DOI:10.19476/j.ysxb.1004.0609.2017.10.06

蛇形轧制对Al-Cu-Mg合金板材强韧性能及微观组织的影响

胥福顺1, 2,张 劲3, 4,邓运来1, 4,张新明1, 4

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 云南冶金集团服份有限公司,昆明 650502;

3. 中南大学 轻合金研究院,长沙 410083;

4. 中南大学 高性能复杂制造国家重点实验室,长沙 410083)

摘 要:基于实验室自制蛇形轧制装置,采用室温拉伸、Kahn撕裂、电子背散射衍射(EBSD)等测试方法对比研究蛇形轧制非对称工艺参数对Al-Cu-Mg合金轧制板材的室温强度、断裂韧性和显微组织的影响。结果表明:合理的蛇形轧制工艺在能够使Al-Cu-Mg合金板材保持强度性能的同时,显著提升其断裂韧性。当偏移量相同时,蛇形轧制板材的强度性能随着异速比增加而提高,但伸长率和断裂韧性降低;当异速比相同时,随着偏移量增加,蛇形轧制板材强度降低,伸长率和断裂韧性明显升高。在偏移量10mm且异速比为1.1的条件下,蛇形轧制试样裂纹单位形核能提升高14%~36%。这是由于蛇形轧制能够增强Al-Cu-Mg合金板材Cube织构并减弱Brass织构,形成具有更高裂纹扩展阻力的织构组态所致。

关键词:Al-Cu-Mg合金;蛇形轧制;力学性能;织构;裂纹扩展

文章编号:1004-0609(2017)-10-2005-07 中图分类号:TG146.2 文献标志码:A

Al-Cu-Mg合金板材是现代民用飞机机身和机翼的重要结构材料,具有强度高、耐疲劳性能好、成形性优良等特点[1-3]。近年来航空工业的快速发展对Al-Cu-Mg合金板材的综合性能提出了更高的要求,如具有变曲率复杂外形薄板、蒙皮类构件,需承受较大的增压载荷,具有高强度和高韧性是延长该类构件使用寿命的重要保证[4-6]。传统轧制工艺的板材心部变形量小,产生的厚向组织与性能不均匀性降低了构件的服役性能[7]。异步轧制就是针对该问题而发展起来的轧制方法,由于上下两个轧辊的转速不同,导致上下面中性点位置发生偏移,使板材同时受到压力和剪切力,增加板材总变形量,使变形更深入,厚向更均匀[8]。但轧件不均匀变形会使板材向慢速辊侧弯曲,影响产品形状[9-11]。

蛇形轧制是新发展的一种上下轧辊同时具有错位量和异速比的金属板材非对称轧制方法,能够通过剪切变形使板材比常规轧制更深入心部,同时辊间错位量又可控制因轧辊异速引起的板材弯曲[12-14]。WU等[15]通过分析7075铝合金板在蛇形轧制和常规轧制过程中的应力和应变,证明蛇形轧制可以使变形迅速渗透到板材心部,且轧辊转速大的一侧板材流变速率和等效应变更大。FU等[16-17]结合有限元模拟和轧制实验,总结蛇形轧制错位量、异速比、压下量和初始板厚对板材弯曲情况的影响规律,并设计合理的轧制条件匹配最大程度减小板材弯曲。LI等[18]研究1060铝板蛇形轧制后的弯曲和织构,发现蛇形轧制具有比常规轧制弱的Brass织构和略为高的立方织构,并且拉伸强度区别不大。WRONSKI等[19]研究了异速比在1~1.5范围内的非对称轧制对铝合金板材晶粒尺寸与各向异性的影响规律及其表征,验证了非对称轧制制备均匀材料的可行性。可见,蛇形轧制铝合金板材具有良好的应用前景和研发潜力。

本文作者以航空高强Al-Cu-Mg合金板材为对象,对比研究经过不同工艺蛇形轧制及常规轧制后合金板材的力学性能、撕裂性能、晶粒组织以及各向异性的影响规律,探索提高Al-Cu-Mg合金板材综合性能的蛇形轧制工艺参数,为航空高性能铝合金板材制备提供参考依据。

