DOI: 10.11817/j.issn.1672-7207.2016.08.015

冲压速度对铝合金5182-O拉深性能的影响

居龙1, 2,毛婷婷2,李洪波1,张杰1

(1. 北京科技大学 机械工程学院,北京 100083;

2. 美国俄亥俄州立大学 精密成形中心,哥伦布,43210)

摘要:成形速度不仅关系到生产效率,且对成形质量具有重要的影响。伺服驱动压力机可实现滑块任意运动模式调节与控制,为多样化冲压过程提供可能性。采用传统机械式和恒速成形式2种滑块运动模式,基于Pamstamp有限元仿真确定了板料尺寸、压边力和拉深深度,利用伺服压力机对汽车通用铝合金材料5182-O进行常温下不同速度下的拉深试验。试验结果表明:随着冲压速度增加,拉深件关键圆角区域颈缩及破裂趋势减小,并且冲压力相比于低速成形时减小量可达8.9%。从材料力学属性及润滑状态2个方面进行进一步的分析与讨论,结合有限元计算,对比分析不同冲压速度下所选截面处板料相对于模具的滑动速度,指出局部区域润滑状态的动态变化成为冲压速度影响拉深成形质量的关键因素。

关键词:铝合金;拉深试验;成形速度;拉深性能

中图分类号:TG 146.21 文献标志码:A 文章编号:1672-7207(2016)08-2643-07

Effects of forming speed on drawability of aluminum alloy 5182-O

JU Long1, 2, MAO Tingting2, LI Hongbo1, ZHANG Jie1

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Center for Precision Forming, the Ohio State University, Columbus 43210, USA)

Abstract: Forming speed is significantly related to parts quality and productivity in automotive industry. Servo presses have the capability to enable flexible ram motions for various stamping operations. Deep drawing tests were conducted on a servo press to investigate the effects of forming speed on the drawability for Al alloy (5182-O) sheets at room temperature. The slide movements used in the tests were basic mechanical ram motion and constant during forming. Blank size, blank holder force and draw depth were determined by finite element simulation with commercial software Pamstamp. The results show that the tendency of necking and fracture in critical corners reduces with high drawing speed, and the decrease of forming force is up to 8.9% compared with low speed forming. Comprehensive discussions from the point view of mechanical properties and lubrication status are carried out. By comparing the calculated sliding speed between sheet and dies along selected section at different forming velocities, the dynamic characteristic of local lubrication is pointed out to be the main reason for the effects of forming speed on drawability.

