文章编号:1004-0609(2012)06-1564-06

7055铝合金厚板的淬透性

刘胜胆1, 2,李承波1, 2,李璐璐1, 2,邓运来1, 2,张新明1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 教育部有色金属材料科学与工程重点实验室,长沙 410083)

摘 要:通过末端淬火的方法研究7055铝合金厚板的淬透性,采用透射电子显微镜对微观组织进行分析。结果表明:该合金板材的淬透深度可达45 mm,使其淬透的冷却速率需大于230 ℃/min;随着冷却速率的减小,淬火过程析出平衡相的数量和尺寸增加,时效后析出的η′ 沉淀强化相的数量减少,晶界无沉淀析出带宽度增加;在所研究的冷却速率范围内,时效后铝合金板材的硬度、晶界无沉淀析出带宽度与冷却速率的对数均呈线性关系。

关键词:7055铝合金厚板;末端淬火;淬透性;微观组织

中图分类号:TG146.21 文献标志码:A

Hardenability of 7055 aluminum alloy plate

LIU Sheng-dan1, 2, LI Cheng-bo1, 2, LI Lu-lu1, 2, DENG Yun-lai1, 2, ZHANG Xin-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The hardenability of a 7055 aluminum alloy plate was studied by end quenching test, the microstructure was investigated by transmission electron microscopy. The results show that the hardened depth is about 45 mm for the plate and the corresponding cooling rate is about 230 ℃/min. With decreasing the cooling rate, the number and size of quench-induced equilibrium phase increase, the number of η′ strengthening precipitates decreases and the width of precipitate free zone near grain boundaries increases. In the range of the studied cooling rates, the relationships among the hardness, width of precipitate free zone near grain boundaries and logarithm of cooling rate are linear.

Key words: 7055 aluminum alloy plate; end quenching; hardenability; microstructure

7×××系铝合金经时效处理后具有较高的强度,一直以来都是航空工业中广泛使用的结构材料。近年来,飞机结构件向着大型化及整体化的方向发展,对大截面的7×××系铝合金厚板及锻件提出了迫切需求。但该系铝合金存在淬火敏感性,即固溶后淬火速率减小时,时效后得到合金的硬度、强度等性能下降[1-2]。这是因为淬火速率减小时,固溶体发生分解,在(亚)晶界、弥散粒子上析出无强化效果的第二相[1-3],消耗了溶质原子,减少了时效沉淀强化相的数量。因此,为了获得最佳的时效强化效果,材料固溶后必须快速淬火。而随着厚度的增加,或由于控制残余应力的需要,材料中心部分的淬火速率往往达不到所需的临界冷却速率,性能下降,出现淬不透的现象。因此,7×××系铝合金厚截面材料的淬透性问题引起了人们广泛的关注。

末端淬火方法是研究时效强化铝合金厚截面材料淬透性的有效途径,如刘君城等[4]和王国军等[5]通过末端淬火试验研究了2124和2D70铝合金的淬透性。在7×××系铝合金方面,张勇等[6]通过末端淬火方法研究了7050铝合金厚板的淬火敏感性,并得到了冷却速率与η平衡相体积分数及硬度值的定量关系;伊琳娜和汝继刚[7] 对7B04锻件的淬透性开展了研究,熊柏青等[8]采用末端淬火方法对7150、7B04及新型合金(Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr)的淬透性进行了评价。NEWKIRK和MACKENZIE[9]通过末端淬火方法研究了冷却速率对7075和7050合金硬度及微观组织的影响。采用这种方法可获得连续变化的冷却速率,建立冷却速率与微观组织演变的定量关系[6],从而深入认识冷却过程中微观组织演变规律和机理。在此,本文作者通过末端淬火方法对7055铝合金厚板的淬透性进行了研究,并采用透射电镜观察分析了冷却速率对微观组织的影响规律,建立起两者的定量关系,以期为7055铝合金厚板组织和性能的调控提供有意义的参考。

