文章编号:1004-0609(2014)01-0025-11

稀土Ce和Y对AZ80镁合金组织和力学性能的影响

王 军,朱秀荣,徐永东,王 荣,聂景江,张立君

(中国兵器科学研究院 宁波分院,宁波 315103)

摘 要:通过元素分析、性能测试、XRD、SEM和TEM等手段分析了稀土Ce和Y对AZ80镁合金熔炼、组织和力学性能的影响规律。结果表明:在AZ80合金熔炼过程中,添加稀土Y元素能够起到有效除Fe的作用; AZ80合金中分别添加1%(质量分数)的Ce和Y,可以显著细化合金的晶界第二相,并在晶界上分别生成针状的Al11Ce3相和块状的Al2Y相;挤压变形后,Al-RE相在晶界上能够通过阻止位错运动而有效抑制再结晶晶粒长大;挤压+ T5处理后,含1%Y的合金具有最好的力学性能,抗拉强度和屈服强度分别达到390和250 MPa,而含1%Ce的合金无论是在挤压态还是T5处理后,其力学性能最低。

关键词:AZ80镁合金;Ce;Y;挤压变形;时效强化

中图分类号:TG146.2 文献标志码:A

Effects of rare-earth Ce and Y on microstructure and mechanical properties of AZ80 Mg alloys

WANG Jun, ZHU Xiu-rong, XU Yong-dong, WANG Rong, NIE Jing-jiang, ZHANG Li-jun

(Ningbo Branch, China Ordnance Academy, Ningbo 315103, China)

Abstract: The effects of rare-earth Ce and Y on the melting, microstructure and mechanical properties of AZ80 Mg alloys were investigated by elementary analysis, mechanical properties examination, XRD, SEM and TEM. The experimental results show that the content of Fe decreases obviously during alloy melting, and the melting time is shortened when Y is added into AZ80. The as-cast microstructure of AZ80 alloys is refined, and needle-like Al11Ce3 and block-like Al2(Y, Mn) phases generate at grain boundary when 1%Ce and 1%Y (mass fraction) are added into AZ80 alloys. After extrusion, the coarsening of recrystallized grain is depressed by Al-RE phases impeding motion of dislocation at grain boundary. And after extrusion+T5(177 ℃, 0-30 h) heat-treatment, the maximum tensile strength of AZ80 alloy containing 1%Y is obtained with ultimate tensile stress of 390 MPa and yield stress of 250 MPa.

Key words: AZ80 Mg alloy; Ce; Y; extrusion deformation; aging strengthening

镁作为最轻的工程金属材料,具有密度小、比强度及比刚度高、阻尼性好、电磁屏蔽能力强和易于回收等一系列独特的优点,满足了航空、航天、汽车工业对减质量、节能的要求,并可替代工程塑料以满足3C产品的轻、薄、小型化、高集成度以及环保方面的要求,成为汽车和3C产业的重要使用材料。因此,镁合金被誉为“21世纪的绿色工程材料”[1-4]。与铸造镁合金相比,变形镁合金更具发展前途与潜力,通过变形可以生产尺寸多样的板、棒、管、型材及锻件产品,并且可以通过材料组织的控制和热处理工艺的应用,获得比铸造镁合金材料更高的强度、更好的延展性、更多样化力学性能的材料,从而满足更多结构件的需要[5]。

通过添加稀土元素来提高镁合金的性能是行之有效的方法[6-10]。已有不少关于利用稀土添加来提高传统Mg-Al系变形镁合金性能的文献报道,例如AZ31[11] 和AZ61[12-13],针对含Al较高的AZ80镁合金的稀土添加的相关文献则较少。对于AZ31和AZ61合金,由于Al含量较低,合金不具有热处理强化效果,因此,可以通过添加少量稀土的细化晶粒作用来改善合金的力学性能,但AZ80镁合金是商业变形Mg-Al合金中强度最高且唯一可以进行淬火时效强化的合金,由于稀土元素能够和Al生成高熔点的化合物,从而降低了固溶处理后α-Mg基体中的Al含量,因此,添加稀土后是否对AZ80合金的时效强化作用有影响并不清楚。本文作者以AZ80合金为研究对象,研究添加稀土Ce和Y元素对AZ80合金的熔炼过程、微观组织和力学性能的影响,并为稀土镁合金的进一步开发和应用提供实验基础。

1 实验

试验合金采用纯镁、纯锌和纯铝及Mg-20%Ce(质量分数)、Mg-30%Y、Al-13%Mn的中间合金配制,合金成分如表1所列。在电阻炉中熔炼,采用熔剂保护,740 ℃进行精炼,精炼后加入稀土元素,搅拌后静置30 min,然后降温至640 ℃进行除铁,升温至680 ℃,采用半连续铸造工艺浇铸成d 95 mm铸锭,其中,铸造速度120 mm/min,冷却水量70 L/min,为了确定合金在熔炼过程中的化学成分变化,分别在合金熔炼过程中的不同阶段分别取样进行成分分析。

