文章编号: 1004-0609(2006)06-1115-05

回转窑窑壁非稳态传热模型及窑皮厚度优化

肖友刚1, 刘义伦2, 马爱纯3

(1. 中南大学 轨道交通安全教育部重点实验室, 长沙 410075; 2. 中南大学 机电工程学院, 长沙 410083;

3. 中南大学 能源与动力工程学院, 长沙 410083)

摘 要: 烟气、 料床、 窑壁是回转窑传热过程的三要素, 在确定这三要素之间传热量的基础上, 建立了回转窑窑壁非稳态传热数学模型。 对中铝河南分公司2号窑窑壁的非稳态传热过程进行了数值计算。 结果表明: 窑体旋转一周, 烧成带窑壁内表面温度将在1232~1334℃变化, 这易导致窑壁热疲劳破坏; 窑皮越厚, 窑壁的径向温度梯度越小, 热应力越低; 将烧成带窑皮厚度控制在252mm, 可使烧成带窑壁外表面温度维持在200℃。

关键词: 回转窑; 窑壁; 窑皮; 优化; 传热 中图分类号: TK124

文献标识码: A

Transient heat transfer model of kiln wall and kiln crust thickness optimization

XIAO You-gang1, LIU Yi-lun2, MA Ai-chun3

(1. Key Laboratory of Track Traffic Safety of Ministry of Education,Central South University, Changsha 410075, China;

2. School of Mechanical and Electrical Engineering,Central South University, Changsha 410083, China;

3. School of Energy and Power Engineering,Central South University, Changsha 410083, China)

Abstract: Gas, material bed, kiln wall are the three main factors effecting kiln heat transfer process. On the basis of confirming the heat transfer equation among the three factors, the transient heat transfer model of kiln wall is set up. The numerical calculation of transient heat transfer process of kiln wall of No.2 rotary kiln was carried out in He’nan branch of China aluminum corporation. The results show the inner kiln wall temperature changes between 1232℃ and 1334℃ in sintering zone, which will make lining break down easily. The thicker the kiln crust, the smaller the radial temperature grade of kiln wall, the lower the heat stress. the outer kiln wall temperature keeps at 200℃ when kiln crust thickness is controlled at 252mm in sintering zone.

Key words: rotary kiln; kiln wall; kiln crust; optimization; heat transfer

颗粒在回转圆筒内的运动划分为6种状态: 滑移、 塌落、 滚落、 泻落、 抛落和离心, 滚落是回转窑内物料运动的理想状态[1]。 在该状态下, 料层表面颗粒从料层高端源源不断地滚落至低端, 并形成一个稳定的活动层, 在下部固定层内, 由于摩擦力作用, 在窑体旋转过程中, 料床随窑壁一起旋转运动, 不产生轴向位移[2, 3]。 由于窑体旋转, 窑壁内表面不断地与热烟气及温度相对比较低的生料接触, 在窑筒体内衬中依次发生蓄热、 放热过程, 窑筒体外表面又向大气散热, 造成热损失。 因此, 窑筒体内衬温度表现出周期性变化, 每个周期的传热过程实质上属于非稳态传热。 Gorog等[4]建立了窑壁蓄热放热模型, 然而对其准确求解的边界条件不合实际。 Boateng、 叶旭初等[5, 6]建立了一个窑壁内表面活动层的二维差分方程, 但没有考虑窑壁内表面和料床间歇性接触时料床的瞬态热效应。 马爱纯等[7]应用数值方法研究了熟料窑喷射干燥段窑内温度分布和水蒸气的浓度分布, 并对操作参数和工艺参数进行了优化, 但没有涉及窑壁温度的变化情况。 据统计, 80%的停窑事故是由窑壁破损引起的[8, 9]。 因此, 综合考虑各因素对窑壁非稳态传热的影响, 掌握窑壁温度的周期性变化规律, 确定粘结在窑壁上的最佳窑皮厚度, 有利于降低窑壁温度及温度梯度, 提高窑壁的热震稳定性, 避免火焰和物料对窑壁的高温冲刷, 提高窑壁的使用寿命和回转窑的运转率。