1 实验

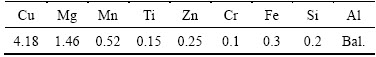

实验所用材料为厚度20 mm的Al-Cu-Mg合金热轧板,其化学成分如表1所示。沿轧制方向切取试样尺寸为110 mm×80 mm×20 mm。

表1 Al-Cu-Mg合金试样的化学成分

Table 1 Chemical composition of Al-Cu-Mg alloy (mass fraction, %)

实验采用自制蛇形轧制装置,轧辊半径为50 mm,如图1所示,采用不同的偏移量(Δd)和异速比(ω1/ω2)将板材试样先热轧至10 mm,其中开轧温度420 ℃,终轧温度不低于350 ℃;之后再冷轧至厚度5 mm,道次压下量均为1 mm。具体的试样编号与试验条件如表2所示。

轧制结束后,对试样进行T39热处理,即495 ℃、1 h固溶处理及水浴淬火,经室温预时效5 h后进行9%冷压变形,最后自然时效96 h。时效结束后用电火花线切割机取样。室温力学性能采用CSS-44100型万能材料试验机测试,拉伸速率为2 mm/min,每个板材试样选取5个平行样品,计算平均值。根据ASTM B871-01标准分别沿板材轧制方向0°、45°和90°方向切取Kahn撕裂试样,撕裂实验在MTS810动态疲劳试验机上进行,拉伸速度为1 mm/min。使用单位面积裂纹形核能(UIE)表征试样的撕裂性能,即形核功与试样撕裂截面积之比,通过UIE值也能够体现铝合金的断裂韧性大小[20]。在FEI HELIOS NanoLab 600i型电子双束显微电镜下进行电子背散射衍射(EBSD)测试,观测分析试样撕裂断口形貌以及晶粒取向。

图1 蛇形轧制示意图及偏移量和异速比

Fig. 1 Schematic illustration of snake rolling with offset distance (Δd) and differential peripheral speed ratio (ω1/ω2)

表2 试样的轧辊参数

Table 2 Rolling parameters of samples

2 实验结果

2.1 合金的力学性能

图2所示为Al-Cu-Mg合金板材经不同偏移量和异速比的蛇形轧制后T39热处理状态试样的室温力学性能测试结果。由图2可见,当偏移量相同时,试样的强度性能随着异速比的增加而提高,但伸长率降低;当异速比相同时,随着偏移量增加,试样的强度降低,但伸长率则明显升高。相比于常规轧制(Δd=0,ω1/ω2= 1),蛇形轧制不会降低试样的强度性能,在一定的工艺参数条件下会使试样的强度性能出现较明显的提高,如偏移量4 mm且异速比为1.3的条件下,试样屈服强度和抗拉强度最高,比常规轧制高14%,但同时伸长率下降了42%。在偏移量10 mm且异速比为1.1的条件下,蛇形轧制试样相比于常规轧制的强度性能接近,仅有1%~2%的略微提升,伸长率则提高6%。

图2 经蛇形轧制后T39热处理状态试样的室温力学性能

Fig. 2 Mechanical properties of snake rolled samples at ambient temperature after T39 heat treatment

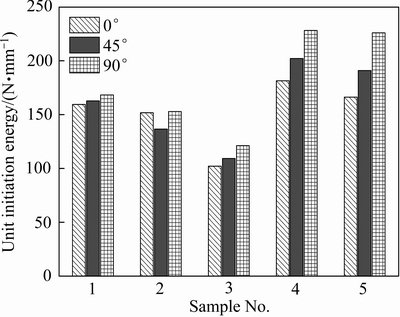

图3 经蛇形轧制后T39热处理状态试样的UIE值

Fig. 3 Unit initiation energy values of snake rolled samples after T39 heat treatment

