DOI: 10.11817/j.ysxb.1004.0609.2020-37552

不同取向对激光快速成形Ti-6Al-4V合金力学性能的影响

孙 坤,向文丽,舒鑫柱

(楚雄师范学院 材料制备及力学行为研究所,楚雄 675000)

摘 要:采用万能材料试验机系统,对激光快速成形TC4钛合金不同取向圆柱形试样进行准静态压缩试验,使用光学显微镜、扫描电镜、XRD等分析手段,研究不同取向对其力学性能的影响。结果表明:不同取向激光快速成形TC4钛合金由于微观结构的差异,其准静态压缩力学性能也不同,其中,与激光扫描方向成45°角试样显示最高的强度,但塑性最差;而沿沉积方向试样则显示最好的塑性性能,其强度与沿激光扫描方向试样的强度相当。

关键词:激光快速成形Ti-6Al-4V;钛合金;准静态压缩;力学性能

文章编号:1004-0609(2020)-03-0566-05 中图分类号:TG113.1 文献标志码:A

Ti-6Al-4V(简称TC4)合金,由于耐腐蚀,密度小,比强度高,广泛用于航空航天及医疗器械等领域[1-5]。应用于这些领域的TC4合金部件,通常结构复杂,采用传统的铸造及锻造方法制备时,后续的切削加工不仅由于切削产生了大量废料增加了成本,而且延长了生产周期。激光快速成形(Laser rapid forming,以下简称LRF)方法,由于其近净成形、制备形状复杂零部件能力、快速制备方面的优势[6],且制备出的材料性能可比于甚至优于传统制备方法生产的材料[7-10],成为了制备形状复杂零部件及稀贵材料的替代方法。

在LRF过程中,由于材料粉末沿垂直于激光扫描方向逐层沉积,组织均匀性及取向有别于传统方法制备的材料,因此,LRF制备材料不同取向的力学性能及性能各向异性成为了一个研究热点。SIMONELLI等[11]研究了LRFTC4沉积方向对力学性能及断裂机制的影响,并研究了该合金应力释放对微结构和拉伸性能的影响。AHUJA等[12]调查了LRF TC4薄壁结构三个不同构建方向(与沉积方向平行、成45°角及成90°角)试样的力学性能,并发现90°角试样有最低的强度。VILARO等[1]研究了LRF TC4 合金直接沉积态及热处理态的微结构及断裂,发现LD方向和TD方向的断裂存在极强的各向异性。CHEN等[13]系统研究了LRF TC4块状试样X平面、Y平面及Z平面的硬度及电化学电阻的各向异性并发现X平面具有较低的硬度较低的电化学电阻。WU等[14]研究了LRF TC4合金垂直构建与水平构建方向对冲击韧性的影响,并发现了明显的各向异性。迄今为止,与激光扫描方向成45°角、与激光扫描方向一致及与沉积方向一致几个方向对LRF TC4合金力学性能的影响还未见报道。

本文利用MTS万能材料试验机,将对激光快速成形TC4钛合金沉积态不同取向试样(与激光扫描方向成45°角、0°及与沉积方向一致)进行室温准静态压缩试验,以深入了解LRF TC4钛合金取向对其力学性能影响规律,对加快LRF TC4钛合金材料的工程应用,具有重要的学术研究意义和工程应用价值。

1 实验

1.1 实验材料及处理方法

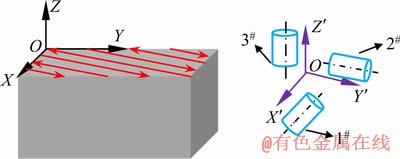

本实验用LRF TC4合金由西安铂力特激光成形技术有限公司提供,成形材料为粒径106~150 μm的TC4球形粉末,其成分列于表1,成形前粉末在真空条件下于120 ℃左右进行干燥处理,去除水分以减少对激光快速沉积过程带来的影响。快速成形系统激光器为Rofin-sinar CO2,激光功率7 kW,扫描速度10~15 mm/s,加粉率15~30 g/min,保护气流量9~12 L/h,光斑直径6 mm,扫描沿与X轴成45°角方向呈之字形进行(图1红线箭头方向),Z轴方向为沉积方向,成形材料尺寸110 mm×110 mm×40 mm,如图1所示。

