Effect of low temperature thermo-mechanical treatment onmicrostructures and mechanical properties of TC4 alloy

来源期刊:中南大学学报(英文版)2010年第3期

论文作者:孙利平 林高用 刘健 曾菊花

文章页码:443 - 448

Key words:Ti-6Al-4V (TC4) alloy; low temperature thermo-mechanical treatment; microstructure; mechanical properties; strain strengthening

Abstract: The effects of low temperature thermo-mechanical treatment (LTTMT) on microstructures and mechanical properties of Ti-6Al-4V (TC4) alloy were studied by optical microscopy (OM), tensile test, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The experimental results confirm that the strength of TC4 alloy can be improved obviously by LTTMT processing, which combines strain strengthening with aging strengthening. The effect of LTTMT on the alloy depends on the microstructure of the refined and dispersed α+β phase on the basis of high dislocation density by pre-deformation below recrystallization temperature. The tensile strength decreases with the increase of pre-deformation reduction. The optimal processing parameters of LTTMT for TC4 alloy are as follows: solution treatment at 900 ℃ for 15 min, pre-deformation in the range of 600-700 ℃ with a reduction of 35%, finally aging at 540 ℃ for 4 h followed by air-cooling.

基金信息:the Science and Technology Plan of Hunan Province, China

J. Cent. South Univ. Technol. (2010) 17: 443-448

DOI: 10.1007/s11771-010-0504-6 ![]()

SUN Li-ping(孙利平)1, LIN Gao-yong(林高用)1,2, LIU Jian(刘健)1, ZENG Ju-hua(曾菊花)1

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract: The effects of low temperature thermo-mechanical treatment (LTTMT) on microstructures and mechanical properties of Ti-6Al-4V (TC4) alloy were studied by optical microscopy (OM), tensile test, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The experimental results confirm that the strength of TC4 alloy can be improved obviously by LTTMT processing, which combines strain strengthening with aging strengthening. The effect of LTTMT on the alloy depends on the microstructure of the refined and dispersed α+β phase on the basis of high dislocation density by pre-deformation below recrystallization temperature. The tensile strength decreases with the increase of pre-deformation reduction. The optimal processing parameters of LTTMT for TC4 alloy are as follows: solution treatment at 900 ℃ for 15 min, pre-deformation in the range of 600-700 ℃ with a reduction of 35%, finally aging at 540 ℃ for 4 h followed by air-cooling.

Key words: Ti-6Al-4V (TC4) alloy; low temperature thermo-mechanical treatment; microstructure; mechanical properties; strain strengthening

1 Introduction

TC4 alloy is one of the typical (α+β) Ti alloys. Since Ti-6Al-4V was first applied in 1954, it has become the most important Ti alloy and has been widely used around the world nowadays, for the products of TC4 alloy account for about 60% of all Ti output [1]. Although the alloy has been used for a number of years, researches on this alloy still attract much attention of researchers from both fundamental and practical point of view, such as superplastic forming and diffusion bonding (SPF/DB) technology [2-3], numerical simulation on forging process [4], stress relaxation behavior [5], surface engineering technologies [6-8], constitutive relationship [9-10], fatigue crack growth behavior [11-12], hydrogen treatment [13], and high temperature thermo-mechanical treatment (HTTMT) technology [14]. However, the study of low temperature thermo- mechanical treatment (LTTMT) on TC4 alloy has not been performed, which may be an effective way for strengthening this alloy. In this work, the influences of LTTMT on microstructures and mechanical properties of TC4 alloy were investigated, aiming to find a more effective technology for improving the properties of this alloy.