图3所示为Al-Cu-Mg合金板材经不同偏移量和异速比的蛇形轧制后T39热处理状态下沿轧向0°、45°、90° 3个方向的裂纹临界耗散能(UIE)。由于UIE值与断裂韧性为正比转换关系,根据UIE值的对比可以获得对试样断裂韧性的评价[20]。由图3中可以看出,3个方向中沿轧向90°方向的断裂韧性最大,UIE值可达到228.19,其次为45°方向,沿轧制方向试样的断裂韧性最低,存在这种趋势的原因是板材在轧制及固溶后的预变形中晶粒被拉长,90°方向的撕裂需要跨过比沿轧制方向更多的晶粒和晶界。当偏移量相同时,试样的断裂韧性随着异速比的增加而降低;当异速比相同时,随着偏移量增加,试样的断裂韧性大幅度提高,如偏移量为10 mm时,异速比由1.1增加至1.3可使试样在沿轧向90°方向的UIE值增幅达到88%。相比于常规轧制,蛇形轧制的偏移量是影响断裂韧性的重要参数,当偏移量较小时(4 mm),蛇形轧制试样的断裂韧性均低于常规轧制;当偏移量较大时(10 mm),蛇形轧制试样的断裂韧性明显提升并高于常规轧制,如在偏移量10 mm且异速比为1.1的条件下,蛇形轧制试样的断裂韧性相比于常规轧制,0°、45°、90° 3个方向的UIE值分别提升了14%、24%、36%。

2.2 合金的显微组织

综合室温拉伸与Kahn撕裂试验的结果可知,蛇形轧制参数的改变能够影响板材最终性能,合理的偏移量与异速比匹配可以实现不同力学性能的协同提升,其中蛇形轧制对板材性能的影响主要表现为裂纹临界耗散能(UIE)的明显提升。为探明蛇形轧制后板材试样抗撕裂性能提升的原因,对比分析偏移量10 mm、异速比1.1的蛇形轧制板材与常规轧制的微观组织。

图4 Al-Cu-Mg合金T39态板材RD-ND面上的IPF图及相应的{111}极图

Fig. 4 IPF maps and {111} pole figures of RD-ND surface in Al-Cu-Mg alloy plates after T39 heat treatment

图4所示为EBSD测得的常规轧制与蛇形轧制(Δd=10 mm,ω1/ω2=1.1)板材T39态试样RD-ND面的晶粒IPF图(Inverse pole figure)以及用OIM分析软件处理得到相应的{111}极图。由图4中可见,轧制后晶粒组织整体呈主要沿轧制方向(RD)扁片状结构形态,相比于常规轧制,蛇形轧制后板材的晶粒尺寸较大。这说明蛇形轧制变形储能较大,在固溶处理时发生了再结晶。对比常规轧制与蛇形轧制试样IPF图的颜色分布可以发现,二者存在较明显的织构差异,因此,基于EBSD取向数据对两种试样的织构组成进行了分析。从图4中的极图可以看出,蛇形轧制与常规轧制试样的织构组成有明显区别,前者织构分布则更为集中。

图5 Al-Cu-Mg合金轧制板材试样的ODF图

Fig. 5 ODF maps of Al-Cu-Mg alloy plates

为了能够更清楚地区分和量化不同轧制试样的织构组成特征,绘制了常规轧制、蛇形轧制试样以及二者经T39热处理后的取向分布函数(ODF)图,如图5所示。图示为含有φ1、Ф、φ2欧拉三维空间的截面,分别用φ2=0°,φ2=45°和φ2=65° 3个截面来表示,这3个截面包含了轧制织构的主要组分:Cu织构 、S织构

、S织构 、Brass织构

、Brass织构 ,Goss织构

,Goss织构 和Cube织构

和Cube织构 。图5(a)所示为主要织构组分在ODF图中的位置标示。对比轧制后板材的ODF图,如图5(b)和图5(d)所示,可见蛇形轧制试样的Brass织构明显减弱,Cube织构、Cu织构和S织构增强,Goss织构差别不大。轧制板材经T39处理后织构组成发生改变,Cu织构和S织构减弱,而Cube织构增强。对比图5(c)和图5(e)可见,相比于常规轧制,蛇形轧制T39态板材中仍然是Brass织构减弱、Cube织构增强,而S织构、Goss织构和Cu织构则差别不大。一般而言,层错能高的面心立方金属中轧制变形使得Brass织构