对铸锭进行400 ℃、12 h固溶处理,铸锭经锯切、车皮(d 92 mm)后,在630 t挤压机上挤压成d 20 mm圆棒,挤压温度为380 ℃ ,挤压比为22,时效温度为177 ℃[5],硬度测试采用布氏硬度仪进行测定,载荷294 N,保压时间为15 s,拉伸试验的试样标尺为d 6 mm×30 mm,拉伸速度为2 mm/min;采用X线衍射(XRD)、MEF4徕卡光学显微镜、Quanta250场发射环境扫描电子显微镜、JEM-2000EX 透射电镜对合金的微观结构和相组成进行观察与分析;化学成分通过直读光谱仪和等离子耦合原子吸收光谱(ICP)测定。

2 结果与分析

2.1 稀土Y对合金熔炼过程的影响

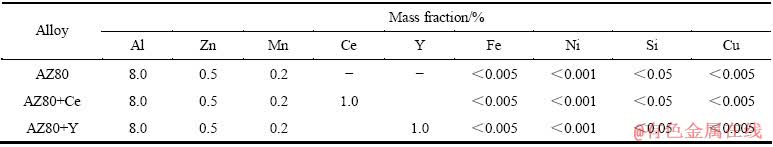

表1 合金的设计成分

Table 1 Nominal composition of alloys

表2 合金在熔炼过程中的成分分析

Table 2 Chemical composition of alloys during melting

合金在熔炼过程中不同阶段的化学成分见表2,表中Ⅰ、Ⅱ、Ⅲ分别表示精炼前、降温前、降温后取样测定的化学成分。AZ80合金中Fe含量一般要求不大于0.005%(质量分数,下同),从表2中可以看出,合金在精炼前的Fe含量均大于0.005%,不能满足合金对Fe含量的要求的。对于AZ80和AZ80+Ce合金,降温前的Fe含量分别是0.0069%和0.0083%,也不符合规定的要求,需要通过降温过程来降低Fe的含量,这是因为Fe在Mg中的溶解度随着熔体温度的降低而降低,当熔体温度降至640 ℃时,Fe的溶解度可以降至0.005%以下;对于AZ80+Y合金,在降温前测定Fe的含量是0.002%,已经符合合金对Fe的含量要求,这表明Y元素有很好的除铁效果,降温后的Fe含量与降温前的含量相比变化很小,这表明降温处理对AZ80+Y合金的Fe含量影响很小。

表3所列为合金的实际测试成分。从表3中可以发现,稀土Ce的含量与添加量相近,达到0.92%,而Y的含量仅有0.21%,与实际添加量差距较大,Y的高损失率可能与合金熔炼过程中Fe含量降低有关。为了分析Y在合金熔炼过程中能够除Fe以及高损失率的原因,制备了不含Mn元素的Mg-8Al-0.5Zn-1Y合金,合金的实际成分是Mg-7.89Al-0.51Zn-0.86Y,Fe含量为0.016%。结果表明,在没有添加Mn的前提下,单纯添加稀土Y不能很好的降低Fe的含量,Y的损失率也较小,这可能是因为Y元素在镁合金熔炼过程中同Al、Fe、Mn等元素形成了难溶化合物并造渣[14], Fe含量降低的同时,Y含量也降低。

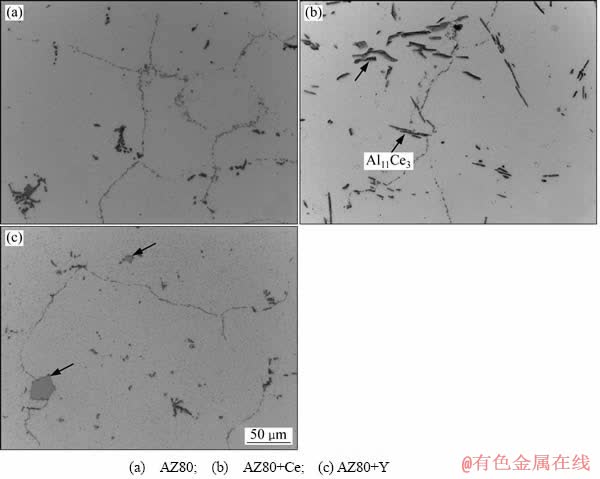

2.2 稀土Ce、Y对铸态显微组织及物相的影响

图1所示为添加不同稀土的AZ80镁合金铸态金相组织。由图1(a)可以看出,铸态AZ80合金呈现典型的离异共晶形貌特征,晶粒较为粗大,其铸态组织主要由α-Mg相和离异共晶相构成,共晶相主要沿晶界呈连续或半连续网状分布。由图1(b)和1(c)可以看出,加入稀土后,合金晶界共晶相被明显细化,除α-Mg相和离异共晶相外,还在晶界处析出了新相。当AZ80中加入Ce后,合金中新相呈深色的杆状或针状(见图1(b)中箭头),离异共晶相减少,由连续或半连续的网状结构转变为弥散分布着的岛状结构;当AZ80中加入Y后,共晶相的分布与数量和添加Ce的合金相似,但合金中的新相是一种多边形块状结构(见图1(c)中箭头)。

