不同应变率下热压缩双辊轧制Mg-5.51Zn-0.49Zr合金动态再结晶的位错机制

来源期刊:中国有色金属学报(英文版)2016年第2期

论文作者:刘志义 黄田田 刘文娟 Sukbong KANG

文章页码:378 - 389

关键词:镁合金;位错;机制;动态再结晶

Key words:magnesium alloy; dislocation; mechanism; dynamic recrystallization

摘 要:通过X射线衍射仪、光学显微镜和透射电镜研究Mg-5.51Zn-0.49Zr镁合金在热压缩实验中动态再结晶的位错机制。结果表明,当应变速率为1×10-3 s-1时,由于位错攀移沿单一方向滑动,合金出现连续动态再结晶;当热压缩温度达到350 °C、应变速率为1×10-2 s-1时,由于位错发生滑移和攀移,合金出现连续动态再结晶;当热压缩温度达到400 °C时,由于亚晶界弓出,合金出现不连续动态再结晶;当应变速率为1×100 s-1时,合金出现连续动态再结晶是由于先导位错在堆积前发生攀移,导致位错在堆积过程中重新排列,形成位错差。一般来说,当应变速率增加时,位错攀移的主要影响机制由空位迁移转变为堆积前先导位错的压应力作用。

Abstract: Dislocation mechanism operating in dynamic recrystallization (DRX) during hot compression of Mg-5.51Zn-0.49Zr alloy was investigated by X-ray diffraction, optical microscopy and transmission electron microscopy. The results showed that the continuous DRX occurred at a low strain rate of 1×10-3 s-1, which was associated with the operation of the single gliding dislocation climbing. At the intermediate strain rate of 1×10-2 s-1, the continuous DRX was associated with the climbing of the gliding dislocation array as deformed at an elevated temperature of 350 °C, and in contrast, the discontinuous DRX was observed and associated with the bulging of subgrain boundaries as the deformation temperature was raised to 400 °C. The continuous DRX was associated with the climbing of the leading dislocation ahead of pile-ups, and resultant rearrangement of misorientated flat dislocation pile-ups as the strain rate was increased to 1×100 s-1. It is suggested that the mechanism predominating the dislocation climbing was changed from the vacancy migration to the stress acting on the leading dislocation ahead of the pile-up as the strain rate was gradually increased.

Trans. Nonferrous Met. Soc. China 26(2016) 378-389

Zhi-yi LIU1,2, Tian-tian HUANG1,2, Wen-juan LIU1,2, Sukbong KANG3

1. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. Korea Institute of Materials Science, Changwon 641010, Korea

Received 5 January 2015; accepted 10 December 2015

Abstract: Dislocation mechanism operating in dynamic recrystallization (DRX) during hot compression of Mg-5.51Zn-0.49Zr alloy was investigated by X-ray diffraction, optical microscopy and transmission electron microscopy. The results showed that the continuous DRX occurred at a low strain rate of 1×10-3 s-1, which was associated with the operation of the single gliding dislocation climbing. At the intermediate strain rate of 1×10-2 s-1, the continuous DRX was associated with the climbing of the gliding dislocation array as deformed at an elevated temperature of 350 °C, and in contrast, the discontinuous DRX was observed and associated with the bulging of subgrain boundaries as the deformation temperature was raised to 400 °C. The continuous DRX was associated with the climbing of the leading dislocation ahead of pile-ups, and resultant rearrangement of misorientated flat dislocation pile-ups as the strain rate was increased to 1×100 s-1. It is suggested that the mechanism predominating the dislocation climbing was changed from the vacancy migration to the stress acting on the leading dislocation ahead of the pile-up as the strain rate was gradually increased.

Key words: magnesium alloy; dislocation; mechanism; dynamic recrystallization

1 Introduction

Magnesium alloys are one of the lightest structural metal materials. However, most of them have poor formability at room temperature due to their hexagonal crystal structure lack of sufficient independent slip system. Fortunately, pyramidal plane slip <c+a> can be activated at elevated temperatures, which together with twinning provides plastic deformation along c axis besides basal plane slip, and prismatic plane slip allows a plastic contribution along <a> direction. Accordingly, investigations on microstructural evolution and deformation mechanism at elevated temperatures have received more and more attention in recent years [1-18]. Recrystallization is an important microstructural phenomenon and has a significant effect on flow behavior during hot deformation of magnesium alloys. Since ION et al [19] proposed a rotational dynamic recrystallization (RDRX), a kind of continuous dynamic recrystallization (CDRX), from pioneer’s work on recrystallization in magnesium alloy in 1982, a great effort has been made to investigate the recrystallization mechanism [20-29]. Most of them were focused on the effect of deformation temperature during hot deformation. KAIBYSHEV et al [30], for instance, conducted an investigation on low-temperature DRX at ambient temperature for producing nanoscale structure in magnesium alloy in 1995. In their work, the formation of small recrystallized grains was attributed to the rearrangement of misorientated flat dislocation pile-ups. GALIYEV et al [22], after investigating the mechanisms of DRX in different ranges of deformation temperature in 2001, summarized the results as follows: 1) Low temperature DRX (LTDRX below 473 K) was associated with the operation of twinning, basal slip and (a+c) dislocation glide; 2) In the intermediate temperature range (473-523 K), CDRX was observed and associated with extensive dislocation cross-slipping due to the Friedel–Escaig mechanism; 3) At temperatures ranging from 573 to 723 K, both bulging of original grain boundaries and subgrain growth were the operating DRX mechanisms and controlled by dislocation climb. From the conclusions drawn by GALIYEV et al [22] and KAIBYSHEV et al [30], it can be seen that the operating DRX mechanism is associated with the dislocation gliding mode. YANG et al [13] have recently suggested that the formation of newly recrystallized grains is dependent on a deformation-induced continuous reaction, which is controlled by straining, and in agreement with Ref. [22,30].

All the previous researches stated above were focused on the effect of deformation temperature and straining on DRX mechanism during hot deformation. Generally, like the deformation temperature and straining, the strain rate, as another deformation parameter, also has a significant effect on dislocation slipping mode and subsequent operating DRX mechanism. Our previous work [31] demonstrated that the low-temperature DRX, which was only observed at ambient temperature [30], occurred at elevated deformation temperatures up to 350 and 400 °C when a high strain rate up to 1×100 s-1 was employed. This suggested that the operating DRX mechanism during hot deformation was greatly influenced by the strain rate externally applied. So far, however, no systematic investigation on the strain rate effect on the dislocation slipping mode and operating DRX mechanism in magnesium alloys has been reported. The present work, therefore, taking twin-roll casting ZK60 alloy as experimental material, aimed at investigating the strain rate effect on dislocation mechanism for DRX during hot deformation by employing the strain rate ranging from 1×10-3 s-1 to 1×100 s-1.