。图5(a)所示为主要织构组分在ODF图中的位置标示。对比轧制后板材的ODF图,如图5(b)和图5(d)所示,可见蛇形轧制试样的Brass织构明显减弱,Cube织构、Cu织构和S织构增强,Goss织构差别不大。轧制板材经T39处理后织构组成发生改变,Cu织构和S织构减弱,而Cube织构增强。对比图5(c)和图5(e)可见,相比于常规轧制,蛇形轧制T39态板材中仍然是Brass织构减弱、Cube织构增强,而S织构、Goss织构和Cu织构则差别不大。一般而言,层错能高的面心立方金属中轧制变形使得Brass织构 减弱,因此,蛇形轧制中的Brass织构特征也说明了轧制应变较常规轧制更高。

减弱,因此,蛇形轧制中的Brass织构特征也说明了轧制应变较常规轧制更高。

3 分析与讨论

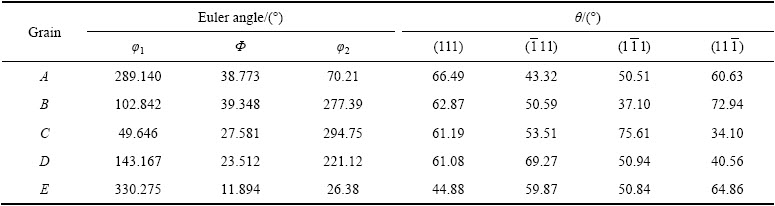

面心立方金属中位错的滑移在{111}密排面上优先启动,对于多晶体材料,裂纹受到扩展路径上晶粒取向的影响。为表征晶粒取向与裂纹扩展的关联,假设含有裂纹的Al-Cu-Mg合金试样加载拉应力,主应力平面为样品坐标系下的(010)面。在该条件下试样裂纹尖端通过EBSD观测结果如图6所示。裂纹经过的晶粒分别以字母A~E标记,裂纹在扩展过程中沿着晶粒A的晶界改变了方向,进入晶粒B中并继续延伸,在遇到晶粒E时停止。表3列出了晶粒A~E的欧拉角及其{111}面与主应力平面的夹角θ。由表3可见,B晶粒的θ角最小在 面,θmin=37.1°,也是晶粒A~E的θ角最小值,说明晶粒B对裂纹扩展阻力最小;裂纹在晶粒B中发生转折,其路径均沿着{111}面组,即(111)→

面,θmin=37.1°,也是晶粒A~E的θ角最小值,说明晶粒B对裂纹扩展阻力最小;裂纹在晶粒B中发生转折,其路径均沿着{111}面组,即(111)→ →

→ ,而未沿着

,而未沿着 面,该面上θ角恰为晶粒B的最大值 (72.94°);晶粒E的θmin= 44.88°,是裂纹尖端附近晶粒中最大的,此晶粒对裂纹扩展的阻力也最大,从而可以解释裂纹为何穿过晶粒B后在晶粒E的晶界处停止。

面,该面上θ角恰为晶粒B的最大值 (72.94°);晶粒E的θmin= 44.88°,是裂纹尖端附近晶粒中最大的,此晶粒对裂纹扩展的阻力也最大,从而可以解释裂纹为何穿过晶粒B后在晶粒E的晶界处停止。

上述分析说明晶粒{111}面组与主应力平面的最小夹角θmin值可以反映晶粒取向对裂纹扩展阻力大小的贡献,因此,板材中不同的织构组分抵抗裂纹的能力也可以用其进行表征。图7所示为铝合金轧制板材中主要织构类型在不同主应力平面的θmin值对比,可见Cube织构的θmin值最高,而Brass织构最低。根据图5中的织构分析结果,蛇形轧制T39态板材的Brass织构减弱、Cube织构增强,而S织构、Goss织构和Cu织构则差别不大,因此其织构组态朝着有利于提高断裂韧性的方向演变,从而与图3中蛇形轧制板材UIE值提升的结果相吻合。