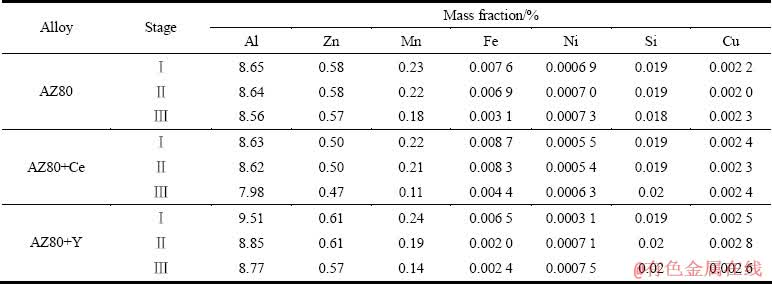

表3 合金的实际化学成分

Table 3 Chemical composition of alloys

图1 镁合金的铸态金相组织

Fig. 1 Microstructures of as-cast Mg alloys

为了确定铸态合金中的相组成,对所制备的合金进行XRD分析,图2所示为AZ80、AZ80+Ce、AZ80+Y 3种合金的XRD谱。结果表明:AZ80合金的组织主要由α-Mg和β-Mg17Al12相组成;在AZ80+Ce中除了有α-Mg和β-Mg17Al12相外,还有Al11Ce3稀土相存在;在AZ80+Y合金中,由于Y的含量较少,XRD谱中没有发现稀土相的存在。在所有含稀土的合金中,β-Mg17All2相对应峰强度降低,这是因为在形成铝稀土相的同时消耗了Al元素,减少了β-Mg17All2相形成的数量,这与上述组织分析结果一致。

图2 铸态镁合金的XRD谱

Fig. 2 XRD patterns of as-cast Mg alloys

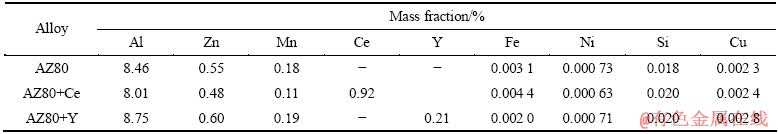

图3 铸态AZ80+Ce和AZ80+Y镁合金的SEM像((a),(b))及其化合物的EDS谱((c)~(e))

Fig. 3 SEM images of as-cast AZ80+Ce and AZ80+Y alloys and EDS spectra of compounds

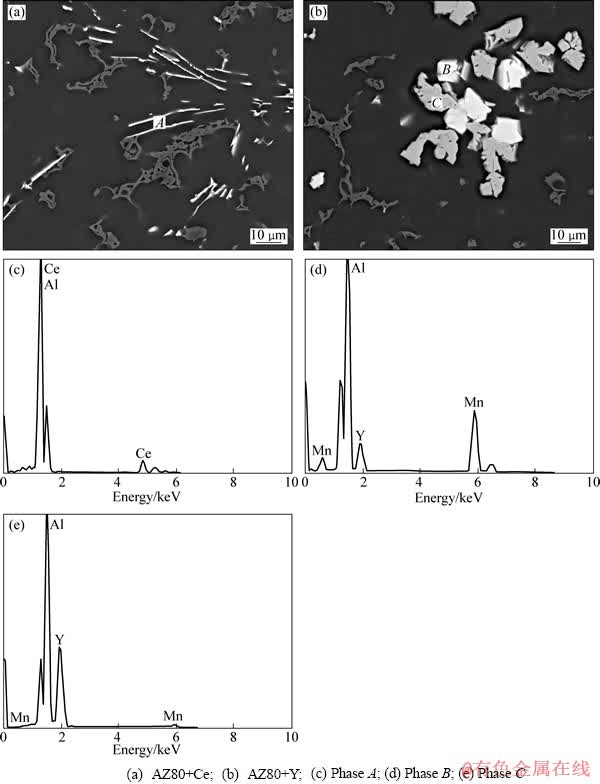

图4 镁合金的固溶态金相组织

Fig. 4 Microstructures of as-homogenized Mg alloys

图5 AZ80+Ce合金固溶态的SEM像及化合物D和E的EDS谱

Fig. 5 SEM image of as-homogenized AZ80+Ce alloy (a) and EDS spectra of phases D (b) and E (c)

图3所示为AZ80+Ce和AZ80+Y合金铸态组织的SEM像。由图3可看出,含有稀土Ce的合金组织中(见图3(a)),β-Mg17All2相被打断,出现了新的针状相,利用电子能谱对这些针状相A分析发现(见图3(c)),这些相是由Al和Ce组成,相成分是85.6Al-14.4Ce,结合XRD分析,这些针状相是Al11Ce3。含有稀土Y的合金组织中(见图3 (c))有两种不同的新相出现,一种是亮白色的块状相,另一种是在亮白色相周围的灰白色的块状相,通过EDS分析(见图3 (d)~(e)),两种相都是Al、Y、Mn这3种元素组成的,其中亮白色相B的成分是67.71Al-29.89Y-2.40Mn,这种相应该是Al2(Y,Mn);灰白色相C的成分是64.25Al-26.93Mn-8.82Y,根据文献[15]可以判断,这种相是Al8YMn4。