1 实验

研究所采用的材料是60 mm厚的7055铝合金板材,其成分如下(质量分数,%):Al-8.10Zn-2.08Mg- 2.25Cu-0.11Zr,w(Fe)<0.07%,w(Si)<0.07%。沿厚板的长横向切取横截面为25 mm×25 mm,长为125 mm的末端淬火样品,一端车出直径为20 mm、深为10 mm的圆形凹槽作为喷水冷却端,另一端加工出直径5 mm、深为15 mm的内螺纹,将样品固定在样品架上。样品在SX-4-10型箱式电阻炉中进行固溶处理,随炉升温至470 ℃,保温1 h后取出对样品凹槽端进行喷水冷却。样品冷却至室温后放入油浴炉中进行120 ℃、24 h人工时效,然后从中切开,沿中心线方向测试维氏硬度,得到硬度与离喷水端距离的关系曲线。硬度测试所采用的载荷为30 N,在每个位置沿垂直中心线的方向测5个值取平均值。另取同样尺寸的样品,在离喷水端不同距离的位置钻小孔埋入热电偶,测试端淬过程中的冷却曲线,计算出420~230 ℃范围的平均冷却速率,结果如图1所示。由图1(a)可知,随着离喷水端距离的增加,温度下降的速率不断减小,即冷却速率不断地减小。在3 mm处,温度下降速率最大,至78 mm和98 mm,冷却曲线基本重合,这说明在大于一定距离时,冷却速率接近。由图1(b)可知,在约60 mm以内,冷却速率随距离增加快速减小,从离喷水端3 mm位置的1 250 ℃/min减至60 mm处约140 ℃/min;大于60 mm的范围内,冷却速率变化很小。因此在离喷水端3 mm(1 250 ℃/min)、23 mm (630 ℃/min)、53 mm(164 ℃/min)及78 mm(138 ℃/min)位置处切取样品进行透射电镜(TEM)组织分析。TEM样品先预磨至约0.08 mm厚,冲成直径3 mm薄片,然后在80% CH3OH+ 20% HNO3(体积分数)溶液中进行双喷减薄,采用液氮冷却,温度控制在-20 ℃以下;组织观察在TECNAIG2 20型透射电镜上进行,加速电压为200 kV。

图1 末端淬火过程中样品不同位置的冷却曲线及冷却速率

Fig. 1 Cooling curves(a) and cooling rates(b) at different positions of end-quenched specimen

2 结果与分析

2.1 合金板材的淬透性曲线

图2所示为7055铝合金厚板末端淬火样品时效后的硬度曲线。由图2可看出,随着离喷水端距离的增加,硬度值呈下降趋势。在约60 mm以内时,硬度随距离的增加而快速下降;大于60 mm时,硬度基本不随距离增加而变化,约为170 HV,与喷水端的硬度相比,下降了约14%。若取硬度值下降10%时的距离为淬透深度,则认为在此淬火条件下,7055铝合金厚板的淬透深度约为45 mm,此时对应的硬度值约为177 HV。据图1(b)和图2(a)的结果,将硬度与冷却速率之间的关系绘制在图2(b)中。显然,样品的硬度随着冷却速率的增加而不断增加。对数据进行线性拟合,发现硬度(H)与冷却速率(vc)的对数有如下的关系:

H=111.0+27.8lg vc (1)

线性相关系数为0.998 1,表明在所研究的速率范围内硬度与冷却速率的对数间有很好的线性关系。硬度值为177 HV的位置所对应的冷却速率约为230 ℃/min,因此要使板材淬透,冷却速率需大于230 ℃/min。

图2 末端淬火样品时效后硬度与距离和冷却速率的关系

Fig. 2 Curves of hardness vs distance from water-cooled end(a) and hardness vs cooling rate(b) for end-quenched and aged specimen

