J. Cent. South Univ. (2018) 25: 646-652

DOI: https://doi.org/10.1007/s11771-018-3767-y

Ignition characteristics and combustion performances of a LO2/GCH4 small thrust rocket engine

ZHANG Jia-qi(张家奇)1, 2, LI Qing-lian(李清廉)1, 2, SHEN Chi-bing(沈赤兵)1, 2

1. College of Aerospace Science and Engineering, National University of Defense Technology,Changsha 410073, China;

2. Science and Technology on Scramjet Laboratory, National University of Defense Technology,Changsha 410073, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract: A 500 N model engine filled with LO2/GCH4 was designed and manufactured. A series of ignition attempts were performed in it by both head spark plug and body spark plug. Results show that the engine can be ignited but the combustion cannot be sustained when head spark plug applied as the plug tip was set in the gaseous low-velocity zone with thin spray. This is mainly because flame from this zone cannot supply enough ignition energy for the whole chamber. However, reliable ignition and stable combustion can be achieved by body spark plug. As the O/F ratio increases from 2.61 to 3.49, chamber pressure increases from 0.474 to 0.925 MPa and combustion efficiency increases from 57.8% to 95.1%. This is determined by the injector configuration, which cannot produce the sufficiently breakup of the liquid oxygen on the low flow rate case.

Key words: LO2/GCH4; small thrust rocket engine; ignition characteristic; combustion performance

Cite this article as: ZHANG Jia-qi, LI Qing-lian, SHEN Chi-bing. Ignition characteristics and combustion performances of a LO2/GCH4 small thrust rocket engine [J]. Journal of Central South University, 2018, 25(3): 646–652. DOI: https://doi.org/10.1007/s11771-018-3767-y.

1 Introduction

LO2/CH4 combination was characterized by high performance, low price, green, low carbon deposit and similar boiling point. In the recent years, it has been considered the most potential candidate for the reusable launch vehicles sketched in governmental [1] and commercial projects [2] all over the world. In addition, another effort has been performed by NASA to develop vehicles filled by LO2/CH4 for in-space exploration and planet landing, including PCAD project aimed for lunar access [3], CPST project [4], Morpheus project [5] and human mission to the Mars before 2040 [6]. This is because CH4 can be produced on the Mars surface.

A typical propulsion system for a spacecraft includes 2 types of engine, RCS (reaction control system) engine and OMS (orbital maneuvering system) engine (or main engine for some spacecraft). They should be ignited reliably by ten thousands and tens circles respectively. However, this propellant combination cannot be hypergolic thus ignition can only be realized by external energy induced. As a result, ignition was considered the most important technical risk for LO2/CH4 propulsion system.

A number of investigations have been put forward to reduce the ignition risk. GRC (Glenn Research Centre, NASA) designed a LO2/LCH4 igniter exited by spark plug for RCS engine. On it a number of experimental ignitions were performed for examining the reliable ignition boundary on various inlet propellant and igniter body temperatures [7]. Furthermore, three types of integrated exciter-plug were examined to evaluate the ignition reliability and duration [8]. For OMS engine, suitable igniter was designed to examine the reliable ignition boundary on the similar conditions with the igniter of RCS engine. In addition, the effect of ignition resources including spark plug [9] and glow plug [10] was evaluated. Conclusions showed that these igniters can be ignited reliably in various inlet conditions of the propellants, whereas the low body temperature actually could reduce the reliability.

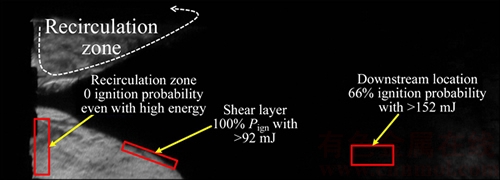

Compared to GRC, DLR (German Aerospace Center) concentrated more on the ignition process and mechanism. It intended to perform LO2/CH4 ignition to compare with LO2/H2 [11, 12] for trying to transfer the broad experience from the latter to the former for reducing the development time and cost of the future upper stage hydrocarbon engine [13]. Related studies were mainly performed on a LO2/GCH4 model engine with a single LO2- centered coaxial injector element and a transparent combustion chamber. Advanced optical diagnostics including Schlieren, optical camera and CCD camera fitted with a narrow band filter were applied to observe the shockwaves, flow field and the chemiluminescence of OH-radical in the chamber. Conclusions showed that with the increase of the momentum ratio between gas and liquid, ignition scheme transformed from stable to violent, and the flame transformed from anchored to lift [13]. It was quite different to LO2/GH2 flame [14]. After that, MANFLETTI [15] applied a series of experimental ignitions by laser on the similar engine fueled by both LO2/GCH4 and LO2/GH2. Characteristics of the flow field in the chamber before ignition were observed [15]. Followed, ignition experiments were applied by laser induced plasma, where various energy deposit areas as well as various laser energies were tried [16]. Conclusions showed that for LO2/GCH4 case, 100% ignition probability can be obtained only when the energy deposit in the shear layer downstream Mach disk parallel the injector plate, with a minimum energy of 92 mJ [17]. In addition, the relationship between pressure peak and ignition delay was discussed as well [18].

