Ti-6Al-4V合金的动态控制等离子焊接

来源期刊:中国有色金属学报(英文版)2011年第7期

论文作者:陈建春 潘春旭

文章页码:1506 - 1512

关键词:动态控制等离子焊接;Ti 合金焊接;显微结构;断口;显微硬度

Key words:dynamically controlled plasma arc welding; Ti alloy welding; microstructure; fracture; microhardness

摘 要:介绍了一种新的动态控制等离子焊接工艺。该工艺能够在保持完全焊透的情况下减少对被焊材料的热输入。利用该工艺对Ti-6Al-4V合金实施平板对焊。利用光学显微镜、扫描电镜(SEM)和显微硬度计对焊接接头的显微组织、断口形貌和显微硬度进行表征。与钨极电弧焊接和常规的等离子焊接相比较,使用本工艺提高了焊接质量,其原因在于:1) 由于热输入的减少,焊缝中先析出的β相晶粒大幅度减少,从而使马氏体的形成得到抑制;2) 焊接接头具有更好的韧性和更高的硬度。

Abstract:

A novel dynamically controlled plasma arc welding process was introduced, which is able to minimize heat input into the workpiece materials while maintaining desired full penetration, and it was used to weld Ti-6Al-4V alloy sheets. The microstructures, facture surfaces and microhardness of the welded joints were characterized by using optical microscope, scanning electron microscope (SEM) and Vickers microhardness tester. Comparing with welds such as gas tungsten arc and conventional plasma arc processes, the experimental results revealed the improvements when using the present process including: 1) reducing prior-beta (β) grain size and prohibiting formation of hard martensite phases in the fusion zone due to the decreased heat input; and 2) better toughness and higher hardness.

CHEN Jian-chun, PAN Chun-xu

Center for Electron Microscopy, School of Physics and Technology, Wuhan University, Wuhan 430072, China

Received 20 August 2010; accepted 7 April 2011

Abstract: A novel dynamically controlled plasma arc welding process was introduced, which is able to minimize heat input into the workpiece materials while maintaining desired full penetration, and it was used to weld Ti-6Al-4V alloy sheets. The microstructures, facture surfaces and microhardness of the welded joints were characterized by using optical microscope, scanning electron microscope (SEM) and Vickers microhardness tester. Comparing with welds such as gas tungsten arc and conventional plasma arc processes, the experimental results revealed the improvements when using the present process including: 1) reducing prior-beta (β) grain size and prohibiting formation of hard martensite phases in the fusion zone due to the decreased heat input; and 2) better toughness and higher hardness.

Key words: dynamically controlled plasma arc welding; Ti alloy welding; microstructure; fracture; microhardness

1 Introduction

Ti-6Al-4V is an alpha (α) + beta (β) titanium alloy widely used in aerospace, marine and some automotive applications as well as surgical implants, due to its high specific strength and stiffness and its inherently good corrosion resistance. However, its weldability is poor [1-2], because of the formation of acicular hard martensite and a large prior beta (β) grain size in the fusion zone (FZ) which leads to a low ductility [1, 3-5]. In general, gas tungsten arc welding (GTAW) process has a larger heat input during welding, resulting in a large solidification grain size [1, 6-8]. Many methods have been used for minimizing the grain size, such as, adding yttrium inoculation [9], microcooler inoculation [10], and using magnetic arc oscillation [11]. The lower heat input processes such as electron beam welding (EBW) [1, 12] and laser beam welding (LBW) [13] can reduce prior-beta (β) grain size; however, they generally have an increased post-weld cooling rate which promotes a more acicular martensite transformation. It is therefore necessary to implement a post-weld heat treatment to impart sufficient ductility to the fusion zone and heat-affected zone (HAZ) [1, 12, 14].

Clearly, it is desirable to have a welding process that can not only reduce the prior-beta (β) grain size in the fusion zone and heat-affected zone (HAZ), but also not adversely affect the intragranular microstructures. In this study, we use a dynamically controlled plasma arc welding process which switches between the keyhole and non-keyhole welding modes [15]. This controlled plasma arc welding process (PAW) process can eliminate excess heat input while guaranteeing the penetration of the sheet workpiece material. It ensures that the heat input is reduced to the minimum necessary for successful welding. This minimization of heat input has advantages in the welding of Ti alloys. The heat input minimization reduces the resulting weld grain size without increasing the intragranular acicular microstructure. This paper reports the detailed microstructure and property characteristics of Ti-6Al-4V alloy weldments produced using the dynamically controlled PAW. For comparison, the welds produced using regular PAW [16-17] and GTAW processes were also evaluated.