2 Experimental

The material employed in present study was commercial magnesium alloy ZK60, with chemical composition of Mg-5.51Zn-0.49Zr (mass fraction, %). The alloy was obtained in the form of as-twin-rolled casting strip with a thickness of 3.0 mm. Plate-form specimens with a length of 50 mm, a width of 20 mm and a thickness of 3 mm were machined from the strip for uniaxial compression tests. Uniaxial compression tests were performed at temperatures of 350 and 400 °C and strain rates ranging from 1.0×10-3 to 1.0×100 s-1 with final true strain of 0.511. The stress was employed in the direction of thickness during hot compression for simulating the subsequent rolling process of the twin-roll casting strip. The specimens were immediately quenched by nitrogen gas after hot compression in order to prevent the microstructure from changing. Texture measurements were carried out by the Schulz reflection method using nickel-filtered Cu Kα radiation. The measurements were conducted on the mid-plane sections. (0002) pole figure for the twin-roll casting strip was constructed using diffracted X-ray intensities measured on (0002) reflection. Specimens for microstructural observation were cut from the strip along the plane formed by the rolling and normal direction, and mechanically ground using emery papers up to 1200 grit followed by final polishing on a Struers OP-Chem polishing cloth using polishing suspension OP-S. The grain structure was revealed by etching for optical microscopy, using a solution of ethanol (50 mL), picric acid (3 g), acetic acid (20 mL) and water (20 mL). The optical microstructures in the center of the samples deformed at different strain rates, as well as the as-received sample, were examined. The TEM microstructure examination of the deformed samples was performed on a JEM-2000FXⅡ instrument. Two-beam technique was employed to distinguish basal slipping and non-basal slipping during hot compression. TEM samples were prepared by cutting from the deformed sample along the plane perpendicular to applied stress direction. Foils were mechanically ground to about 0.1 mm, and electrolytically polished to a thickness suitable for analysis by the window method with a solution of 5% HClO4, 35% butanol and 60% methanol at 10 V while keeping the electrolyte at 20 °C.

3 Results and discussion

3.1 (0002) pole figure and optical microstructure of as-twin-rolled casting ZK60 strip

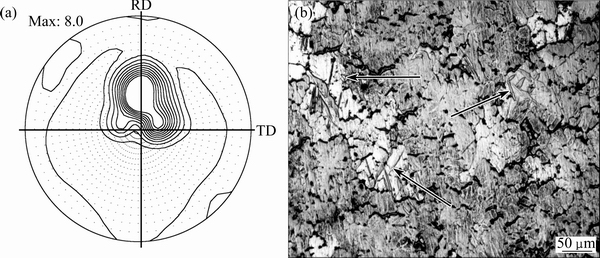

(0002) pole figure of as-twin-rolled casting ZK60 strip is shown in Fig. 1(a), which illustrated the main component of (0001) crystal plane deviating 35° from the normal direction. Furthermore, the normal direction of the (0001) plane inclines towards the rolling direction. The optical microstructure along the plane formed by rolling and normal direction of the strip is shown in Fig. 1(b), illustrating fine dentrite of 10-15 μm in size and a small amount of twins arrowed in Fig. 1(b).

3.2 Stress-strain curves

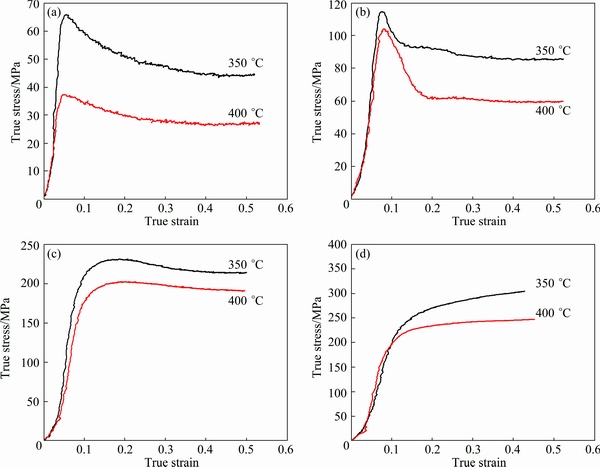

The stress-strain curves at elevated deformation temperatures of 350 and 400 °C and constant strain rates of 1×10-3-1×100 s-1 are plotted in Fig. 2. All the stress-strain curves, except that deformed at the high strain rate of 1×100 s-1, show a softening flow behavior, which was followed by a steady state flow, as shown in Figs. 2(a)-(c). This suggested that the dislocation density in samples reduced with increasing strain during softening flow, and kept a constant dislocation density during subsequent steady flow. Figures 2(a)-(c) show that the stress drops in the stress-strain curves reduced with increasing strain rate. Moreover, the largest stress drop occurred as compressed at a strain rate of 1×10-2 s-1 and an elevated temperature of 400 °C (Fig. 2(b)). The stress drop before the steady flow appeared, which generally suggested a degradation of dislocation density during hot compression. The larger the stress drop is, the greater the degradation of dislocation density is. The increasing dislocation number caused by hot deformation must be in a dynamic balance with the decreasing one due to dynamic recrystallization during steady flow, leading to a constant dislocation density. In contrast, a flow-hardening behavior appeared when samples were compressed at a strain rate of 1×100 s-1, as shown in Fig. 2(d). The hardening flow implied that the dislocation density increased with increasing strain during hot compression. Figure 2, thus, suggested that different kinds of DRX predominated the hot deformation when different strain rates were employed.

Fig. 1 (0002) pole figure (a) and micrograph (b) of as-twin-rolled casting strip of ZK60 alloy

Fig. 2 Stress-strain curves compressed at deformation temperatures of 350, 400 °C and different strain rates of 1×10-3 s-1 (a), 1×10-2 s-1 (b), 1×10-1 s-1 (c) and 1×100 s-1 (d)

3.3 Optical microstructure

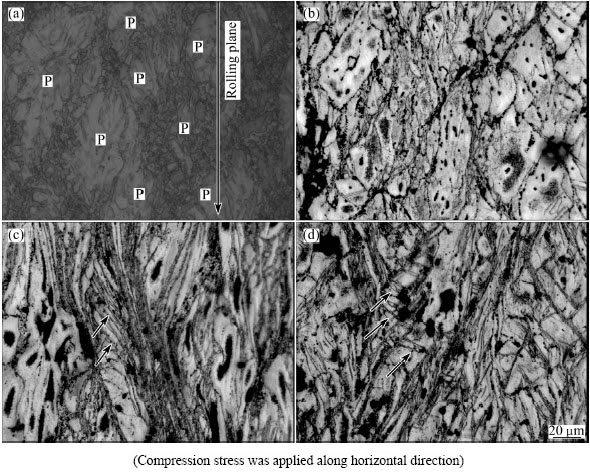

Figure 3(a) shows the optical microstructure of the sample compressed at a constant strain rate of 1×10-3 s-1 and an elevated temperature of 350 °C, showing that almost undeformed dendrite grains, marked as P, and recrystallized grains formed at grain boundaries. The recrystallized grains were distributed around dendrite grains, resulting in the formation of a successive necklace of recrystallized grains. Dendrite grains were apparently elongated as compared with Fig. 3(a) while small size recrystallized grains formed at the grain boundary when compressed at a strain rate of 1×10-2 s-1, as shown in Fig. 3(b). Dynamically recrystallized grains formed in slip band, as well as in the twinning-grains pointed by arrows, besides the dendrite grains were severely elongated when the strain rate was raised to 1×10-1 s-1 and 1×100 s-1, respectively, as shown in Figs. 3(c) and (d). Less boundary migration accompanied the formation of new recrystallized grains when hot compressed at higher strain rates of 1×10-1 s-1 and 1×100 s-1, respectively, as compared with Figs. 3(a) and (b).