FLORES et al [19] and SANCHEZ et al [20] from the University of Texas at El Paso published their progresses on the development of a LO2/CH4 torch igniter for main engine ignition. The ignition reliability of the igniter was examined on various propellant condition including gas, low temperature gas and liquid, and the igniter was optimized on the design scheme and electrode of the spark plug by two rounds [20, 21]. The design schemes were quite different compared to the igniters from GRC and the reliable igniter boundary shows much narrower. CH4, the major component of nature gas, which is used widely in chemical and metallurgical industry [22], can be ignited by compression [23] like other fuels in internal engine [24], spark plug, laser and many other energy sources. However, for the engine and further the propulsion system, the presence of the igniter may induce the increase of hardware weight and complexity to reduce the systematical reliability. In the present study, a 500 N LO2/GCH4 model engine ignited by spark plug was designed to examine the feasibility of direct ignition for an OMS engine by spark plug. Furthermore, the effect of energy deposit position on the ignition characteristics and combustion performance of the present model engine would be discussed.

2 Experimental method

2.1 Model engine

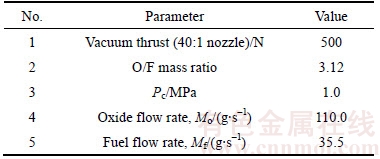

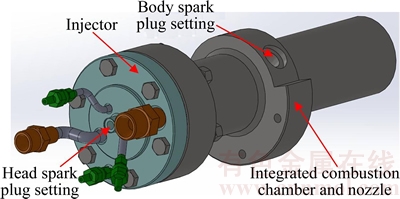

A model engine was designed and manufactured. It was filled with liquid oxygen (LO2) and gaseous methane (GCH4). 9 groups of impingement orifice distributed uniformly on the circular injector plate. Each group of impingement was composed of 2 oxidant orifices and 2 fuel orifices. Table 1 lists the primary design parameters of the present engine. As shown in Figure 1, an integrated assembly combining combustion chamber and nozzle was adopted for validating the ignition characteristic and combustion performance. Likewise, the spark plug can be fixed either on the head or the body of the engine.

Table 1 Design parameters of model engine

Figure 1 Model engine of present study

2.2 Experiment process

Before the start, the liquid oxygen pipe and the injector would be pre-cooled by liquid oxygen induced to avoid the two-phase flow when ignition. Fuel and oxidant would be cut off at 0.4 s after spark plug starting to prevent over heat of the engine.

3 Experiment

13 ignitions were conducted on the present model engine and corresponding results are listed in Table 2.

In the beginning, 4 ignitions were performed by head plug, of which the tip was placed on 1 mm from the injector plate, but unfortunately the ignitions were all failed. More accurately, it is evident that spark plug ignited the propellants but immediately the kernels quenched during propagating. For another try, 4 more ignitions were approved by head plug, of which the tip was extended to 10 mm from the injector plate. But unfortunately the ignitions were failed again and plots showed the same phenomena. For the last try, body spark plug was adopted to perform another 5 ignitions and both successful ignition and sustain combustion were obtained.

4 Discussion

4.1 Head ignition

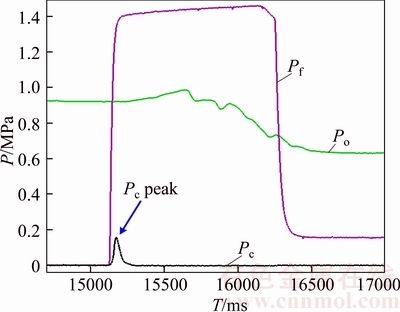

Figure 2 shows the typical data plot for the head plug cases, where the Pc, Po and Pf stand to the pressure in the combustion chamber, oxidant manifold and fuel manifold respectively. As shown in the figure, Pc increases to 0.15 MPa and decreases immediately at the beginning. After that Pc keeps 0 MPa from 15300 to 15500 ms as the cold fuel and oxidant flow into the combustion chamber. This pressure peak of Pc indicates that propellants in the combustion chamber were actually ignited. This implies that the spark plug can provide sufficient energy for ignition, and there is appropriate O/F ratio surrounding the spark plug tip to kernel formation. However, the kernel quenched during propagation.

