铝合金热冲压成形质量影响因素

傅垒1,王宝雨1,孟庆磊2,周靖1,林建国1, 3

(1. 北京科技大学 机械工程学院,北京,100083;

2. 北京航空制造工程研究所 金属成形技术研究中心,北京,100024;

3. 帝国理工学院 机械工程系,伦敦,SW72AZ)

摘要:建立铝合金热冲压成形的有限元模型,研究坯料初始温度、冲压速度、压边力及摩擦因数对板料成形质量的影响,通过铝合金热冲压实验验证有限元模拟的可靠性。研究结果表明:400~500 ℃是可行的坯料成形初始温度范围;冲压速度增大,成形质量较差,超过一定限度时,冲压速度的增大对板料成形质量影响较小;压边力超过15 kN时,铝合金板料可能产生破裂失效;良好的润滑是铝合金热冲压成形的必要条件,摩擦因数小于0.15时,板料不会被拉裂。

关键词:铝合金;成形质量;有限元模拟;热冲压

中图分类号:TU512.4 文献标志码:A 文章编号:1672-7207(2013)03-0936-06

Factors affecting quality in hot stamping of aluminum alloy

FU Lei1, WANG Baoyu1, MENG Qinglei2, ZHOU Jing1, LIN Jianguo1, 3

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Research Center of Metal Forming Technology, Aeronautical Manufacturing Technology Research Institute Beijing, Beijing 100024, China;

3. Department of Mechanical Engineering, Imperial College, London SW72AZ, UK)

Abstract: A finite element model was established for hot stamping of aluminum alloy, and the factors affecting quality were investigated including initial blank temperature, stamping velocity, blank holder force (BHF) and friction coefficient. The reliability of finite element simulation was proved by the hot stamping experiments of aluminum alloy. The results indicate that initial blank temperature of 400-500 ℃ is feasible in hot stamping. The quality will be weakened with the increase of stamping velocity, however, the effects are limited when certain extents are exceeded. Fracture occurs when BHF is more than 15 kN. Good lubrication is necessary for hot stamping of aluminum alloy. Forming will be successful while friction coefficient is less than 0.15.

Key words: aluminum alloy; forming quality; finite element simulation; hot stamping

随着汽车行业的迅速发展,环境污染和资源短缺问题日益突出,节约资源和减少污染成为汽车行业亟待解决的两大问题。着眼于可持续发展,减轻汽车质量,降低燃油消耗及减少排放污染的任务显得尤为迫切,汽车轻量化技术是解决这些问题的重要途径之一[1-2]。研究结果表明,汽车质量每减少10%就可以降低6%~8%的燃油消耗[3]。铝合金具有密度小、比强度高、耐腐蚀性强,抗冲击性能好和再回收能力强等一系列优良特性,并且资源相对丰富,将成为汽车工业中最具竞争的轻质材料[4-5]。但是铝合金在室温条件下其成形性能较差,总伸长率小,且弹性系数仅为钢板的1/3,成形时金属流动困难,从而其应用受到一定的限制[6]。在高温下铝合金塑性好、变形抗力低、成形难度低,因此,铝合金的热冲压成形技术受到人们的广泛关注[7-8]。本文作者以某汽车门内防撞梁为例,研究了铝合金热冲压成形质量的影响因素,包括坯料初始温度、压边力、摩擦因数和冲压速度,得出了适合铝合金热冲压成形的工艺条件,为铝合金热冲压技术在汽车行业的应用提供了理论参考。

1 有限元模型的建立

门内防撞梁是汽车重要零部件,其结构如图1所示,该防撞梁长1 090 mm,宽122 mm,厚2 mm,最大拉深深度为35 mm(图1中的危险区域处),危险区域处的厚度分布是衡量该防撞梁成形质量的重要标准之一,该区域由于受到各向应力的作用而厚度使发生变化,严重到一定程度就会导致成形失败。破裂是板材成形最重要的失效形式,一般通过最大减薄率或最小厚度来判断,认为最大减薄率超过30%[9],即最小厚度为1.4 mm时防撞梁发生破裂失效。本文以危险区域内长度方向距对称中心400 mm的危险截面(图1中A-A截面)的厚度分布为研究对象,来分析各因素对铝合金热冲压成形质量的影响。