Fig. 3 Optical microstructures of specimens compressed at 350 °C and different constant strain rates of 1×10-3 s-1 (a), 1×10-2 s-1 (b), 1×10-1 s-1 (c) and 1×100 s-1 (d)

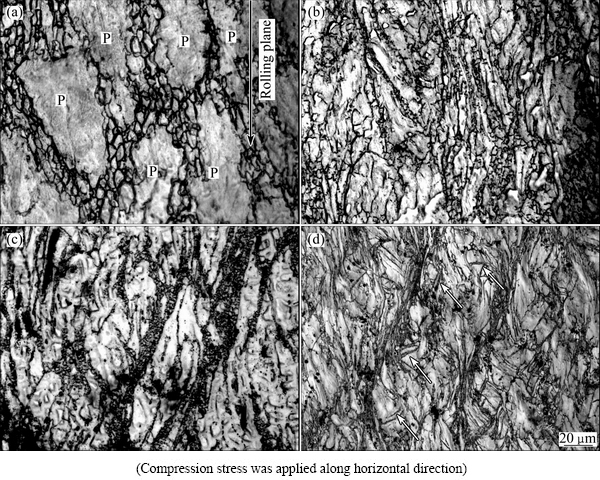

Fig. 4 Optical microstructures of specimens compressed at 400 °C and different constant strain rates of 1×10-3 s-1 (a), 1×10-2 s-1 (b), 1×10-1 s-1 (c) and 1×100 s-1 (d)

Figure 4 shows the optical microstructure compressed at 400 °C and strain rate range of 1×10-3- 1×100 s-1. In Fig. 4(a), the recrystallized grains were observed to form around parent grains marked as P, when compressed at a strain rate of 1×10-3 s-1. This led to the formation of the necklace of recrystallized grains similar to Fig. 3(a). Compared with Fig. 3(a), Fig. 4(a) showed that more evident boundary migration occurred when deformed at 400 °C, resulting in more equiaxed recrystallized grains at grain boundary. This was attributed to the greater thermal activation caused by the deformation temperature as high as 400 °C. Similarly, dendrite grains were elongated, and numerous smaller recrystallized grains formed when the strain rate was raised to 1×10-2 s-1 (Figs. 4(a) and (b)), as compared with Figs. 3(a) and (b). The formation of smaller recrystallized grains was attributed to the little boundary migration, which was caused by the time-dependent atom diffusion as the strain rate was increased. Like the deformation at 350 °C, dynamically recrystallized grains also formed in slip band, as well as in twinning-grains pointed by white arrows in Fig. 4(d), when hot compressed at an elevated temperature of 400 °C and strain rates of 1×10-1s-1 and 1×100 s-1 (see Figs. 4(c) and (d)).

As can be seen in Fig. 1(a), the main component of (0001) crystal plane of as-received strip deviates 35° from the rolling plane. The compressive stress externally applied in present work, is normal to the strip plane, i.e., horizontal direction as shown in Figs. 3 and 4. In this case, the (0001) crystal plane is close to the maximum shear stress direction (45°). Basal-slipping accommodated by non-basal slipping, therefore, readily occurred, which contributed to the formation of slip band and resultant recrystallized grains in slip band, as shown in Figs. 3(c), (d) and Figs. 4(c), (d). This was confirmed by our previous work [31]. It was worthy to note that Figs. 3(c) and 4(c) corresponded to the flow-softening behavior in Fig. 2(c), whereas, Figs. 3(d) and 4(d) to the flow-hardening behavior shown in Fig. 2(d), although all of them showed the dynamic recrystallization occurring in slip band. Evidently, the dislocation multiplication rate was smaller than the dislocation annihilation rate when compressed at a strain rate of 1×10-1 s-1, resulting in the degradation of dislocation density and resultant flow-softening behavior in the former case. In contrast, the dislocation multiplication rate became greater than its annihilation rate as the externally applied strain rate was raised to 1×100 s-1. This, therefore, led to the flow-hardening behavior in the later case. From Figs. 3 and 4, it was suggested that different kinds of dynamic recrystallization occurred when hot compressed at different strain rates. Nevertheless, the mechanism for dynamic recrystallization, in fact, depended on operating dislocation mechanism. It is necessary, therefore, to identify the operating dislocation mechanism during dynamic recrystallization.

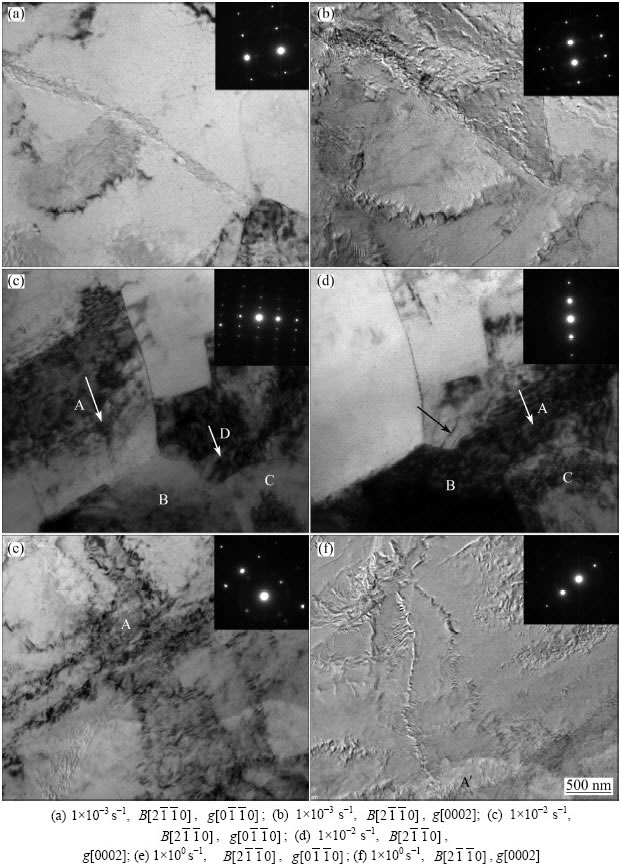

Fig. 5 TEM images under two-beam diffraction patterns of samples compressed at 350 °C and different strain rates

