文章编号:1004-0609(2011)08-1904-06

U-Nb合金的可逆塑性变形及其消除方法

何立峰,黄 海,杨建雄,任大鹏,张延志

(中国工程物理研究院,绵阳 621900)

摘 要:研究淬火态和时效态U-Nb合金在机械加工和静拉伸时的可逆塑性变形,采用透射电子显微镜进行原位拉伸观察,结合变形前后及二次时效后合金的X射线衍射分析探讨U-Nb合金的塑性变形机制,利用时效方法探索消除加工变形的可行性。结果表明:高密度孪晶的相互吞并、长大及发生择优取向是该合金在变形初期的主要变形机制;淬火态和经150 ℃时效U-Nb合金的变形量差别不大,而经200 ℃时效U-Nb合金的加工变形量与前两者相比相对较小;利用200 ℃二次时效的方法消除塑性变形时,U-Nb合金的变形回复量可达50%以上。

关键词 U-Nb合金;形状记忆效应;变形;消除;孪晶;马氏体

中图分类号:TG139;TG146 文献标志码:A

Reversible plastic deformation and

elimination method of U-Nb alloy

HE Li-feng, HUANG Hai, YANG Jian-xiong, REN Da-peng, ZHANG Yan-zhi

(China Academy of Engineering Physics, Mianyang 621900, China)

Abstract: The reversible plastic deformation during machining and static tensile test was studied for as-quenched and aged U-Nb alloy. The deformation mechanism of U-Nb alloy was probed by X-ray diffraction analysis and in-situ tensile test on transmission electron microscope. The feasibility of eliminating the machining deformation was probed by aging method. The results show that the growing up, incorporation and reorientation of martensite variants with high density twins is the primary deformation mechanism for U-Nb alloy at the initial stage of deformation. The plastic deformation in as-quenched and 150 ℃ aged U-Nb alloy after machining is similar, but larger than that of 200 ℃ aged alloy. The recovery deformation can reach 50% after the alloy aging at 200 ℃ for 30 min.

Key words: U-Nb alloy; shape memory effect; deformation; elimination; twin; martensite

偏共析成分的U-Nb合金(名义铌含量为6.3%,质量分数)具有优异的抗腐蚀性能和良好的塑性,是核工程中常用的集结构和功能于一体的材料[1]。具有滞弹性[1]、超塑性[2]以及形状记忆效应[3-12]等许多令人感兴趣的特性。该合金在淬火过程中发生γ(bcc)? γ°(正方)? (单斜)转变,随后的时效过程中产生偏聚等细微变化,最终的力学性能对时效温度十分敏感,且会随时间的变化而变化[13-16]。

(单斜)转变,随后的时效过程中产生偏聚等细微变化,最终的力学性能对时效温度十分敏感,且会随时间的变化而变化[13-16]。

20世纪80年代初,VANDERMEER[17]就已发现U-Nb合金在机械加工过程中的尺寸不稳定性问题,并

对U-Nb合金的变形机制及形状记忆效应进行了大量的研究。内容涉及该合金的热弹性马氏体相变[3-4]、形状记忆机制[5-8]、显微力学行为[9-10]以及变形机理[11-12]等。国外研究表明: U-Nb合金的最大可逆应变为7%,可逆应变中的大部分在试样加热至200 ℃时可以得到回复。国内在加工U-Nb合金工件也发现可逆塑性变形问题,以至于最终的成形尺寸难以控制。虽然经过尺寸修正可以达到使用要求,但由于形状记忆合金本质上具有尺寸不稳定性,故随环境温度和时间变化,可逆变形会因形状记忆效应仍会显现,从而导致U-Nb合金部件在长期贮存时可能发生尺寸上的变化。目前,有关消除该合金可逆塑性变形的机理未见相关报道。

本文作者利用透射电子显微镜(TEM)、X射线衍射(XRD)等分析手段对该合金的塑性变形及其回复机制进行探讨,试图揭示U-Nb合金部件在机械加工过程中产生塑性变形的原因,并利用该合金具有形状记忆效应这一特性,采用200 ℃二次时效的方法,探索消除或减小部件塑性变形的可行性。由于在机械加工产生塑性变形的同时,合金内微观组织已经发生变化(产生形变孪晶),二次时效处理在消除塑性变形的同时,还可以提高该合金内部组织的均匀性,从而有助于提高部件的尺寸稳定性以及在长期贮存、使用过程中的安全性和可靠性。