图1 汽车门内防撞梁与危险截面

Fig.1 Anti-collusion bumper inside door and most dangerous section

防撞梁具有轴对称性,为了减少计算量,取梁的1/4建立有限元模型,热冲压有限元模型如图2所示。其中板料为弹塑性变形体,凸凹模及压料板为刚性体,模型中各部分网格均采用自动剖分功能来划分,总单元数为2 900,其中板料单元采用热机耦合4节点B-T壳单元,单元数为1 000。坯料厚度为2 mm,凸凹模间隙为2.2 mm。材料采用汽车工业应用比较广泛的AA6111铝合金,其基本参数为:弹性模量E=70 GPa,泊松比μ=0.3,密度ρ=2 700 kg/m3,与轧制方向成0°,45°和90°时的厚向异性系数r0=0.66,r45=0.6,r90=0.76。

图2 铝合金防撞梁热冲压有限元模型

Fig.2 Finite element model of anti-collusion bumper in hot stamping

材料的热物性系数是影响热成形的重要参数[10],AA6111铝合金的热物性参数为:比热容cp=920 J/(kg·℃),热传递系数H=167 W/(m·℃),热耗散系数F=2.5×10-5。热边界条件通过对模具设置强制温度来定义,在室温条件下,将凸模、凹模和压料板的温度设为25 ℃。热接触条件通过设置可变的热传递系数来定义,本模型根据模具和板料的间隙来定义可变的热传递系数,为简化计算,当模具与板料距离小于2.01 mm,热传递系数设为14 kW/(m2·℃)[11],模具与板料距离超过2.01 mm,热传递系数设为0 kW/(m2·℃),即模具与板料之间无热传递。

计算中采用Hill90屈服准则,考虑了板料弯曲和非弯曲状态下的各种行为。其主应力表达式为[12]:

(1)

(1)

式中:a和b均为表征各向异性的材料参数;α为应力主轴 到

到 逆时针方向的夹角;

逆时针方向的夹角; 为等双拉屈服应力;τ为材料纯剪切状态下的屈服应力;m为屈服参数;r45和σ45分别为与轧制方向成45°时的厚向异性指数和屈服应力。

为等双拉屈服应力;τ为材料纯剪切状态下的屈服应力;m为屈服参数;r45和σ45分别为与轧制方向成45°时的厚向异性指数和屈服应力。

在热冲压成形过程中,必须考虑温度变化引起的增塑效应和内能变化,需要多条不同温度下的硬化曲线,AA6111铝合金在不同温度及应变速率下的应力-应变曲线如图3所示。

图3 AA6111铝合金应力-应变曲线

Fig.3 Stress-strain curves of AA6111 aluminum alloy

2 模拟结果及分析

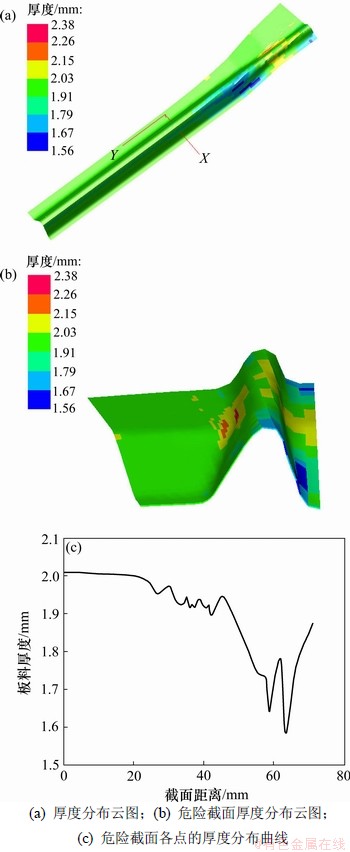

基于上述有限元模型,改变相应的工艺参数对AA6111铝合金的热冲压成形进行模拟,压边力为10 kN,摩擦因数为0.12,冲压速度为100 mm/s,坯料初始温度为500 ℃时板料的厚度分布如图4所示。可见:该工况下没有发生破裂失效。

图4 板料的厚度分布

Fig.4 Distribution of blank thickness

2.1 坯料初始温度对成形质量的影响

图5所示为压边力10 kN,冲压速度为100 mm/s,摩擦因数0.12条件下,坯料初始温度为400,450,500 ℃时危险截面各点的厚度分布曲线。从图5可知:距边缘截面距离为0~20 mm处,各工况下的板料厚度比较均匀,为2 mm左右,此处为压边区,在压边力合适的情况下,该处的成形质量较好;截面距离为20~45 mm处,各工况下板料厚度相差不大,且减薄率只有10%以下,但是各自出现了一些波动,此处为传力区,主要起着连接压边区与成形区的作用,只要压边区的材料能够顺利地进入凹模型腔,传力区的金属流动就会比较顺畅,从而使该处板料的成型质量较好;截面距离为45 mm到截面中心处的区域为主要成形区,该处的成形质量好坏决定着板料成形是否失效,各工况下板料厚度相差较大,且减薄率都达到了15%以上,为危险截面的危险区,研究此处的厚度分布,对分析板料的成形质量有着重要意义。

