Trans. Nonferrous Met. Soc. China 22(2012) 1907-1911

Low frequency damping capacities of commercial pure magnesium

HU Xiao-shi1, WANG Xiao-jun1, HE Xiao-dong2, WU Kun1, ZHENG Ming-yi1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Center for Composite Materials and Structures, Harbin Institute of Technology, Harbin 150001, China

Received 10 November 2011; accepted 11 June 2012

Abstract: The amplitude-dependent and temperature-dependent low frequency damping capacities of magnesium with 99.96% purity were studied by a dynamic mechanical analyzer. The pure magnesium alloys include CPM1 and CPM2 castings having textures of columnar grains which extraordinarily influence the damping behaviours. The commercial pure magnesium alloy CPM was re-melted to obtain equiaxed grains, which could remove the effect of texture orientation on the damping behaviours of these pure magnesium alloys. The results of strain amplitude-dependent damping spectrums of these pure magnesium alloys show that the pure magnesium with equiaxed grains possesses the highest damping capacity. In temperature-dependent damping plot for all these three pure magnesium alloys, there are two damping peaks P1 and P2 located at 80 and 230 ℃, respectively. These two damping peaks are considered to be caused by the interaction between dislocation and point defects, and the movement of grain boundaries, respectively.

Key words: commercial pure magnesium; crystal orientation; damping capacity; casting texture; aging; crystal defects

1 Introduction

Magnesium alloys are very attractive in the applications for aerospace, automotive and other transport industries due to their low density, high specific strength and high damping capacity. As known, the cast polycrystalline pure magnesium and some magnesium alloys such as Mg-Zr, Mg-Ni and Mg-Si alloys exhibit extraordinary high damping capacity [1].

The damping capacity of metallic materials is considered to be connected with the presence, movement and interaction of crystal defects, such as dislocations, grain boundaries, secondary phases and impurity atoms [2-4]. The amount of these crystal defects and their movability codetermine the damping capacity of a metallic material under certain vibration conditions. For Mg alloys, at room temperature, the key damping mechanism is the movement of dislocations, and at higher temperature, there must be some other crystal defects activated to contribute for the damping capacities of the alloys [5-7].

The damping capacities of magnesium alloys have been recognized to be dependent on the maximum strain amplitude and considered to be caused by the movement of dislocations which are pinned by impurity atoms, second phases and nodes of dislocation network on the basal plane [8-11]. Normally,two different stages of damping in amplitude-dependent damping curves of magnesium alloys could be clearly observed. Therefore, the type, amount and distribution condition of dislocations and point defects in magnesium alloys, and crystal orientations could dramatically influence their damping capacities. For the research of the mechanism of the damping capacities of magnesium alloys, more emphasises should be paid to the basic study of very simple structures (such as pure magnesium alloy) with no (or very less) solute and un-solute atoms, second phases, deformation induced crystal defects and so on. In the present study, the damping behaviours of commercial pure magnesium (CPM) alloys CPM1 and CPM2 with purity of 99.96% cut from different directions of the commercial pure magnesium ingot, which has different columnar grain orientations, and the as-cast pure magnesium CPM with equiaxed grains, were studied.

2 Experimental

2.1 Materials

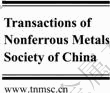

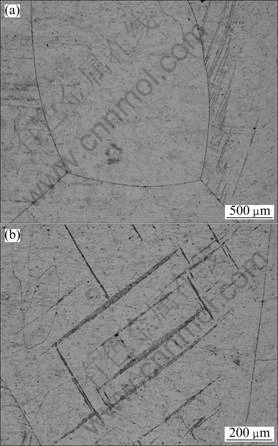

The purity of the experimentally commercial pure magnesium was 99.96% (mass fraction) with micro-scale Si, Fe, Zn and S elements. Figure 1 shows the optical microstructure of the commercial pure magnesium alloys. The CPM alloy had very large grain size, smooth grain boundaries and obvious twin structures. The commercial pure magnesium had very obvious columnar grains, and the ingots were cut from different directions according to the columnar grains to obtain damping test samples with different texture orientations. In Fig. 2, the schematic diagrams of the damping test samples with different texture orientations are displayed, and significant differences between these two samples could be seen. The first sample was named CPM1 with columnar grains vertical to the surface of damping test samples, and the second one shown in Fig. 2(b) was named CPM2 with columnar grains parallel to the surface of the damping test sample. The average size of the columnar grains was 2.7 mm in the transverse cross- section direction and 12 mm in the longitudinal direction. The longitudinal length was 3-5 times longer than that of the transverse size.