稀土元素对AZ80镁合金微观组织的影响主要归因于镁合金凝固过程中稀土所起到的作用。没有添加稀土元素时,AZ80镁合金凝固初期的形核数量较少,凝固过程中α-Mg枝晶凝固前沿的成分过冷较小,枝晶能够充分长大且不产生更多的分枝。因此,各枝晶间相互生长连接的机会相对较低,剩余的液相可以相互联通,这有利于不完全离异共晶β-Mg17Al12相的充分生长。此外,在α-Mg枝晶长大过程中,由于溶质再分配的结果,在凝固前沿产生了稀土元素的富集,形成较为强烈的成分过冷,促使α-Mg产生更多的分枝。这些分枝相互连接,把剩余的液相分割成无数封闭孤立的细小液岛,这些封闭孤立的微小区域限制了共晶β-Mg17Al12相生长并有利于形成完全离异共晶[16]。

2.3 稀土Ce、Y对固溶处理和挤压组织的影响

图4所示为AZ80、AZ80+Ce和AZ80+Y合金固溶态的微观组织。图5所示为AZ80+Ce合金固溶态的SEM像及化合物D和E的EDS谱。所有合金经固溶处理后,β-Mg17Al12相大部分溶于基体。AZ80+Ce镁合金在晶界和晶内仍然保留有针状相(见图4(b)中箭头所示)和少量块状相,通过对这两种相进行电子能谱分析发现,针状相是Al11Ce3相(见图5(a)中D相所示),块状相是Al8CeMn4相(见图5(a)中E相所示),这是由于Al11Ce3相的熔点高(熔点1235℃),几乎不溶于基体造成的;AZ80+Y镁合金在晶界附近残留有少量块状相,这些相应该是Al2Y和Al8YMn4相(见图4(c)箭头),Al2Y的熔点高达1 485 ℃,也不溶于基体。

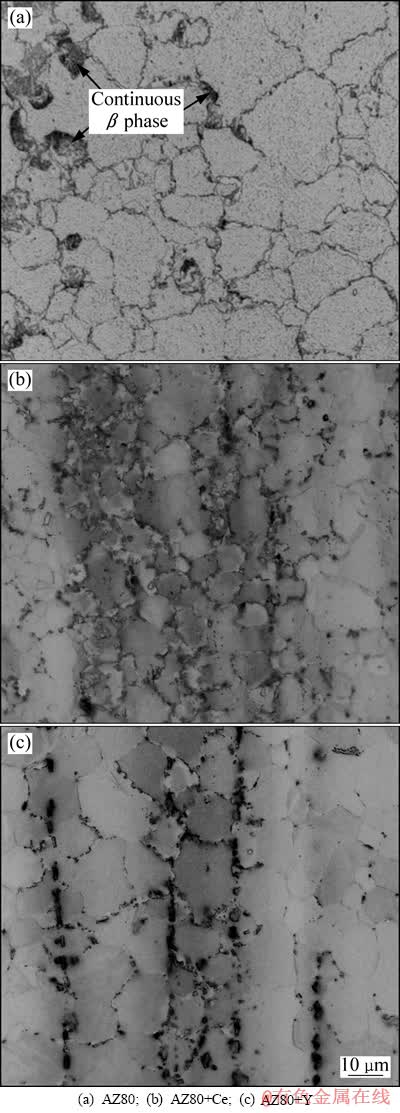

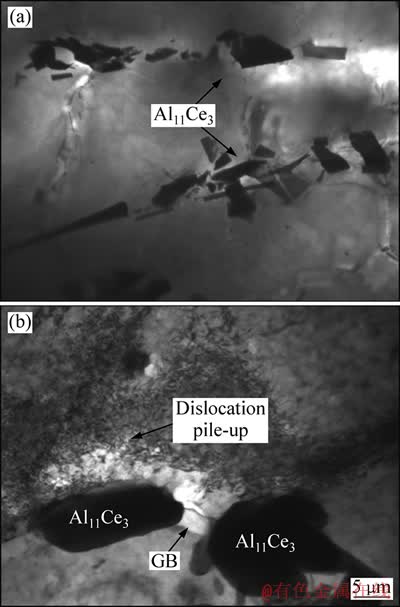

图6所示为AZ80、AZ80+Ce和AZ80+Y合金挤压态微观组织。图7所示为AZ80+Ce合金经热挤压后的TEM像。由图6可看出,由于挤压温度高于再结晶温度,合金都发生了明显的再结晶。AZ80在热挤压后,组织再结晶并严重粗化,晶粒尺寸在20~50 μm范围内。对于AZ80+Ce合金,合金组织也发生了再结晶,但晶粒细小且比较均匀,平均晶粒尺寸约为15 μm,沿挤压方向,在晶界上可以看到破碎的Al-RE相;AZ80+Y合金的再结晶晶粒也很细小,平均晶粒尺寸约为20 μm。