2.2 合金板材的微观组织

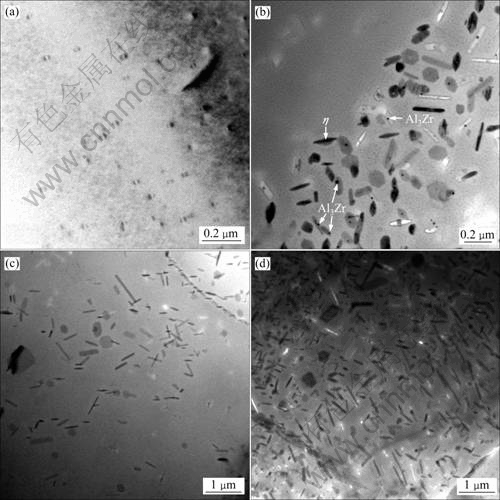

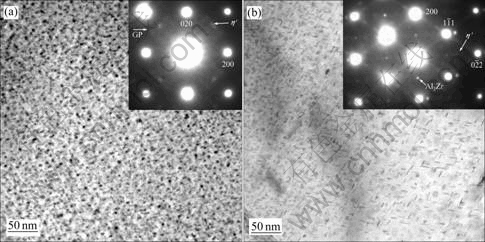

图3所示为不同冷却速率条件下样品时效后的TEM像。冷却速率为1 250 ℃/min时,晶内可观察到大量的豆瓣状Al3Zr弥散粒子,尺寸大都约为30 nm,如图3(a)所示。此时由于冷却速率较高,淬火过程中平衡相的析出被抑制,晶内几乎观察不到粗大平衡相的存在。当冷却速率降至630 ℃/min时,晶内可观察到很多粗大η平衡相,尺寸在0.15 μm左右,如图3(b)所示。这些平衡相大都和粒状Al3Zr弥散相粒子联系在一起。这些粒子由于再结晶时晶界的运动或本身的粗化而逐渐失去与基体的共格性,易成为平衡相的形核位置,增加了淬火敏感性[2, 10-11]。时效后,这些平衡相周围形成了明显的无沉淀析出带,应该是因为冷却过程中平衡相的析出导致周围基体中溶质原子浓度显著降低,时效时无沉淀强化相析出[2]。当冷却速率降至164 ℃/min时,晶内的粗大η平衡相的数量和尺寸都在增加,如图3(c)所示,个别η平衡相的长度可达1 μm。当冷却速率降至138 ℃/min时,晶内的粗大η平衡相的数量和尺寸显著增加,如图3(d)所示。这说明在冷却过程中η平衡相不断形核并长大,先形核的相尺寸较后形核的相尺寸更大。在更高倍数下观察发现,晶内覆盖着大量细小弥散的沉淀强化相,典型结果如图4所示。冷却速率为1 250 ℃/min时,晶内沉淀强化相主要是η′相及少量的GP区,如图4(a)所示。冷却速率降低时,时效后晶内析出的仍是η′相,如图4(b)所示,但η′沉淀强化相的密度减小,尺寸增加,数量减少。

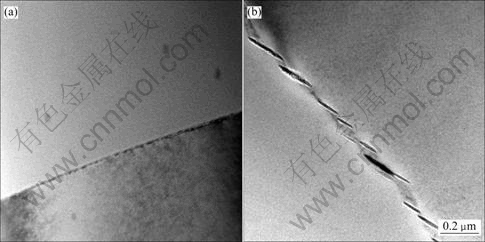

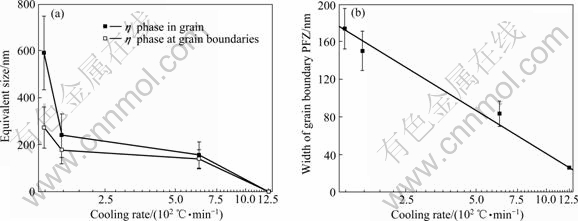

采用透射电镜对晶界析出状态观察发现,随着冷却速率的减小,大部分晶界上第二相的尺寸增加,分布不连续,晶界无沉淀析出带的宽度不断增加,典型结果如图5所示。在冷却速率为1 250 ℃/min时,大部分晶界上的第二相较细小,且呈连续分布状态;晶界无沉淀析出带很窄,宽度约为25 nm,如图5(a)所示。冷却速率减小至164 ℃/min时,如图5(b)所示,晶界上的第二相的尺寸明显增加,大的达数百纳米;晶界无沉淀析出带宽度也明显增加。显然,这些第二相在淬火过程中已经析出,在时效过程可继续长大。对多个晶界的无沉淀析出带的宽度进行测量取平均值,与冷却速率之间的关系如图6所示。

2.3 分析与讨论

7055铝合金是热处理可强化合金,其高硬度和高强度是通过时效后在基体中形成高密度的沉淀强化相而获得的。沉淀强化相的析出是一个均匀形核和长大的过程[12],其数量和分布受到固溶体中溶质和空位浓度的影响。溶质原子浓度降低会减少沉淀相的数量,空位浓度低不利于沉淀相的均匀弥散析出,从而导致时效强化效果差[1]。7055铝合金中合金元素含量较高,因此淬火敏感性高[13]。固溶后冷却速率较小时,固溶体发生分解而析出粗大η平衡相(见图3)。这些相尺寸大,没有强化效果,减少了基体中Zn、Mg溶质原子的含量,进而减少了时效η′ 沉淀强化相的数量,同时空位浓度的降低导致强化相的密度减小,尺寸增加(见图4),合金最终的硬度下降。在该合金厚板的末端淬火样品中,冷却速率随离喷水端距离的增加而不断降低(见图1(b)),时效后的硬度也呈现出相同的变化趋势(见图2),因此淬透深度有限,约为45 mm。从淬火工艺角度讲,可采用合适的淬火介质或加强冷却强度来提高其淬透性[14]。