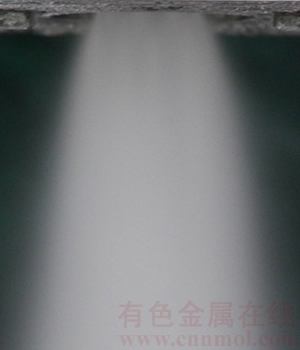

It is the flow field in the combustion chamber that determines the propagation of the initial kernel.For evaluating the flow field in the combustion chamber, spray field of the present injector was investigated and recorded as shown in Figure 3, where the oxidant and the fuel were substituted by water and air respectively. In this way, the flow field in the combustion chamber near the injector plate can be drawn schematically as shown in Figure 4 compared with plug position. For the sake of kernel propagation analysis, only plug tip and surrounding spray are involved in the figure. After impingement, gaseous fuel gasifies part of LO2 and O/F mixture diffuses to fill the chamber and the plug tip adjacency. However, as shown in the figure, plug tip is very far from the spray core no matter in the 1 mm or 10 mm case. Therefore, zone surrounding the plug tip can be characterized as thin spray, gaseous mixture and low velocity compared to the spray core signed as thick spray,multiphase and high velocity.

Table 2 Experimental results for present model engine

Figure 2 Typical plot for head plug cases (gauge pressure)

Figure 3 Spray of present injector (water and air instead)

Figure 4 Spray flow on injector plate side

This seems very similar with the investigations conducted by MANFLETTI [16, 17], who performed laser ignition of LO2/GCH4 combination in a RCS thruster. Before ignition, cold flow field of LO2 and gaseous CH4 in the combustion chamber was recorded by schlieren camera as shown in Figure 5. Picture gives that in the combustion chamber, apart from LO2/GCH4 spray core, a recirculation zone near the injector plate can be found [15]. As shown in the photo, the recirculation zone is characterized by thin spray, gaseous mixture and low velocity compared to the spray core, which is very similar with the gaseous low-velocity zone in the present study. Ignition experiments showed that in the recirculation zone, 0 ignition probability could be gotten no matter how high the laser energy was used [16, 17].

Figure 5 LO2/GCH4 flow field (schlieren photo) [15]

Undoubtedly, gaseous propellant can be ignited easily by the spark, and the kernel would grow to make the flame fill the gaseous low-velocity zone immediately. However, it is necessary to note that propellants in the gaseous low-velocity zone are generated by the recirculation of the spray, which is enveloped entirely by the dense spray with high-velocity. The velocity of the dense spray comes to an order of 100 m/s, which is much higher than the propagation velocity of the flame. As a result, after ignition, no sufficient propellants can complement the consumption to sustain the flame in the gaseous low-velocity zone. Furthermore, on the boundary of the two zones, the dissipated energy from the flame caused by convection from dense spray is higher than the energy generated in the combustion zone. These indicate that the energy from the gaseous low- velocity zone is not sufficient to ignite the dense spray. Therefore, flame would be blown out and quenching happens.

For applying head ignition, feasible approach would be adopted to improve the ignition energy for the combustion chamber. A general method comes to induce partial propellant here to make a stable flame zone that can supply enough energy to ignite the engine. This implies that the flow field adjacent the plug tip should be designed carefully.

4.2 Body ignition

As the development of the flow field, liquid oxygen is atomized and vaporized to mix well with the fuel. On the other hand, after impinging and mixing, velocity of the O/F mixture becomes more and more uniform in the combustion chamber downstream. Thus the O/F ratio for the body spark case is appropriate to kernel formation and the flow field helps to the kernel propagation.

In this case, kernel grows and develops along the propellant flow. As the similar velocity and well mixing, flame kernel grows easily in the spray. Once the flame encounters the contraction section before nozzle, flame propagated back to fill the chamber. This scheme was defined as “upstream flame kernel growth”, which is mainly in the case where the growth velocities in the upstream direction are lower than those in the downstream direction. It can be usually observed when the energy is deposited at downstream locations or when a flame kernel created upstream is transported downstream before its macroscopic development [18].

4.3 Combustion performance

Experimental results on the 5 successful ignitions are illustrated in Table 2 and Figure 6. Obviously, as the increase of the liquid oxygen flow rate from 82.8 to 109.2 g/s and correspondingly the increase of O/F ratio from 2.61 to 3.49, the pressure in the chamber increases from 0.474 to 0.925 MPa to enhance the combustion efficiency dramatically from 57.8% to 95.1%.