1 实验

1.1 试样制备

使用了3种热处理状态的U-Nb合金,热处理条件分别为淬火态、(150 ℃,1 h)时效、(200 ℃,2 h)时效,以下分别简称A、B、C状态。

X射线衍射试样为40 mm×10 mm×2 mm的板状试样,对试样表面进行研磨后电解抛光,采用相同分析条件分别对拉伸前、拉伸后和二次时效后的同一试样在X'Pert型X射线衍射仪上进行分析。制备透射电子显微镜原位拉伸试样时,将试样进行粗磨、精磨直至厚约50 μm,然后切成7 mm×4 mm薄片,利用双喷电解减薄仪穿孔后切成两半,在日立H-800型透射电子显微镜上进行原位拉伸观察。弯曲试样是将XRD板状试样在INSTRON 4482材料试验机上进行弯曲后得到的。

1.2 塑性变形的获得

利用静拉伸的方法获取轴向塑性变形。对不同直径薄壁圆环试样的内壁进行车加工使之产生环向塑性变形(见图1),采用相同的加工参数以避免加工工艺本身带来的影响,主要加工参数为转速90 r/min、进刀量35~50道。由于机械加工过程中产生的变形量有限,因此又利用图1所示的压缩模具对圆环试样进行压缩使之产生更大的环向塑性变形。

1.3 拉伸及加热试验

拉伸试验在INSTRON 4482材料试验机上进行,将直径为5 mm标准拉伸试样加载到一定变形量后卸载,确定其塑性变形量。试样的二次时效试验在烘箱中进行,以3 ℃/min的速度加热至200 ℃后保温 30 min,然后取出试样空冷至室温。利用未经变形和变形8%的力学拉伸试样在高温炉中进行加热过程中的应变回复过程测量。

图1 圆环试样实物照片和压缩模具示意图

Fig.1 Photo of ring specimen(a) and schematic diagram(b) of compressing die

2 结果与讨论

2.1 塑性变形机制

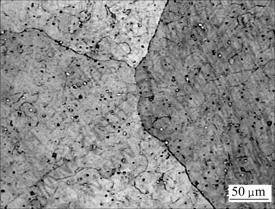

U-Nb合金具有板条状马氏体组织,内含大量孪晶。在时效过程中产生Nb的偏聚导致时效强化,但仍保留 相原貌,金相组织并无明显差别。图2所示为150 ℃时效后U-Nb合金的光学组织。

相原貌,金相组织并无明显差别。图2所示为150 ℃时效后U-Nb合金的光学组织。

图2 150 ℃时效U-Nb合金光学组织

Fig.2 Optical micrograph of 150 ℃ aged U-Nb alloy

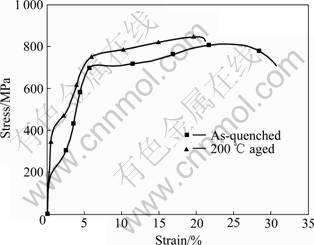

U-Nb合金的应力—应变曲线(见图3)是典型的形状记忆合金应力—应变曲线,塑性区分成3个阶段,即低应力平台、快速硬化和永久塑性变形阶段。第一阶段(ε<3%)具有较低的流变应力,通常认为在该阶段孪生变形为主要变形机制;第二阶段(3%<ε<7%)是快速硬化阶段。根据CARPENTER[5]的研究结果,合金在该变形区域的特点是单斜角 变化较大,并且在卸载后可以恢复,因此认为变形后孪晶的弹性变形为该阶段的主导机制。但VOLZ等[6]认为在此阶段主要发生次生孪生变形,考虑到试样卸载后大约有5%的残余应变,且通过加热可以回复(可逆变形),因此,本文作者更倾向于后者的观点,即在该变形区域是以次生孪生变形为主导的;第三阶段(ε>7%),试样开始永久塑性变形直至断裂。