2 Principle of dynamically controlled plasma arc welding process

In comparison with existing arc welding processes, keyhole PAW technology has the lowest heat input. However, to practise keyhole PAW technology, the keyhole must be maintained without allowing it to close. Yet we lack practical solutions to monitor how far the keyhole is from closing. Thus, because of process variables, a heat input much larger than the necessary is typically used to ensure the keyhole. As a result, excess heat is input and an amount of molten metal is increased.

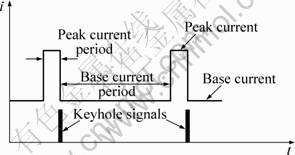

Dynamic control may offer a way to further reduce the heat input from the keyhole PAW process. In this study, the keyhole is deliberately allowed to close for a specified period of time to reduce the heat input and the mass of the weld pool, as shown in Fig. 1. After this closure period, a peak current is applied to re- establishing the keyhole. After the keyhole is re-established, the current is switched to the base level again to allow reclosure of the keyhole. In this way, the process is not exactly maintained at the keyhole mode of the classical definition, but at a quasi-keyhole mode. The resultant process can be referred to be dynamically controlled PAW or simply controlled PAW.

Fig. 1 Controlled quasi-keyhole process

The most desirable characteristic of the dynamically controlled PAW process is its mechanism to minimize excess heat input, and mass of the weld pool. In fact, after the current is switched to the base level, the mass of the molten metal or the size of the weld pool decreases. Before it reduces excessively, the current is switched back to the peak level. As a result, the mass of the molten metal grows. When it becomes just sufficient, the keyhole quickly resumes due to the large plasma arc pressure associated with the peak current (The pressure is proportional to the square of the current and the heat input is proportional to the current [15]). After the re-establishment of the keyhole is detected, the current is again switched to the base level. At this instant, the mass of the molten metal reaches its maximum. Of course, this maximum is only just sufficient to allow the large plasma arc pressure associated with the peak level current to re-establish the keyhole and only needs to be maintained for a short period of time. Hence, the dynamically controlled PAW process can minimize excess heat input as well as excessive mass of molten metal.

3 Experimental

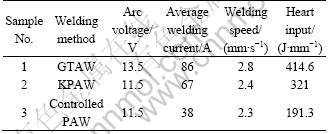

In this work, a 3.2 mm-thick (1/8 inch) commercial hot rolled Ti-6Al-4V alloy plate was used. In addition to the dynamically controlled PAW, GTAW and regular keyhole PAW were selected to make comparative welds. Table 1 gives the major welding conditions. The shielding gas of pure argon was used on both sides of the workpiece during welding. Prior to welding, all samples were pickled in a solution containing 35% HNO3+ 5% HF+60% H2O (volume fraction), rinsed in water and methanol, and dried.

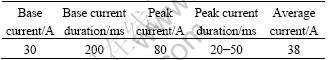

Table 1 Process parameters of different welding methods

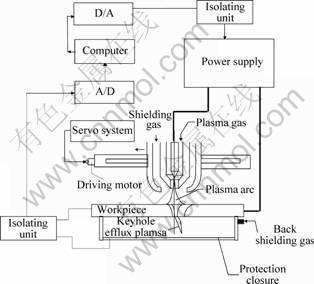

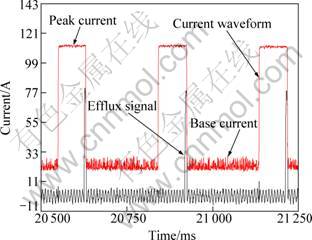

Figure 2 shows the control system used to implement the dynamically controlled PAW. The establishment of the keyhole was detected using the efflux plasma charge sensor which measures the voltage signal produced by the plasma exit from the bottom surface of the workpiece. This sensor has been detailed previously [18]. The signal from the sensor was imported into the computer via an analog-to-digital converter (A/D). Figure 3 illustrates a typical waveform of the sensor signal recorded during welding. The threshold for the keyhole establishment was set to be 0.5 V. That is, if the signal is greater than 0.5 V, it is determined that the keyhole is present. Otherwise, the keyhole is not present.

