文章编号:1004-0609(2012)05-1270-06

搅拌摩擦加工铸态铝铁合金的显微组织

王快社,林兆霞,周龙海,孔 亮,王 文

(西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:采用普通熔铸法制备含铁3%(质量分数)的铝铁二元合金,研究多道次往复搅拌摩擦加工(Friction stir processing, FSP)对合金显微组织的影响。结果表明:进行1~3道次往复FSP后,各道次加工区组织不均匀;随着加工道次的增加,组织均匀细化程度增大。合金铸态组织由α-Al和粗大针状Al3Fe相组成,经3道次FSP后,搅拌区组织明显细化。原始铸态组织转变为细小等轴的再结晶晶粒,尺寸为2~5 μm,并且部分晶粒中出现层错;粗大的Al3Fe针状相被破碎成长度小于1 μm的细小粒状,弥散分布在铝基体晶界和晶粒内部,细化的Al3Fe粒子呈现孪晶结构。

关键词:铝铁合金;Al3Fe相;显微组织;搅拌摩擦加工

中图分类号:TG146.2 文献标志码:A

Microstructure of friction stir processed as-cast Al-Fe alloy

WANG Kuai-she, LIN Zhao-xia, ZHOU Long-hai, KONG Liang, WANG Wen

(School of Metallurgical Engineering, Xi’ an University of Architecture and Technology, Xi’ an 710055, China)

Abstract: Al-3%Fe (mass fraction) binary alloy was prepared by fusion casting. The effect of reciprocating multi-pass friction stir processing (FSP) on the microstructure of the alloy was studied. The results show that the microstructure of each pass in stir zone is non-uniform after one to three passes reciprocating FSP. With the increase of processing passes, the degree of uniformity and refinement of the microstructure increases. The as-cast alloy is composed of the α-Al and coarse needle Al3Fe phases. The microstructure in stir zone is significantly refined after three passes FSP. The as-cast microstructure in the stir zone is changed into fine equiaxed recrystallized grains with the size of 2-5 μm, and stacking fault appears in some grains. Coarse needle Al3Fe phases are broken into granular phases with the length of less than 1 μm, and disperse in Al matrix grain boundary and grain interior. Refined Al3Fe particles present twin structure.

Key words: Al-Fe alloy; Al3Fe phase; microstructure; friction stir processing (FSP)

铝铁合金因具有高硬度、高模量、耐热和抗腐蚀等诸多优良性能,在汽车和航天航空领域具有广泛的应用前景。但普通熔铸铝铁合金中,铁在铝中的固溶度很低,生成Al3Fe等金属间化合物。Al3Fe等金属间化合物呈脆性,且形状为针状或片状,严重割裂基体,成为应力集中源,显著降低铝铁合金的力学性能,所以,铝铁合金的工业应用受到了很大限制。目前,采用添加合金元素[1-2]、快速凝固[3]、机械合金化[4]和铸件强塑性变形[5-6]等方法细化铝铁合金中的Al3Fe相,以提高该合金的力学性能。添加合金可改变铝铁合金中粗大Al3Fe相的形貌和分布,然而细化作用不明显;快速凝固和机械合金化技术都能有效地细化合金组织,使铝铁合金成功应用于航天航空中,但生产成本高、制造工艺复杂;强塑性变形方法能显著细化组织和Al3Fe金属间化合物,增加铁元素在铝基体中的固溶度,但强塑性加工工序复杂,且得到的试样尺寸较小,因此,以上加工方法在实际应用中受到限制。所以,寻求一种简单而有效细化Al-Fe合金方法是解决铝铁合金大规模应用的主要途径。搅拌摩擦加工(Friction stir processing, FSP)能有效地细化合金组织,适合连续加工制备大面积的块状细晶材料和材料表面改性,是一种很有潜力的材料细化和改性方法[7-8]。

FSP是在搅拌摩擦焊接基础上发展起来的一种新型有效的材料加工技术,加工过程中通过高速旋转搅拌头的搅拌和摩擦作用,使金属发生强塑性变形。FSP可破碎粗大枝晶组织和第二相,溶解沉淀相,消除铸态气孔,使加工区组织细化、均匀化和致密化,显著改善金属材料的性能。本文作者采用普通熔铸方法制备铝铁合金,进行1~3道次往复FSP,研究加工道次对铝铁合金宏观和显微组织的影响。