通过对挤压组织分析表明,稀土加入到AZ80合金后有明显的细化晶粒作用。这是由于稀土添加后,形成了高熔点Al-RE相,经挤压后明显破粹变细。再结晶时,处于晶界上的Al-RE相,通过抑制位错的滑移(见图7(b)),阻碍了晶界或亚晶界的迁移。另外,在Al-RE相周围,挤压时明显产生畸变,畸变区域具有高的位错密度和相对大的晶界取向差,成为再结晶的核心,增大了形核率。

2.4 稀土Ce、Y对合金性能的影响

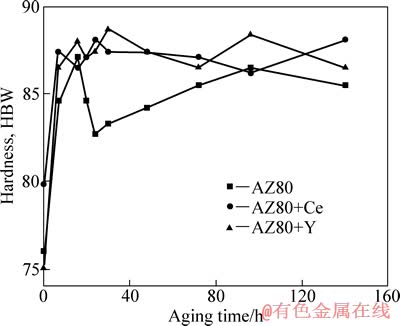

图8所示为挤压态合金在177℃的时效硬化曲线。由图8可看出,AZ80合金时效16 h后,达到峰值硬度,合金的硬度由76HBW增加到87HBW,合金的硬度通过时效增加了11HBW。当AZ80合金添加稀土Ce和Y元素后,合金时效硬化的速率降低,AZ80+Ce和 AZ80+Y合金达到峰值硬度的时间分别是24 h和30 h,这表明稀土添加延长了AZ80合金的时效峰值硬化时间。AZ80+Y合金达到峰值硬度后,合金的硬度增加了13HBW,AZ80+Ce合金在挤压态时具有最高的硬度,达到80HBW,这是由于高熔点Al11Ce3相在固溶处理过程中仍然保留,因此提高了合金挤压态的硬度,但是因为稀土Ce减少了固溶在基体中的Al含量,所以时效硬化后的硬度增加较少,仅有8HBW。

图6 AZ80镁合金和AZ80+RE镁合金的挤压态组织

Fig. 6 As-extruded microstructures of AZ80 (a) and AZ80+RE (b), (c) Mg alloys

根据WANG等[17]的研究,添加稀土Nd后能够通过阻碍基体中Al和Mg原子的扩散和Al-Nd相占据晶体空穴抑制β-Mg17Al12相的形核,从而在时效过程中阻碍晶界上连续β-Mg17Al12相的生成,导致AZ80+1%Nd (质量分数)合金峰值时效时间滞后。本研究中添加稀土Ce和Y也导致AZ80合金时效硬化的速率明显降低,其原因应该也与Nd元素的添加一致。

图7 AZ80+Ce合金经热挤压后的TEM像

Fig. 7 TEM image of as-extruded AZ80+Ce alloy

图8 挤压态 AZ80合金和AZ80+RE合金在177 ℃的时效硬化曲线

Fig. 8 Aging hardening curves of extruded AZ80 and AZ80+RE alloys at 177 ℃

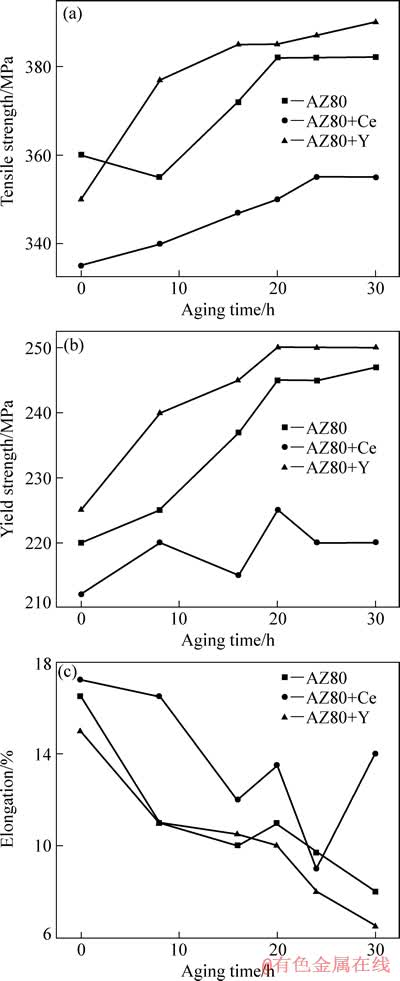

图9所示为合金热挤压后力学性能随时效时间增加的变化曲线。从图9(a)和(b)可以看出,合金在时效过程中均具有时效强化效果,所有合金的抗拉强度和屈服强度随时效时间的增加而增加;在达到最高强度后继续时效,合金的抗拉强度和屈服强度的变化较小。AZ80合金达到最大抗拉强度的时间是20 h,而添加稀土Ce和Y后,合金抗拉强度达到最大所需的时间也增加,分别达到24和30 h,根据图8和9的分析表明,合金力学性能随时效时间的变化与合金硬度随时效时间的变化是一致的。其中,AZ80+Y的时效反应最强,抗拉强度和屈服强度通过时效增加的幅度是40 MPa和25 MPa;其次是AZ80合金,抗拉强度和屈服强度通过时效增加的幅度均是22 MPa;AZ80+Ce合金的时效强化幅度最小,合金的抗拉强度和屈服强度也最小。