由图5可知,随着温度的升高,各曲线的最低点相应降低,即危险截面的最小厚度逐渐减小,在500 ℃,为1.56 mm,大于破裂失效的最小厚度(1.4 mm),说明在上述3种工况下,板料均未发生破裂失效,在坯料初始温度为400 ℃成形质量最好。铝合金在热冲压条件下,应变率相同时,随着温度的升高,其流变应力逐渐减小,成形极限逐渐提高[13-14]。但是,在成形深度一定的情况下,流变应力越小,成形区的金属越容易发生流动,应变率相同时,压边区的材料通过传力区到达成形区的材料反而减少,从而使板料在不发生破裂的情况下减薄越严重,即最小厚度越小。由此可见,对于确定的零件,在保证成形不失效的情况下,选择合适的坯料初始温度对板料的成形质量有重大的影响。

图5 板料危险截面各点在不同坯料初始温度下的厚度分布曲线

Fig.5 Thickness curves of dangerous section at different initial blank temperatures

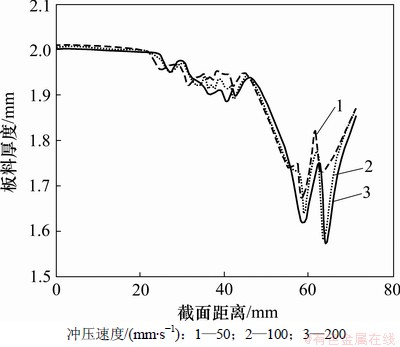

2.2 冲压速度对成形质量的影响

图6所示为坯料初始温度500 ℃,压边力10 kN,摩擦因数0.12条件下,冲压速度为50,100和200 mm/s时危险截面各点的厚度分布曲线。从图6可知:压边区与传力区的成形质量较好,减薄率均在10%以下。随着冲压速度的提高,成形区各曲线的最低点逐渐降低。当冲压速度为100 mm/s和200 mm/s时,2条曲线的变化趋势几乎一样,即危险截面的厚度分布相差不大,最小厚度都在1.55 mm左右;而冲压速度为50 mm/s时,危险截面的最小厚度为1.68 mm,其成形质量最好。

冲压速度对铝合金热冲压时材料的应变率及成形过程中铝合金的动态回复与动态再结晶有着重大影响。在相同温度下,随着冲压速度的提高,材料的应变率相应增大,高温下铝合金发生动态回复与动态再结晶受到限制,应变硬化得不到松弛,使得变形抗力增加[15]。当冲压速度为50 mm/s时,铝合金能够较好的发生动态回复与动态再结晶,变形抗力小,压边区的材料能够顺利地通过传力区进入到成形区,从而使板料危险截面的最小厚度较大,成形质量较好;当冲压速度为100 mm/s和200 mm/s时,由于应变率较大,动态回复和动态再结晶都受到抑制,变形抗力较大,使成形区材料的流入受到一定的阻碍,从而板料危险截面的最小厚度较小。高温下,当冲压速度达到一定程度时,铝合金的动态回复与动态再结晶受抑制的程度基本上相同,此时,在其他条件不变的情况下,增加冲压速度对板料的成形质量影响较小。

图6 板料危险截面各点在不同冲压速度下的厚度分布曲线

Fig.6 Thickness curves of dangerous section at different drawing velocities

2.3 压边力对成形质量的影响

图7所示为坯料初始温度500 ℃,冲压速度100 mm/s,摩擦因数0.12条件下,压边力分别为2.5,10和15 kN时危险截面各点的厚度分布曲线。从图7可知:压边区与传力区的成形质量较好,减薄率均在10%以下。随着压边力的增大,成形区各曲线的最低点逐渐降低,并且趋势非常明显。当压边力为15 kN时,成形区的最小厚度为1.38 mm,小于破裂失效的最小厚度(1.4 mm),此时,板料发生了破裂失效,成形失败。

压边力是板料成形中的一个重要工艺参数,合理控制压边力可以有效地控制材料的流动,对板料的成形质量有着重要影响,当板料不发生破裂时,增大压边力可以提高材料的极限拉伸比,避免起皱等[16]。在其他条件相同的情况下,当压边力增大到一定程度,压边区的材料很难通过传力区进入成形区,使成形区材料过度减薄,引起该区域的等效应力急剧增大,当等效应力大于材料的抗拉强度时发生破裂。在保证压边区不起皱的条件下,压边力越小,板料的成形质量越好。