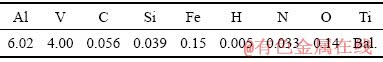

表1 TC4粉末的化学成分

Table 1 Chemical Constitution of TC4 powder (mass fraction , %)

图1 LRF TC4材料成形示意图及取样方向

Fig. 1 Schematic diagram of LRF TC4 formed and direction of LRF TC4 sample

1.2 实验方法

经激光快速成形后的沉积态TC4合金,不经任何后续处理,使用线切割,分别沿与激光扫描方向成45°角( 方向)、激光扫描方向(

方向)、激光扫描方向( 方向)及沉积方向(

方向)及沉积方向( 方向)截取圆柱试样(见图1),分别称为试样1#、2#、3#,为了避免基板和空气冷却因素对材料微结构造成的影响,样品取自图1块体的中部位置。

方向)截取圆柱试样(见图1),分别称为试样1#、2#、3#,为了避免基板和空气冷却因素对材料微结构造成的影响,样品取自图1块体的中部位置。

采用日本理学TTR III型转靶X射线衍射仪测试3种方向试样的晶粒取向,试验条件为:Cu靶,电流为200 mA,加速电压为40 kV,记速率仪的时间为0.5 s,测角仪连续扫描速度为0.02°,扫描范围为25°~80°。

使用MTS万能材料试验机对3个方向圆柱试样(d 7 mm×10 mm)进行室温准静态压缩试验,应变率为0.001 s-1。

使用线切割方法从沉积块状样品(见图1)分别沿与激光扫描方向成45°,0°和沉积方向取方块样,经过不同粒度的砂纸研磨后,机械抛光至镜面,用克氏试剂(5%HF,20%HNO3,75%H2O)进行腐蚀,使用LEICA DMI5000 M型金相显微镜(OM)观察各方向的微观形貌,并使用Quanta 200扫描电子显微镜(SEM)对断裂试样进行断口形貌分析。