Key words: aluminum alloys; deep drawing test; forming speed; drawability

随着能源、环境以及安全问题的日益严峻,汽车轻量化设计成为了现代汽车工业发展的主流趋势。与传统钢板相比,铝合金的强度和钢板的相近,且密度只有钢板的1/3,并且具有良好的力学性能、抗腐蚀性和抗冲击性等特性[1]。因此在轻质合金中,铝合金是目前在汽车制造中用量最多、发展最快的材料,具有广阔的研究前景。5000系(Al-Mg)铝合金具有固溶强化特点,在强度、成形性、抗腐蚀性及焊接性能等方面已与常用钢板接近,主要用于汽车内板等形状复杂不注重外观质量的部位[2-3]。其他汽车覆盖件如车盖、后备箱盖及空气过滤器等零件的成形对板料延展性要求较高,因此,研究5000系铝合金板料的拉深性能对其在汽车覆盖件上的应用具有重要的意义。国内外对汽车用5000铝合金材料的成形性能及工艺技术研究成果较多。利用单向拉伸、液压胀形和十字双向拉伸等实验,可获得材料在不同加载路径下的力学参数[4]。通过实验与数值模拟相结合,能够建立铝合金板材料力学参数与其在冲压过程中零件的破裂、起皱、回弹等缺陷的相关性,有助于模具的设计和冲压工艺参数的优化[5]。温成形和变压边力等新型成形工艺的出现,加快了铝合金在汽车工业上的应用。在升温条件下,铝合金5083,5754和5182等材料的力学性能随温度和变形速率而变化,通过对温度及冲压速度的合理匹配,可很大程度地提高铝合金材料的成形性能[6-8]。随着冲压设备及控制系统的不断发展,变压边力控制技术可有效地提高冲压件的成形性能及质量,包括了压边力随时间、位置等变量的变化,以及根据零件局部成形质量(减薄率和起皱高度)自适应调整冲压过程中所施加的压边力,以提高冲压件的成形性能[9-11]。拉深成形是板料冲压加工中最常见的工艺之一,影响铝合金的拉深性能及零件质量的主要因素有材料力学性能、模具设计、界面接触及润滑状态以及压边力和冲压速度等[12]。其中,冲压成形速度不仅关系到实际生产效率,而且对金属材料拉深成形性能具有重要影响,而冲压速度曲线的多样化设计对冲压设备的调控性能要求较高。在国内外冲压设备的设计与研究中,采用伺服电机驱动技术已逐渐成为一个重要发展方向,伺服驱动压力机可根据不同工艺要求,实现压力机滑块的任意运动特性,克服了传统曲柄压力机运动特性不可调节的缺点。滑块运动特性设计有助于提高设备工作效率及工作性能,并且能够实现零件成形性能的提高[13-14]。在冲压过程中特殊设计的压力机滑块运动,如脉冲式或阶梯式,能够有效地提高拉深成形零件的极限拉深比,并抑制零件边部及壁部起皱[14-15]。但受到实际生产及设备应用的限制,该类复杂运动特性很难得到广泛应用。通过对铝合金门板进行不同速度冲压实验发现,拉深深度不仅受到成形速度的影响,且与成形速度变化率有密切的关系[16]。国内学者主要针对汽车用钢进行了不同成形速度下的板料拉深性能研究。通过对比研究传统曲柄压力机和伺服压力机的工作特性,认为合理的压力机运动模式可增加拉深深度,并提高拉深产品的质量,但对于成形速度如何影响拉深性能并没有进行深入分析[17-18]。因此,对于常温下成形速度对铝合金板料拉深成形性能的影响,国内研究依然较少。5182-O铝合金在汽车车身轻量化材料设计中体现出了良好的研究前景,该材料拉伸强度高,并且具有一定的成形性能。因此,本文作者利用伺服驱动压力机对铝合金5182-O进行了常温下的拉深试验,通过调节伺服压力机滑块的运动,对比分析了常规机械曲柄滑块式运动及恒速运动下,冲压速度对拉深成形性能的影响。并从材料力学性能及摩擦与润滑的角度对试验结果进行了深入讨论,分析了成形速度对拉深性能的影响机理,对于提高常温下铝合金拉深性能与产品质量具有一定指导意义。

1 试验材料及方法

1.1 试验材料的拉伸试验及性能参数

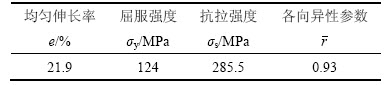

为获得5182-O材料的基本力学参数,根据JIS(Japanese Industrial Standards)拉伸试验标准对厚度为1.2 mm的铝合金5182-O试样进行拉伸试验,获取了该材料在常温下的力学性能,具体参数如表1所示。