图7 板料危险截面各点在不同压边力下的厚度分布曲线

Fig.7 Thickness curves of dangerous section at different BHFs

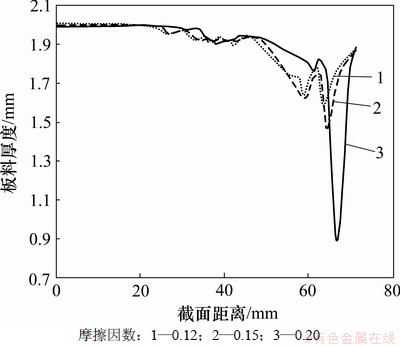

2.4 摩擦因数对成形质量的影响

图8所示为坯料初始温度500 ℃,冲压速度100 mm/s,压边力10 kN条件下,摩擦因数分别为0.12,0.15,0.20时危险截面各点的厚度分布曲线。从图10可知:压边区与传力区的成形质量较好,减薄率均在10%以下。随着摩擦因数的增大,成形区各曲线的最低点急剧降低。摩擦因数为0.15时,板料最小厚度仅为1.42 mm,濒临破裂,而摩擦因数为0.20时,板料最小厚度为0.85 mm,板料早已发生破裂失效,成形失效。由此可知:在板料成形过程中,良好的润滑条件是成形成功的必要条件。

在其他条件相同的情况下,摩擦因数的增大,不仅会增加压边区材料进入成形区的难度,并且在成形区内,由于摩擦力的作用,危险截面各处材料流动不均,容易在应力集中地方产生急剧减薄而发生破裂。协调好压边力与冲压力的关系,创造良好的润滑条件,对提高板料的成形质量有着极其重要的意义。

图8 板料危险截面各点在不同摩擦因数下的厚度分布曲线

Fig.8 Thickness curves of dangerous section at different friction coefficients

3 实验结果验证

通过设置不同的工艺参数对AA6111铝合金防撞梁进行了一系列热冲压实验。取坯料初始温度450 ℃,冲压速度100 mm/s,压边力10 kN,摩擦因数0.12的实验结果与其比较。危险截面的模拟仿真结果与实际测量结果厚度分布如图9所示。通过比较发现,模拟仿真结果与冲压实验结果比较接近,厚度变化趋势大致相同,说明模拟仿真结果可靠,为指导实际工艺生产奠定了理论基础。

图9 板料危险截面的厚度分布对比

Fig.9 Comparison of thickness of dangerous section by experiment and simulation

4 结论

(1) 在成形不失效的情况下,坯料初始温度提高,铝合金板料减薄增大,AA6111铝合金成形的初始温度范围为400~500 ℃。

(2) 冲压速度越高,成形质量较差,但当超过一定限度时,冲压速度的增大对板料成形质量影响较小。

(3) 压边力是影响铝合金成形质量的重要因素,板料最小厚度随着压边力增大而减小, 当超过15 kN时,就可能产生破裂失效,导致成形失败。

(4) 良好的润滑是铝合金热冲压成形的必要条件,当摩擦因数小于0.15时,成形可以顺利进行,而超过0.15时,就会使零件严重减薄,导致成形失败。

参考文献:

[1] 邵光杰, 张恒华, 许珞萍. 汽车用铝合金材料及热处理进展[J]. 金属热处理, 2004, 29(1): 29-32.

SHAO Guangjie, ZHANG Henghua, XU Luoping. Progress on aluminum alloys and their heat treatment for automobile materials[J]. Heat Treatment of Metals, 2004, 29(1): 29-32.

[2] 丁向群, 何国求. 6000系汽车车用铝合金的研究进展[J]. 材料科学与工程学报, 2005, 23(2): 302-305.

DING Xiangqun, HE Guoqiu. Advance in studies of 6000 aluminum alloy for automobile[J]. Journal of Materials Science & Engineering, 2005, 23(2): 302-305.

[3] 马鸣图, 游江海, 路洪洲. 汽车轻量化以及铝合金汽车板的应用[J]. 新材料产业, 2009(9): 34-37.

MA Mingtu, YOU Jianghai, LU Hongzhou. Lightweight automobile and application of aluminum alloys automotive sheet[J]. Advanced Materials Industry, 2009(9): 34-37.