2 结果及分析

2.1 微观结构

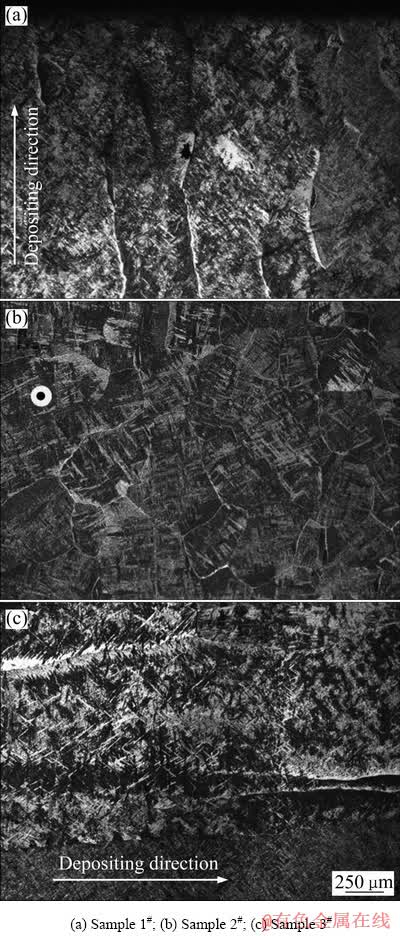

图2 LRF TC4 3个方向试样的光学微观形貌

Fig. 2 OM microstructures of three directions samples of LRF TC4

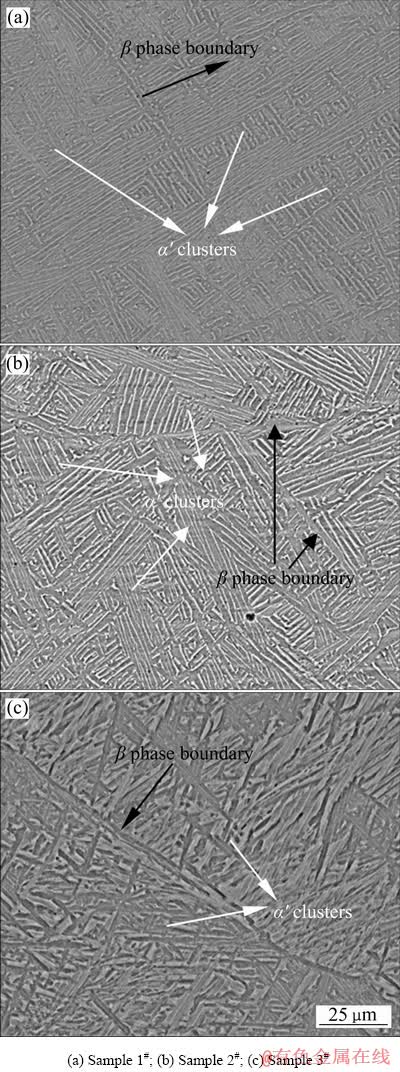

图3 LRF TC4 3个方向试样的SEM微观形貌

Fig. 3 SEM microstructures of three directions samples of LRF TC4

图2所示为激光快速成形TC4钛合金3个方向试样的低倍光学微观形貌,其中,图2(a)~(c)所示分别为与激光扫描方向成45°角、与激光扫描方向一致、与沉积方向一致(图1中的Z轴方向)试样的微观形貌。图2(a)与图2(c)中沉积方向如箭头所示,而图2(b)的沉积方向与纸面垂直。在激光快速成形材料过程中,由于沿沉积方向的温度梯度最大,故β相沿沉积方向外延生长,呈现柱状晶形貌(如图2(a)、图2(c)所示),而其横截面为等轴形貌(如图2(b)所示),β相柱状晶晶界清晰可见,平均宽度约为400 μm。由于激光快速成形的快热快冷过程,一方面,β相沿温度梯度最大的沉积方向外延生长;另一方面,由于高的过冷度,β相快速转变为针状马氏体 相,在β相晶界内沿一定取向形成

相,在β相晶界内沿一定取向形成 丛束。图3所示为3个方向试样β柱状晶晶内的SEM显微形貌,可见3个方向试样柱状晶内部均为快冷过程中形成的

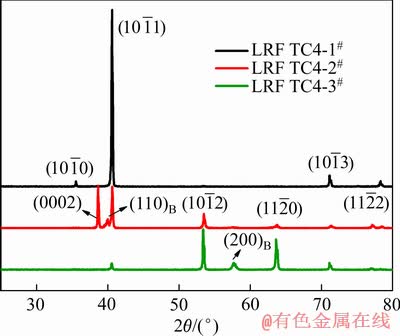

丛束。图3所示为3个方向试样β柱状晶晶内的SEM显微形貌,可见3个方向试样柱状晶内部均为快冷过程中形成的 丛束及晶间残余β相,其形貌区别不大,但取向各不相同。图4所示为3个方向试样的XRD谱,由图中衍射峰的位置可知,3个方向试样主要由密排六方结构的

丛束及晶间残余β相,其形貌区别不大,但取向各不相同。图4所示为3个方向试样的XRD谱,由图中衍射峰的位置可知,3个方向试样主要由密排六方结构的 相构成,这与CHEN等[13]的结果一致。同时,由衍射峰的位置看,3个方向试样成形过程中的晶面取向不尽相同,与激光扫描方向成45°角方向的试样1#形成以

相构成,这与CHEN等[13]的结果一致。同时,由衍射峰的位置看,3个方向试样成形过程中的晶面取向不尽相同,与激光扫描方向成45°角方向的试样1#形成以 为主的择优取向,与激光扫描方向相同试样则在(0002)、