表1 AA 5182-O材料拉伸试验力学参数

Table 1 Mechanical properties of AA 5182-O from tensile test

1.2 拉深试验模具及其运动方式

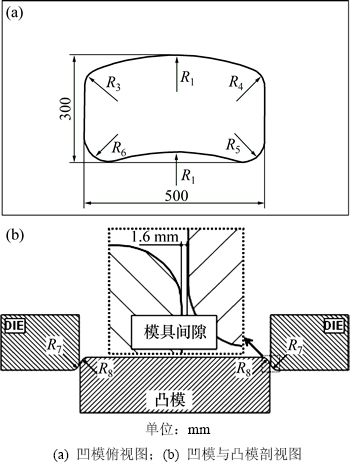

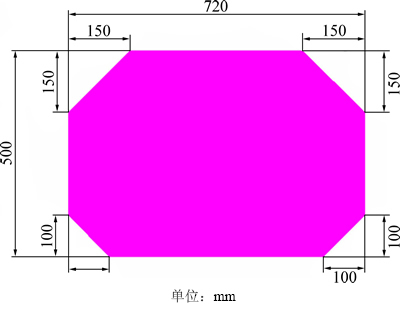

拉深试验所用模具如图1所示。凹模腔内具有多处圆角设计,凹模与凸模圆角分别为20 mm(R7)和10 mm(R8),凹模与凸模间隙为1.6 mm。

在铝合金拉深过程中,合理使用润滑剂可减小摩擦力,并抑制零件成形过程中的擦伤缺陷。干膜润滑剂使用了剪切强度低于成形金属流动剪切强度的固体物质作为润滑介质。研究发现,使用硼酸盐干膜润滑剂,可将铝合金成形过程中的摩擦因数降低至0.04[20],并且在拉深过程中成形零件可得到更均匀的厚度分布[21-22]。在之前的研究中,通过杯突试验,对14中铝合金冲压润滑剂(包含矿物油、干膜润滑剂等)进行了性能测试及评价。在相同压边力下,使用干膜润滑剂可使杯形件获得更大拉深深度。因此,试验过程中采用的硼酸盐干膜润滑剂,以镀层形式预先涂于试样表面,故可视试验中所有试件润滑条件基本一致。

图1 拉深试验模具示意图[19]

Fig. 1 Schematic of deep drawing test tooling[19]

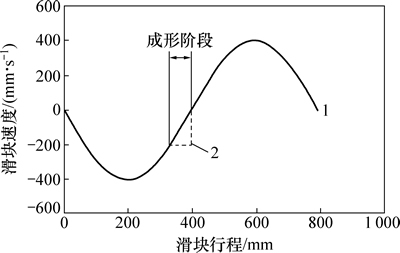

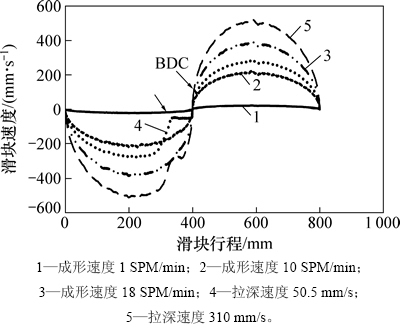

利用300 t伺服驱动压力机进行了2类不同滑块运动模式下的拉伸试验,结果如图2所示。一类基于传统机械式曲柄滑块运动(正弦曲线),另一类为在成形过程中保持速度恒定。针对2类运动曲线,采用了由低到高不同级别成形速度。试验中通过调节数控液压垫,以实现液压垫预加速,从而缓解高速下冲击对拉深试验的影响。由于设备限制,凹模最大行程为80 mm,可使用最大压边力为250 kN。

图2 压力机滑块运动模式示意图

Fig. 2 Schematic of press slide movement

2 试验条件的有限元仿真计算

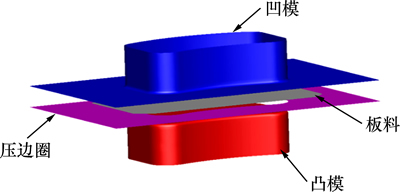

有限元仿真在板料成形研究中具有重要的地位。通过有限元仿真可合理地指导试验设计;并且可减少试模次数及时间,降低试验成本。本研究利用Pamstamp建立了模具三维有限元模型,如图3所示,用于初步设计板料尺寸,并计算在拉深成形过程中使用的压边力(blank holder force,BHF)及允许拉深深度。

图3 拉深试验三维有限元模型

Fig. 3 3D finite element model of deep drawing test

2.1 有限元模型建立

有限元模型采用壳单元四边形网格;相比于模具,所用铝合金强度低,因此,可忽略成形过程中模具变形,将其设置为刚体。根据有限元模型计算的材料流动情况,确定板料尺寸如图4所示。该模型采用了Yld2000-2d屈服准则,通过8个屈服参数可准确预测该铝合金材料在冲压过程中的塑性变形[23]。

图4 板料设计尺寸

Fig. 4 Dimension of blank

通过拉伸试验获取的材料流变曲线,通常可由下式拟合得到:

(1)

(1)

其中:K和n为材料属性常数,K=519.5,n=0.27。

在板料成形中,库仑摩擦模型为应用最广泛的摩擦模型之一,摩擦力τ可由接触体间正压力p及摩擦因数μ计算得到:

(2)

(2)

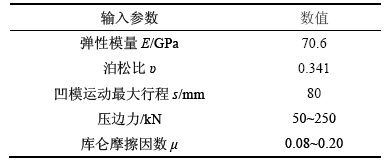

此前通过杯突试验对所用干膜润滑剂进行了性能评价研究,并利用有限元模型对杯突试验进行了模拟计算。通过对比杯形件法兰周长及冲压力,确定该润滑剂在拉深过程中的库伦摩擦因数范围。输入有限元模型的其他材料参数及工艺参数如表2所示。

表2 有限元模型输入参数

Table 2 Input parameters of finite element model

2.2 有限元预测

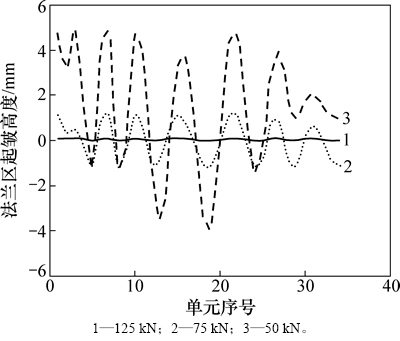

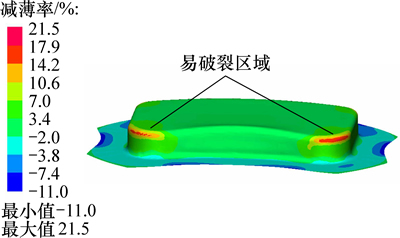

合理选择压边力和凹模行程对拉深试验极为重要。通过压边力的控制,可有效抑制法兰区域起皱。使用有限元模型计算可初步掌握试验中所需的压边力及可成形深度。图5所示为有限元模型计算得出的不同压边力下法兰区域起皱高度,当压边力提高到125 kN时,起皱高度可控制在0.3 mm内。但过高的压边力容易导致拉深件在关键区域过早出现破裂。由于模具设计特点(图1),凹模内多处圆角不同(R3>R4>R5>R6),破裂将先出现于材料流动性较差的小圆角处。有限元模型仿真得出的易破裂位置如图6所示,在压边力为125 kN,使用最大摩擦因数0.2时,拉深至60 mm时最大减薄率可达21.5%。

图5 不同压边力下法兰区域起皱高度预测

Fig. 5 Prediction of wrinkle hight on flange under different blankholder force

因此,基于所设计板料尺寸及有限元模型预测,试验中将采用恒定压边力125 kN,拉深深度设定为 60 mm。

图6 压边力为125 kN时的拉深件减薄率分布

Fig. 6 Thinning distribution of drawing part under BHF of 125 kN

3 拉深试验的结果及讨论

3.1 试验结果

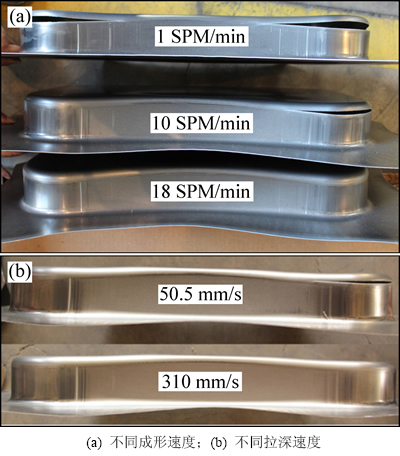

基于有限元预测结果,拉深试验中采用125 kN压边力以有效抑制法兰区域起皱,并通过预先调节滑块运动模式以实现不同速度曲线。在传统机械式运动模式下设定冲程(stroke per minute,SPM)为18,10和1 SPM/min,图7所示为伺服压力机输出的滑块运行速度曲线。拉深试验结果如图8(a)所示,当使用较低成形速度1 SPM/min时,5182-O拉深至60 mm时出现了凸模圆角部位破裂,该破裂位置与图6预测一致;当增加成形速度至10 SPM/min,破裂只出现在图示右侧圆角处(圆角半径较左侧小),而左侧圆角处出现颈缩;当使用最高成形速度18 SPM/min时,可将板料成形至60 mm。因此,从上述试验结果可以初步证明速度的增加有利于减小板料拉裂趋势。