3.4 TEM microstructure

Figures 5(a), (c), (e) and Figs. 6(a), (c), (e) show TEM images when two-beam diffraction parameters of  and

and  were employed, by which only basal segment of dislocations was visible in those figures. Correspondingly, Figs. 5(b), (d), (f) and Figs. 6(b), (d), (f) show TEM images under two beam diffraction patterns of

were employed, by which only basal segment of dislocations was visible in those figures. Correspondingly, Figs. 5(b), (d), (f) and Figs. 6(b), (d), (f) show TEM images under two beam diffraction patterns of  and

and  therefore, only showing non-basal segment of dislocations. Figures 5(a) and (b) respectively show basal and non-basal dislocations forming subgrain boundaries during hot compression at a strain rate of 1×10-3 s-1 and an elevated temperature of 350 °C. The subgrain boundary was poorly developed, consisting of the recrystallized grains with non-equilibrium boundary around dendrite grains P(Fig. 3(a)). No bulging of grain boundaries was found in Figs. 5(a) and (b), suggesting a continuous dynamic recrystallization (CDRX) occurring under this deformation condition. The formation of the successive necklace of new recrystallized grains around the parent grains shown in Figs. 3(a) and 4(a), thus, was attributed to the CDRX occurring in twin-roll casting Mg-5.51%Zn-0.49%Zr alloy, although WANG et al [29] claimed that the necklace of recrystallized grains could form as a result of the discontinuous DRX in Cu, Ni and γ-Fe. Figures 5(c) and (d) show the recrystallized grains, as marked by B and C, formed during hot deformation at a strain rate of 1×10-2 s-1 and an elevated temperature of 350 °C. Basal and non-basal dislocation glided in grains A and D in Fig. 5(c) and grain A in Fig. 5(d), respectively. Gliding direction of dislocations was pointed by white arrows in Figs. 5(c) and (d). It is worthy to note that a non-basal dislocation was climbing into the boundary of the recrystallized grain B in Fig. 5(d), as pointed by black arrow. This is a solid evidence for both gliding basal dislocation and non-basal dislocation climbing into the boundary of the recrystallized grains marked as B and C in Figs. 5(c) and (d). This resulted in grain boundary tilting and progressive grain rotation during hot compression at 350 °C with a strain rate of 1×10-2 s-1. In addition, no bulging of the recrystallized grain boundaries was found in Figs. 5(c) and (d). There is no doubt that the dynamic recrystallization occurring in Figs. 5(c) and (d), is a kind of continuous DRX, although it is difficult to be identified as a rotational dynamic recrystallization(RDRX) proposed by ION et al [19]. Figure 5(e) revealed that misorientated flat dislocation pile-ups, which were composed of basal segments of dislocations, formed when hot compressed at a strain rate of 1×100 s-1 and an elevated temperature of 350 °C. At the junction of misorientated flat dislocation pile-ups, a small subgrain, marked as A, was formed. Also, non-basal dislocations were found to construct dislocation pile-ups when diffraction parameters of

therefore, only showing non-basal segment of dislocations. Figures 5(a) and (b) respectively show basal and non-basal dislocations forming subgrain boundaries during hot compression at a strain rate of 1×10-3 s-1 and an elevated temperature of 350 °C. The subgrain boundary was poorly developed, consisting of the recrystallized grains with non-equilibrium boundary around dendrite grains P(Fig. 3(a)). No bulging of grain boundaries was found in Figs. 5(a) and (b), suggesting a continuous dynamic recrystallization (CDRX) occurring under this deformation condition. The formation of the successive necklace of new recrystallized grains around the parent grains shown in Figs. 3(a) and 4(a), thus, was attributed to the CDRX occurring in twin-roll casting Mg-5.51%Zn-0.49%Zr alloy, although WANG et al [29] claimed that the necklace of recrystallized grains could form as a result of the discontinuous DRX in Cu, Ni and γ-Fe. Figures 5(c) and (d) show the recrystallized grains, as marked by B and C, formed during hot deformation at a strain rate of 1×10-2 s-1 and an elevated temperature of 350 °C. Basal and non-basal dislocation glided in grains A and D in Fig. 5(c) and grain A in Fig. 5(d), respectively. Gliding direction of dislocations was pointed by white arrows in Figs. 5(c) and (d). It is worthy to note that a non-basal dislocation was climbing into the boundary of the recrystallized grain B in Fig. 5(d), as pointed by black arrow. This is a solid evidence for both gliding basal dislocation and non-basal dislocation climbing into the boundary of the recrystallized grains marked as B and C in Figs. 5(c) and (d). This resulted in grain boundary tilting and progressive grain rotation during hot compression at 350 °C with a strain rate of 1×10-2 s-1. In addition, no bulging of the recrystallized grain boundaries was found in Figs. 5(c) and (d). There is no doubt that the dynamic recrystallization occurring in Figs. 5(c) and (d), is a kind of continuous DRX, although it is difficult to be identified as a rotational dynamic recrystallization(RDRX) proposed by ION et al [19]. Figure 5(e) revealed that misorientated flat dislocation pile-ups, which were composed of basal segments of dislocations, formed when hot compressed at a strain rate of 1×100 s-1 and an elevated temperature of 350 °C. At the junction of misorientated flat dislocation pile-ups, a small subgrain, marked as A, was formed. Also, non-basal dislocations were found to construct dislocation pile-ups when diffraction parameters of  and

and were employed. Under this diffraction condition, a new subgrain marked as A′, was observed at the end of dislocation pile-ups, as shown in Fig. 5(f). The formation of new recrystallized grains at both junction and end of misorientated flat dislocation pile-ups, as shown in Figs. 5(e) and (f), consisted with the results as shown in Figs. 3(d) and 4(d), where recrystallized grains formed in slip band. Researchers in Refs. [1-3,9] have already demonstrated that this kind of dynamic recrystallization was caused by dislocation pile-up rearrangement, although their work was conducted below 200 °C. In fact, the deformation temperature as high as 350 °C and 400 °C employed in present work, could greatly facilitate the dislocation pile-up rearrangement. In addition, the formation of the dislocation pile-up produced a long-range stress field, and resulted in strain-hardening effect shown in Fig. 2(d), during hot compression. All these are in agreement with the characteristics described in Refs. [1-3,9].

were employed. Under this diffraction condition, a new subgrain marked as A′, was observed at the end of dislocation pile-ups, as shown in Fig. 5(f). The formation of new recrystallized grains at both junction and end of misorientated flat dislocation pile-ups, as shown in Figs. 5(e) and (f), consisted with the results as shown in Figs. 3(d) and 4(d), where recrystallized grains formed in slip band. Researchers in Refs. [1-3,9] have already demonstrated that this kind of dynamic recrystallization was caused by dislocation pile-up rearrangement, although their work was conducted below 200 °C. In fact, the deformation temperature as high as 350 °C and 400 °C employed in present work, could greatly facilitate the dislocation pile-up rearrangement. In addition, the formation of the dislocation pile-up produced a long-range stress field, and resulted in strain-hardening effect shown in Fig. 2(d), during hot compression. All these are in agreement with the characteristics described in Refs. [1-3,9].

