG Zhi-qi, ZHOU Nai-jun. Numerical simulation of temperature field during gas preheating and start-up of drained aluminum reduction cell[J]. Transaction of Nonferrous Metals Society of China, 2006, 16(4): 960-964.

[16] ZHOU Nai-jun, MEI Chi, JIANG Chang-wei, ZHOU Ping, LI Jie. Couple computation method of physics fields in aluminum reduction cell[J]. Transaction of Nonferrous Metals Society of China, 2003, 13(2): 431-437.

[17] LIU Ye-xiang, LI Xiang-peng, LAI Yan-qing, LI Jie, ZHOU Xiang-yang, ZHAO Heng-qin. Heat balance simulation of drained aluminum reduction cell[J]. Transaction of Nonferrous Metals Society of China, 2003, 13(5): 1199-1202.

[18] KVANDE H. The 6th australasian aluminium smelting technology conference and workshop[J]. Light Metal Age, 1999(2): 68-77.

[19] 冯乃祥, 戚喜全, 彭建平. 1.35 kA TiB2/C阴极泄流式铝电解槽电解实验[J]. 中国有色金属学报, 2005, 15(12): 2047-2053.

FENG Nai-xiang, QI Xi-quan, PENG Jian-ping. Electrolysis test of 1.35 kA drained cathode reduction cell with TiB2-coated cathode[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 2047-2053.

[20] 冯乃祥. 铝电解[M]. 北京: 化学工业出版社, 2006: 68-73.

FENG Nai-xiang. Aluminum electrolysis[M]. Beijing: Chemical Industry Press, 2006: 68-73.

基金项目:国家自然科学基金资助项目(50274031);高等学校博士学科点专项科研基金资助项目(20050145005)

收稿日期:2007-07-26;修订日期:2007-12-26

通讯作者:彭建平,博士研究生;电话:024-83686463;E-mail: pengjp@smm.neu.edu.cn

(编辑 何学锋)