2 Experimental

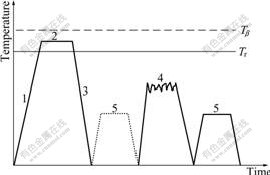

The testing materials used were 1.7 mm-thick hot-rolled TC4 sheets. The finish hot-rolling temperature was 900 ℃. The process flow of LTTMT is illustrated in Fig.1, which includes three stages as follows: solution treatment and quenching, pre-deformation, and aging. The processing parameters of LTTMT were set as follows: solution treatment at 900 ℃ for 15 min, followed by quenching in room-temperature water; pre-deformation in the range of 600-700 ℃, with the pre-deformation reductions of 35%, 50%, and 55%, respectively; aging treatment at 540 ℃ in air for 4 h followed by air-cooling. Besides, the artificial aging before pre-deformation was conducted at 540 ℃ for 2 h, and the natural aging was carried out at the room temperature for 6 d. For the sake of comparing the mechanical property and microstructure at every stage of LTTMT, serial routes are set and shown in Table 1.

Fig.1 Schematic illustration of LTTMT: 1—Heating; 2—Solution treatment; 3—Water cooling; 4—Pre-deformation; 5—Aging; Tβ—Transition temperature of β phase; Tr—Temperature of recrystallization

Table 1 Routes of different samples

The microstructure observation was performed using POLYVAR-METⅡ metallographic microscope. Specimens for optical microscopy (OM) were etched by a solution of nitric acid (30 mL)+hydrofluoric acid (20 mL)+H2O (50 mL). Tensile tests were performed on a CSS-44100 universal electronic tensile test machine. Additionally, the fracture cross-sections of TC4 samples by tensile test were analyzed by scanning electron microscopy (SEM), using KYKY-Amray 2800 in this work. The TEM investigations were carried out on an H-800 transmission electron microscope to observe the sub-structure in TC4 alloy at different stages of the LTTMT.

3 Results and discussion

3.1 Mechanical properties

The measuring values of mechanical properties (tensile strength σb, yield strength σ0.2, and elongation δ) of TC4 alloy processed by LTTMT and other comparing routes are obtained and compiled in Table 2.

Comparing mechanical properties of TC4 alloy prepared by SA, SD1A, SD2A and SD3A routes, it is evident that the strength and the plasticity of TC4 alloy can be improved obviously by LTTMT processing. Pre-deformation reduction influences mechanical properties of TC4 alloy acutely. The tensile strength decreases with the increase of pre-deformation reduction, which is opposite to the variation of HTTMT [14]. And it is remarkable that the plasticity of TC4 alloy rises slightly with the increase of pre-deformation reduction from 35% to 55% in the process of LTTMT.

Table 2 Mechanical properties of TC4 alloy after treated by LTTMT and other routes

Comparing σb of SAD2A and SD2A routes, it can be found that there is little difference for σb (1 072.76 MPa and 1 076.29 MPa, respectively) of the two routes, indicating that the artificial aging before pre-deformation is not necessary. The tensile strength of TC4 alloy processed by SAD2A route differs a lot from that by SND2A route, which indicates that strengthening effect by artificial aging before pre-deformation is stronger than that by natural aging. Besides, the elongations of these two routes are the same (4.20%), indicating that the effects of natural aging and artificial aging before pre-deformation on plasticity of this alloy may be the same when the pre-deformation reductions are both 50%.

The lowest tensile strength σb (748.78 MPa) and the lowest elongation δ (1.00%) occur in the route of SD0. It is evident that room-temperature rolling after solution treatment is not an effective way for improving the properties of TC4 alloy. From the data in Table 2, it can also be noticed that the value of σb is close to the value of σ0.2 in every route, i.e., the yield ratio (σ0.2/σb) is high, which may result in difficulty in cold-deformation.

3.2 Microstructural evolution

Fig.2 shows the optical micrographs of hot-rolled, solution treated and aged TC4 alloy.

As shown in Fig.2(a), the microstructure of TC4 alloy after hot-rolling is mainly equiaxed structure with the prior α phase and transformed β phase. During hot- rolling carried out at 900 ℃, above the recrystallization temperature (Tr), the recrystallization and deformation occur simultaneously. In the sequent air-cooling, β phase will transform to secondary α phase, which nucleates in β grains or the grain boundary of prior α phase [1].