1 实验

实验以99.9%工业纯铝和Al-20Fe中间合金为原材料,配制含铁3%(质量分数)的Al-3%Fe铝铁合金。合金在箱式电阻炉中用石墨坩埚熔炼,经除气和精炼后,于820 ℃在铜模中浇注成100 mm×80 mm×5 mm板坯试样。FSP实验在改进的X5032型立式升降台铣床上进行。搅拌头材料为W18Cr4V,轴肩直径为16 mm,搅拌针直径为5 mm,高度为3.8 mm。搅拌头旋转速度为1 180 r/min,焊接速度为47.5 mm/min。分别进行1~3道次往复FSP。采用Keller试剂腐蚀后用Neophot-21型光学显微镜观察显微组织。在加工区中心部位切取透射试样,研磨至60 μm后采用MTP-1型双喷电解减薄机进行减薄,电解液为30%硝酸和70%甲醇,液氮冷却。减薄后的试样在JEM-200CX型透射电子显微镜(TEM)下观察,加速电压为200 kV。

2 结果与分析

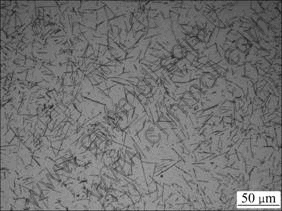

2.1 铸造组织

图1所示为Al-3%Fe合金的铸态组织。由图1可见:合金铸态组织主要由α-Al和针状Al3Fe相组成,Al3Fe相尺寸为20~50 μm,Al3Fe相以细针状分布在 基体组织中。铝铁合金中,铁在铝中的固溶度很低,主要与铝化合生成金属间化合物Al3Fe。由铝铁合金二元相图(见图2)可知:合金熔体在820 ℃保温,熔体中的Al3Fe相基本溶解。在凝固过程中,Al3Fe相的形核温度高,在凝固初期就从熔体中直接形核并优先于α-Al以针状形式生长,且生长速度较快,造成Al3Fe相与α-Al相的离异生长,得到非规则共晶组织[2]。试样采用铜模铸造,冷却速度较快,凝固前沿区域Fe向熔体深处的扩散受到一定限制;Al3Fe是小平面相,Fe原子与晶体表面的结合力较小,Fe原子的堆砌比较困难。所以,Al3Fe相以细针状分布在基体组织中。

图1 Al-3%Fe合金的铸态组织

Fig. 1 As-cast microstructure of Al-3%Fe alloy

图2 Al-Fe二元合金相图

Fig. 2 Phase diagram of Al-Fe binary alloy

2.2 FSP区的宏观组织

对铸态Al-3%Fe合金分别进行1、2和3道次往复FSP,不同道次FSP区的宏观形貌如图3所示。由图3可见:FSP区主要分为母材(Base metal, BM)、搅拌区(Stir zone, SZ)和热机影响区(Thermo-mechanically affected zone, TMAZ)。搅拌头旋转方向与焊接方向一致的一侧为前进侧(Advancing side, AS);搅拌头旋转方向与焊接方向相反的一侧为后退侧(Retreating side, RS)。1、2和3道次往复FSP区尺寸相同,宏观形貌呈现盆状。FSP过程中,轴肩及搅拌针的旋转摩擦和剪切搅拌产生大量摩擦热,使加工区金属软化,并发生塑性流动。当轴肩驱使金属流动时,沿垂直方向(Vertical direction,VD)距离轴肩越远,金属黏性逐渐增大,应变率逐渐减小;当搅拌针驱使金属流动时,沿横向(Horizontal direction,HD)距离搅拌针越远,由于温度和应力梯度的影响,流动速率逐渐降低[9]。加工区上部金属在轴肩摩擦作用下,塑性流动范围较大,下部金属主要在搅拌针的作用下发生变形,塑性流动范围相对较小,因此,整个FSP区域呈现盆状形貌。

图3 FSP区截面宏观形貌

Fig. 3 Cross-sectional macrographs in FSP zone: (a) One pass FSP; (b) Two passes FSP; (c) Three passes FSP

由图3可见:搅拌区组织呈现衬度较亮的区域(Bright zone, BZ)和衬度较暗的区域(Dark zone, DZ)。1道次FSP后,前进侧搅拌区与母材分界线明显,而后退侧搅拌区与母材分界线不明显;亮区面积较小,只分布在前进侧。2道次往复FSP后,搅拌区两侧都呈现前进侧的特征。随着加工道次的增加,亮区的面积逐渐增大,暗区的面积逐渐减小。当经过3道次往复FSP后,暗区主要集中在加工区中心和表层,并表现出层带混合结构。这说明搅拌区的组织在高速旋转的搅拌针和轴肩作用下,不同区域经历了不同程度的塑性变形,各个区域组织分布不均匀[10]。