图3 不同冷却速率时样品时效后晶内的典型TEM像

Fig. 3 TEM micrographs of aged specimen subjected to different cooling rates: (a) 1 250 ℃/min; (b) 630 ℃/min; (c) 164 ℃/min; (d) 138 ℃/min

图4 不同冷却速率时样品时效后晶内沉淀强化相

Fig. 4 Hardening precipitates in matrix of aged specimen subjected to different cooling rates: (a) 1 250 ℃/min,  selected area diffraction pattern(SADP); (b) 138 ℃/min,

selected area diffraction pattern(SADP); (b) 138 ℃/min,  SADP

SADP

从微观组织分析结果可知,冷却过程中η平衡相大都在晶内的Al3Zr粒子和(亚)晶界上形核析出,这与以往的研究结果相同[2, 10, 15-17]。这些平衡相的数量和尺寸取决于冷却速率的大小。冷却速率足够大时,晶内和晶界都没有观察到粗大平衡相的存在。随着冷却速率的减小,形成的η平衡相的数量不断地增加,因此认为平衡相在晶内的形核过程不是位置饱和的。这可能与晶内Al3Zr粒子的特性有关,与基体非共格的大Al3Zr粒子更有利于平衡相的形核析出[2]。从图6可以看出,随冷却速率的减小,平衡相的尺寸增加,而晶内和晶界的平衡相的尺寸有相同的变化规律。在冷却速率由1 250 ℃/min减至630 ℃/min时,平衡相尺寸快速增加,至164 ℃/min时,平衡相尺寸略有增加,至138 ℃/min时,其尺寸又快速增加。晶内平衡相的平均尺寸总是大于晶界的平衡相,这可能是因为在冷却过程中,晶内平衡相较晶界平衡相先形核有关[16-17]。冷却速率减小还使晶界无沉淀析出带(PFZ)宽度增加,如图6(b)所示。晶界是一种面缺陷,往往是平衡相形核的有利位置,也是溶质原子的快速扩散通道[18]。在缓慢冷却过程中,大量平衡相可在晶界上形核并长大,而在后续的时效过程中还可吸收周围的溶质原子进一步长大粗化,导致周围溶质的贫乏;此外冷却过程中空位向晶界扩散而造成晶界附近空位浓度的降低[18],因此时效时这些区域没有沉淀强化相的析出,形成无沉淀析出带,因此得到如图5所示的分布状态。采用线性方程对图6(b)中的晶界PFZ宽度(W)与冷却速率(vc)关系进行拟合,结果为:

W=499.4-152.7lg vc (2)

线性相关系数为0.994 8,这说明在所研究的冷却速率范围内,晶界PFZ的宽度与冷却速率之间具有很好的线性关系,据此可估计样品中其它位置的晶界PFZ的宽度。

图5 不同冷却速率时样品时效后晶界的TEM像

Fig. 5 TEM images of grain boundary in aged specimen subjected to different cooling rates: (a) 1 250 ℃/min; (b) 164 ℃/min

图6 冷却速率对η平衡相的尺寸和晶界无沉淀析出带宽度的影响

Fig. 6 Influence of cooling rates on size of η phase(a) and width of grain boundary precipitates free zone(b)

3 结论

1) 7055铝合金厚板末端淬火样品的淬透深度可达45 mm,使其淬透的冷却速率需大于230 ℃/min。在所研究的冷却速率范围内,时效后的硬度与冷却速率的对数呈线性关系。

2) 冷却速率减小,η平衡相的数量和尺寸增加,时效后析出沉淀强化相的体积分数减少,尺寸增加,导致硬度下降。

3) 相同冷却速率时,晶内η平衡相的尺寸大于晶界η平衡相的;晶界无沉淀析出带的宽度随着冷却速率的减小而增加,并与冷却速率的对数呈线性关系。

REFERENCES

[1] LIU S D, ZHANG X M, CHEN M A. Influence of aging on quench sensitivity effect of 7055 aluminum alloy[J]. Materials Characterization, 2008, 59(1): 53-60.

[2] LIU S D, LIU W J, ZHANG Y, ZAHNG X M. Effect of microstructure on the quench sensitivity of AlZnMgCu alloys[J]. Journal of Alloys and Compounds, 2010, 507(1): 53-61.