Fig.2 Optical micrographs of TC4 alloy by different procedures: (a) Hot rolling; (b) Solution treatment; (c) Solution treatment+ aging

The microstructure of TC4 alloy upon solution treatment followed by water-quenching is shown in Fig.2(b). From the image, it can be found that the high cooling rate after solution treatment in α+β phase field results in martensite transformation, for acicular α′ phase can be recognized in Fig.2(b). Besides, it can also be found that there exist small amounts of prior α phase and untransformed β phase. Because the martensite in Ti alloy cannot improve the strength as the martensite does in steel, the strengthening efficiency in TC4 alloy is low [1], resulting in that the strength of state S is a little higher than that of state H shown in Table 2.

The microstructure of specimen after solution treatment and aging at 540 ℃ for 4 h is shown in Fig.2(c). It can be seen from Fig.2(c) that the microstructure of TC4 alloy is mainly composed of the modified and dispersed α+β phase indicating that artificial aging following solution treatment is a good way to improve the mechanical properties of TC4 alloy as shown in Table 2. In the process of decomposition of α′ phase, α phase, which has a hexagonal lattice with the parameter comparable with α′ phase, may precipitate first, along with the increase of the β-stabilized element content, resulting in that the rest meta-stable phase is reconstructed into β crystal lattice, shown as follows: α′→α′+α→α+β.

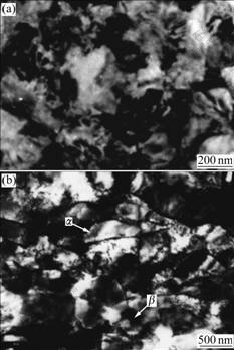

TEM image of the specimen after solution treatment and pre-deformation (Fig.3(a)) shows the microstructure modified by pre-deformation. This reveals that the grain boundary regions have higher defect density than the grain interior due to the dislocation accumulation along the grain boundaries during rolling. It may also be seen in this image that the grains contain the substructure. As the density of dislocation increases, the dislocations will pile up in localized areas and tangle with each other, leading to the inhomogenous distribution. Based on the increase of dislocations and their motion, cellular structure will occur in the grains. It is known that the density inside the cellular structure is much lower than that near the cellular wall. The substructure in grains makes the strength of TC4 alloy slightly increased.

Fig.3 TEM images of TC4 alloy by different procedures: (a) Solution treatment+pre-deformation (35%); (b) Solution treatment+pre-deformation (35%)+aging

On the basis of the pre-deformation, the aging was carried out in order to modify the microstructure and consequently improve the mechanical properties. It is shown in Fig.3(b) that after aging treatment the structure is relatively regular, and the density of dislocation decreases in the heating process. According to the former observation (Fig.3(a)), the dislocations accumulate and tangle with each other, leading to the distortion energy storing in the material, which should be released during heating. Meanwhile, the decomposition of meta-stable phase will occur under the influence of the normalization of sub-grains. Being different from the aging without pre-deformation, the decomposition and the dislocation reaction influence each other in this alloy, which leads to the aging strengthening and the strain strengthening.

As shown in Fig.4, the microstructures of TC4 alloy by procedures of SD1A, SD2A and SD3A are mainly refined and dispersed α+β phases. Comparing the micrographs in Figs.4(a) and (b), it can be found that the size of α particles (light phase) increases with the increase of pre-deformation reduction. Additionally, the particles are in the similar size when the pre-deformation reduction is in a small discrepancy, shown in Figs.4(b) and (c). Comparing the microstructures of SA, SD1A, SD2A and SD3A routes, it is evident that the particles of TC4 alloy become smaller and more dispersive by

Fig.4 Optical micrographs of TC4 alloy by different procedures: (a) Solution treatment+pre-deformation(35%)+aging; (b) Solution treatment+pre-deformation(50%)+aging; (c) Solution treatment+pre-deformation(55%)+aging

LTTMT technology.

In general, the strength will be enhanced with the increase of pre-deformation reduction, which can be proved in the study of HTTMT on TC4 alloy. However, the inverse law is obtained in this work that the tensile strength decreases with the increase of pre-deformation reduction.