[4] 关绍康, 姚波, 王迎新. 汽车铝合金车身板材的研究现状及发展趋势[J]. 机械工程材料, 2001, 25(5): 12-14.

GUAN Shaokang, YAO Bo, WANG Yingxin. The progress and prospect of research on aluminum alloys for auto sheets[J]. Materials for Mechanical Engineering, 2001, 25(5): 12-14.

[5] 王孟君, 黄电源, 姜海涛. 汽车用铝合金的研究进展[J]. 金属热处理, 2006, 31(9): 34-38.

WANG Mengjun, HUANG Dianyuan, JIANG Haitao. Research progress of aluminum alloys for the automotive industry[J]. Heat Treatment of Metals, 2006, 31(9): 34-38.

[6] Palumbo G, Tricarico L. Numerical and experimental investigations on the warm deep drawing process of circular aluminum alloy specimens[J]. Journal of Materials Processing Technology, 2007, 184(1/3): 115-123.

[7] LI Daoming, Amit K G. Biaxial wall forming behavior of aluminum sheet alloys[J]. Journal of Materials Processing Technology, 2004, 145(1/3): 281-193.

[8] Mohamed S M, Alistair D F, LIN Jianguo. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modeling[J]. International Journal of Machine Tools & Manufacture, 2012, 53(1/3): 27-38.

[9] 陈文亮. 板料成形CAE分析教程[M]. 北京: 机械工业出版社, 2005: 147-149.

CHEN Wenliang. Analysis tutorial of sheet metal forming CAE[M]. Beijing: China Machine Press, 2005: 147-149.

[10] 刘红生, 包军, 刑忠文. 高强钢板热冲压成形热力耦合数值模拟[J]. 材料科学与工艺, 2010, 18(4): 459-463.

LIU Hongsheng, BAO Jun, XING Zhongwen. Numerical simulation on channel shape hot stamping of 22MnB5 high-strength sheet metal based on thermo-mechanical coupled method[J]. Materials Science & Technology, 2010, 18(4): 459-463.

[11] 张立文, 朱德才, 刑磊, 等. 铝合金与5CrMnMo模具钢界面接触换热系数实验研究[J]. 大连理工大学学报, 2009, 49(1): 60-64.

ZHANG Liwen, ZHU Decai, XING Lei, et al. Experimental measurement on thermal contact conductance coefficient between aluminum alloys and 5CrMnMo die steel[J]. Journal of Dalian University of Technology, 2009, 49(1): 60-64.

[12] 吴向东, 万敏, 周贤宾. 比例加载路径下板料本构模型的建立及实验验证[J]. 中国机械工程, 2006, 17(19): 1993-1996.

WU Xiangdong, WAN Min, ZHOU Xianbin. Theoretical and experimental study on constitutive modeling of sheet metal under proportional loading path[J]. China Mechanical Engineering, 2006, 17(19): 1993-1996.

[13] 刘合军, 郎利辉, 李涛. 铝合金板材温热成形性能[J]. 塑性工程学报, 2009, 16(3): 145-148.

LIU Hejun, LANG Lihui, LI Tao. Investigation of formability of aluminum alloy sheet at elevated temperature[J]. Journal of Plasticity Engineering, 2009, 16(3): 145-148.

[14] Tstuso N, Fusahito Y. Deep drawability of type 5083 aluminum-magnesium alloy sheet under various conditions of temperature and forming speed[J]. Journal of Materials Processing Technology, 1999, 80/90: 19-23.

[15] 林钧品, 程荆卫. Al-2Mg合金的动态再结晶[J]. 中国有色金属学报, 1999, 9(3): 510-514.

LIN Junping, CHENG Jingwei. Dynamic recrystallization during hot torsion of Al-2Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(3): 510-514.

[16] 王孟君, 周威. 汽车用5182铝合金的温拉深成形性能[J]. 中南大学学报: 自然科学版, 2010, 41(3): 936-939.

WANG Mengjun, ZHOU Wei. Forming properties of 5182 aluminum alloy for automotive body sheet during warm deep drawing processes[J]. Journal of Central South University: Science and Technology, 2010, 41(3): 936-939.

(编辑 赵俊)

收稿日期:2012-07-02;修回日期:2012-09-15

基金项目:国家自然科学基金资助项目(50975023);国家科技重大专项(2009ZX04014-074-02)

通信作者:王宝雨(1964-),男,山东成武人,研究员,博士生导师,从事零件轧制成形技术及模具数字化设计与制造方面的研究;电话:010-82375396;E-mail: bywang@ustb.edu.cn