图7 拉深成形过程中滑块速度曲线

Fig. 7 Slide speed profiles during deep drawing

图8 不同速度下拉深试验结果

Fig. 8 Deep drawing test results under various speeds

为了探究不同恒定拉深速度下5182-O的拉深成形趋势,在该模式下设定了拉深速度为310 mm/s和50.5 mm/s。由于滑块运行至下死点(bottom dead center,BDC)前需要一段减速距离,因此,在整个拉深行程(60 mm)中无法保持速度恒定,如图5所示。从图8(b)可以看出:拉深速度从50.5 mm/s增加到310 mm/s时,拉深件可无缺陷成形。

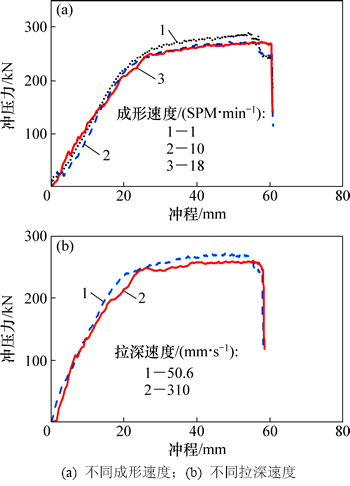

图9所示为不同速度下冲压力随着冲程的变化。从图9(a)和(b)可以看出:较低速度(1 SPM/min,10 SPM/min和50.5 mm/s)条件下,冲压力从某拐点处出现突然降低趋势,可预示拉深过程中板料出现破裂。并且,当使用较大成形速度(18 SPM/min和拉深速度310 mm/s)拉深时,所需冲压力有明显的降低,最大冲压力的减小量可达8.9%。

3.2 拉深速度对成形性能的影响

为了分析拉深速度对成形性能的影响,本研究从铝合金的材料力学性能及接触界面润滑状态2个方面对拉深过程进行了探讨。

3.2.1 材料力学性能

在常温下(100 ℃以下),通过不同速率下(10-6~1 s-1)单向拉伸试验可知:5182-O屈服后加工硬化程度随着应变率增加而略有减小,但屈服平台基本不受应变率影响[24]。而根据下式可估测成形过程中法兰区域等效应变率[25]:

(3)

(3)

其中: 为法兰区域等效应变率,

为法兰区域等效应变率, 为冲模运行速度,

为冲模运行速度, 和r 分别为冲模半径及拉深时法兰外缘半径。在本文所研究的矩形件拉深试验中,板料流入过程中外接圆半径r=710~762 mm,冲模半径

和r 分别为冲模半径及拉深时法兰外缘半径。在本文所研究的矩形件拉深试验中,板料流入过程中外接圆半径r=710~762 mm,冲模半径 可等效为最大边长500 mm(如图1)。冲模在成形过程中的速度

可等效为最大边长500 mm(如图1)。冲模在成形过程中的速度 在5 ~ 310 mm/s之间,可计算得出等效应变率在10-3~10-1 s-1之间。因此,在该试验中冲模速度对5182-O材料的加工硬化程度影响甚微。在试验中发现,由于塑性变形及摩擦导致了拉深件局部温度升高。当使用最高速310 mm/s冲压时,拉深件在凹模圆角处出现最高温度,且温度低于50 ℃;对该铝合金材料力学性能基本不产生影响。

在5 ~ 310 mm/s之间,可计算得出等效应变率在10-3~10-1 s-1之间。因此,在该试验中冲模速度对5182-O材料的加工硬化程度影响甚微。在试验中发现,由于塑性变形及摩擦导致了拉深件局部温度升高。当使用最高速310 mm/s冲压时,拉深件在凹模圆角处出现最高温度,且温度低于50 ℃;对该铝合金材料力学性能基本不产生影响。