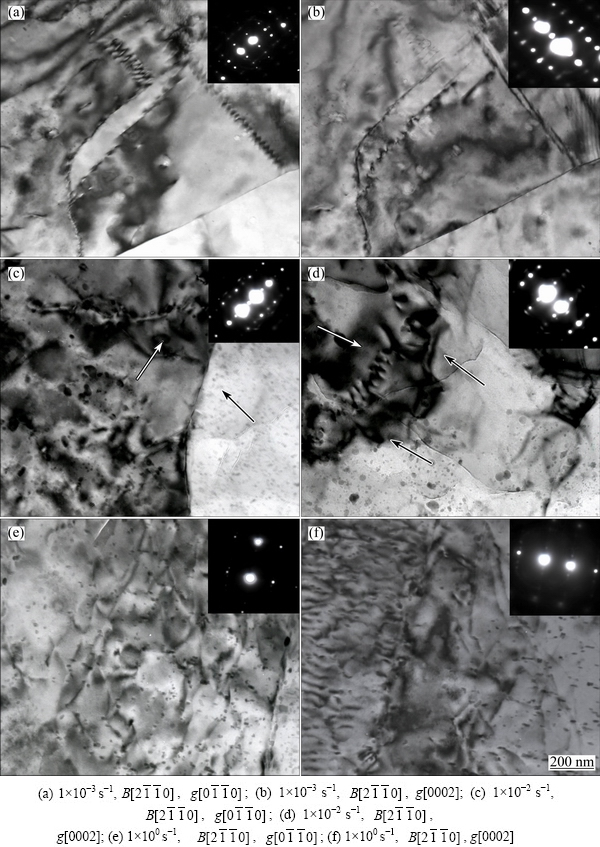

Figure 6(a) and (b) respectively show basal dislocation and non-basal dislocation constructed subgrain boundaries when compressed at a strain rate of 1×10-3 s-1 and an elevated temperature of 400 °C. Compared with Figs. 5(a) and (b), the subgrain boundary shown in Figs. 6(a) and (b), was well developed during hot compression at 400 °C, which was in agreement with the straight recrystallized grain boundaries shown in Fig. 4(a). This was attributed to the high thermal activation externally provided. Few dislocations were accumulated in front of the subgrain boundary. This suggested that the subgrain boundary readily formed by dislocation gliding and climbing. In addition, no bulging of grain boundary was found in Figs. 6(a) and (b), suggesting that continuous DRX occurred during hot compression. Nevertheless, Figs. 6(c) and (d) show an evident bulging of subgrain boundaries when hot compressed at a strain rate of 1×10-2 s-1 and an elevated temperature of 400 °C. This suggested discontinuous DRX occurring under this deformation condition. From Figs. 6(c) and (d), it can be seen that both basal and non-basal dislocations, as pointed by white arrows respectively in Figs. 6(c) and (d), were accumulated in front of migrating subgrain boundaries when an increasing strain rate (1×10-2 s-1) was employed. The migrating direction of the subgrain boundary was pointed by black arrows in Figs. 6(c) and (d). This undoubtedly enhanced the driving force for migration of subgrain boundaries. The bulging of subgrain boundaries (Figs. 6(c) and (d)), thus, was induced, leading to the degradation of dislocation density and the resultant greatest stress drop shown in Fig. 2. By comparing Figs. 5(c) with (d), high deformation temperature up to 400 °C facilitated the migration of the recrystallized grain boundary in Figs. 6(c) and (d). This contributed to the bulging of subgrain boundaries. Correspondingly, no bulging of recrystallized grain boundaries occurred in Figs. 5(c) and (d) due to a lower deformation temperature employed and less thermal activation. Figures 6(e) and (f) show dislocation pile-ups formed as hot compressed at a strain rate of 1×100 s-1 and an elevated deformation temperature of 400 °C. This corresponded to the slip band shown in Fig. 4(d). Nevertheless, the dislocation pile-up was mainly constructed by non-basal dislocations as shown in Fig. 6(f) , which was different from the hot deformation at 350 °C (Figs. 5(e) and (f)). This was probably related to the reduction in critical resolved shear stress (CRSS) for non-basal slipping when the deformation temperature was raised [30-33]. Dislocation pile-ups constructed by either basal dislocation or non-basal dislocation produced long-range stress field, resulting in strain- hardening effect, as shown in Fig. 2(d). Also, the formation of new recrystallized grains depended on the rearrangement of dislocation pile-ups, as described by KAIBYSHEV et al [30]. This was in agreement with the result hot-deformed at 350 °C (Figs. 5(e) and (f)). As claimed by researchers in Refs. [30,34-38], this is a kind of continuous DRX.

Fig. 6 TEM images under two-beam diffraction patterns of samples compressed at 400 °C and different strain rates

In fact, the free energy change during the rearrangement of the dislocation pile-ups and climbing force of the leading dislocation ahead of the pile-up were calculated in our previous work [31], demonstrating that the rearrangement of the dislocation pile-ups was attributed to the climbing of the leading dislocation ahead of the pile-up. This was caused by the externally applied stress and thermal activation, rather than cross-slipping of the leading dislocation ahead of the pile-up by the externally applied stress alone during the low-temperature DRX, suggested by GALIYEV et al [22], even though the same characteristics such as the low-temperature DRX described in Refs. [1-3,9], were presented with the strain rate raising to 1×100 s-1.

The dislocation behavior during hot compression at different strain rates, therefore, could be summarized as follows. 1) At a low strain rate of 1×10-3 s-1, single gliding dislocations climb into subgrain boundaries when deformed at both 350 °C and 400 °C, resulting in a progressive increasing misorientation of the subgrain boundary and resultant continuous DRX. This corresponded to the successive necklace of new recrystallized grains around parent grains. 2) At a intermediate strain rate of 1×10-2 s-1, the leading dislocations of the gliding dislocation array climbed into subgrain boundaries in sequence when deformed at 350 °C, resulting in the occurrence of the continuous DRX. Nevertheless, gliding dislocations were accumulated in front of the subgrain boundaries, which induced the bulging of subgrain boundaries due to an enhanced thermal activation when the deformation temperature was raised to 400 °C, showing a discontinuous DRX. 3) At a high strain rate of 1×100 s-1, the misorientated flat dislocation pile-ups formed, and subsequent new recrystallized grains formed at both junction and end of misorientated dislocation pile-ups as a result of the rearrangement of the pile-up. This corresponded to the dynamic recrystallization occurring in slip band as shown in Figs. 3(d) and 4(d). Also, it has already been recognized as a kind of continuous DRX.

4 Discussion

From the results presented above, the continuous DRX was the dominant microstructural evolution during hot compression of twin-roll-cast ZK60 strip except as-hot-compressed at an elevated deformation temperature of 400 °C and a strain rate of 1×10-2 s-1. The formation of the subgrain boundaries during the continuous DRX was due to the climbing of gliding dislocations as compressed at a lower strain rate of 1×10-3 s-1, as-well as an intermediate strain rate of 1×10-2 s-1 and a lower deformation temperature of 350 °C. This was confirmed by the well-developed subgrain boundaries formed at relatively high deformation temperature of 400 °C, by comparing with the result at 350 °C, as shown in Figs. 3(a)-(d) and Figs. 4(a), (b), respectively. WEERTMAN and MECH [39] and WONG and JONAS [40] already confirmed that subgrains formed in creep by the climbing of dislocations were consistent with activation energy as for vacancy migration. This consisted with the results in present work. Gliding dislocations continued climbing at the subgrain boundaries after subgrains formed, leading to the increase of the misorientation of the subgrain boundaries. The climbing of gliding dislocations, therefore, was the operating mechanism for the continuous DRX occurring in Figs. 3(a)-(d) and Figs.4(a), (b). The increase of the misorientation of the recrystallized grain boundary was certainly accompanied by grain boundary migration, as shown in Figs. 3 and 4. The grain boundary migration, however, became difficult due to its time-dependence as the strain rate employed was raised, as shown in Figs. 3(a), (b) and Figs. 4(a), (b).