图6 Al-Cu-Mg合金T39态板材试样中裂纹尖端附近 EBSD图

Fig. 6 EBSD map of crack tip in Al-Cu-Mg alloy plates after T39 treatment

图7 铝合金轧制板材主要织构类型在不同主应力平面的θmin平均值

Fig. 7 Averaged θmin values of main texture components in aluminum alloy plates with different principal stress planes

表3 裂纹尖端附近晶粒的欧拉角及其θ角计算值

Table 3 Calculated Euler and θ angles of grains near crack tip

4 结论

1) 当偏移量相同时,蛇形轧制Al-Cu-Mg合金板材的强度性能随着异速比增加而提高,但伸长率降低;当异速比相同时,随着偏移量增加,蛇形轧制板材强度降低,但伸长率则明显升高;当偏移量和异速比合理匹配时(Δd=10 mm,ω1/ω2=1.1),能够同时提高轧制板材的强度和伸长率。

2) 相比于常规轧制,蛇形轧制的偏移量增大能够显著提升Al-Cu-Mg合金板材试样的断裂韧性。当偏移量相同时,试样的断裂韧性随着异速比的增加而降低。在偏移量10 mm且异速比为1.1的条件下,蛇形轧制试样UIE值提升高14%~36%。

3) 相比于常规轧制,蛇形轧制能够增强Al-Cu-Mg合金板材的Cube织构,并显著减弱Brass织构,形成具有更高裂纹扩展阻力的织构组态,从而有利于轧制板材断裂韧性的提高。

REFERENCES

[1] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] MOGHANAKI S K, KAZEMINEZHAD M. Effects of non-isothermal annealing on microstructure and mechanical properties of severely deformed 2024 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 1-9.

[3] ZHOU Z P, ZHANG J, DENG Y L, ZHANG X M. Creep forming heat treatment technology of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 26(8): 1607-1614.

[4] LIU J, KULAK M. A new paradigm in the design of aluminum alloys for aerospace applications[J]. Materials Science Forum, 2000, 331(1): 127-140.

[5] BUCCI RJ, WARREN C J, STARK E J. Need for new materials in aging aircraft structures[J]. Journal of Aircraft, 2000, 37(1): 122-129.

[6] 张新明, 刘胜胆. 航空铝合金及其材料加工[J]. 中国材料进展, 2013, 32(1): 39-55.

ZHANG Xin-ming, LIU Sheng-dan. Aerocraft aluminum alloys and their materials processing[J]. Materials China, 2013, 32(1): 39-55.

[7] ZHANG J, DENG Y L, WANG Y, HU S S, ZHANG X M. Design of the multi-stage quenching process for 7050 aluminum alloy[J]. Materials & Design, 2014, 56(1): 334-344.

[8] 刘 刚, 齐克敏, 王 福, 王 刚, 梁志德. 异步轧制速比对3%硅钢织构转变的影响[J]. 金属学报, 1998, 34(4): 400-405.

LIU Gang, QI Ke-ming, WANG Fu, WANG Gang, LIANG Zhi-de. The influence of mismatch speed ratio on texture development in cross shear rolled 3% silicon steel[J]. Acta Metallurgica Sinica, 1998, 34(4): 400-405.

[9] LU J S, HARRER O K, SCHWENZFEIER W, FISCHER F D. Analysis of the bending of the rolling material in asymmetrical sheet rolling[J]. International Journal of Mechanical Sciences, 2000, 42(1): 49-61.

[10] GAO H, RAMALINGAM S C, BARBER G C, CHEN G. Analysis of asymmetrical cold rolling with varying coefficients of friction[J]. Journal of Materials Processing Technology, 2002, 124(1): 178-182.

[11] ANDERS D, MUNKER T, ARTEL J, WEINBERG K. A dimensional analysis of front-end bending in plate rolling applications[J]. Journal of Materials Processing Technology, 2012, 212(6): 1387-1398.

[12] JIANG L Y, ZHAO C J, YUAN G, SHI J H, WANG G D. Thicker steel plate shape-changing law and control method during the snake rolling process[J]. Metallurgical Research & Technology, 2016, 113(3): 309-312.