图9 不同速度下冲压力对比

Fig. 9 Comparisons of punch load under various speeds

3.2.2 摩擦与润滑

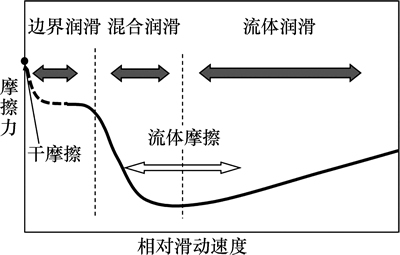

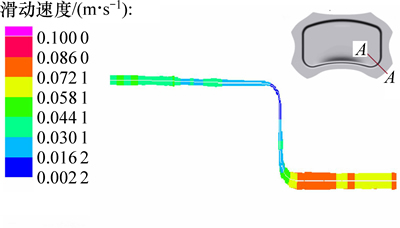

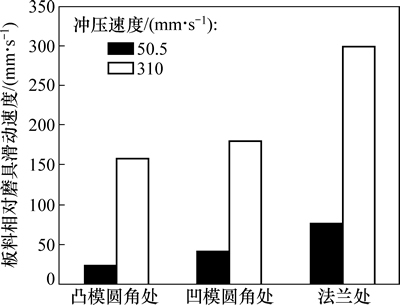

在拉深过程中,润滑剂在板料与模具之间形成一层润滑膜。随着拉深过程的进行,在法兰区域、凸模圆角区域和凹模圆角区域,板料与模具之间的接触状态不断地变化。在对润滑机理的研究中,具有相对运动的接触体间主要存在3种润滑机制:1) 边界润滑;2) 混合润滑;3) 流体润滑。在润滑与摩擦研究领域中受到广泛应用的Stribeck模型可用于简便地区分润滑状态,该模型描述了不同润滑剂黏度、单位面积接触压力及相对滑动速度下摩擦力的动态变化趋势。在润滑剂黏度及接触压力相对不变情况下,随着接触体间相对滑动速度的不断增加,润滑状态由边界润滑向着流体润滑转变,摩擦力呈降低趋势,如图10所示[26-27]。图11所示为利用以上建立的有限元模型计算出的某工况面A-A处板料相对于模具滑动速度的分布。可见法兰及凹模圆角区域材料的相对滑动速度明显大于凸模圆角处。同时,当改变冲压速度时,3个区域板料的滑动速度随之改变。图12所示为不同冲压速度下板料相对滑动速度变化。由图12可见:当拉深速度从50.5 mm/s提高至310 mm/s时,各区域板料的相对滑动速度都有明显的提升,根据Stribeck润滑模型,该区域的摩擦力随之减小。因此,在本研究中,使用较高的冲压速度时,润滑状态的改变及摩擦力的减小,是有助于零件拉深成形的主要因素。

图10 润滑状态及摩擦力随着相对滑动速度的变化[26]

Fig. 10 Description of lubrication status and friction force change with sliding speed[26]

图11 截面A-A处板料相对于接触模具的滑动速度分布 (拉深速度50.5 mm/s,冲程40 mm)

Fig. 11 Relative sliding speed distribution of material in section A-A

图12 不同冲压速度下板料相对滑动速度变化

Fig. 12 Variation of sliding speed under different punch velocities

4 结论

1) 对汽车用铝合金材料5182-O实施不同速度下拉深试验,基于伺服驱动压力机设定了2类多级滑块运行速度。通过Pamstamp建立的三维有限元模型,设计计算板料尺寸、压边力及拉深深度等试验条件,并准确预测零件易破裂区域。试验结果发现:在所设定2类运行模式下,冲压速度越低,零件圆角处出现的破裂越严重。随着成形速度和拉深速度分别增加至18 SPM/min和310 mm/s时,该铝合金板料可拉深至60 mm无缺陷;并且相比于低速拉深时成形下冲压力降低可达8.9%。

2) 从材料力学属性及润滑状态对试验结果进行分析与讨论,并结合有限元计算,对比分析不同拉深速度下(50.5和310 mm/s)关键区域板料相对于模具的相对滑动速度。根据Stribeck润滑模型,由于板料与拉深模具间相对滑动速度的变化,润滑状态及摩擦力随之改变,导致冲压速度对铝合金拉深件成形性能产生一定的影响。

参考文献:

[1] 关绍康, 姚波. 汽车铝合金车身板材的研究现状及发展趋势[J]. 机械工程材料, 2001, 25(5): 12-18.