为主的择优取向,与激光扫描方向相同试样则在(0002)、 、

、 间随机分布外,在2θ≈39.5°位置还检测到了体心立方结构的β相(110)晶面[15],沿沉积方向试样除了

间随机分布外,在2θ≈39.5°位置还检测到了体心立方结构的β相(110)晶面[15],沿沉积方向试样除了 相在

相在 、

、 、

、 、

、 间随机分布外,在2θ≈57°位置还检测到了体心立方结构的β相(200)晶面[15],检测结果与3个方向的扫描面有关,同时也体现了3个试样微观结构的各向异性,微观结构的各向异性将影响3个方向试样的力学性能。

间随机分布外,在2θ≈57°位置还检测到了体心立方结构的β相(200)晶面[15],检测结果与3个方向的扫描面有关,同时也体现了3个试样微观结构的各向异性,微观结构的各向异性将影响3个方向试样的力学性能。

图4 LRF TC4 3个方向试样的XRD谱

Fig.4 XRD patterns of three directions samples of LRF TC4 alloy

2.2 力学性能

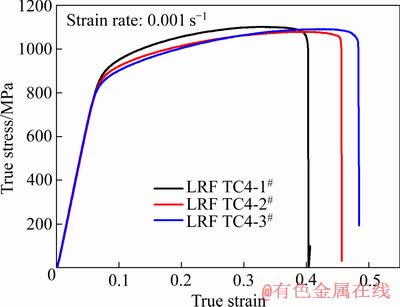

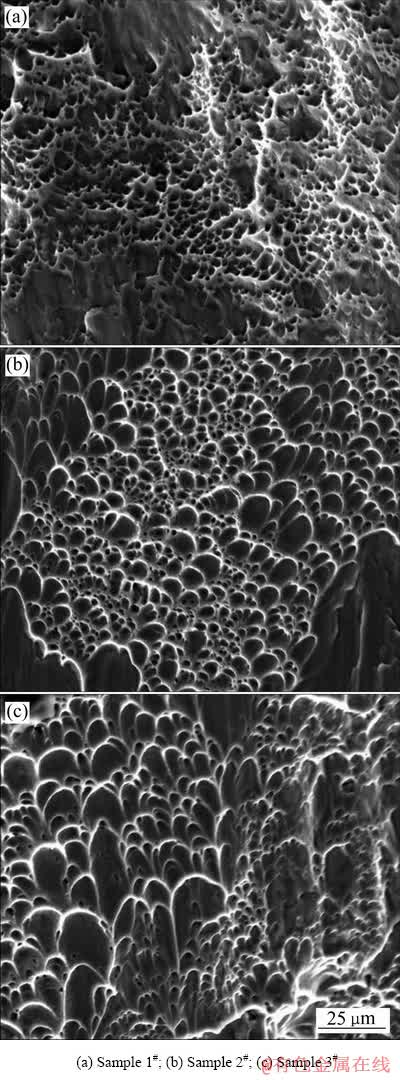

图5所示为LRF TC4钛合金3个方向试样的压缩应力-应变曲线。在压缩状态下,3个方向的试样均展现了良好的塑性,与激光扫描方向成45°角的试样1#最低达到了0.4,与激光扫描方向一致的试样2#达到0.45,沿沉积方向取样的3#试样塑性最好达到约0.5。图6所示为3个方向试样在静态压缩下的SEM断口形貌,3个方向试样断口均存在大量韧窝及撕裂棱,体现了断裂以韧性断裂为主,同时,3个方向试样的断口形貌也有差异,图6(a)所代表的试样1#,韧窝较小,而图6(c)所代表的试样3#,韧窝大而长,图6(b)的韧窝大小居于二者之间,韧窝形貌的差异代表了塑性的好坏,结果与应力-应变曲线的结果一致。强度方面,LRF TC4试样1#展现了较其他两个方向更高的强度,屈服强度约900 MPa,断裂强度达到了1100 MPa,试样2#及3#,其屈服强度和断裂强度较为接近,分别为860 MPa、1060 MPa和830 MPa、1070 MPa。由2.1小节,由于激光快速成形过程快热快冷过程,3个方向试样的微观组织均为针状马氏体 及晶间残余β相,但与激光扫描方向成45°角的试样1#形成了

