文章编号:1004-0609(2009)06-1105-08

多齿刀具斜角切削微细铝纤维

贺占蜀1,王 军2,汤 勇1,万珍平1,魏小玲1

(1. 华南理工大学 机械与汽车工程学院,广州510640;

2. 广东轻工职业技术学院 机电工程系,广州 510300)

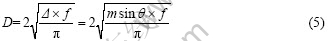

摘 要:为了高效加工表面粗糙的微细铝纤维,设计开发了一种新型的多齿刀具,利用该刀具能够同时加工出多根金属纤维。通过建立该刀具斜角切削的几何模型,分析其切削机理,并通过试验分析切削用量对铝纤维当量直径和表面形貌的影响。结果表明:该多齿刀具切削时,与工件接触的所有细齿同时参与切削,并均可分屑出纤维;选择合适的刀具参数和切削用量,即可获得当量直径在100 μm以下的表面粗糙的铝纤维。本试验中切削速度v、进给量f和单齿切削深度Δ的最佳参数分别约为6 m/min、0.10 mm/r和0.037 mm。

关键词:多齿刀具;铝纤维;当量直径;表面形貌

中图分类号:TG 506 文献标识码: A

Oblique cutting aluminium fiber with multi-tooth tool

HE Zhan-shu1, WANG Jun2, TANG Yong1, WAN Zhen-ping1, WEI Xiao-ling1

(1. School of Mechanical and Automotive Engineering, South China University of Technology,

Guangzhou 510640, China;

2. Department of Mechanical and Electrical Engineering, Guangdong Industry Technical College,

Guangzhou 510300, China)

Abstract: In order to efficiently manufacture slim aluminium fiber with rough surface, a new type multi-tooth tool was developed, with which several pieces of metal fibers can be manufactured simultaneously. Its oblique cutting geometric model was built, and its cutting mechanism was also studied. The influences of cutting parameters on the equivalent diameter and surface topography of the aluminium fiber were analyzed by experiment. The results show that during cutting process the whole cutting layer can be split into pieces of fibers as all tiny tooth contacting the workpiece are involved in cutting. Aluminium fiber with rough surface and equivalent diameter below 100 μm can be manufactured through adjusting tool and cutting parameters. In this experiment, the optimum parameters of cutting speed v, feedrate f and cutting depth per tooth Δ are about 6 m/min, 0.10 mm/r and 0.037 mm, respectively.

Key words: multi-tooth tool; aluminium fiber; equivalent diameter; surface topography

金属纤维是20世纪70年代后期发展起来的新型工业材料。它具有金属本身的高导电、高导热、高强度、耐高温等优点,目前已广泛应用于航空航天、石油化工、电子机械、纺织等领域[1?2]。其中铝纤维不仅具有金属纤维的普遍优点,还具有密度小、刚度大、耐磨性与耐蚀性好等优点,可以制作成多孔吸声材料、电磁屏蔽材料、网状过滤材料等,此外铝纤维由于具有优良的特性,在催化剂载体、热交换器、气液分离等方面也有着良好的应用前景。但目前仅有日本等少数发达国家能够生产,且成本较高[3]。随着应用领域的不断扩大,对金属纤维性能的要求也越来越高。不仅要求金属纤维具有较小的当量直径,还要求表面粗糙以提高金属纤维与基体的结合强度[4],如将金属纤维应用于导电聚合物复合材料时便有该方面要求[5?6]。因此,研究新型高效的铝纤维加工方法,对于提高铝纤维性能并扩大其应用领域具有重要意义。

金属纤维的制造主要有熔抽法、拉拔法和切削法等方法[7],但目前国内外针对铝纤维制造工艺的报道较少,BAIK等[8]利用悬滴熔抽法制取铝纤维,但其工艺复杂,而且加工的铝纤维表面过于光滑。相比而言,切削法使用的设备简单,成本低廉,生产周期短,可广泛适用于铝、铜、不锈钢等不同材质纤维的加 工[9?12]。本文作者研制了能够实现“一刀多纤”制备纤维的多齿刀具,并建立其斜角切削的几何模型,分析其切削机理;通过试验研究切削用量对纤维当量直径和表面形貌的影响。

1 多齿刀具的形状和斜角切削几何 模型

1.1 多齿刀具的几何形状

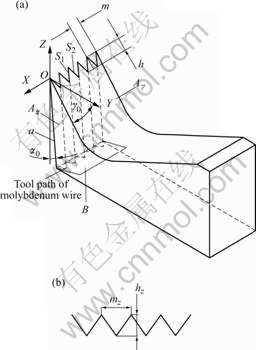

图1所示为多齿刀具的形状示意图。在图中,Aγ为前刀面;Aα为后刀面;B为直线a的垂直面(即线切割时钼丝的垂直面);S1和S2分别为细齿切削刃;γ0为前角;α0为后角;m为相邻两细齿齿间间距;h为细齿齿尖到齿根的距离(前刀面内测量);mz和hz为细齿加工时钼丝走刀轨迹的控制参数。