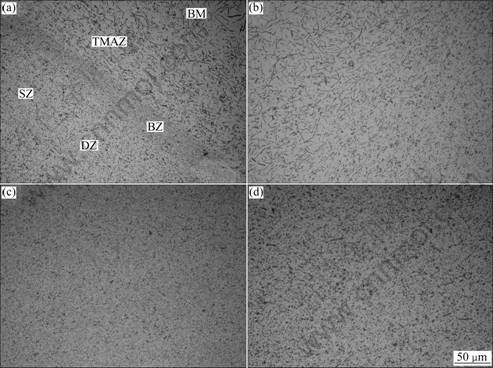

2.3 FSP区的显微组织

图4所示为图3中A、B、C和D区域的显微组织。其中:A区组织为前进侧热机影响区组织,B区组织为后退侧热机影响区组织。从图4(a)和(b)可以看出:搅拌区组织明显细化,粗大的Al3Fe针状相被破碎成细小粒状。前进侧的变形金属与母材的分界线较后退侧的明显,且在搅拌区与热机影响区交界处出现衬度较亮的带状区域,此区域中的组织较其他区域的组织更均匀细小(见图4(a))。这是因为搅拌区上层金 属在轴肩粘着摩擦作用下发生塑性流动,塑性流动金属与母材交界处发生剪切变形[11]。前进侧大部分金属沿着焊接方向向前流动,流动金属与母材的变形差较大,剪切应变速率更大,所以,流动金属与母材分界线明显,且存在一层组织细小的剪切变形区域。后退侧金属的塑性流动方向与旋转方向一致,与母材几乎平滑地一起变形,金属只发生简单的挤压变形作用,变形程度较低,组织细化不明显,因而分界线不明显[10, 12]。

图4 图3中A、B、C和D区域的显微组织

Fig. 4 Microstructures of areas A (a), B (b), C (c) and D (d) in Fig. 3

如图4(c)和(d)所示,亮区的显微组织由均匀细小的Al3Fe相组成,而暗区的显微组织中含有较粗大的针状Al3Fe相,分布不均匀。结合图3可知:随着加工道次的增加,组织细小区域的面积增加,均匀化程度增大;经3道次往复FSP后,搅拌区前进侧和底部区域细化显著,显微组织均匀细小,而表层和上部中心区域组织较粗大。

搅拌区上部金属受搅拌针和轴肩共同作用发生塑性流动,搅拌针使金属层状流动,轴肩使金属整体流动,塑性流动范围大。搅拌针驱使流动的金属在前进侧发生剧烈的剪切变形,应变速率大,沿横向方向存在黏度梯度,并轴肩的锻压作用使此区域金属发生旋涡混合流动[13]。所以,上部前进侧金属变形程度大、组织细小、衬度较亮(见图3和4)。搅拌区底部金属在搅拌针的搅拌和挤压作用下发生剪切变形,并随着搅拌针旋转方向层状流动。搅拌针在旋转前进过程中,在前进侧与金属摩擦形成剪切层,然后随着搅拌针旋转方向向后退侧流动。剪切层从前进侧到后退侧逐渐增大,在后退侧与搅拌针分离,只有很少的金属随着搅拌针继续转动。分离层在新的剪切层挤压作用下继续流动到前进侧,沉积在搅拌针后面[14]。所以,搅拌区底部金属流动程度高,变形剧烈,其组织均匀细小,衬度较亮。因此,经1道次FSP后,搅拌区底部前进侧金属比后退侧的均匀细小(见图4)。在2、3道次往复加工过程中,上底部金属反复经历剪切和塑性流动,产生剧烈变形和混合作用,所以,整个区域组织均匀细化程度增加,Al3Fe粒子细化显著(见图3和4)。