图9 挤压态AZ80和AZ80+RE合金时效时间与力学性能的关系

Fig. 9 Relationship between ageing time and mechanical properties of extruded AZ80 and AZ80+RE alloys

从图9(c)可以看出,合金的断裂伸长率与强度结果正好相反,AZ80+Ce合金的断裂伸长率最高, AZ80+Y合金的断裂伸长率最低。这表明添加Y元素能够提高AZ80合金的抗拉强度和屈服强度,添加Ce元素能够提高AZ80合金的塑性,但降低了合金的强度。

对于AZ80合金和AZ80+RE合金,在挤压态时,合金的力学性能是细晶强化、固溶强化和挤压过程中第二相析出弥散强化共同作用的结果。通过挤压变形,可以细化合金晶粒,提高合金的强度和塑性;AZ80合金在挤压态时的抗拉强度最高,这表明尽管稀土元素Ce和Y的添加细化合金挤压态晶粒,但固溶强化对AZ80和AZ80+RE合金挤压态力学性能起到了主导作用,这是因为当添加稀土元素Ce和Y后,生成了高熔点Al-RE相,难以在固溶处理过程中分解,导致Al对合金的固溶强化作用降低,其中添加稀土Ce的合金消耗了更多的Al元素,AZ80+Ce合金的固溶强化作用最弱。另外,在合金挤压过程中,第二相析出的弥散强化也是重要因素,从图6(a)可以观察到,AZ80合金挤压后在晶界附近由于挤压后冷却而析出的连续β相,这些析出相也能够提高合金的挤压态力学性能,而由于稀土对连续β相的抑制作用,没有在AZ80+Ce合金和AZ80+Y合金挤压态组织中观察到明显的连续β相析出(见图6(b)和(c))。

AZ80合金是淬火热处理强化镁合金,在时效过程中析出β-Mg17Al12相,大量第二相析出对合金起到沉淀强化作用,其中不连续β相的强化效果强于连续β相[18]。研究表明[17],稀土的添加能够抑制连续β相的析出,促进不连续β相的析出,从而改善合金的力学性能。稀土Ce添加AZ31和AZ61合金中能改善合金的力学性能[11-13],这是由于AZ31和AZ61合金中Al的含量较低,不能通过热处理强化,只能利用塑性变形来提高合金的力学性能,细化晶粒是提高这两种合金强度的重要途径,稀土Ce可以与Al元素形成高熔点A1-Ce相,在热挤压和退火的过程中,能够阻碍晶粒或亚晶粒的长大,使晶粒细化,从而达到提高合金力学性能的目的,这与AZ80合金的强化途径是有差异的。稀土Ce的添加尽管能够细化AZ80合金的挤压态晶粒,并且促进不连续β相的析出,但由于Ce消耗了较多的Al元素,并且由于凝固过程中Ce元素的偏析,造成了Al元素在合金中的偏析加剧,导致在合金时效时出现析出贫乏区,从而减弱了合金的时效强化作用。

稀土Y在AZ80合金中的含量很少,在抑制连续β相析出和促进不连续β相析出的同时,对Al元素在合金中的固溶量影响很小,同时Y对合金有很好的组织细化作用,通过固溶处理和挤压变形后能够使Al元素均匀分散在合金组织中,因此AZ80+Y合金具有很好的时效强化效果;相对于AZ80+Y合金,AZ80合金中Al元素固溶量没有受到稀土元素的影响而减少,但是由于较多连续β相的析出,减弱了沉淀相对合金的强化作用,同时,挤压后动态再结晶晶粒发生严重长大,一定程度上造成了Al元素在合金中的偏析,因此,AZ80合金的时效强化效果弱于AZ80+Y合金的。