The peak current can be selected in a relatively large range as long as it is sufficient to ensure the establishment of the keyhole under all possible manufacturing conditions of interest but not so excessive to burn the orifice and cause double arcs. In this study, the welding speed was 2.3 mm/s and the diameter of the orifice was 1.8 mm which permits maximally current of 200 A. The peak current was selected to be 80 A.

Fig. 2 Experimental set-up of control system

Fig. 3 Typical current waveform and efflux signal during dynamically controlled plasma arc welding

The base current can also be selected in a relatively large range as long as the keyhole can be rapidly closed and the arc can be maintained after the base current is applied. The period of the base current should be selected so that the weld pool size is substantially reduced before the peak current is reapplied. However, if the period of the base current is too long, the weld metal melted in each pulse may not be well connected to form a quality weld. In this study, the base current and its period were 30 A and 200 ms, respectively.

Although the base current, its period, and the peak current were set to be constant, the duration of the peak current varied because the peak current was switched to the base current when the keyhole was detected. Hence, the end instant of the peak current period was determined by the process which was subjected to the influence of complicated welding conditions. In this study, the period of the peak current varied from 20 ms to 50 ms. This implies that the frequency of the keyhole establishment was approximately 4 Hz. The average current was 38 A. The welding parameters used are listed in Table 2.

Table 2 Process parameters for dynamically controlled PAW

Specimens cut from the weld samples were mechanically polished and chemically etched with a solution of HF to reveal the macrostructure, and etched with a solution of 3 mL HF+6 mL HNO3+100 mL H2O to determine the microstructure. The macrostructures were examined using a Nikon SMZ800 stereoscopic zoom microscope. The microstructures were observed by using a Nikon Epiphot 300 optical metallurgical microscope. The Vickers microhardness measurements along the center line were taken in a Future-Tech FM-7 digital microhardness tester.

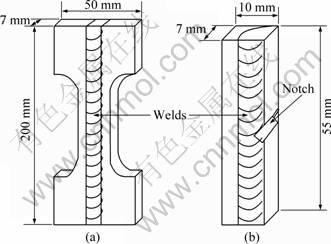

In order to evaluate the toughness of the welded joints, non-standard tensile and impact samples were designed [19], as shown in Fig. 4. The dimensions of the tensile samples were 200 mm×50 mm×7 mm (30 mm in the center), and the impact samples 55 mm×10 mm×7 mm, respectively. The designed specimen basically should include all parts of the individual regions in the joint, such as the weld metal, transition zone or interfacial region, HAZ and base metal. Therefore, the dimensions of the specimen were not strictly limited as for a standard Charpy V notch impact specimen of 55 mm×10 mm×10 mm. It can be designed optionally according to the actual weldment. Uncertain mechanical data may be obtained when using the regular standard tensile or impact test, because it is very difficult to locate a V-notch and required cracked surface in a consistent microstructural region when various samples are tested. In the present experiments, a cross-section of fracture surface including the weld metal zone, heat-affected zone and base metal can be obtained in one sample. Then a qualitative comparison of the morphology of fracture surfaces between joints can be implemented easily and clearly, and the experimental data are not necessarily comparable with each other or with standard data, because it arises from a mixture of different regions which have varied microstructures. Those samples were fractured at room temperature.

Fig. 4 Schematic diagram of non-standard designed samples: (a) Tensile sample; (b) Impact sample

4 Results and discussion

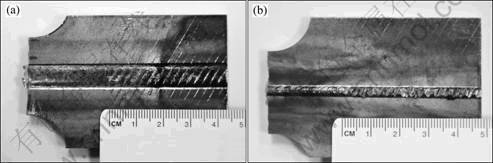

PAW is an extension of GTAW in which the arc is forced through a constricting nozzle and thus the energy is more concentrated. When using the keyhole technique for PAW, the welds are generally free of porosity [20] and the heat input is significantly reduced due to the concentration of the (plasma) heat jet, which is a desirable technique for welding of titanium (Ti) alloys. The present dynamically controlled PAW process not only ensures the advantages of keyhole PAW, but also reduces the heat input to a minimum, while still maintaining the desired full penetration, as shown in Fig. 5.