Fig. 1 Optical microstructures of commercial pure magnesium alloys: (a) Grain boundaries; (b) Twins structures

Fig. 2 Schematic diagram of columnar grains in commercial pure magnesium alloys: (a) Transverse cross-sectional view; (b) Longitudinal cross sectional view

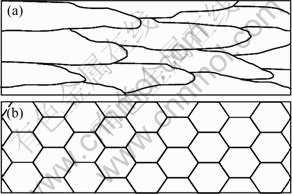

In order to remove the influence of columnar grains on the damping test results, the commercial pure magnesium was re-melted and the as-cast pure magnesium CPM with equiaxed grains was obtained. Figure 3 displays the optical microstructure of the CPM. Though the grain size was not uniform, equiaxed grains were obtained and the average grain size was less than 1 mm, which was far smaller than that of CPM1 and CPM2 shown above. The detailed casting procedure could be seen elsewhere [10].

Fig. 3 Optical microstructure of as-cast pure magnesium alloy

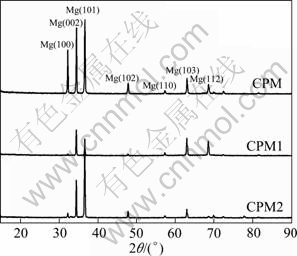

Figure 4 shows the XRD patterns of the above three pure magnesium alloys by testing the largest surface of the damping test sample. The significant differences of the diffraction peak intensities among those three pure magnesium alloys could be clearly identified. The diffraction peak intensities of CPM had normal diffraction spectrum of magnesium alloys and those of CPM1 and CPM2 were quite different. That means, the grain orientations toward to the applied vibration force during the damping test, were quite different for these three pure magnesium alloys. And then, different damping behaviours were displayed during the damping tests.

Fig. 4 XRD diffraction patterns of commercial and as-cast pure magnesium alloys

2.2 Damping test

The damping capacities of commercial and as-cast pure magnesium alloys were investigated via a TA Q800 dynamic mechanical analyzer (DMA Q800) with single cantilever vibration mode. Rectangular bending beam specimens for damping measurement with dimensions of 38 mm×6 mm×1 mm were machined out using an electric spark cutting method. The damping capacity was determined by Q-1=tan φ, where φ was the lag angle between the applied strain and the response stress. Measurements were made at various maximum strain amplitudes (e) from 4×10-6 to 8×10-4 and the vibration frequency (?) was 1 Hz. For the measurements of temperature-dependent damping capacities, the test conditions were the maximum strain amplitude of 4×10-5, vibration frequency (?) of 1 Hz, temperature (t) range from 25 to 400 ℃ and the heating rate ( ) of 5 ℃/min.

) of 5 ℃/min.

3 Results and discussion

3.1 Strain amplitude-dependent damping of pure magnesium alloys

Many damping test results of Mg and Mg alloys [4,12,13] show that the strain-dependent damping can be divided into two regions. The first is strain independent or weakly dependent region, which usually exists at low strain region. In high strain region, the damping value increases rapidly with increasing strain. According to the G-L dislocation damping model [14,15], the strain- independent damping is proportional to ρl4, where ρ is the dislocation density and l is the mean distance of the weak pinning points on a dislocation. The critical strain ecr corresponds to the joint of these two strain regions.