The misorientated flat dislocation pile-ups formed as the strain rate was raised to 1×100 s-1, as shown in Figs. 3(e), (f) and Figs. 4(e), (f). In this case, the formation of new recrystallized grains depended on the climbing of the leading dislocation ahead of the pile-ups and the resultant rearrangement of the dislocation pile-ups, which was confirmed by Ref. [31]. The characteristics of this kind of continuous DRX occurring at a strain rate as high as 1×100 s-1 were the same as that of the low-temperature DRX described in Ref. [3]. However, the rearrangement of the dislocation pile-ups was predominated by the climbing of the leading dislocations in present work, rather than the leading dislocation cross-slipping as deformed at ambient temperature [3]. This was attributed to the difference of the deformation temperature between the present work and work in Ref. [30]. Evidently, the deformation temperatures as high as 350 and 400 °C employed in present work, facilitated the climbing of the leading dislocations and resultant rearrangement of the dislocation pile-ups.

As analyzed above, the formation of recrystallized grains depended on the accumulation of gliding dislocations during the continuous DRX occurring in the twin-roll casting Mg-5.51%Zn-0.49%Zr alloy, whether deformed at high strain rate or low strain rate. The recrystallized grain boundary formed by the dislocation accumulation has already been demonstrated in copper alloy by McQUEEN and BERGERSON [41] in 1972, as well as in the Al-Li-Cu-Mg-Zr alloy by LIU et al [42] in 1992, and in AZ31 alloy by YANG et al [13] in 2009. All of them were in agreement with the results in present work. In fact, the operating dislocation mechanism for the continuous DRX occurring at elevated deformation temperatures in present work, yet is different from the dynamic recovery (DRV) proposed by McQUEEN [32] or the low-temperature DRX described in Ref. [3], even as-deformed at high strain rates up to 1×100 s-1 . In present work, the operating dislocation mechanism for the continuous DRX, was the operation of the gliding dislocation climbing after subgrains formed. Both externally applied stress and thermal activation contributed to the gliding dislocation climbing. However, either the DRV or the low-temperature DRX respectively was associated with the dislocation cross-slipping and the dislocation rearrangement into a low-energy array. Only the externally applied stress contributed to the dislocation cross-slipping and subsequent rearrangement. Consequently, the microstructural evolution during hot compression of twin-roll casting ZK60 strip, except as-hot-compressed at an elevated deformation temperature of 400 °C and a strain rate of 1×10-2 s-1, therefore, is still defined as a continuous DRX, which is associated with the operation of the climbing of the single gliding dislocation or the leading dislocation ahead of the pile-up.

Commonly, the climbing of dislocations necessary for continuous DRX, is a rate-controlling process due to the slowest rate, as compared with the dislocation gliding or the dislocation cross-slipping during the formation of new recrystallized grains [32,43]. At a lower strain rate of 1×10-3 s-1, dislocations interact with dislocation wall in a single form, correspondingly in a pile-up form when a higher strain rate is employed. Moreover, the dislocation number of the pile-ups increases with increasing strain rate employed, as shown in Figs. 5(c), (d) and Figs. 5(e), (f). In this case, the subgrain boundary can be taken as a single array of dislocation wall, and correspondingly, the dislocation pile-up as a superdislocation for simplicity. The stress field created by the dislocation wall, therefore, is introduced for the lower strain rate deformation, while both the stress field created by the dislocation pile-up and the dislocation wall are introduced for the higher strain rate deformation. The shear component in the stress field of a single array of the dislocation wall can be expressed as [44]

(1)

(1)

(2)

(2)

where D is the dislocation spacing; ν is the Poisson ratio; μ is the shear modulus; b is the Burgers vector. Let y=0, Eq. (1) becomes

(3)

(3)

From Eq. (3), it can be seen that σxy decreases exponentially to zero with increasing x, thus expressing a short-range stress field. Taking first approximation of  when x is very small, Eq. (3) becomes

when x is very small, Eq. (3) becomes

(4)

(4)

Equation (4) suggests that σxy will be negative in case of x<0, providing an attractive force on moving dislocations with a positive Burgers vector; on the contrary, σxy will be positive when x>0, a repulsive force acting on the moving dislocation with the same Burgers vector. In the former case, the moving dislocations will be attracted into the dislocation wall, i.e., subgrain boundary, facilitating the occurrence of dynamic recrystallization. In the latter case, σxy greatly increases with reducing x. A great backward stress same as the σxy, therefore, will be correspondingly created to balance the external stress acting on the climbing dislocations as dislocations move close to the dislocation wall.

Consider a dislocation pile-up that is composed of N edge dislocations in the presence of a resolved external shear stress σ. This pile-up is taken as a superdislocation. Supposing the leading dislocation is fixed, the force acting on the leading dislocation can be expressed as [44]

τ=σN (5)

In the presence of both external normal stress σxy and vacancy concentration c (which is different from the standard-state concentration c0), the total climbing force (F) per unit length (L) acting on the climbing dislocation is [44]

(6)

(6)

where k is the Boltzmann constant; T is the thermodynamic temperature and Va is vacancy volume. Commonly, the shear stress is approximately taken as a half of normal one (σxy). Thus, σxy can be replaced by 2σ because the single gliding dislocation interacts with the dislocation wall when deformed at a low strain rate of 1×10-3 s-1, and correspondingly by 2τ due to the formation of the dislocation pile-up at a high strain rate of 1×100 s-1 was employed. Equation (6), therefore, can be respectively rewritten as Eqs. (7) and (8) for both cases

, for lower strain rate (7)

, for lower strain rate (7)

, for higher strain rate (8)

, for higher strain rate (8)

Equation (7) suggests that vacancy migration predominates the dislocation climbing due to a small stress effect during hot deformation at low strain rates. This confirms a relatively evident boundary migration occurring during dynamic recrystallization when deformed at low strain rates, as shown in Figs. 3(a) and 4(a). Comparing Eq. (7) with Eq.(8) suggests a great stress which is N times the stress term in Eq. (7), attributing to the formation of the dislocation pile-ups, predominates the climbing of the leading dislocation ahead of the pile-up because the vacancy migration reduces with increasing strain rate due to its time-dependence. This theoretically confirms little boundary migration occurring during the formation of new recrystallized grains in slip band when a high strain rate is employed, as shown in Figs. 3(d) and 4(d). Moreover, it is suggested that the mechanism or the driving force dominating the dislocation climbing is changed from the vacancy migration to the stress acting on the leading dislocation ahead of the pile-up as the strain rate is raised by comparing Eq. (7) with Eq. (8) .