There may be two mechanisms for the explanation to this phenomenon. One possible mechanism may be that during the pre-deformation before artificial aging, the density of dislocation in the alloy increases with the increase of pre-deformation reduction, leading to the serious distortion of crystal lattice. On the other hand, the distortion of crystal lattice is a form of inner energy in the alloy. Thus, the inner distortion energy increases with the increase of pre-deformation reduction, inducing that the phases decomposed in the aging treatment agglomerate and grow into larger size, which results in the lower efficiency of strengthening. Additionally, the crystal lattices of decomposition phase may be different transitional crystal lattices based on different pre-deformation reductions, which may influence the effect of hardening.

Another possible mechanism may be that during the heating of aging treatment, the recovery and polygoniza- tion occur along with the phase transformation, which weakens the effect of strain strengthening provided by pre-deformation. The phases decomposed during the aging will influence the polygonization, and on the other hand, the polygonization will change the density and the diffusion form of the decomposed phases (Fig.3(b)). As the pre-deformation reduction increases, the influence of recovery and polygonization on the diffusion decomposition phases will become greater during aging, which may be one reason for the lower hardening.

From the above explanations, it seems that the mechanisms of the pre-deformation reduction on the strength of TC4 alloy during LTTMT should be further studied.

From Table 2, it can be noted that the values of elongation (δ) of S and SD1A routes differ a lot (from 7.18% to 3.00%), indicating that the plasticity of TC4 alloy upon LTTMT is lower than that upon solution treatment, which may be identified in Fig.5. Besides, it is suggested that the structure of continuous β phase with diffusive α phase can represent large brittleness, which may be the possible reason for the lower plasticity by LTTMT [15].

Comparing the morphologies of dimples in Figs.5(a) and (b), it can be found that the dimples in Fig.5(a) are more uniform and deeper than those in Fig.5(b). Besides, the size of dimples in Fig.5(a) is larger than that in Fig.5(b). Generally, the plasticity will be better when the size of dimples is larger and the rupture condition of the material is the same. Therefore, the plasticity of TC4 alloy upon LTTMT is lower than that upon solution treatment, consisting with the results in Table 2.

Fig.5 SEM images of tensile fractures of TC4 alloy by different procedures: (a) Solution treatment; (b) Solution treatment+ pre-deformation(35%)+aging; (c) Higher magnification of Fig.5(a); (d) Higher magnification of Fig.5(b)

According to the observation in Fig.2(b), the structure after solution treatment may primarily contain hexagonal α′ martensite and small amount of prior α phase along the grain boundary. It may be considered that the particles in Fig.5(c) exist in the form of prior α phase, and those in Fig.5(d) exist in the form of diffusion α phase. It can also be observed that there are dimples with different sizes in Fig.5(d). The reason for this phenomenon may depend on the particles with different sizes [16]. The micro-cavities form in the nucleation site of larger particles at first, and then other micro-cavities form in the smaller particles. Finally, different micro-cavities couple with each other, forming dimples with different sizes. In this work, it may be predicted that the phase decomposes from the meta-phase and grows to different sizes.4 Conclusions

(1) The strength of TC4 alloy can be improved obviously by the process of LTTMT, which combines the strain strengthening with aging strengthening. And the optimal processing parameters of LTTMT for TC4 alloy are: solution treatment at 900 ℃ for 15 min, pre- deformation in the range of 600-700 ℃ with a reduction of 35%, finally aging at 540 ℃ for 4 h followed by air-cooling.

(2) The tensile strength decreases with the increase of pre-deformation reduction, which can be explained by two mechanisms proposed in this work. Besides, the plasticity rises slightly with the increase of pre-deformation reduction.

(3) The effect of LTTMT on the alloy depends on the microstructure of refined and dispersed α+β phase on the basis of high dislocation density by pre-deformation below recrystallization temperature.

(4) The room temperature deformation is not an effective way to improve the properties of TC4 alloy, for the tensile strength, yield strength and elongation are all the lowest values in all routes.