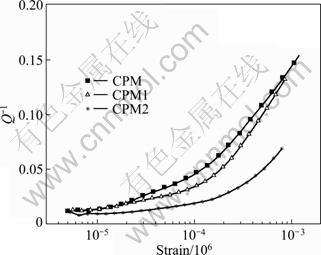

Figure 5 shows the strain amplitude-dependent damping capacities of these three magnesium alloys. The strain-dependent damping spectra of these three pure magnesium alloys could be divided into two regions as described above. But the critical strains for these pure magnesium alloys are different. The critical strains of CPM and CPM1 are about 1×10-5, which are much lower than that of the CPM2. In the whole strain amplitude range, the CPM shows the highest damping value, and the CPM2 possesses the lowest damping value. That means, the crystal orientation plays an important role on the damping behaviours of magnesium alloys. When most of the close-packed atomic planes are distributed along the direction, which is easy for the dislocations moving back and forth under the applied outer forces, high damping capacity could be obtained. On the contrary, under special texture orientations, the dislocations are quite difficult to move even at a relative high applied stress. For CPM, it possesses the highest damping capacity among these three alloys. The damping value of CPM is about 0.015 at a very small strain amplitude region, and it increases rapidly with increasing strain amplitude. When the strain is 2×10-4 (that is 1/10 of the engineering yield strain), the damping value is about 0.056, which is about 5 times higher than the high damping standard Q-1≥0.01 for metals. SUGIMOTO et al [4,8] also studied the effect of crystal orientation on the strain-dependent damping of magnesium alloys using different testing method. According to their test results, the polycrystalline pure magnesium also shows the highest damping value compared with other single grain pure magnesium alloys with different crystal orientations. Though at room temperature, the grain boundaries are not easy to slide under applied force during damping test, the main contribution for the high damping at this temperature could be caused by the movement of dislocations. Therefore, the effect of the magnitude and the movability of dislocations in the polycrystalline are very important for magnesium alloys to obtain high damping values.

Fig. 5 Strain amplitude-dependent damping capacities of pure magnesium alloys

3.2 Temperature-dependent damping of pure magnesium alloys

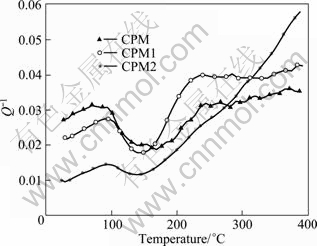

Figure 6 shows the temperature-dependent damping of these three pure magnesium alloys with vibration frequency of 1 Hz, strain of 4×10-5 and heating rate of 5 ℃/min. For all these three alloys, there are two damping peaks P1 and P2 found at about 80 and 230 ℃, respectively. These two peaks have also been found in Mg-Si and Mg-Ni alloys [9,10,14]. As a matter of fact, Si and Ni are the elements which have very low solubility in magnesium. Then, the Mg-Si and Mg-Ni alloys with Si or Ni content lower than the eutectic content of those alloy elements in magnesium could be actually considered pure magnesium. The difference is that the Mg-Si and Mg-Ni alloys possess primary α-Mg and Mg2Si or Mg2Ni phases. The primary α-Mg plays the role of pure magnesium on offering high damping capacity for these alloys. When the primary α-Mg occupies a certain percentage in the Mg-Si and Mg-Ni alloys, the damping capacities of these alloys are very high and even higher than that of pure magnesium, which is caused by the increase of the movable dislocations for the relatively high stress concentration of the dendrite grains. P1 is considered to be related to the interaction between dislocations and impurity atoms or vacancies in Mg, and P2 is caused by the grain boundaries sliding [9,10,14]. Damping peak P1 is the reason for offering high damping for pure magnesium alloys. For this damping peak, the peak temperature is not influenced by testing frequencies, and then this is not a thermal activated damping peak. It is considered that P1 is caused by the interaction between dislocations and point defects in pure magnesium. When the temperature is higher than the P1 peak temperature, the redistribution of point defects occurs and then the pinned dislocations decrease the damping values of the pure magnesium alloys. The lowest damping value at about 150 ℃ is obtained, and then the damping begins to increase with increasing temperature, which is caused by the sliding of grain boundaries at relatively high temperature.

Fig. 6 Temperature-dependent damping capacities of pure magnesium alloys

4 Conclusions

1) The damping capacities of magnesium alloys are significantly influenced by the crystal orientations. The texture orientation, which is advantageous to the movement of dislocations when the alloy is subjected to the applied force, causes high damping capacities. CPM with equiaxed grains has the highest amplitude- dependent damping value among these three pure magnesium alloys.

2) The temperature-dependent damping spectra of these three pure magnesium alloys show that there are two damping peaks P1 and P2 located at 80 and 230 ℃, respectively. These two peaks have already been detected in as-cast Mg-Si and Mg-Ni alloys, and they are related to the movement of dislocations and grain boundaries defects in the crystals. P1 is reasonable to obtain high damping capacities at room temperature for these pure magnesium alloys.

References

[1] JAMES D W. High damping metals for engineering application [J]. Mater Sci Eng, 1969, 4: 1-8.