图5所示为Al-3%Fe合金3道次往复FSP区组织的TEM像。由图5(a)可知:加工区原始铸态组织转变为细小等轴的再结晶晶粒,尺寸为2~5 μm。从图5(b)可以看出:部分晶粒呈现明暗相间的条纹,表明这些晶粒中出现层错。铝属于高层错能金属,在高温变形过程中易通过交滑移和攀移产生动态回复,但在高应变条件下发生连续动态再结晶[15-16]。加工区金属在轴肩和搅拌针的摩擦搅拌作用下发生剧烈的变形,产生大量位错,通过回复过程产生亚晶,在随后的热机循环作用下,位错在亚晶中不断产生,迁移至亚晶界经过积累和重组使亚晶发生转动和长大,亚晶间取向差增大[17];具有相近取向差的亚晶通过转动合并成一个较大的亚晶,亚晶合并或转动的结果使得大量亚晶界消失,亚晶发展成大角度晶粒[18],从而形成具有大角度晶界的低位错等轴晶粒。部分晶粒中产生层错的原因可能是:在FSP过程中,金属经历高应力应变作用,产生的大量空位缺陷形成空位簇,在密排面上的空位簇塌陷使晶体中原子发生错排;晶粒内部和晶界处的Al3Fe粒子使晶体局部产生应力,对原子的排列产生一定的影响。

图6(a)所示为3道次FSP区Al3Fe粒子的TEM像。从图6(a)可以看出:含铁相被破碎成长度小于1 μm 的粒状,弥散分布在铝基体晶界和晶粒内部。图6(b)所示为含铁粒子的能谱分析,表明细小的含铁相主要为Al3Fe相。破碎细化后的Al3Fe相的选区衍射花样如图6(c)所示,其指数标定如图6(d)所示。由衍射花样可以看出:细化Al3Fe相结构为旋转孪晶。金属经轴肩和搅拌针反复地旋转剪切和挤压变形后,粗大的针状Al3Fe相被破碎成粒状,并与铝基体搅拌混合,弥散分布在铝基体中。Al3Fe相属于单斜晶系,有形成孪晶的强烈倾向。当Al3Fe粒子受到搅拌针的剪切变形作用时,局部因产生高应力和应变而发生滑移,但受到未滑移区域的剧烈阻碍,晶体中已滑移部分以一定的晶面为对称面,与晶体的另一部分发生均匀切变,从而形成(100)面孪晶(见图6(d))。由图4和6可知:经多道次FSP后,部分Al3Fe相进一步破碎不明显。这主要是因为在高应变变形时,脆性Al3Fe相中产生位错滑移和孪晶,塑性增加;Al-Al3Fe的界面在变形过程中,两者之间的滑移系可能发生转变而发生位错滑移[19]。所以,在多道次FSP强塑性剪切变形过程中,Al3Fe相的破碎程度降低。

图5 3道次FSP区组织的TEM像

Fig. 5 TEM images in stir zone after three passes FSP: (a) Recrystallized grain; (b) Stacking fault

图6 3道次FSP区Al3Fe粒子的TEM像

Fig. 6 TEM images of Al3Fe particles in stir zone after three passes FSP: (a) Al3Fe particles; (b) Energy spectrum analysis; (c) Selected area diffraction pattern; (d) Diffraction pattern index in (c)

3 结论

1) 铜模铸造Al-3%Fe合金的铸态组织主要由α-Al和针状Al3Fe相组成,Al3Fe相尺寸为20~50 μm。

2) 搅拌摩擦加工区宏观形貌呈现盆状,加工区组织细化程度不均匀。随着加工道次的增加,组织细化均匀程度增加。经3道次往复搅拌摩擦加工后,搅拌区前进侧和底部区域显微组织较表层和上部中心区域的均匀细小。

3) 搅拌加工区铸态组织转变为细小等轴的再结晶晶粒,尺寸为2~5 μm,部分晶粒中出现层错。粗大针状Al3Fe相被破碎成长度小于1 μm的粒状,弥散分布在铝基体晶界和晶粒内,细化Al3Fe粒子呈现孪晶结构。

REFERENCES

[1] 向青春, 王静媛, 周振平, 曲迎东, 李荣德. 铝铁合金的研究进展与应用状况[J]. 铸造, 2006(9): 875-879.

XIANG Qing-chun, WANG Jing-yuan, ZHOU Zhen-ping, QU Ying-dong, LI Rong-de. Survey on the development and application of Al-Fe alloys [J]. Foundry, 2006(9): 875-879.

[2] 马建超, 李荣德, 周振平. Mg对共晶 Al-2%Fe合金显微组织的影响[J]. 材料科学与工艺, 2006, 14(1): 57-59.

MA Jian-chao, LI Rong-de, ZHOU Zhen-ping. Influence of Mg addition on microstructure of eutectic Al-2%Fe alloy [J]. Materials Science and Technology, 2006, 14(1): 57-59.