变化较大,并且在卸载后可以恢复,因此认为变形后孪晶的弹性变形为该阶段的主导机制。但VOLZ等[6]认为在此阶段主要发生次生孪生变形,考虑到试样卸载后大约有5%的残余应变,且通过加热可以回复(可逆变形),因此,本文作者更倾向于后者的观点,即在该变形区域是以次生孪生变形为主导的;第三阶段(ε>7%),试样开始永久塑性变形直至断裂。

图3 U-Nb合金的工程应力—应变曲线

Fig.3 Engineering stress—strain curves of U-Nb alloy

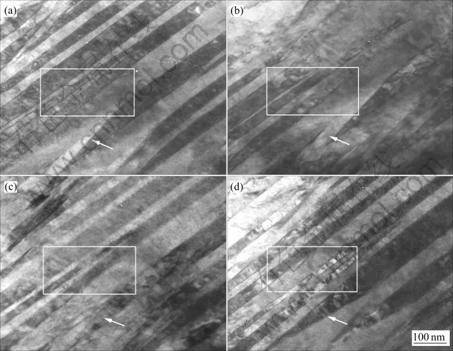

为了解U-Nb合金在机械加工时易产生塑性变形及拉伸时产生屈服平台的原因,利用透射电子显微镜进行原位拉伸观察。图4所示为经150 ℃时效U-Nb合金内孪晶组织在原位拉伸过程中的变化情况。当试样受力变形时,试样中的高密度孪晶会像波浪一样产生移动,同时其位置、大小和方向均会发生改变。由图4中可见,白色框内孪晶的粗细逐渐地发生变化,即发生相互吞并、长大,且在图中白色箭头所指位置孪晶界面的取向也在逐渐地发生变化。在相对较低的放大倍数下,还会观察到马氏体板条间也同样会相互吞并长大,因为这些马氏体板条间也都是互为孪晶的。与拉伸轴方向有更好取向的孪晶和马氏体吞并其他的孪晶和马氏体,即发生择优取向,最终变形的结果是马氏体板条又大又少,且形状和位置均发生了改变。理论上讲,试样在完全变形后会形成单一的马氏体而所有的孪晶和马氏体均会消失。原位拉伸实验结果表明:U-Nb合金在变形过程中的主要机制是孪晶和马氏体间的相互吞并、长大及择优取向。CARPENTER[5]的研究表明,U-Nb合金在拉伸过程中主要以(110)、(111)和(112)等的衍射峰强度变化为主。

2.2 加工变形行为

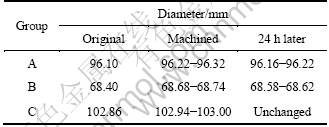

在进行机械加工时,很明显地发现该合金在机械加工过程中,切削时不容易断屑、刀具磨损也大。在加工过程中,产生明显的径向变形,径向变形表现为两个方面:一是工件口部直径在不同方位测量具有不同的值,其最大直径差达到0.16 mm;另外就是工件口部直径在加工后整体膨胀。本研究的d 68.4 mm圆环试样在加工后其直径最大膨胀量达到0.34 mm(见表1),相比于其直径而言,变形量达到0.5%。

图4 150 ℃时效U-Nb合金原位拉伸过程中的显微组织变化

Fig.4 Microstructures evolution of 150 ℃ aged U-Nb alloy during in-situ tensile process: (a) Original; (b)-(d) Evolution of twins during TEM in-situ tensile test

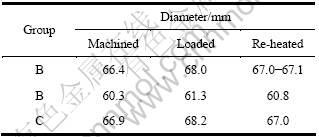

表1 圆环试样在机械加工前后的外径变化

Table 1 Ring outside diameter change before and after machining

比较这3种状态U-Nb合金的加工变形行为,淬火态和150 ℃时效态的加工变形量差别不大,而且试样在变形后尺寸会缓慢地回复。表1所列为试样在放置一天后测量的尺寸。由表1可以看到,试样直径在放置过程中会缓慢地收缩,尚不清楚究竟是应力释放的结果还是该合金所具有的滞弹性造成的。而经200 ℃时效态的加工变形量与前两者比较相对较小,主要是其屈服强度较高,切削力不足以使其产生塑性变形或变形量很小的缘故。