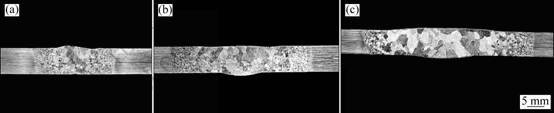

The macrostructures of the weldments using GTAW, keyhole PAW (without heat minimization), and dynamically controlled PAW processes are shown in Fig. 6. Clearly, the average prior-beta (β) grain size and width of the fusion zone and the heat-affected zone (HAZ) in the dynamically controlled PAW joint are much finer and smaller than those in both GTAW and keyhole PAW joints. However, higher magnification observations revealed that all these samples exhibit very similar microstructures within the fusion zones and the adjacent HAZ consisting of retained beta (β), intragranular acicular α and few acicular α′ martensite phases, as shown in Fig. 7.

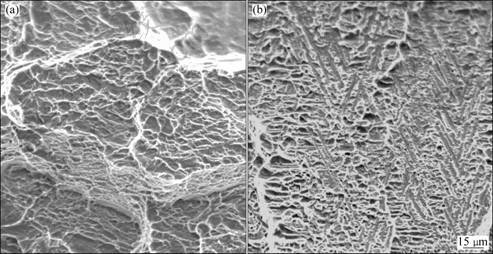

Examinations of the tensile and impact fracture surfaces of the fusion zone indicate that the dynamically controlled PAW process yields relatively high toughness, due to the presence of typical dimples inside the relatively small grains and obvious ridges at the boundary, as shown in Fig. 8 and Fig. 9. However, the fusion zone of the GTAW process shows a brittle fracture surface, in which the dimple growth was terminated by many acicular facets which actually are the cleavage cracking of acicular hard martensites. In other words, the acicular hard martensite unusually plays a decisive factor in the initiation of cracking. It inhibits the development of dimples and results in the smaller dimples inside the grains. Therefore, the materials with acicular sub-microstructure generally lead to a brittle facture.

Fig. 5 Keyhole PAW joint: (a) Front surface; (b) Bottom surface

Fig. 6 Macro-morphologies of welded joints: (a) Controlled PAW joint; (b) Keyhole PAW joint; (c) GTAW joint

Fig. 7 Microstructures of weld metal zone: (a) Controlled PAW joint; (b) Keyhole PAW joint; (c) GTAW joint

In general, the prior-beta (β) grain size and microstructure in the fusion zone, and the width of the weld zone are associated with both heat input and cooling rate during welding. In these three comparative processes, GTAW provides the highest heat input, while the dynamically controlled PAW delivers the lowest heat input. This means that dynamically controlled PAW has a higher cooling rate than either keyhole PAW or GTAW processes. This explains the reduced prior-beta (β) grain size and width of the joint when using the dynamically controlled PAW process. Moreover, an interesting phenomenon is that the lower heat input and higher cooling rate of the dynamically controlled PAW do not noticeably change the microstructures of the weld joint over those of GTAW and regular PAW, whereas lots of acicular hard martensite phases are induced when using EBW and LBW processes [1, 12-17].

The microstructural variation in titanium alloys usually arises in the region between 1 371 °C and the liquidus temperature [5]. During cooling, two kinds of phase transformation processes will happen in Ti-6Al-4V alloy. One is the diffusion-controlled β?α phase transformation; the other is the shear-controlled β?α′ phase transformation. According to the continuous cooling transformation diagram (CCT) [5], the temperature for β?α transformation decreases with increasing cooling rate (815.5 °C at 4 °C/s and 665.5 °C at 185.5 °C/s), and the temperature for β?α′ transformation (Ms=560 °C) is not affected by cooling rate. Thus, the fraction of α′ martensite will greatly increase with increasing cooling rate. In the present work, though the heat input is low and the cooling rate is relatively high in the dynamically controlled PAW process, it is still low compared to that in EBW or LBW. Therefore, on cooling, the β?α phase transformation principally occurs by diffusion and only few unstable β phase particles are available to transform into α′ martensite phase.