[2] RITCHIE I G, PAN Z L. High damping metals and alloys [J]. Metall Trans A, 1991, 22: 607-616.

[3] ZHANG J, PEREZ R J, LAVERNIA E J. Documentation of damping capacity of metallic, ceramic and metal-matrix composite materials [J]. J Mater Sci, 1993, 28: 2395-2404.

[4] SUGIMOTO K, NIIYA K, OKAMOTO T, KISHITAKE K. Effect of crystal orientation on amplitude-dependent damping in magnesium [J]. Trans JIM, 1975, 16: 647-655.

[5] LIAO L H, ZHANG X Q, LI X F, WANG H W, MA N H. Effect of silicon on damping capacities of pure magnesium and magnesium alloys [J]. Mater Lett, 2007, 61: 231-234.

[6] XIE X Q, FAN T X, ZHANG D, SAKATA T, MORI H. Mechanical properties and damping behavior of woodceramics/ZK60 Mg alloy composite [J]. Mater Res Bull, 2002, 37(6): 1133-1140.

[7] SCHWANEKE A E, NASH R W. Effect of preferred orientation on the damping capacity of magnesium alloys [J]. Metal Trans, 1971, 2: 3454-3457.

[8] SUGIMOTO K, NIIYA K, OKAMOTO T, KISHITAKE K. A study of damping capacity in magnesium alloys [J]. Trans JIM, 1977, 18: 277-288.

[9] HU X S, ZHANG Y K, ZHENG M Y, WU K. A study of damping capacities in pure Mg and Mg-Ni alloys [J]. Scr Mater, 2005, 52: 1141-1145.

[10] TROJANOV? Z, RIEHEMANN W, FERKEL H, LUK?C P J. Internal friction in microcrystalline magnesium reinforced by alumina particles [J]. Alloys Compd, 2000, 310: 396-399.

[11] HU X S, WU K, ZHENG M Y, GAN W M, WANG X J. Low frequency damping capacities and mechanical properties of Mg-Si alloys [J]. Mater Sci Eng A, 2007, 452-453: 374-379.

[12] NISHIYAMA K, MATSUI R, IKEDA Y, NIWA S, SAKAGUCHI T. Damping properties of a sintered Mg-Cu-Mn alloy [J]. J Alloy Compd, 2003, 355: 22-25.

[13] GRANATO A, LUCKE K. Application of dislocation theory to internal friction phenomena at high frequencies [J]. J Appl Phys, 1956, 27: 789-805.

[14] GRANATO A, LUCKE K. Theroy of mechanical damping due to dislocation [J]. J Appl Phys, 1956, 27: 583-593.

[15] HU X S, WU K, ZHENG M Y. Effect of heat treatment on the stability of damping capacity in hypoeutectic Mg-Si alloy [J]. Scr Mater, 2006, 54: 1639-1643.

商业纯镁的低频阻尼性能

胡小石1,王晓军1,赫晓东2,吴 昆1,郑明毅1

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 复合材料与结构研究所,哈尔滨 150001

摘 要:采用机械动态分析仪测试纯度为99.96%纯镁的阻尼性能随应变振幅和温度的变化。测试的纯镁包括具有不同晶体学取向的商业镁合金铸锭CPM1和CPM2以及重新熔炼的等轴晶纯镁CPM。商业纯镁柱状晶粒的织构显著影响纯镁的阻尼性能,而重新熔炼的纯镁获得等轴晶,从而避免铸造织构对其阻尼性能测试结果产生的影响。结果表明:在阻尼应变谱中,等轴晶纯镁的阻尼性能明显高于有柱状晶织构的纯镁。对于三种纯镁,阻尼温度谱在80和230 ℃分别存在两个阻尼峰P1和P2,这两个阻尼峰分别是由位错与点缺陷交互作用以及晶界运动引起的。

关键词:商业纯镁;晶体取向;阻尼性能;铸造织构;时效;晶体缺陷

(Edited by FANG Jing-hua)

Foundation item: Project (50801017) supported by the National Natural Science Foundation of China; project (20080440843) supported by Postdoctoral Science Foundation, China; Project (HIT.NSRIF.2009028) supported by the Natural Scientific Research Innovation Foundation of Harbin Institute of Technology, China

Corresponding author: HU Xiao-shi; Tel: +86-451-86402291; Fax: +86-451-86413922; E-mail: huxiaoshi@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61406-4