Figure 6 Pc and η versus O/F mass ratio

Referring to the injector configuration, the liquid oxygen impingement point is 2 mm upstream from the gaseous methane impingement point. In the chamber, initially liquid jet impinges in the low velocity area. After that, the liquid spray develops downstream and mixes with the low-velocity gaseous fuel after injection and impingement. This implies that in such a configuration, gaseous fuel cannot help to liquid atomization or O/F mixing. For a low liquid oxygen flow rate case, the atomization of liquid oxygen is inefficient to format low spray angle, velocity and big drop size, this causes poor mix with gaseous fuel and thus low combustion efficiency. As the increase of liquid oxygen flow rate, higher spray angle, velocity and finer drop can be obtained to enhance the O/F mixing to achieve the efficient combustion.

It is necessary to emphasize that the experimental results are determined by the injector configuration. However, it is also necessary to denote that the model engine operate on the designed liquid oxygen flow rate.

5 Conclusions

1) Reliable ignition and stable combustion have been achieved in a LO2/GCH4 model engine by body spark plug.

2) As the O/F ratio increases from 2.61 to 3.49, chamber pressure increases from 0.474 to 0.925 MPa and combustion efficiency increases from 57.8% to 95.1%. This is determined by the injector configuration, by which the liquid oxygen cannot breakup sufficiently on the low flow rate case.

3) The propellant can be ignited by head spark plug but the combustion cannot be sustained as the plug tip was set in the gaseous low-velocity zone with thin spray. This is primarily because the flame from this zone cannot supply enough ignition energy for the dense spray. Feasible approach would be to induce partial propellant to the plug tip adjacency.

References

[1] FUJII K, ISHIMOTO S, MUGITANI T, MINAMI Y. Present status and prospects of JAXA’s research on future space transportation system [C]// 18th AIAA/3AF International Space Planes and Hypersonic Systems and Technologies Conference. Tours, France: AIAA, 2012: AIAA –2012–5849.

[2] VALTON P, HAMEURY M S, DUTHEIL J P. LOX/methane re-usable propulsion system development with implementation of concurrent engineering [C]// 65th International Astronautical Congress. Toronto, Canada: IAC. 2014: IAC–14, C4, 1×25370.

[3] SMITH T D, KLEM M D, FISHER K L. Propulsion risk reduction activities for nontoxic cryogenic propulsion [C]// Space 2010 Conference and Exposition. Anaheim, California: AIAA, 2010: AIAA–2010–8680.

[4] PLACHTA D W, JOHNSON W L, FELLER J R. Cryogenic boil-off reduction system testing [C]// 50th AIAA/ ASME/SAE/ASEE Joint Propulsion Conference. Cleveland, OH: AIAA: 2014: AIAA–2014–3579.

[5] OLANSEN J B, MUNDAY S R, DEVOLITES J L. Project morpheus: Lander technology development [C]// 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. Cleveland, OH: AIAA: 2014: AIAA–2014–4314.

[6] POLSGROVE T, THOMAS D, SUTHERLIN S, STEPHENS W, RUCKER M. Mars ascent vehicle design for human exploration [C]// SPACE 2015 Conference and Exposition. Pasadena, California: AIAA, 2015: AIAA–2015–4416.

[7] SCHNEIDER S J, JOHN J W, ZOECKLER J G. Design, fabrication, and test of a LOX/LCH4 RCS igniter at NASA [C]// 43rd Joint Propulsion Conference. Cincinnati, Ohio: AIAA, 2007: AIAA–2007–5442.

[8] KLEINHENZ J, SARMIENTO C, MARSHALL W. Spark ignition characteristics of a LO2/LCH4 engine at altitude conditions [C]// 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Atlanta, Georgia: AIAA, 2012: AIAA–2012–4219.

[9] BREISACHER K J, AJMANI K. LOX/Methane main engine igniter tests and modeling [C]// 44th AIAA/ASME/SAE/ ASEE Joint Propulsion Conference & Exhibit. Hartford, Connecticut: AIAA, 2008: AIAA–2008–4757.

[10] BREISACHER K J, AJMANI K. LOX/Methane main engine glow plug igniter tests and modeling [R]. Cleveland: Glenn Research Center, NASA, 2009.

[11] SCHMIDT V, WEPLER U, HAIDN U J, OSCHWALD M. Characterization of the primary ignition process of a coaxial GH2/LOX spray [C]// 42nd AIAA Aerospace Sciences Meeting and Exhibit. Reno, Nevada: AIAA, 2004: AIAA–2006–4539.