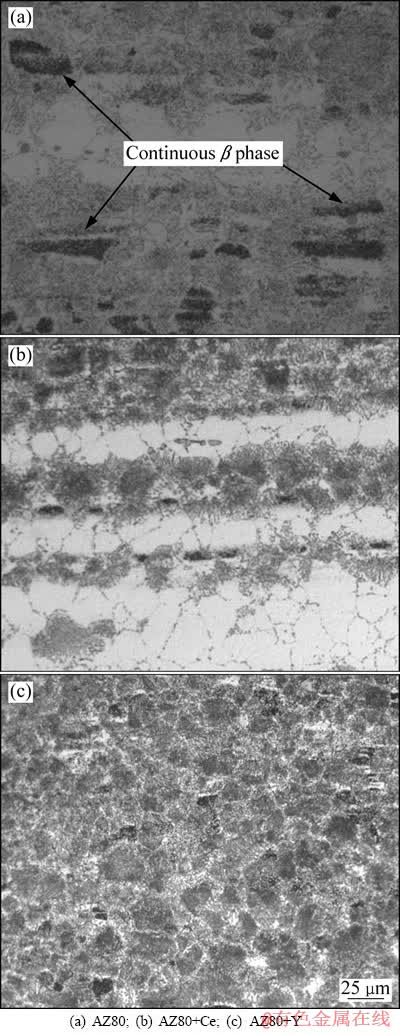

图10 挤压态AZ80和AZ80+RE合金峰值时效后的金相组织

Fig. 10 Metallographs of extruded AZ80 Mg alloy and peak-aged AZ80+RE Mg alloy

通过对AZ80合金和AZ80+RE合金时效后的金相分析也证实了这个解释。图10所示为合金热挤压时效后的金相组织。由图10中看出,合金时效后,晶粒内部析出了大量沉淀相。其中,从图10(a)可以看出,AZ80合金中有较多连续β相的析出(见图中箭头);而在AZ80+Ce合金(见图10(b))中,连续β相的析出明显减少,但沿挤压方向也有明显的被拉长的析出贫乏区。AZ80+Y合金的沉淀析出均匀分布(见图10(c)),几乎没有析出贫乏区。

2.4 断口形貌分析

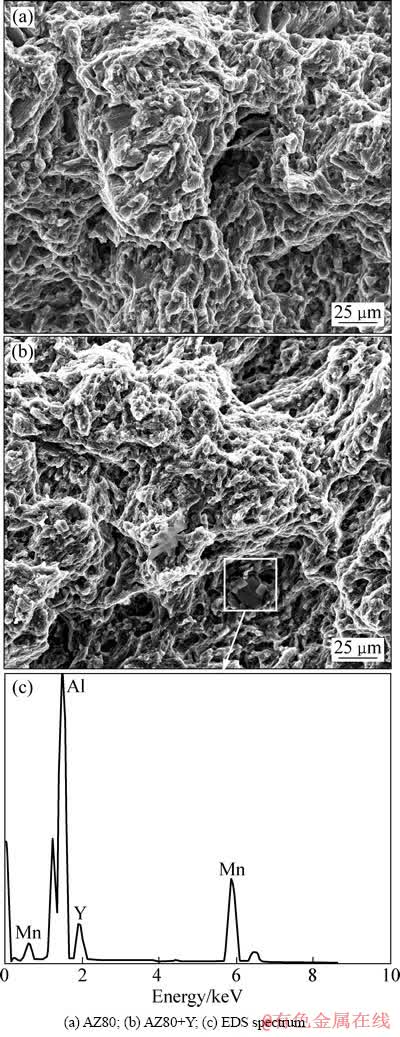

图11 合金的断裂形貌及其选择区化合物的EDS谱

Fig. 11 Fracture morphologies of alloys and EDS spectrum of selected area

AZ80合金和AZ80+Y合金的断口形貌如11所示。从图11(a)可以看出,AZ80合金的室温拉伸断口上除了存在大量的韧窝外,还有很多小的解理台阶和撕裂棱,表现出混合断裂特征。AZ80+Y合金的断口形貌转变为韧性断裂特征,有大量的小韧窝以及撕裂棱存在,一些块状相发生碎裂(见图11(b)选择区),通过EDS分析发现,这些相是Al8YMn4相(见图11(c)),这可能成为合金的断裂源,也是添加Y降低AZ80合金伸长率的原因。

3 结论

1) 稀土元素Y能够在AZ80合金熔炼过程中通过同Al、Fe、Mn等元素以化合物的形式沉淀,起到降低Fe含量的作用,同时,合金中Y含量也明显损失。

2) AZ80合金中分别添加稀土Ce和Y后,可以显著细化合金的铸态组织,β-Mg17Al12相由连续网状分布转变为弥散断续状分布,并在晶界上分别析出针状Al11Ce3相和块状Al2Y相。

3) 稀土元素能够显著细化AZ80合金的挤压再结晶晶粒,由于稀土Ce和Y能够抑制连续β-Mg17Al12相的析出,导致合金达到时效峰值硬化的时间被延长;通过人工时效,AZ80+Y合金的性能最高,抗拉强度、屈服强度和伸长率分别是390 MPa、250 MPa和6%,AZ80+Ce合金的性能最低,抗拉强度、屈服强度和伸长率分别是355 MPa、220 MPa和9%。

REFERENCES

[1] MORDIKE BL, EBERT T. Magnesium properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] 师昌绪, 李恒德, 王淀佐, 李依依, 左铁镛. 加速我国金属镁工业发展的建议[J]. 材料导报, 2011, 15(4): 5-6.

SHI Chang-xu, LI Heng-de, WANG Dian-zuo, LI Yi-yi, ZUO Tie-yong. A proposal on acceleration development of metallic magnesium industry in China[J]. Materials Review, 2011, 15(4): 5-6.

[3] 王渠东, 丁文江. 镁合金研究开发现状与展望[J]. 世界有色金属, 2004, 7: 8-11.

WANG Qu-dong, DING Wen-jiang. The status and outlook of magnesium alloy research and exploration[J]. World Nonferrous Metals, 2004, 7: 8-11.