GUAN Shaokang, YAO Bo. The progress and prospect of research on aluminum alloys for auto body sheets[J]. Materials for Mechanical Engineering, 2001, 25(5): 12-18.

[2] 马鸣图, 游江海, 路洪洲, 等. 铝合金汽车板性能及其应用[J]. 中国工程科学, 2010, 12(9): 4-20.

MA Mingtu, YOU Jianghai, LU Hongzhou, et al. Research progress of aluminum alloy automotive sheet and application technology[J]. Engineering Science, 2010, 12(9): 4-20.

[3] DUNWOOD B J. The production of automotive body panels in 5083 SPF aluminium alloy[J]. Materials Science Forum, 2001, 43(7): 59-64.

[4] BRUSCHI S, ALTAN T, BANABIC D, et al. Testing and modeling of material behavior and formability in sheet metal forming[J]. CIRP Annals-Manufacturing Technology, 2014, 63(2): 727-749.

[5] 于忠奇. 汽车用铝合金板冲压成形仿真精度与机罩外板拉深工艺设计研究[D]. 上海: 上海交通大学机械与动力工程学院, 2005: 33-41.

YU Zhongqi. Investigation on automotive aluminum alloy sheet stamping simulation precision and deep drawing process of hood outer[D]. Shanghai: Shanghai Jiao Tong University. School of Mechanical Engineering, 2005: 33-41.

[6] TOROS S, OZTURK F, KACAR I. Review of warm forming of aluminum-magnesium alloys[J]. Journal of Materials Processing Technology, 2008, 207(1): 1-12.

[7] 王孟君, 周威, 任杰, 等. 汽车用5182铝合金的温拉深成形性能[J]. 中南大学学报(自然科学版), 2010, 43(3): 936-941.

WANG Mengjun, ZHOU Wei, REN Jie, et al. Forming properties of 5182 aluminum alloy for automotive body sheet during warm deep drawing processes[J]. Journal of Central South University (Science and Technology), 2010, 43(3): 936-941.

[8] 傅垒, 王宝雨, 孟庆磊, 等. 铝合金热冲压成形质量影响因素[J]. 中南大学学报(自然科学版), 2013, 44(3): 936-941.

FU Lei, WANG Baoyu, MENG Qinglei, et al. Factors affecting quality in hot stamping of aluminum alloy[J]. Journal of Central South University (Science and Technology), 2013, 44(3): 936-941.

[9] 胡志华. 变压边力对铝合金板拉深成形性能的影响研究[J]. 热加工工艺, 2013, 42(13): 119-121.

HU Zhihua. Influences of variable blank-holder force on drawing formability of aluminum alloy sheet[J]. Hot Working Technology, 2013, 42(13): 119-121.

[10] 王武荣, 陈关龙, 林忠钦, 等. 基于PID闭环控制的变压边力优化设计[J]. 上海交通大学学报, 2007, 41(4): 515-519.

WANG Wurong, CHEN Guanlong, LIN Zhongqin, et al. Variable blank holder force optimization based on PID closed-loop control[J]. Journal of Shanghai Jiaotong University, 2007, 41(4): 515-519.

[11] 赵洪梅. 铝合金冲压成形的变压边力技术研究[D]. 合肥: 合肥工业大学, 2013: 34-40.

ZHAO Hongmei. Study on variable blank holder force in aluminum alloys stamping[D]. Hefei: Hefei University of Technology. 2013: 34-40.

[12] EMMENS, WILKO C. Some frictional aspects of aluminium in deep drawing[C]//International Congress on Tribology of Manufacturing Processes. 1997: 225-230.