及晶间残余β相,但与激光扫描方向成45°角的试样1#形成了 的择优取向,择优取向结构的形成,使材料在变形过程中的相邻晶粒间的协调能力变弱,加大了变形难度,使得其强度在3个方向中最大,同时塑性最差;LRF TC4 2#及LRF TC4 3#试样,内部

的择优取向,择优取向结构的形成,使材料在变形过程中的相邻晶粒间的协调能力变弱,加大了变形难度,使得其强度在3个方向中最大,同时塑性最差;LRF TC4 2#及LRF TC4 3#试样,内部 相均随机分布,故二者的强度及塑性相差不大,而两者有较多的体心立方结构的β相存在,故显示了较LRF TC4 1#更好的塑性。

相均随机分布,故二者的强度及塑性相差不大,而两者有较多的体心立方结构的β相存在,故显示了较LRF TC4 1#更好的塑性。

图5 LRF TC4 3个方向试样的准静态压缩应力-应变曲线

Fig. 5 Stress-strain curves of three directions samples of LRF TC4 alloy under condition of quasi-static compression

图6 LRF TC4 3个方向试样的SEM断口形貌

Fig. 6 SEM fracture morphologies of three directions samples of LRF TC4 alloy

3 结论

1) 由于激光快速成形过程快热快冷过程,LRF TC4 3个方向试样的微观组织均为针状马氏体 及晶间残余β相。

及晶间残余β相。

2) 激光扫描方向成45°角的LRF TC4 1#试样内的 相形成了

相形成了 的择优取向,LRF TC4 2#及LRF TC4 3#试样,内部

的择优取向,LRF TC4 2#及LRF TC4 3#试样,内部 相均随机分布,且LRF TC4 3#试样内还存在较多的残余β相。

相均随机分布,且LRF TC4 3#试样内还存在较多的残余β相。

3) 在室温准静态压缩条件下,LRF TC4 1#试样有最高的强度,但最小的塑性;试样2#和3#由于体心立方结构的β相存在,强度相似,塑性较好。

REFERENCES

[1] VILARO T, COLIN C, BARTOUT J D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting[J]. Metallurgical and Materials Transactions A, 2011, 42(10): 3190-3199.

[2] MERTENS A, REGINSTER S, PAYDAS H, CONTREPOIS Q, DORMAL T, LEMAIRE O, LECOMTE-BECKERS J. Mechanical properties of alloy Ti-6Al-4V and of stainless steel 316L processed by selective laser melting: Influence of out-of-equilibrium microstructures[J]. Powder Metallurgy, 2014, 57(3): 184-189.

[3] FACCHINI L, MAGALINI E, ROBOTTI P, ALBERTO M. Microstructure and mechanical properties of Ti-6Al-4V produced by electron beam melting of pre-alloyed powders[J]. Rapid Prototyp J, 2009, 15(3): 171-178.

[4] YAO J, SUO T, ZHANG S Y, ZHAO F, WANG H T, LIU J B, CHEN Y Z, LI Y L. Influence of heat-treatment on the dynamic behavior of 3D laser-deposited Ti-6Al-4V alloy[J]. Materials Science & Engineering A, 2016, 677(20): 153-162.

[5] ZHAO Z, CHEN J, LU X F, TAN H, LIN X, HUANG W D. Formation mechanism of the α variant and its influence on the tensile properties of laser solid formed Ti-6Al-4V titanium alloy[J]. Materials Science & Engineering A , 2017, 691(13): 16-24.

[6] THIJS L, VERHAEGHE F, CRAEGHS T, Van HUMBEECK J, KRUTH J P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V[J]. ActaMaterialia, 2010, 58(9): 3303-3312.

[7] 黄卫东, 林 鑫. 激光立体成形高性能金属零件研究进展[J]. 中国材料进展, 2010, 129(16): 12-27.

HUANG Wei-dong, LIN Xin. Research progress in laser solid forming of high performance metallic component[J]. Materials China, 2010, 129(16): 12-27.