Additionally, the deformation parameters corresponding to different kinds of DRX in present work were different from those presented by GALIYEV et al [22]. In present work, the deformation temperature where the continuous DRX occurred was 350 °C in the strain rate range of 1×10-3-1×100 s-1, and even 400 °C as the lowest strain rate of 1×10-3 s-1 and the highest one of 1×100 s-1 were respectively employed, much higher than that (<300 °C) reported in Ref. [22]. This is probably attributed to the difference in the initial grain size between the present work and work in Ref. [22]. In present work, the grain size was 10-15 μm, much smaller than that (~85 μm) in Ref. [22]. Both basal and non-basal dislocation gliding in neighbouring grains can readily occur when the grain size is small, especially at elevated deformation temperatures up to 350 °C and 400 °C. This can be confirmed by the subgrain boundaries and dislocation pile-ups constructed by both basal and non-basal dislocations shown in Figs. 3 and 4 during hot compression. SONG et al [45] has demonstrated that the dislocation gliding is the controlling deformation mechanism for the fine-grained twin-roll casting ZK60 alloy modified by a small content of Cu. Furthermore, Fig. 1 shows that the basal dislocation gliding of most grains, including neighboring grains, can readily occur due to their slip plane close to the maximum stress direction externally applied. The difference of the stored energy (i.e., dislocation density) between the neighbouring grains, thus, is reduced, which leads to a degradation of the driving force for the bulging of subgrain boundaries. In addition, smaller grain size implies more grain boundaries and more active thermal activation, facilitating the gliding dislocation climbing at the subgrain boundary. This reduces the gliding dislocation accumulation in front of the subgrain boundaries, resulting in the degradation of the driving force for the bulging of the subgrain boundary. The operating mechanism for the DRX, therefore, is changed from the bulging of subgrain boundaries to the gliding dislocation climbing at subgrain boundary, leading to the increase of the deformation temperature for the occurrence of the continuous DRX. PENG et al [46] demonstrated the deformation temperature that discontinuous DRX occurred was raised up to 400 °C in a fine-grained twin-roll casting magnesium alloy sheet, which is in agreement with the present work.

5 Conclusions

1) At a low strain rate of 1×10-3 s-1, the continuous DRX of the twin-roll casting Mg-5.51Zn-0.49Zr alloy was associated with the operation of single gliding dislocation climbing predominated by vacancy migration, by which, the new recrystallized grains accompanied by apparent boundary migration formed around parent grains, resulting in the formation of a successive necklace of recrystallized grains.

2) At an intermediate strain rate of 1×10-2 s-1, the continuous DRX was associated with the operation of dislocation climbing, both the vacancy migration and the stress acting on the leading dislocation of the dislocation array contributed to, and subsequently recrystallized grains accompanied by little boundary migration formed at grain boundaries as-deformed at an elevated temperature of 350 °C. In contrast, the discontinuous DRX was associated with the bulging of grain boundaries induced by both gliding dislocation accumulation in front of subgrain boundaries and enhanced grain boundary mobility attributing to the elevated deformation temperature as high as 400 °C.

3) At a high strain rate of 1×100 s-1, continuous DRX was associated with the operation of dislocation climbing predominated by the stress acting on the leading dislocation ahead of pile-ups and resultant rearrangement of misorientated flat dislocation pile-ups, leading to the formation of recrystallized grains in slip band whether as-deformed at 350 °C or 400 °C.

Acknowledgements

The authors are grateful for the financial support presented by Brain Pool Program of Korea and Core Technology R & D Program for the Development of High Performance Eco-friendly Structural Materials funded by the Korean Ministry of Commerce, Industry and Energy (Project No. 10020072), and 2011 Program of Ministry of Education of China.

References

[1] Spigarelli S, Mehtedi M E, Cabibbo M, Evangelista E, Kaneko J, Jager A, Gartnerova V. Analysis of high-temperature deformation and microstructure of an AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2007, 462: 197-201.

[2] Eddahbi M, del Valle J A, P'erez-Prado M T, Ruano O A. Comparison of the microstructure and thermal stability of an AZ31 alloy processed by ECAP and large strain hot rolling [J]. Materials Science and Engineering A, 2005, 410-411: 308-311.

[3] Kim W J, Park J D, Kim W Y . Effect of differential speed rolling on microstructure and mechanical properties of an AZ91 magnesium alloy [J]. Journal of Alloys and Compounds, 2008, 460: 289-293.

[4] Cerri E, Leo P, de Marco P P. Hot compression behavior of the AZ91 magnesium alloy produced by high pressure die casting [J]. Journal of Materials Processing Technology, 2007, 189: 97-106.

[5] Barnett M R. Twinning and the ductility of magnesium alloys. Part I: “Tension” twins [J] Materials Science and Engineering A, 2007, 464: 1-7.

[6] Barnett M R. Twinning and the ductility of magnesium alloys. Part II: “Contraction” twins [J]. Materials Science and Engineering A, 2007, 464: 8-16.

[7] Walde T, Riedel H. Modeling texture evolution during hot rolling of magnesium alloy AZ31 [J]. Materials Science and Engineering A, 2007, 443: 277-284.

[8] Proust G, Tome′ C N, Kaschner G C. Modeling texture, twinning and hardening evolution during deformation of hexagonal materials [J]. Acta Materialia, 2007, 55: 2137-2148.

[9] Jiang L, Jonas J J, Mishra R K, Luo A A, Sachdev A K, Godet S. Twinning and texture development in two Mg alloys subjected to loading along three different strain paths [J]. Acta Materialia, 2007 55: 3899-3910.

[10] Cottam R, Robson J, Lorimer G, Davis B. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development [J]. Materials Science and Engineering A, 2008, 485: 375-382.

[11] El-Morsy A, Ismail A, Waly M. Microstructural and mechanical properties evolution of magnesium AZ61 alloy processed through a combination of extrusion and thermomechanical processes [J]. Materials Science and Engineering A, 2008, 486: 528-533.

[12] Yang Z, Guo Y C, Li J P, He F, Xia F, Liang M X. Plastic deformation and dynamic recrystallization behaviors of Mg-5Gd-4Y-0.5Zn-0.5Zr alloy [J]. Materials Science and Engineering A, 2008, 485: 487-491.

[13] YANG X Y, JI Z S, MIURA H, SAKAI T. Dynamic recrystallization and texture development during hot deformation of magnesium alloy AZ31 [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 55-60.

[14] HE Yun-bin, PAN Qing-lin, CHEN Qin, ZHANG Zhi-ye, LIU Xiao-yan, LI Wen-bin. Modeling of strain hardening and dynamic recrystallization of ZK60 magnesium alloy during hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 246-254.

[15] BERGE F,  L, OUAZIZ H, ULLRICH C. Influence of temperature and strain rate on flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 1-13.

L, OUAZIZ H, ULLRICH C. Influence of temperature and strain rate on flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 1-13.

[16] XU Yan, HU Lian-xi, SUN Yu. Dynamic recrystallization kinetics of as-cast AZ91D alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1683-1689.

[17] SHI Bao-liang, LUO Tian-jiao, WANG Jing, YANG Yuan-sheng. Hot compression behavior and deformation microstructure of Mg-6Zn-1Al-0.3Mn magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2560-2567.

[18] JIAN Wei-wei, KANG Zhi-xin, LI Yuan-yuan. Effect of hot plastic deformation on microstructure and mechanical property of Mg-Mn-Ce magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1158-1163.

[19] Ion S E, Humphreys F J, White S H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium [J]. Acta Materialia, 1982, 30: 1909-1919.