Fig. 8 SEM images of tensile fracture surface in fusion zone: (a) Controlled PAW joint; (b) GTAW joint

Fig. 9 SEM images of impact fracture surface in fusion zone: (a) Controlled PAW joint; (b) GTAW joint

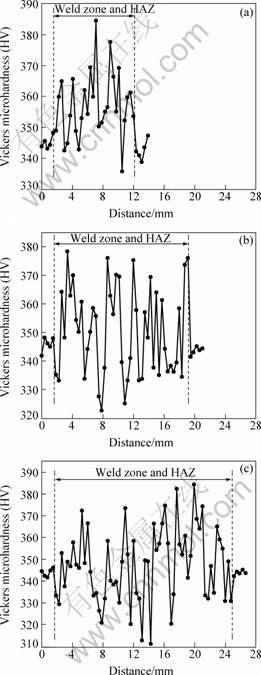

Figure 10 shows the relatively large variations and scattering of the Vickers microhardness values in the martensite phase. In fact, this average hardness level in weld zone and heat-affected zone (HAZ) indicates that the testing indentations were probably sometimes on the soft β phase and sometimes on the hard α′ martensite phase. Figure 10 indicates that the average hardness value of the dynamically controlled PAW joint is very slightly higher than that of the keyhole PAW and GTAW joints, presumably because of the higher cooling rate which may be expected to induce a slightly greater amount of α′, much lower than that of EBW or LBW joins [14, 21].

Fig. 10 Vickers microhardness profiles in welded joints: (a) Controlled PAW joint; (b) Keyhole PAW joint; (c) GTAW joint

5 Conclusions

1) Compared with GTAW and regular PAW processes, the present dynamically controlled PAW process offers a way to further reduce the heat input from the keyhole PAW process, that is, the keyhole is deliberately allowed to close for a specified period of time to reduce the heat input and the mass of the weld pool.

2) When the dynamically controlled PAW process is used to weld Ti alloys, it exhibits advantages of reducing prior-beta (β) grain size and prohibiting formation of hard martensite phases in the fusion zone.

3) The experimental results from fracture surface and microhardness in the welded zones demonstrate that the dynamically controlled PAW process greatly improves the ductility and hardness of the welded joint, which shows a desirable technique for application in titanium alloys welding.

Acknowledgements

The authors would like to thank Professor ZHANG Yu-ming from Department of Electrical and Computer Engineering and Center for Manufacturing at University of Kentucky, USA, for his samples and discussion.

References

[1] CHENG D H. Microstructure and mechanical analysis of Ti-6Al-4V laser butt weld joint [J]. Transactions of the China Welding Institution, 2009, 30(2): 103-106.

[2] YUAN Bao-guo, LI Chun-feng, YU Hai-ping, SUN Dong-li. Effect of hydrogen content and stress state on room-temperature mechanical properties of Ti-6Al-4V alloy [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: s423-s428.

[3] ZHAO H, HAN, Z, CHEN X F. Effect of scanning electron beam on solidified structure of welded Ti-6A1-4V alloy [J]. Transactions of the China Welding Institution, 2005, 26(1): 78-80.

[4] MOHANDAS T, BANERJEE D, KUTUMBA RAO V V. Fusion zone microstructure and porosity in electron beam welds of an alpha + beta titanium alloy [J]. Metallurgical and Materials Transactions A, 1999, 30(3): 789-798.

[5] WU K C. Correlation of properties and microstructure in welded Ti-6Al-6V-2Sn [J]. Welding Journal, 1981, 60(11): 219s-226s.

[6] KUMAR A, SAPP M, VINCELLI J, GUPTA M C. A study on laser cleaning and pulsed gas tungsten arc welding of Ti-3Al-2.5V alloy tubes [J]. Journal of Materials Processing Technology, 2010, 210: 64-71.

[7] LIN Y C, LIN Y C. Elucidation of microstructure and wear behaviors of Ti-6Al-4V cladding using tungsten boride powder by the GTAW method [J]. Journal Coating Technology Research, 2011, 8(2): 247-253.

[8] ROKHLIN S I, GUU A C. A study of arc force, pool depression, and weld penetration during gas tungsten arc welding [J]. Welding Journal, 1993, 72(8): 381s-390s.