1 窑壁非稳态传热数学模型

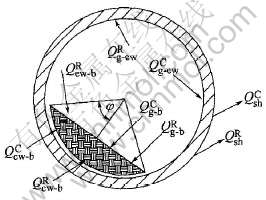

窑体周向和轴向的导热对传热的影响很小, 仅占总传热量的2%[4], 可忽略不计。 对整个系统来说, 窑内任一截面上的物性参数可视为不随时间而变。 并且假定: 1) 每个截面上的烟气温度均匀, 成分一致, 烟气具有吸收-发射性, 不具有散射性。 2)在窑体旋转作用下, 窑内物料充分混合, 在各个截面, 物料为温度均匀的灰体。 这样, 回转窑的换热过程可用以下5个方面来描述: 封盖窑壁和料床间的热交换; 敞开窑壁和料床间的辐射换热; 敞开窑壁和烟气之间的对流及辐射换热; 料床与烟气之间的对流及辐射换热; 窑外壁和周围空气的对流及辐射换热, 如图1所示。 图中Q表示热量, 上标C表示对流, R表示辐射, 下标g表示烟气, b表示料床, cw表示封盖窑壁, ew表示敞开窑壁, sh表示窑外壁。

图1 筒体截面的热交换途径示意图

Fig.1 Schematic diagram of heat transfer paths in kiln cross-section

在料床贴壁运动过程中, 窑壁非稳态导热方程为

在确定各传热量的基础上, 窑壁的非稳态传热方程应用有限差分法求解。

1.1 各传热量的确定

1.1.1 封盖窑壁和料床间的对流传热

在简化的完全混合情况下, 封盖窑壁和料床间的对流换热主要受两个机制控制, 即热阻主要由两部分组成: 料床与窑壁间的接触热阻Rc及料床的有效导热热阻Rb。

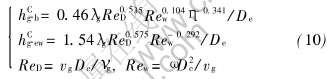

若颗粒是球状的, 料床与窑壁间的接触热阻Rc可采用以下模型[10]:

式中 dp为颗粒直径; λg为导热系数。

在完全混合状态下, 料床内的瞬时导热热阻Rb由“扩散理论”求出[11]:

封盖窑壁与料床的瞬时总传热系数hτ可表示为

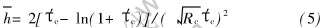

将式(2)和式(3)代人式(4), 并在接触时间τc内对hτ积分, 得料床与封盖窑壁间的平均对流传热系数h[TX-]:

式中 , τc为料床和窑壁的接触时间, 也就是单个颗粒经过固定层的时间, 由于固定层内料床相对于窑壁静止不动, 因而τc=φ/(πn)。 其中, φ为物料填充角的一半, n为窑转速。

, τc为料床和窑壁的接触时间, 也就是单个颗粒经过固定层的时间, 由于固定层内料床相对于窑壁静止不动, 因而τc=φ/(πn)。 其中, φ为物料填充角的一半, n为窑转速。

料床与封盖窑壁间的对流传热量:

式中 Acw为封盖窑壁面积; 为封盖窑壁的平均温度。

为封盖窑壁的平均温度。

1.1.2 封盖窑壁和料床间的辐射传热

基于颗粒群的多相反射, 可以推出料床吸收率εb的计算公式[12]:

式中 ε为吸收率; p为料床颗粒。

料床与封盖窑壁间的辐射可表示为[13]

1.1.3 敞开窑壁、 料床及烟气间的对流换热

烟气与料床的对流传热量QCg-b, 烟气与敞开窑壁内表面的对流传热量QCg-ew满足:

式中 Aew、 Ab分别为单位窑长上敞开窑壁及料床表面积。

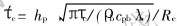

除了烟气流速和窑体结构尺寸的影响外, 窑体转速和料床填充率对窑内对流换热系数也有很大影响。 烟气与料床的对流换热系数hCg-b及烟气与敞开窑壁的对流换热系数hCg-ew采用如下计算公式[14]:

式中 De=D[π-φ+0.5sin(2φ)]/(π-φ-sin φ); η为物料填充率; D为窑直径; vg、 νg、 λg分别为烟气的速度、 粘度及热导率; ω为窑转动角速度。

式(10)的适用范围: 1600〈ReD〈7800, 20〈Rew〈800。

1.1.4 敞开窑壁、 料床及烟气间的辐射换热

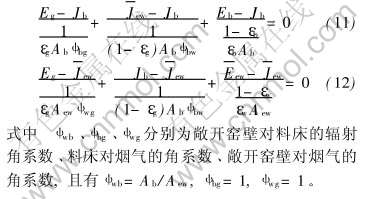

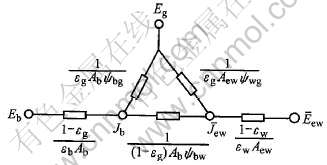

回转窑轴向某一区域的热辐射受其它轴向区域的影响很小[4], 因此, 烟气、 窑壁、 料床的轴向温度梯度对回转窑横截面辐射传热的影响可以忽略, 可将回转窑横截面作为一个封闭系统处理。 窑内辐射换热可简化为封闭腔内吸收性烟气与灰体表面间的辐射换热, 如图2所示。 图中A表示面积, E表示辐射能力, 由此可得节点的热平衡方程:

图2 回转窑截面辐射换热网络

Fig.2 Radiant heat transfer of kiln cross-section

解式(11)、 (12), 得到节点有效辐射 、 Jb, 结合热网络图, 可得料床净辐射换热量QRb, 敞开窑壁净辐射换热量QRew, 烟气净辐射换热量为QRg:

、 Jb, 结合热网络图, 可得料床净辐射换热量QRb, 敞开窑壁净辐射换热量QRew, 烟气净辐射换热量为QRg:

1.1.5 窑壁散热方程

窑壁外表面向周围环境的散热包括辐射散射和对流散热两方面, 热平衡方程为

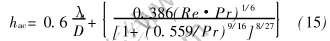

通常情况下, 窑壁与空气进行自然对流, hac的计算公式为[15]

式(15)的适用范围为: 10-4〈Re·Pr〈1012。

2 计算结果与分析

中铝河南分公司2号回转窑(简称2号窑)为氧化铝熟料窑, 窑体直径为4m, 长度为100m, 转速为1.83r/min, 产量为43000kg/h。 烧成带烟气温度在1450~1500℃之间, 物料温度在1250~1280℃之间。 对于烧成带以外的其它区域, 烟气温度在1300℃以下, 窑衬温度在1000℃以下, 使用厚度为200mm的耐火粘土砖可很好地保护窑壁。 因此, 只研究窑皮厚度为0、 150、 250mm, 烟气温度为1500℃, 物料温度为1280℃时, 烧成带窑壁的温度变化规律。

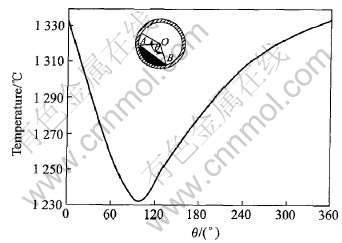

图3所示为窑皮厚度为0时, 窑壁内表面温度的周向变化曲线。 从图中可以看出, 当窑壁内表面与物料在B点开始接触时, 温度最高达到1334℃, 热量由窑壁内表面传递给物料, 窑壁内表面温度逐渐降低; 当窑壁内表面与物料在A点脱离接触时, 窑壁内表面温度最低, 为1232℃。 当窑壁内表面与热烟气换热后, 又不断升温, 初期升温较快, 后期趋于平缓。 窑体旋转一周, 窑壁内表面温度将在1232~1334℃变化, 变化幅度为102℃, 这会使窑壁产生周期性热冲击, 导致窑壁热疲劳破坏。 由于窑壁破损将迫使回转窑停产, 因此采取措施使窑衬免受周期性热冲击, 是提高回转窑运转率的重要环节。 当窑皮厚度为150 mm和250 mm时, 窑壁内表面温度基本为常数, 分别约为821℃和613℃(图中没有画出), 即窑壁内表面温度基本不随时间而变。 因此粘结一层一定厚度的窑皮, 能有效提高窑壁的热震稳定性。