(5) There is little difference between normal LTTMT and complex LTTMT (including pre-artificial or pre-natural aging before pre-deformation), indicating that the aging before pre-deformation may not be needed.

References

[1] ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Titanium alloy and its application [M]. Beijing: Chemical Industry Press, 2005: 287-305. (in Chinese)

[2] HAN Wen-bo, ZHANG Kai-feng, WANG Guo-feng. Superplastic forming and diffusion bonding for honeycomb structure of Ti-6Al-4V alloy [J]. Journal of Materials Processing Technology, 2007, 183(2/3): 450-454.

[3] LEE H S, YOON J H, CHAN H P, YOUNG G K, DONG H S, LEE C S. A study on diffusion bonding of superplastic Ti-6Al-4V ELI grade [J]. Journal of Materials Processing Technology, 2007, 187/188: 526-529.

[4] LU Cheng, ZHANG Li-wen. Numerical simulation on forging process of TC4 alloy mounting parts [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(6): 1386-1390.

[5] HYUKJAE L, SHANKAR M. Stress relaxation behavior of shot-peened Ti-6Al-4V under fretting fatigue at elevated temperature [J]. Materials Science and Engineering A, 2004, 366(2): 412-420.

[6] LIU Yong, YANG De-zhuang, WU Wan-liang, YANG Shi-qin. Dry sliding wear behavior of Ti-6Al-4V alloy in air [J]. Journal of Harbin Institute of Technology: English Letter, 2002, 9(1): 67-71.

[7] LIU Y, YANG D Z, HE S Y, WU W L. Microstructure developed in the surface layer of Ti-6Al-4V alloy after sliding wear in vacuum [J]. Materials Characterization, 2003, 50(4/5): 275-279.

[8] BISWAS A, DUTTA M J. Surface characterization and mechanical property evaluation of thermally oxidized Ti-6Al-4V [J]. Materials Characterization, 2009, 60(6): 513-518.

[9] NIE Lei, LI Fu-guo, FANG Yong. New constitution relationship for TC4 alloy [J]. Aeronautical Materials Transaction, 2001, 21(3):13-18. (in Chinese)

[10] LI L X, PENG D S. Development of constitute equations for Ti-6Al-4V alloy under hot-working condition [J]. Acta Metallurgica Sinica: English Letter, 2000, 13(1): 263-269.

[11] SHADEMAN S, SOBOVEJO W O. An investigation of short fatigue crack growth in Ti-6Al-4V with colony microstructures [J]. Materials Science and Engineering A, 2002, 335(1/2): 116-127.

[12] SINHA V, MERCER C, SOBOYEJO W O. An investigation of short and long fatigue crack growth behavior of Ti-6Al-4V [J]. Material Science and Engineering A, 2000, 287(1): 30-42.

[13] LUO Liang-shun, SU Yan-qing, GUO Jing-jie, FU Heng-zhi. Formation of titanium hydride in Ti-6Al-4V alloy [J]. Journal of Alloys and Compounds, 2006, 425(1/2): 140-144.

[14] HUANG Hui. Effect of high temperature thermo-mechanical treatment (HTTMT) on the structure and properties of TC4 alloy [J]. Optic and Precision Engineering, 1996, 4(4): 48-52. (in Chinese)

[15] KUBIAK K, SIENIAWSKI J. Development of the microstructure and fatigue strength of two phase titanium alloys in the processes of forging and heat treatment [J]. Journal of Materials Processing Technology, 1998, 78(1/3): 117-121.

[16] CUI Niu-xian. Fracture analysis of metals [M]. Harbin: Harbin Institute of Technology Press, 1998: 34-45. (in Chinese)

Foundation item: Project(2008WK2005) supported by the Science and Technology Plan of Hunan Province, China

Received date: 2009-06-25; Accepted date: 2009-08-29

Corresponding author: LIN Gao-yong, PhD, Professor; Tel: +86-731-88830266; Fax: +86-731-88876692; E-mail: mater218@163.com

(Edited by CHEN Wei-ping)