[12] ROSA M D, SENDER J, ZIMMERMANN H, OSCHWALD M. Cryogenic Spray ignition at high altitude conditions [C]// 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Sacramento, California: AIAA, 2006: AIAA–2006–4539.

[13] CUOCO F, YANG B, BRUNO C, HAIDN O J, OSCHWALD M. Experimental investigation on LOx/CH4 ignition [C]// 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Fort Lauderdale, Florida: AIAA, 2004: AIAA–2004–4005.

[14] YANG B, CUOCO F, OSCHWALD M. Atomization and flames in LOX/H2 and LOX/CH4-Spray combustion [J]. Journal of Propulsion and Power, 2007, 23(4): 763–771.

[15] MANFLETTI C. Low ambient pressure injection and consequences on ignition of liquid rocket engines [C]// 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Atlanta, Georgia: AIAA, 2012: AIAA–4131.

[16] MANFLETTI C. Laser ignition of a research 200N RCS LOx/GH2 and LOx/GCH4 engine [C]// 48th AIAA/ASME/ SAE/ASEE Joint Propulsion Conference & Exhibit. Atlanta, Georgia: AIAA, 2012: AIAA–2012–4132.

[17] MANFLETTI C. Laser ignition of an experimental cryogenic reaction and control thruster: Ignition energies [J]. Journal of Propulsion and Power, 2014, 30 (4): 952–961.

[18] MANFLETTI C, BORNER M. Ignition overpressure in laser ignited reaction and control thrusters [C]// 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. Cleveland, OH: AIAA, 2014: AIAA–2014–3792.

[19] FLORES J R, SANCHEZ L E, DORADO V, ELLIS R, CHOUDHURI A. An experimental evaluation of a torch ignition system for propulsion research [C]// 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. San Jose, CA: AIAA, 2013: AIAA–2013–4152.

[20] SANCHEZ L E, ELLIS R, DORADO V, CHOUDHURI A. An experimental investigation of a LOx/CH4 torch ignition system for propulsion research [C]// 50th AIAA/ASME/ SAE/ASEE Joint Propulsion Conference. Cleveland, OH: AIAA, 2014: AIAA–2014–3986.

[21] Sanchez L E, Chaparro J, Torres S, Love N, Choudhuri A. Development and testing of a O2/CH4 torch igniter for propulsion systems [C]// 52th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. Salt Lake City, UT: AIAA 2016: AIAA–2016–4795.

[22] ZHANG J, ZHOU N, ZHOU S. Combustion and energy balance of aluminum holding furnace with bottom porous brick purging system [J]. Journal of Central South University, 2012, 19(1): 200–205.

[23] LESCHEVICH V V, MARTYNENKO V V, PENYAZKOV O G, SEVROUK K L, SHABUNYA S I. Auto-ignitions of a methane/air mixture at high and intermediate temperatures [J]. Shock Waves, 2016, 26(5): 657–672.

[24] RAHBARI A. Effect of inlet temperature and equivalence ratio on HCCI engine performance fuelled with ethanol: Numerical investigation [J]. Journal of Central South University, 2016, 23(1): 122–129.

(Edited by HE Yun-bin)

中文导读

小推力液氧气甲烷火箭发动机的点火特性与燃烧性能

摘要:设计制造了一台推力为500 N的液氧气甲烷模型发动机,对其开展了一系列点火试验,火花塞的安装位置分头部与身部两种情况。结果表明,当使用头部火花塞点火时,发动机内的推进剂可以正常起火但火焰无法持续稳定,这主要是因为火花塞末端被置于喷雾浓度与气流速度均较低的区域,使得这个区域内产生的火焰无法为整个发动机提供足够的点火能量。然而,当使用身部火花塞时,发动机内的推进剂可以同时实现可靠点火与稳定燃烧,这主要是因为在身部,二种推进剂浓度与流速均足够。当氧燃混合比从2.61增加到3.49时,试验得到的燃烧室压力从0.474 MPa增加到0.925 MPa,同时燃烧效率从57.8%增加到95.1%,这主要是因为喷注器配置,导致在低工况下液氧无法得到充分破碎。

关键词:液氧气甲烷;小推力火箭发动机;点火特性;燃烧性能

Foundation item: Project(613239) supported by the National Basic Research Program of China

Received date: 2016-07-11; Accepted date: 2017-12-20

Corresponding author: LI Qing-lian, Professor, PhD; Tel: +86–731–84574133; E-mail: peakdreamer@163.com; ORCID: 0000-0003- 3224-8804