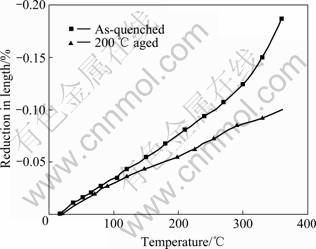

利用线切割切取d 5 mm拉伸试样的平行长度部分(30 mm),试样未进行形变处理,利用自制的变形测量装置对试样在加热过程中的尺寸变化过程进行测试(见图5)。结果表明,未经变形的U-Nb合金在加热过程中会产生收缩,这说明在加工力学性能试样时,已经产生了轴向伸长(可逆塑性变形),由于合金具有形状记忆效应,所以在加热过程中才会产生变形的回复。从图中还可发现,淬火态试样的收缩量明显大于200 ℃时效试样的,这主要是由于淬火态试样屈服强度低(约150 MPa),加工过程中孪生变形易于启动造成的。由此可见,对于U-Nb合金,加工变形不可避免。

图5 未变形试样在加热过程中的长度缩减

Fig.5 Reduction in length of undeformed specimen during heating

2.3 塑性变形的消除

VANDERMEER[3]认为U-Nb合金要经400 ℃时效15 min以上才能完全消除记忆效应。本研究小组过去的研究工作也表明,样品加热至200 ℃(高于热弹性马氏体逆相变终了温度170 ℃)时,大约80%的塑性变形可以得到回复。因此,利用U-Nb合金具有形状记忆效应这一特性,采用二次时效的方法探索消除其塑性变形的可行性。首先利用2 mm厚的板状试样进行实验,将试样弯曲至约30°后,加热时发现弯曲角度增大至大约90°(见图6),显然是由于弯曲过程中试样内部组织发生变化,试样弯曲后外侧发生孪晶的长大,而内侧则相反。

图6 150 ℃时效弯曲试样加热前后的实物照片

Fig.6 Photos of 150 ℃ aged specimen before and after heating: (a) Original; (b) Bending; (C) Reheated

对机械加工和扩张变形这两种塑性变形后的圆环试样均采用加热至200 ℃进行二次时效的方法进行变形消除实验,测量时效后试样的尺寸回复量。结果表明,由于机械加工试样的变形量较小,另外加工变形在放置一天后大部分已经得到回复,因此变形回复很难测量,但是,仍然观察到试样在时效后有变圆的现象;而利用压缩模具变形后的圆环试样在加热后其变形回复量可达50%以上(见表2)。出于工程可行性的考虑,对二次时效前后试样力学性能的变化情况进行了简单分析,结果表明:二次时效会提高合金的强度和硬度,而塑性会有所降低,但变化并不明显,这是由于影响U-Nb合金力学性能的主要因素是时效温度,而时效时间对其影响不大的缘故。

表2 圆环试样在加载前后和加热后直径的变化

Table 2 Change of diameter for ring specimen before and after loading and heating

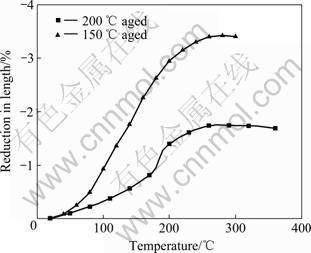

将拉伸试样施加8%变形量后切取平行长度部分进行高温下的应变回复测量,图7所示为测量结果。由图7可见,150 ℃时效态试样的回复量要大于200 ℃时效态试样。从U-Nb合金在加热过程中的变化过程来看,由于热弹性马氏体逆相变温度为170 ℃,因此150 ℃时效试样并未发生马氏体逆相变而200 ℃时效试样则经历 ?γ°?

?γ°? 过程[13],其中

过程[13],其中 ?γ°为热弹性马氏体逆相变,在随后的保温过程中通过偏聚发应发生γ°?