图3 无窑皮时窑壁内表面周向温度的分布

Fig.3 Circular temperature distribution of inner kiln wall without crust

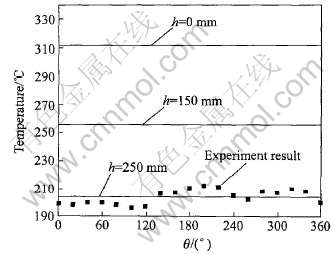

当窑皮厚度为0、 150、 250mm时, 窑外壁的温度分布基本是常数, 分别约为311、 256、 204℃(图4)。 说明窑壁换热虽然是一个非稳态过程, 但是当窑正常操作时, 窑筒体外表面的散热损失基本不变, 如果将一个周期内窑体的蓄热、 散热过程作为一个整体考虑, 就可以将窑内的换热过程简化为稳态换热。 这为将回转窑的传热数学模型转化为工程上应用简洁、 方便的一维模型, 提供了理论依据。 从图4还可得出, 烧成带外表面的理论计算温度和实测温度的误差在8%以内(2号窑稳定生产时, 窑皮厚度为250 mm)。 由于回转窑稳态运行时, 窑皮厚度基本不变, 窑壁外表面温度和窑内烟气、 物料温度存在一种确定的关系, 因而通过测定窑壁外表面温度, 就能推知烟气、 物料温度的变化情况。 测出的窑壁外表面温度和计算温度基本相符, 说明回转窑窑壁非稳态传热模型是正确的。

图4 不同窑皮厚度下窑壁外表面周向温度的分布

Fig.4 Circular temperature distribution of outer kiln wall under different crust thicknesses

图5所示为窑皮厚度为0、 150、 250mm时, 窑壁温度在A、 B处的径向变化(坐标原点在窑壁内表面上)。 可以看出, 当窑皮厚度为0时, 在靠近窑壁内表面的一薄层窑衬内(约20mm), 其温度才受到窑壁内表面温度周期性变化的影响, 而在窑壁的大部分区域, 其温度基本呈线性分布。 因此, 在窑壁内表面粘结一层厚度约20 mm的窑皮, 就可使窑壁内表面免除周期性热冲击。 但此时窑壁仍然存在较大温度梯度, 因此窑皮宜更厚一些, 以减少窑壁热应力, 提高窑衬使用寿命。 在窑皮厚度为150、 250mm时, 窑壁径向温度不受窑皮温度周期性变化的影响(在同一窑皮厚度下, A、 B处的窑壁径向温度变化曲线重合), 基本呈线性分布, 而且, 窑皮越厚, 窑壁的径向温度梯度越小, 热应力越低, 有利于提高窑衬使用寿命, 但窑皮过厚, 将缩小烧成带的有效截面积, 从而限制熟料窑提产。 根据工艺要求, 2号窑适宜的窑壁外表面温度为200℃, 通过逆推, 可以求得此时烧成带窑皮的厚度为252mm。

图5 不同窑皮厚度下窑壁径向温度的分布

Fig.5 Radial temperature distribution of kiln wall under different crust thicknesses

3 结论

1) 窑体旋转一周, 2号窑烧成带窑壁内表面温度将在1232~1334℃变化, 变化幅度为102℃, 这将使窑衬产生周期性热冲击, 导致窑衬热疲劳破坏。

2) 当窑皮厚度为0时, 在靠近窑壁内表面的一薄层窑衬内, 其温度才受到窑壁内表面温度周期性变化的影响。 窑皮越厚, 窑壁的径向温度梯度越小, 热应力越低, 但窑皮过厚, 将降低熟料窑的生产效益。 将烧成带窑皮厚度控制在250mm左右, 可使烧成带窑壁外表面温度维持在200℃。

3) 窑壁外表面的温度基本不受窑壁非稳态传热的影响, 这为将回转窑的传热数学模型转化为工程上应用简洁、 方便的一维模型, 提供了理论依据。

REFERENCES

[1]Boateng A A, Barr P V. Granular flow behavior in the transverse plane of a partially filled rotating cylinder[J]. J Fluid Mech, 1997, 330(5): 233-249.