[8] 王华明. 金属材料激光表面改性与高性能金属零件激光快速成形技术研究进展[J]. 航空学报, 2002, 23(5): 473-478.

WANG Hua-ming. Research progress on laser surface modifications of metallic materials and laser rapid forming of high performance metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2002, 23(5): 473-478.

[9] 赵剑峰, 马智勇, 谢德巧, 韩雪谦, 肖 猛. 金属增材制造技术[J]. 南京航空航天大学学报, 2014, 46(5): 675-683.

ZHAO Jian-feng, MA Zhi-yong, XIE De-qiao, HAN Xue-qian, XIAO Meng. Metal additive manufacturing technique[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2014, 46(5): 675-683.

[10] 孙兵兵, 张学军, 郭绍庆, 李 能, 唐思熠, 张文扬. 金属材料激光快速成形的研究进展[J]. 电焊机, 2013, 43(5): 79-84.

SUN Bing-bing, ZHANG Xue-jun, GUO Shao-qing, LI Neng, TANG Si-yi, ZHANG Wen-yang. Research development on the laser rapid prototyping of metal material[J]. Electric Welding Machine, 2013, 43(5): 79-84.

[11] SIMONELLI M, TSE Y Y, TUCK C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V[J]. Materials Science & Engineering A, 2014, 616(20): 1-11.

[12] AHUJA B, SCHAUB A, KARG M, LECHNER M, MERKLEIN M, SCHMIDT M. Developing LBM process parameters for Ti-6Al-4V thin wall structures and determining the corresponding mechanical characteristics[J]. Physics Procedia, 2014, 56: 90-98.

[13] CHEN L Y, HUANG J C, LIN C H, PAN C T, CHEN S Y, YANG T L, LIN D Y, LIN H K, JANG J S C. Anisotropic response of Ti-6Al-4V alloy fabricated by 3D printing selective laser melting[J]. Materials Science & Engineering A, 2017, 682(13): 389-395.

[14] WU Ming-wei, LAI Pang-hsin, CHEN Jhewn-kuang. Anisotropy in the impact toughness of selective laser melted Ti-6Al-4V alloy[J]. Materials Science & Engineering A, 2016, 650(5): 295-299.

[15] da SILVA S L R, KERBER L O, AMARAL L, dos SANTOS C A. X-ray diffraction measurements of plasma-nitrided Ti-6Al-4V[J]. Surf Coat Technol,1999, 116/119(9): 342-346.

Effects of different orietations on mechanical proprieties of laser rapid forming Ti-6Al-4V alloy

SUN Kun, XIANG Wen-li, SHU Xin-zhu

(Research Institute on Preparation and Mechanical Behavior of Materials, Chuxiong Normal University, Chuxiong 675000, China)

Abstract: Using the electronic universal test machine, the quasi-static compression experiment on three different orietations cylindrical sample of laser rapid forming Ti-6Al-4V(LRF TC4) titanium alloy were conducted, and effect of the different orietations on mechanical proprieties of LRF TC4 alloy was investigated by methods of optical microscope (OM), scanning electronic microscope (SEM) and X-ray diffractometer (XRD). The results show that the different orietations sample of LRF TC4 has different quasi-static compression mechanical proprieties owing to the different of microstructure. The sample at an angle of 45° to the scanning direction of Laser has the maximal strength, but the minimal plasticity. The sample cut along depositing direction takes on the best plasticity and its strength is equivalent to the sample cut along the scanning direction of laser.

Key words: laser rapid forming Ti-6Al-4V; titanium alloy; quasi-static compression; mechanical proprieties

Foundation item: Project(51561002) supported by the National Natural Science Foundation of China

Received date: 2019-03-28; Accepted date: 2019-09-02

Corresponding author: SUN Kun; Tel: +86-13638702095; E-mail: sunkun@cxtc.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51561002)

收稿日期:2019-03-28;修订日期:2019-09-02

通信作者:孙 坤,教授,博士;电话:13638702095;E-mail:sunkun@cxtc.edu.cn