?γ°为热弹性马氏体逆相变,在随后的保温过程中通过偏聚发应发生γ°? 转变,由于在此过程中发生一系列的内部变化,因此200 ℃时效试样的形状记忆效应已不明显。实际上,对U-Nb合金变形和时效机制的研究迄今仍在进行[11-16],各研究者的观点也有所差异,这里不再赘述。

转变,由于在此过程中发生一系列的内部变化,因此200 ℃时效试样的形状记忆效应已不明显。实际上,对U-Nb合金变形和时效机制的研究迄今仍在进行[11-16],各研究者的观点也有所差异,这里不再赘述。

综上所述,无论是淬火态﹑150 ℃时效态还是200 ℃时效态U-Nb合金的塑性变形通过二次时效的方法均可以得到部分回复。

图7 8%变形试样在加热过程中的长度衰减

Fig.7 Reduction in length for 8% strained specimen during heating

2.4 消除方法和机理探讨

U-Nb合金在淬火时经过热弹性马氏体相变形成单斜的 相,在250 ℃以下时效时,发生Nb在微区富集同时使邻区贫Nb,即溶质的偏聚分解,造成不同微区产生与

相,在250 ℃以下时效时,发生Nb在微区富集同时使邻区贫Nb,即溶质的偏聚分解,造成不同微区产生与 晶体结构相同而成分和晶格参数不同的调变相,它与母相

晶体结构相同而成分和晶格参数不同的调变相,它与母相 共格并引起强化。因为热弹性马氏体相变是可逆的,且U-Nb合金在变形并卸载后,其单斜角基本不会发生变化,使其基本晶体结构不发生变化,这样变形后相互吞并、长大的孪晶和马氏体在加热时会按照原来的取向重新分解,整体上看,试样又会回复到变形前的尺寸。图8所示为150 ℃时效和200 ℃时效试样在拉伸前后和拉伸后二次时效的衍射峰强度的变化情况。由图8可见,试样在拉伸后,

共格并引起强化。因为热弹性马氏体相变是可逆的,且U-Nb合金在变形并卸载后,其单斜角基本不会发生变化,使其基本晶体结构不发生变化,这样变形后相互吞并、长大的孪晶和马氏体在加热时会按照原来的取向重新分解,整体上看,试样又会回复到变形前的尺寸。图8所示为150 ℃时效和200 ℃时效试样在拉伸前后和拉伸后二次时效的衍射峰强度的变化情况。由图8可见,试样在拉伸后, 、

、 和

和 峰强度降低,(112)和

峰强度降低,(112)和 峰强度增强;而在时效后,衍射峰又得到部分程度的恢复,这与VANDERMEER[3]和CARPENTER[5]的分析结果一致。由于U-Nb合金在形变初期加载-卸载后基本上没有晶格畸变[3],说明这些衍射峰强度的变化不是由晶格畸变引起的,即试样在拉伸过程中发生择优取向,且在随后的时效过程中又得到部分回复。

峰强度增强;而在时效后,衍射峰又得到部分程度的恢复,这与VANDERMEER[3]和CARPENTER[5]的分析结果一致。由于U-Nb合金在形变初期加载-卸载后基本上没有晶格畸变[3],说明这些衍射峰强度的变化不是由晶格畸变引起的,即试样在拉伸过程中发生择优取向,且在随后的时效过程中又得到部分回复。

图8 经变形及二次时效后U-Nb合金的XRD谱

Fig.8 XRD patterns of U-Nb alloy after deformed and second aged: (a) 150 ℃ aged; (b) 200 ℃ aged

从以上讨论中可以看出,要消除或减小塑性变形,可以探讨采用如下方法进行:

a) 工件在淬火后先经粗加工再进行时效,最后进行精加工,此方法既能消除机加变形又能使其组织具有均匀性。

b) 工件在精加工后进行二次时效,此方法的好处是由于合金屈服强度高,因而加工时的变形量较 小,但要利用此方法必须先研究合金经过二次时效后,其力学性能和耐腐蚀性能变化程度究竟能否达到产品要求。

3 结论

1) U-Nb合金变形初期的主要变形机制是孪生变形和择优取向。

2) 淬火态和150 ℃时效态U-Nb合金的加工变形行为差别不大,且在试样产生加工变形后,放置一段时间后会部分回复;而200℃时效态的加工变形量与前两者比较,相对较小。

3) U-Nb合金在机械加工过程中的塑性变形不可避免,对150 ℃时效态和200 ℃时效态U-Nb合金利用低温时效的方法消除其塑性变形时,变形回复量可达50%以上。

致谢:

在本工作完成过程中,得到了郎定木和张丽等同志的帮助,在此表示衷心感谢!