[13] 孙友松, 周先辉, 黎勉, 等. 交流伺服压力机及其关键技术[J]. 锻压技术, 2008, 33(4): 1-8.

SUN Yousong, ZHOU Xianhui, LI Mian, et al. AC servo presses and their key techniques[J]. Forging & Stamping Technology, 2008, 33(4): 1-8.

[14] OSAKADA K, MORI K, ALTAN T, et al. Mechanical servo press technology for metal forming[J]. CIRP Annals-Manufacturing Technology, 2011, 60(2): 651-672.

[15] MORI K, MAENO T, MAKI S. Mechanism of improvement of formability in pulsating hydroforming of tubes[J]. International Journal of Machine Tools and Manufacture, 2007, 47(6): 978-984.

[16] HAYASHI H, NISHIMURA H. The application of servo press machine to forming of sheet metals with low formability[C]//The Annals of “Dunarea De Jos” University of Galati Fascicle V. Technologies in Machine Building, 2009: 3-10.

[17] 王博. 压力机运动模式对冲压成形质量的影响[J]. 上海工程技术大学学报, 2010, 24(1): 30-33.

WANG Bo. Influence of press motion modes on punching forming quality[J]. Journal of Shanghai University of Engineering Science, 2010, 24(1): 30-33.

[18] 常琛扬, 翟敬梅, 夏琴香, 等. 基于伺服压力机的凸缘筒形件拉深成形数值分析[J]. 锻压技术, 2011, 36(4): 59-63.

CHANG Chenyang, ZHAI Jinmei, XIA Qinxiang, et al. Numerical analysis of deep drawing of cylindrical cuup with flange based on servo-press[J]. Forging & Stamping Technology, 2011, 36(4): 59-63.

[19] GROSECLOSE A, ALTAN T. Forming of AHSS using servo press[R]. Columbus, OH: The Ohio State University, 2014: 15-18.

[20] WEI J J, ERDEMIR A, FENSKE G R. Dry lubricant films for aluminum forming[J]. Tribology Transactions, 2000, 43(3): 535-541.

[21] RAO K P, WEI J J. Performance of a new dry lubricant in the forming of aluminum alloy sheets[J]. Wear, 2001, 249(1): 85-92.

[22] MEILER M, PFESTORF M, GEIGER M, et al. The use of dry film lubricants in aluminum sheet metal forming[J]. Wear, 2003, 255(7): 1455-1462.

[23] BREM J C, BARLAT F, DICK R E, et al. Characterizations of aluminum alloy sheet materials Numisheet 2005[J]. Numisheet: Internat, 2005, 778(1): 1179-1190.

[24] LADEMO O G, ENGLER O, BENALLAL A, et al. Effect of strain rate and dynamic strain ageing on work-hardening for aluminum alloy AA5182-O[J]. International Journal of Materials Research, 2012, 103(8): 1035-1041.

[25] NAKA T, YOSHIDA F. Deep drawability of type 5083 aluminium-magnesium alloy sheet under various conditions of temperature and forming speed[J]. Journal of Materials Processing Technology, 1999, 89/90(8): 19-23.

[26]  B, DUPONT P, DE WIT C C. A survey of models, analysis tools and compensation methods for the control of machines with friction[J]. Automatica, 1994, 30(7): 1083-1138.

B, DUPONT P, DE WIT C C. A survey of models, analysis tools and compensation methods for the control of machines with friction[J]. Automatica, 1994, 30(7): 1083-1138.

[27] GROCHE P, NORMAN M. Tribological Investigation of Deep-Drawing Processes Using Servo Presses[C]//ASME 2012 International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2012: 127-137.

(编辑 陈爱华)

收稿日期:2015-10-11;修回日期:2016-01-16

基金项目(Foundation item):国家自然科学基金资助项目(U1330121)(Project(U1330121) supported by National Natural Science Foundation of China)

通信作者:李洪波,博士,副教授,从事板带轧制等塑性变形过程技术研究;E-mail:lihongbo@ustb.edu.cn