[13] LIU X J, JIANG L Y, YUAN G, WANG G D. Research on deformation permeability changing law during snake rolling process[J]. Materials Science Forum, 2014, 788(1): 367-371.

[14] YANG J, LI S, LIU J, LI X, ZHANG X. Finite element analysis of bending behavior and strain heterogeneity in snake rolling of AA7050 plates using a hyperbolic sine-type constitutive law[J]. Journal of Materials Processing Technology, 2017, 240: 274-283.

[15] ZHANG T, WU Y X, GONG H, ZHENG X Z, JIANG S S. Effects of rolling parameters of snake hot rolling on strain distribution of aluminum alloy 7075[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2150-2156.

[16] FU Y, XIE S S, XIONG B Q, HUANG G J, CHENG L. Calculation of rolling force in snake rolling by slab method[J]. Journal of Plasticity Engineering, 2010, 17(6): 103-109.

[17] FU Y, XIE S S, XIONG B Q, HUANG G J, CHENG L. Effect of rolling parameters on plate curvature during snake rolling[J]. Journal of Wuhan University of Technology (Mater Sci Ed), 2012, 27(2): 247-251.

[18] LI S Y, QIN N, LIU J, ZHANG X M. Microstructure, texture and mechanical properties of AA1060 aluminum plate processed by snake rolling[J]. Materials & Design, 2015, 90: 1010-1017.

[19] WRONSKI S, BACROIX B. Microstructure evolution and grain refinement in asymmetrically rolled aluminium[J]. Acta Materialia, 2014, 76(9): 404-412.

[20] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy[J]. Materials Science and Engineering A, 2003, 356(1): 326-336.

Effect of snake rolling on strength, toughness and microstructure of Al-Cu-Mg alloy plate

XU Fu-shun1, 2, ZHANG Jin3, 4, DENG Yun-lai1, 4, ZHANG Xin-ming1, 4

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Yunnan Metallurgical Group Co., Ltd, Kunming 650502, China;

3. Light Alloy Research Institute, Central South University, Changsha 410083, China;

4. State Key Laboratory of High Performance and Complex Manufacturing, Central South University, Changsha 410083, China)

Abstract: Based on the lab-made snake rolling mill, the effect of asymmetric boundary conditions on the mechanical properties and the microstructure of Al-Cu-Mg alloy rolled plates were investigated by room-temperature tensile, Kahn tear and electron back scattering diffraction (EBSD) tests. The results indicate that choosing a proper boundary condition can significantly improve the fracture toughness while maintaining the strength property. With increasing the differential peripheral speed ratio, the strength of the snake rolled plates rises, but the elongation and the fracture toughness decreases at the same offset distance. And with increasing the offset distance, the strength decreases with the dramatically elongation and fracture toughness increases at the same speed ratio. Under the condition of the offset distance of 10 mm and the speed ratio of 1.1, the crack unit initiation energy (UIE) of the snake rolled plates increase by 14%~36%. It is due to the enhanced Cube texture and the weakened Brass texture of the Al-Cu-Mg alloy plates rolled by snake rolling compared with the conventional rolling, which means the better texture components with higher crack propagation resistance.

Key words: Al-Cu-Mg alloy; snake rolling; mechanical property; texture; crack propagation

Foundation item: Project(2017YFB0306301) supported by National Key R&D Program of China; Project(ZZYJKT2016-01) supported by the State Key Laboratory of High Performance Complex Manufacturing, China

Received date: 2017-06-16; Accepted date: 2017-10-10

Corresponding author: ZHANG Jin; Tel: +86-731-88876913; E-mail: zhangjin19861003@csu.edu.cn

(编辑 李艳红)

基金项目:国家重点研究发展计划重点专项项目(2017YFB0306301);高性能复杂制造国家重点实验室自主课题(ZZYJKT2016-01)

收稿日期:2017-06-16;修订日期:2017-10-10

通信作者:张 劲,讲师,博士;电话:0731-88876913;E-mail: zhangjin19861003@csu.edu.cn