[4] KANEKO T, SUZUKI M. Automotive applications of magnesium alloys[J]. Materials Science Forum, 2003, 419/422: 67-72

[5] 陈振华 变形镁合金[M]. 北京: 化学工业出版社, 2005: 1.

CHEN Zhen-hua. Wrought magnesium[M]. Beijing: Chemical Industry Press, 2005: 1.

[6] SMOLA B, STULIKOVA I, PELCOVA J, MORDIKE B L. Significance of stable and metastable phases in high temperature creep resistant magnesium-rare earth base alloys[J]. Journal Alloy and Compound, 2004, 378: 196-201.

[7] 吴安如, 夏长清, 董丽君. 稀土Ce和Y在ZK60合金中的分布及其对性能的影响[J]. 稀有金属材料与工程, 2007, 36(11): 1955-1959.

WU An-ru, XIA Chang-qing, DONG Li-jun. Distributing, evolvement and effect on the mechanical properties of the rare-earth Ce, Y in ZK60 alloys[J]. Rare Metal Materials and Engineering, 2007, 36(11): 1955-1959.

[8] ROKHLIN L L. Magnesium alloys containing rare earth metals[M]. New York: Taylor and Francis, 2003: 12-13.

[9] KHOMAMIZADEH F, NAMI B, KHOSHKHOOEI S. Effect of rare-earth element additions on high-temperature mechanical properties of AZ91 magnesium alloy[J]. Metallurgical and Materials Transactions A, 2005, 36(12): 3489-3493.

[10] WANG J, ZHOU J X, TONG W H, YANG Y S. Effect of purification treatment on properties of Mg-Gd-Y-Zr alloy[J]. Transaction of Nonferrous Metals Society of China, 2012, 20(5): 1235-1239.

[11] 王少武, 夏长清, 吴安如. 稀土铈对AZ31镁合金显微组织和力学性能的影响[J]. 矿冶工程,2006, 26(4): 76-78.

WANG Shao-wu, XIA Chang-qing, WU An-ru.Effects of Ce on the microstructure and mechanical properties of AZ31 magnesium alloy[J]. Mining and Metallurgical Engineering, 2006, 26(4): 76-78.

[12] 周海涛, 曾小勤, 刘文法, 丁文江, 朱燕萍. 稀土铈对AZ61变形镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2004, 14(1): 99-104.

ZHO Hai-tao, ZENG Xiao-qin, LIU Wen-fa, DING Wen-jiang, ZHU Yan-ping. Effect of Ce on microstructures and mechanical properties of AZ61 wrought magnesium[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 99-104.

[13] 吴 伟, 盛晓方, 邹智厚, 王 珏, 陈立佳, 刘 正. 稀土元素Nd在热挤压AZ61镁合金中的作用[J]. 沈阳工业大学学报, 2007, 29(1): 24-27.

WU Wei, SHENG Xiao-fang, ZOU Zhi-hou, WANG Jue, CHEN Li-jia, LIU Zheng. Effect of neodymium in hot-extruded AZ61 magnesium alloy[J]. Journal of Shenyang University of Technology, 2007, 29(1): 24-27.

[14] 张洪杰, 孟 健, 唐定骧. 高性能镁-稀土结构材料的研制、开发与应用[J]. 中国稀土学报, 2004, 22(1): 40-45.

ZHANG Hong-jie, MENG Jian, TANG Ding-xiang, Investigation, exploitation and application of magnesium-rare earth alloy as a structure material[J]. Journal of the Chinese Rare Earth Society, 2004, 22(1): 40-45.

[15] 吴国华, 樊 昱, 翟春泉, 丁文江. 稀土La对AZ91D镁合金在NaC1溶液中耐蚀性的影响[J]. 金属学报, 2008, 44(10): 1247-1252.

WU Guo-hua, FAN Yu, ZHAI Chun-quan DING Wen- jiang. Effect of La on the corrosion resistance of AZ91D magnesium alloy in NaCl aqueous solution[J]. Acta Metallurgica Sinica, 2008, 44(10): 1247-1252.

[16] 宋雨来. 稀土改性AZ91镁合金组织和腐蚀性能[D]. 长春: 吉林大学, 2006: 46-47.

SONG Yu-lai. Mcrostructure and corrosion resistance of AZ91 magnesium alloy modified by rare earth[D]. Changchun: Jilin University, 2006: 46-47.

[17] WANG Y X, FU J W, YANG Y S. Effect of Nd addition on microstructures and mechanical properties of AZ80 magnesium alloy[J]. Transaction of Nonferrous Metals Society of China, 2012, 22(16): 1322-1328.

[18] 潘复生, 韩恩厚. 高性能变形镁合金及加工技术[M]. 北京: 科学出版社, 2007: 85.

PAN Fu-sheng, HAN En-hou. High performance wrought magnesium alloys and processing technology[M]. Beijing: Science Press, 2007: 85.

(编辑 李艳红)

基金项目:浙江省自然科学基金资助项目(LQ12E01002)

收稿日期:2012-12-13;修订日期:2013-10-22

通信作者:王 军,副研究员,博士;电话:0574-87902702;E-mail:nafion412@163.com