[3] Yaneva S, Kalkanli A, Petrov K, Petrov R, Yvan Houbaert I r, Kassabov S. Structure development in rapidly solidified Al-Fe-V-Si ribbons [J]. Materials Science and Engineering A, 2004, 373: 90-98.

[4] Nayaka S S, Wollgarten M, Banhart J, Pabi S K, Murty B S. Nanocomposites and an extremely hard nanocrystalline intermetallic of Al-Fe alloys prepared by mechanical alloying [J]. Materials Science and Engineering A, 2010, 527: 2370-2378.

[5] Stolyarov V V, Lapovok R, Brodova I G, Thomson P F. Ultra?ne-grained Al-5wt%Fe alloy processed by ECAP with backpressure [J]. Materials Science and Engineering A, 2003, 357: 159-167.

[6] Senkov1 O N, Froes F H, Stolyarov V V, Valiev R Z, Liu J. Microstructure of aluminum-iron alloys subjected to severe plastic deformation [J]. Scripta Materialia, 1998, 10: 1511-1516.

[7] SU J Q, NELSON T W, STERLING C J. Microstructure evolution during FSW/FSP of high strength aluminum alloys [J]. Materials Science and Engineering A, 2005, 405: 277-286.

[8] Ma Z Y, Pilchak A L, Juhas M C, Williams J C. Microstructural refinement and property enhancement of cast light alloys via friction stir processing [J]. Scripta Materialia, 2008, 58: 361-366.

[9] Nandan R, Roy G G, Lienert T J, Debroy T. Three-dimensional heat and material flow during friction stir welding of mild steel [J]. Acta Materialia, 2007, 55: 883-895.

[10] Colligan K. Material flow behavior during friction stir welding of aluminum [J]. Weld J, 1999(s): 229-237.

[11] Schneider J, Beshears R, Arthur C, Nunes J r. Interfacial sticking and slipping in the friction stir welding process [J]. Materials Science and Engineering A, 2006, 435/436: 297-304.

[12] 王希靖, 韩晓辉, 李常锋, 包 孔, 郭瑞杰. 厚铝合金板搅拌摩擦焊塑性金属不同深度的水平流动状况[J]. 中国有色金属学报, 2005, 15(2): 198-204.

WANG Xi-jing, HAN Xiao-hui, LI Chang-feng, BAO Kong, GUO Rui-jie. Horizontal flow status of plastic metal in different depth during friction stir welding for thick aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 198-204.

[13] Zhang H W, Zhang Z, Chen J T. 3D modeling of material flow in friction stir welding under different process parameters [J]. Journal of Materials Processing Technology, 2007, 183: 62-70.

[14] Chen Z W, Pasang T, Qi Y. Shear flow and formation of Nugget zone during friction stir welding of aluminium alloy 5083-O [J]. Materials Science and Engineering A, 2008, 474: 312-316

[15] Hallberg H, Wallin M, Ristinmaa M. Modeling of continuous dynamic recrystallization in commercial-purity aluminum [J]. Materials Science and Engineering A, 2010, 527: 1126-1134.

[16] Jata K V, Semiatin S L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys [J]. Scripta Mater, 2000, 43: 743-749.

[17] Su J Q, Nelson T W, Mishra R, Mahoney M. Microstructural investigation of friction stir welded 7050-T651 aluminium [J]. Acta Materialia, 2003, 51: 713-729.

[18] 李慧中, 梁霄鹏, 张新明, 黄伯云, 张传福. 2519 铝合金热变形组织演化[J]. 中国有色金属学报, 2008, 18(2): 226-231.

LI Hui-zhong, LIANG Xiao-peng, ZHANG Xin-ming, HUANG Bai-yun, ZHANG Chuan-fu. Microstructure evolution of 2519 aluminum alloy during hot deformation [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 226-231.

[19] Yoneyama N, Mizoguchi K, Kumai S, Sato A, Kiritani M. Plastic deformation of Al13Fe4 particles in Al-Al13Fe4 by high-speed compression [J]. Materials Science and Engineering A, 2003, 350: 117-124.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51074119);教育部高等学校博士学科点专项科研基金资助项目(20096120110012)

收稿日期:2011-04-28;修订日期:2011-08-11

通信作者:王快社,教授,博士;电话:029-82205096; E-mail: wangkuaishe888@126.com