[20] Sitdikov O, Kaibyshev R. Dynamic recrystallization in pure magnesium [J]. Materials Transactions, 2001, 42: 1928-1937.

[21] YASUMASA C, MOTOHISA K, MAMORU M. Compressive deformation behavior at room temperature –773 K in Mg–0.2mass%(0.035at.%)Ce alloy [J]. Acta Materialia, 2008, 56: 387-394.

[22] Galiyev A, Kaibyshev R, Gottstein G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60 [J]. Acta Materialia, 2001, 49: 1199-1207.

[23] del Valle J A, Ruano O A. Influence of texture on dynamic recrystallization and deformation mechanisms in rolled or ECAPed AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2008, 487: 473-480.

[24] Liu Juan, Cui Zhen-shan, Li Cong-xing. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B [J]. Computational Materials Science, 2008, 41: 375-382.

[25] Srinivasan N, Prasad Y V R K, Rama Rao P. Hot deformation behaviour of Mg-3Al alloy—A study using processing map [J]. Materials Science and Engineering A, 2008, 476: 146-156.

[26] Wang C Y, Wang X J, Chang H, Wu K, Zheng M Y. Processing maps for hot working of ZK60 magnesium alloy [J]. Materials Science and Engineering A, 2007, 464: 52-58.

[27] Mirzadeh H. Constitutive modeling and prediction of hot deformation flow stress under dynamic recrystallization conditions [J]. Mechanics of Materials, 2015, 85: 66-79.

[28] Mirzadeh H. Roostaei M,Parsa M H,Mahmudi R. Rate controlling mechanisms during hot deformation of Mg–3Gd–1Zn magnesium alloy: Dislocation glide and climb, dynamic recrystallization, and mechanical twinning [J]. Materials and Design, 2015, 68: 228-231.

[29] Wang Yan-nan, Xin Yun-chang, Yu Hui-hui,  Liang-chen,Liu Qing. Formation and microstructure of shear bands during hot rolling of a Mg-6Zn-0.5Zr alloy plate with a basal texture [J]. Journal of Alloys and Compounds, 2015, 644: 147-154.

Liang-chen,Liu Qing. Formation and microstructure of shear bands during hot rolling of a Mg-6Zn-0.5Zr alloy plate with a basal texture [J]. Journal of Alloys and Compounds, 2015, 644: 147-154.

[30] Kaibyshev R, Galiev A, Sitdikov O. On the possibility of producing a nanocrystalline structure in magnesium and magnesium alloys [J]. Nanostructured Materials, 1995, 6: 621-624.

[31] LIU Z Y, BAI S, KANG S B. Low-temperature dynamic recrystallization occurring at a high deformation temperature during hot compression of twin-roll-cast Mg-5.51Zn-0.49Zr alloy [J]. Scripta Materialia, 2009, 60: 403-406.

[32] McQueen H J. Development of dynamic recrystallization theory [J]. Materials Science and Engineering A, 2004, 387-389: 203-208.

[33] OBARA T, YOSHINGA H, MOROZUMI S. {1122}<1123> slip system in magnesium [J]. Acta Materialia, 1973, 21: 845-853.

[34] STOHR J F, POIRIER J P. Electron microscope study of pyramidal slip  in magnesium [J]. Philosophical Magazine, 1972, 25: 1313-1329.

in magnesium [J]. Philosophical Magazine, 1972, 25: 1313-1329.

[35] COURET A, CAILLARD D. An in situstudy of prismatic glide in magnesium. I: The rate controlling mechanism [J]. Acta Materialia, 1985, 33: 1447-1454.

[36] JAIN A, AGNEW S R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet [J]. Materials Science and Engineering A, 2007, 462: 29-36.

[37] GERTSMAN V Y, BININGER R, VALIEV R Z, GLEITER H. On the structure and strength of ultrafine-grained copper produced by severe plastic deformation [J]. Scripta Metallurgica et Materialia, 1994, 30: 229-234.

[38] BELYAKOV A, KAIBYSHEV R. Structural changes of ferritic stainless steel during severe plastic deformation [J]. Nanostructured Materials, 1995, 6: 893-896.

[39] WEERTMAN J, MECH J. Creep of polycrystalline aluminium as determined from strain rate tests [J]. Journal of the Mechanics and Physics of Solids, 1956, 4: 230-234.

[40] WONG W A, JONAS J J. Aluminum extrusion as a thermally activated process [J]. Trans TMS AIME, 1968, 242: 2271-2280.

[41] McQUEEN H J, BERGERSON S. Dynamic recrystallization of copper during hot torsion [J]. Metal Science, 1972, 6: 25-29.

[42] LIU Qing, HUANG Xiao-xu, YAO Mei, YANG Jin-feng. On deformation-induced continuous recrystallization in a superplastic Al-Li-Cu-Mg-Zr alloy [J]. Acta Metallurgica et Materialia, 1992, 40: 1753-1762.

[43] DOUGHERTY L M, ROBERTSON I M, VETRANO J S. Direct observation of the behavior of grain boundaries during continuous dynamic recrystallization in an Al-4Mg-0.3Sc alloy [J]. Acta Materialia, 2003, 51: 4367-4378.

[44] HIRTH J P, LOTHE J. Theory of dislocation [M]. 2nd ed. New York: John Wiley & Sons, 1982: 556-733.

[45] SONG S X, HORTON J A, KIM N J, NIEH T G. Deformation behavior of a twin-roll-cast Mg-6Zn-0.5Mn-0.3Cu-0.02Zr alloy at intermediate temperatures [J]. Scripta Materialia, 2007, 56: 393-395.

[46] PENG W P, LI P J, ZENG P, LEI L P. Hot deformation behavior and microstructure evolution of twin-roll-cast Mg-2.9Al-0.9Zn alloy: A study with processing map [J]. Materials Science and Engineering A, 2008, 494: 173-178.

刘志义1,2,黄田田1,2,刘文娟1,2,Sukbong KANG3

1. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. Korea Institute of Materials Science, Changwon 641010, Korea

摘 要:通过X射线衍射仪、光学显微镜和透射电镜研究Mg-5.51Zn-0.49Zr镁合金在热压缩实验中动态再结晶的位错机制。结果表明,当应变速率为1×10-3 s-1时,由于位错攀移沿单一方向滑动,合金出现连续动态再结晶;当热压缩温度达到350 °C、应变速率为1×10-2 s-1时,由于位错发生滑移和攀移,合金出现连续动态再结晶;当热压缩温度达到400 °C时,由于亚晶界弓出,合金出现不连续动态再结晶;当应变速率为1×100 s-1时,合金出现连续动态再结晶是由于先导位错在堆积前发生攀移,导致位错在堆积过程中重新排列,形成位错差。一般来说,当应变速率增加时,位错攀移的主要影响机制由空位迁移转变为堆积前先导位错的压应力作用。

关键词:镁合金;位错;机制;动态再结晶

(Edited by Wei-ping CHEN)

Corresponding author: Zhi-yi LIU; Tel: +86-731-88836011; Fax: +86-731-88876692; E-mail: liuzhiyi@mail.csu.edu.cn

DOI: 10.1016/S1003-6326(16)64126-2