[9] SIMPSON R P. Controlled weld-pool solidification structure and resultant properties with yttrium inoculation of Ti-6Al-6V-2Sn welds [J]. Welding Journal, 1977, 56(3): 67s-77s.

[10] HALLUM D L, BAESLACK III W A. Nature of grain refinement in titanium alloy welds by microcooler inoculation [J]. Welding Journal, 1990, 69(9): 326s-336s.

[11] SUNDARESAN S, JANAKI RAM G D. Use of magnetic arc oscillation for grain refinement of gas tungsten arc welds in alpha-beta titanium alloys [J]. Science and Technology of Welding and Jointing, 1999, 4(3): 151-160.

[12] BARREDA J L, AZPIROZ X, IRISARRI A M. Influence of the filler metal on the mechanical properties of Ti-6Al-4V electron beam weldments [J]. Vacuum, 2010, 85: 10-15.

[13] WANG G, ZHANG G L, JIN H, SUN J P. Superplasticity of Ti-6Al-4V butt-welding plate by high energy beam welding [J]. Hot Working Technology, 2007, 36(23): 4-7.

[14] WANG Guo-qing, WU Ai-ping, ZHAO Yue, ZOU Gui-sheng, CHEN Qiang, REN Jia-lie. Effect of post-weld heat treatment on microstructure and properties of Ti-23Al-17Nb alloy laser beam welding joints [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 732-739.

[15] ZHANG Y M, LIU Y C. Control of dynamic keyhole welding process [J]. Automatica, 2007, 43: 876-884.

[16] WU C S, WANG H G, ZHANG Y M. A new heat source model for keyhole plasma arc welding in FEM analysis of the temperature profile [J]. Welding Journal, 2006, 85(12): 284s-291s.

[17] SHU Hai-tao. Automatic micro-plasma arc welding of Ti alloy [J]. Aeronautical Manufacturing Technology, 2001(4): 54-56. (in Chinese)

[18] ZHANG S B, ZHANG Y M. Efflux plasma charge based sensing and control of joint penetration during keyhole plasma arc welding [J]. Welding Journal, 2001, 80(7): 157s-162s.

[19] PAN C X. Direct fractographic and microstructural evaluation of different zones within welded dissimilar steel joints [J]. Materials Science and Technology, 2005, 21(6): 657-664.

[20] OATES W R, DAITTA A M. Welding handbook: Vol.4, Materials and applications-part 2)[M]. 8th ed. Miami, F L, USA: American Welding Society, 1996: 517.

[21] TORSTER F, DOS SANTOS J F, KOCAK M, PENASA M. Mechanical and microstructural characterization of laser beam welded titanium alloys [C]//VITEK J M, DAVID S A, JOHNSON J A, SMARTT H B, DEBROY T. Trends in Welding Research, Proc 5th Inter Conf on International Trends in Welding Research. Materials Park, Ohio, USA: ASM International, 1999: 887-892.

陈建春,潘春旭

武汉大学 物理科学与技术学院,电子显微镜中心,武汉 430072

摘 要:介绍了一种新的动态控制等离子焊接工艺。该工艺能够在保持完全焊透的情况下减少对被焊材料的热输入。利用该工艺对Ti-6Al-4V合金实施平板对焊。利用光学显微镜、扫描电镜(SEM)和显微硬度计对焊接接头的显微组织、断口形貌和显微硬度进行表征。与钨极电弧焊接和常规的等离子焊接相比较,使用本工艺提高了焊接质量,其原因在于:1) 由于热输入的减少,焊缝中先析出的β相晶粒大幅度减少,从而使马氏体的形成得到抑制;2) 焊接接头具有更好的韧性和更高的硬度。

关键词:动态控制等离子焊接;Ti 合金焊接;显微结构;断口;显微硬度

(Edited by YANG Hua)

Foundation item: Project (2009CB939705) supported by the National Basic Research Program of China; Project (200233) supported by the Foundation for the Author of National Excellent Doctoral Dissertation of China (FANEDD)

Corresponding author: PAN Chun-xu; Tel: +86-27-68752969; E-mail: cxpan@whu.edu.cn

DOI: 10.1016/S1003-6326(11)60888-1