REFERENCES

[1] BURKE J J. Physical metallurgy of uranium alloys[M]. Massa- chusetts, USA: Brook Hill Publishing Company, 1976: 216-231.

[2] LUDTKA G M. An investigation of superplaticity in a thermomechanically processed U-6Nb alloy[J]. Metallurgical Transactions A-Physical Metallurgy and Materials Science, 1993, 24A: 379-393.

[3] VANDERMEER R A. Martensitic transformation, shape memory effects and other curious mechanical effects, Y/DV-207[R]. Oak Ridge, Tennessee: Oak Ridge Y-12 Plant, 1982.

[4] FIELD R D, BROWN D M, THOMA D J. Shape memory behavior in U-Nb alloy[C]//HOWE J M. Solid-to-Solid Phase Trasformations in Inorganic Materials. TMS, 2005: 227-232.

[5] CARPENTER D A. X-ray-diffraction study of shape memory in uranium-niobium alloys, Y/DW-341[R]. Oak Ridge, Tennessee: Oak Ridge Y-12 Plant, 1982.

[6] VOLZ H M, HACKENBERG R E, KELLY A M. X-ray diffraction analyses of aged U-Nb alloys[J]. Journal of Alloys and Compounds, 2007, 444/445: 217-225.

[7] VANDERMEER R A. Shape memory effect in uranium-niobium alloys below room temperature, UCRL-15666[R]. Livermore, USA: Lawrence Livermore National Laboratory, 1985.

[8] BROWN D W, BOURKE M A M. Neutron diffraction study of the deformation mechanisms of the uranium–7 wt.% niobium shape memory alloy[J]. Materials Science and Engineering A, 2006, 421: 15-21.

[9] CLARKE A J, FIELD R D. A microcompression study of shape memory deformation in U–13at.% Nb alloy[J]. Scripta Materialia, 2009, 60: 890-892.

[10] WHEELER D W, MORRIS S T. Micro-mechanical characterisation of uranium[J]. Journal of Nuclear Materials, 2009, 385: 122-125.

[11] FIELD R D, BROWN D W,THOMA D J. Texture development and deformation mechanisms during uniaxial straining of U-Nb shape-memory alloys[J]. Philosophical Magazine, 2005, 85(13): 1441-1457.

[12] CLARKE A J, FIELD R D. EBSD and FIB/TEM examination of shape memory effect deformation structures in U–14 at.% Nb[J]. Acta Materialia, 2008, 56: 2638-2648.

[13] HSIUNG L, ZHOU Ji-kou. Low-temperature aging kinetics of a 15-year old water-quenched U-6wt.%Nb alloy, UCRL-TR- 235973[R]. Livermore, USA: Lawrence Livermore National Laboratory, 2007.

[14] SUNWOO A J, HIROMOTO D S. Effects of natural aging on the tensile properties of water-quenched U–6%Nb alloy[J]. Journal of Nuclear Materials, 2004, 327: 37-45.

[15] BROWN D W, HACKENBERG R E, TETER D F, BOURKE M A. Aging and deformation of uranium-niobium alloys[J]. Los Alamos Science, 2006, 30: 79-83.

[16] HACKENBERG R E, HEMPHILL G M. Property and lifetime prediction in aged U-Nb alloys, LA-14389[R]. New Mexico, USA: Los Alamos National Laboratory, 2009.

[17] VANDERMEER R A. Reversible strain mechanisms in uranium niobium alloys near the monotectoid composition, Y-2285[R]. Oak Ridge, Tennessee: Oak Ridge Y-12 Plant, 1983.

(编辑 李艳红)

收稿日期:2010-07-24;修订日期:2010-11-24

通信作者:何立峰,高级工程师;电话:0816-3626394;E-mail: he-lifeng@163.com