[3] 李培跃, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 7050铝合金淬火特性与微观组织[J]. 中国有色金属学报, 2011, 21(3): 513-521.

LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Hardenability characteristic and microstructure of 7050 Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 513-521.

[4] 刘君城, 张永安, 刘红伟, 李锡武. 基于末端淬火试验2124铝合金的淬透性[J]. 中国有色金属学报, 2010, 20(11): 2118-2123.

LIU Jun-cheng, ZHANG Yong-an, LIU Hong-wei, LI Xi-wu. Hardenability of 2124 aluminum alloy based on Jominy end quench test[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2118-2123.

[5] 王国军, 熊柏青, 张永安, 李志辉. 2D70铝合金淬透性研究[J]. 稀有金属, 2009, 33(3): 304-308.

WANG Guo-jun, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui. Hardenability of 2D70 aluminum alloy[J]. The Chinese Journal of Rare Metals, 2009, 33(3): 304-308.

[6] 张 勇, 邓运来, 张新明, 刘胜胆. 7050铝合金热轧板的淬火敏感性[J]. 中国有色金属学报, 2008, 18(10): 1788-1794.

ZHANG Yong, DENG Yun-lai, ZHANG Xin-ming, LIU Sheng-dan. Quenching sensitivity of 7050 aluminum alloy hot-rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1788-1794.

[7] 伊琳娜, 汝继刚. 7B04铝合金锻件淬透性的研究[J]. 航空材料学报, 2003(Z1): 288.

YI Lin-na, RU Ji-gang. A study on quenching degree of 7B04 aluminum alloy forging[J]. Journal of Aeronautical Materials, 2003(Z1): 288.

[8] 熊柏青, 李锡武, 张永安, 李志辉. 新型高强韧低淬火敏感性Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr合金[J]. 中国有色金属学报, 2009, 19(9): 1539-1547.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui. Novel Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr alloy with high strength high toughness and low quench sensitivity[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1539-1547.

[9] NEWKIRK J W, MACKENZIE D S. The Jominy end quench for light-weight alloys development[J]. Journal of Materials Engineering and Performance, 2000, 9(4): 408-415.

[10] ZHANG X M, LIU W J, LIU S D. Effect of processing parameters on quench sensitivity of an AA7050 sheet[J]. Materials Science and Engineering A, 2011, 528(3): 795-802.

[11] KIKUCHI S, YAMAZAKI H, OTSUKA T. Peripheral- recrystallized structures formed in Al-Zn-Mg-Cu-Zr alloy materials during extrusion and their quenching sensitivity[J]. Journal of Materials Processing Technology, 1993, 38(4): 689-701.

[12] HORNBOGEN E. Hundred years of precipitation hardening[J]. Journal of Light Metals, 2001(1): 127-132.

[13] LIU S D, ZHONG Q M, ZHANG Y, LIU W J, ZHANG X M. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials & Design, 2010, 31(6): 3116-3120.

[14] 张 勇. 7050铝合金材料淬透性的末端淬火研究[D]. 长沙: 中南大学, 2008: 38-39.

ZHANG Yong. Study on hardenability of aluminum alloy 7050 by end quenching method[D]. Changsha: Central South University, 2008: 38-39.

[15] DUMONT D, DESCHAMPS A, BR?CHET Y. Characterization of precipitation microstructures in aluminium alloys 7040 and 7050 and their relationship to mechanical behavior[J]. Materials Science and Technology, 2004, 20(5): 567-576.

[16] DESCHAMPS A, TEXIER G, RINGEVAL S, DELFAUT- DURUT L. Influence of cooling rate on the precipitation microstructure in a medium strength Al-Zn-Mg alloy[J]. Materials Science and Engineering A, 2009, 501(1/2): 133-139.

[17] GODARD D, ARCHAMBAULT P, AEBY-GAUTIER E. Precipitation sequences during quenching of the AA7010 alloy[J]. Acta Materialia, 2002, 50(9): 2319-2329.

[18] PORTER D A, EASTERLING K E. Phase transformation in metals and alloys[M]. Oxford: Alden Press, 1981: 283-304.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2012CB619501);中南大学自由探索计划资助项目(201012200238)

收稿日期:2011-08-23;修订日期:2011-10-17

通信作者:刘胜胆,副教授,博士;电话:0731-88830265;E-mail: csuliusd@163.com