[2]Heydenrych M D, Greeff P, Heesink A, et al. Mass transfer in rolling rotary kilns: A novel approach[J]. Chemical Engineering Science, 2002, 57(2): 3851-3859.

[3]严建华, 李水清, 黄景涛, 等. 回转窑内MSW轴向传输和扩散的数学模型和仿真[J]. 工程热物理学报, 2002, 23(3): 380-383.

YAN Jian-hua, Ll Shui-qing, HUANG Jing, et al. Simulation on axial transport and dispersion of MSW in rotary kiln[J]. Journal of Engineering Thermophysics, 2002, 23(3): 380-383.

[4]Gorog J P, Adams T N, Brimacombe J K. Regenerative heat transfer in rotary kilns[J]. Metallurgical Transactions B, 1982, 13B(6): 153-163.

[5]Boateng A A, Barr P V. Thermal model for the rotary kiln including heat transfer within the bed[J]. International Journal of Heat and Mass Transfer, 1996, 39(10): 2131-2147.

[6]叶旭初. 新型干法回转窑内煤粉燃烧、 高温传热、 煅烧熟料热工过程的应用基础研究[D]. 南京: 南京化工大学, 1998.

YE Xu-chun. Application Basis Research for Coal Combustion, Heat Transfer, Calcinations in Thermal Engineering Process of Dry-process Rotary Kiln[D]. Nanjing: Nanjing University of Chemical Technology, 1998.

[7]马爱纯, 周孑民, 李旺兴. 氧化铝熟料窑喷射干燥段参数的仿真优化[J]. 中国有色金属学报, 2004, 14(1): 138-141.

MA Ai-chun, ZHOU Jie-min, LI Wang-xin. Parameters optimization of spray drier zone in alumina clinker rotary kiln[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 138-141.

[8]Joseph F. Novel refractory lining technology offers benefits to cement manufacturers[J]. Ceramic Industry, 1998, 148(2): 55-57.

[9]Shubin V I. The effect of temperature on the lining of rotary cement kilns[J]. Refractories and Industrial Ceramics, 2001, 42(5): 216-221.

[10]Schlunder E U. Particle heat transfer[A]. Proceedings of the 7th of the International Heat Transfer Conference[C]. Munchen: Hemisphere Publishing Corporation, 1982. 195-211.

[11]Basu P, Large J F. Circulating Fluidized Bed Technology[M]. Oxford: Pergamon Press, 1988.

[12]Basu P, Nag P K. Heat transfer to walls of a circulating fluidized bed furnace[J]. Chemical Engineering Science, 1996, 51(1): 1-26.

[13]《有色冶金炉设计手册》编委会. 有色冶金炉设计手册[M]. 北京: 冶金工业出版社, 2000.

Editing Committee for Nonferrous Metallurgical Furnances Design manual. Nonferrous Metallurgical Furnances Design Manual[M]. Beijing: Metallurgical Industry Press, 2000. 780-785.

[14]Tscheng S H, Watkinson A P. Convective heat transfer in a rotary kiln[J]. Can J Chem Eng, 1979, 57(6): 433-443.

[15]Martins M A, Oliveira L S, Franca A S. Modelling and simulation of limestone calcinations in rotary kilns[J]. ZKG International, 2002, 55(4): 76-87.

基金项目: 中国博士后科学基金资助项目(2005038227); 湖南省自然科学基金资助项目(04JJ3050)

收稿日期: 2005-09-06; 修订日期: 2006-01-05

通讯作者: 肖友刚, 讲师; 电话: 0731-2655345; 传真: 0731-2655636; E-mail:csuxyg@163.com

(编辑陈爱华)