图1 多齿刀具的形状、参数及钼丝走刀轨迹

Fig.1 Shape of multi-tooth tool: (a) Shape and parameters of multi-tooth tool; (b) Tool path of molybdenum wire

刀具切削金属纤维时应尽量选用较大的刀具前 角[13],这是由于纤维的强度和伸长率随切削时变形系数的减小而提高,而变形系数的大小又主要取决于刀具前角。刀具前角越大,前刀面挤压切削层时引起的塑性变形越小,而且切屑流经前刀面的摩擦阻力也越小,金属纤维的变形系数随之减小,只有这样才能得到连续稳定的金属长纤维。但前角过大,刀具楔角(即前刀面Aγ与后刀面Aα之间的夹角)将很小,对刀具强度和散热不利。经综合考虑,本试验中选用刀具前角γ0=50?。考虑到刀具的耐用度,后角α0=5?~8?是最佳角度[14],本试验选用α0=5?。

1.2 刀具细齿的加工参数

刀具的各细齿是在线切割机床上由钼丝沿着刀具后刀面Aα走刀切出的三角形细齿,钼丝的走刀轨迹见 图1(b)。mz和hz为线切割时钼丝走刀轨迹的控制参数,在垂直于直线a的平面B内测量。根据文献[12]可知,mz、hz的值在0.2~0.4 mm之间比较适合连续纤维的加工,本试验选用mz=0.3 mm,hz=0.2 mm。线切割出的刀具细齿的形状及参数由钼丝的轨迹控制生成,每个细齿都有S1和S2两个切削刃。刀具相邻两细齿齿间间距m=mz,细齿齿尖到齿根距离(在前刀面Aγ内测量) h=hz/ sin(90??γ0?α0)。经计算,m=0.3 mm,h=0.348 7 mm。

1.3 多齿刀具的斜角切削几何模型

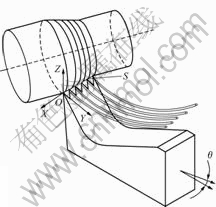

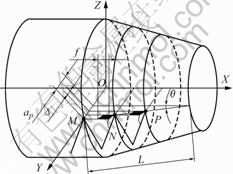

图2所示为多齿刀具斜角切削几何模型。刀具安装时,将刀具绕Z轴旋转θ角,XOY面位置保持不变,刀具各细齿齿尖连线S与工件轴线同处在XOY面上。切削纤维时,与工件接触的所有细齿同时参与切削,细齿的两个切削刃S1和S2都担负切削工作;而且刀具细齿具有分屑作用,即将整个切削层切下的同时把切屑分屑成纤维。因此,与工件接触的所有细齿均能切出纤维,提高了纤维的生产效率。

图2 多齿刀具斜角切削几何模型

Fig.2 Oblique cutting geometric model of multi-tooth tool

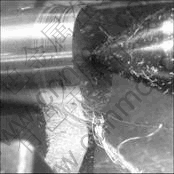

图3所示为多齿刀具切削铝纤维的现场加工照片。由图3可知,此刀具能高效快速地同时切削出多根连续铝纤维。试验发现,纤维之间无粘接现象,证明该多齿刀具的分纤效果较好。通过选取恰当的m和h,并调整切削用量,即可得到当量直径在100 μm以下的微细纤维,成功解决了切削法难以加工当量直径小于100 μm微细纤维的难题。

图3 多齿刀具切削铝纤维的现场加工

Fig.3 Process of manufacturing aluminium fiber with multi-tooth tool

2 多齿刀具的切削机理

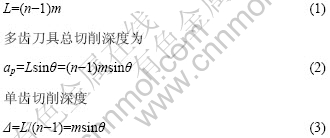

多齿刀具切削模型示意图如图4所示。图中ap为多齿刀具切削深度,Δ为单齿切削深度,f为进给量,L为多齿刀具与工件的接触长度,M、N和P为多齿刀具参与切削的3个细齿齿尖。由于多齿刀具由多个细齿组成,所以多齿刀具切削微观上是多个细齿同时参与的双刃斜角切削。设刀具与工件接触长度内的细齿总数为n,假设与工件接触的细齿中左端第一齿仅刚好与工件接触(即理论上无切削深度),因此将有(n?1)个细齿同时参与切削并形成纤维。经计算,多齿刀具与工件的接触长度为

图4 多齿刀具的切削模型示意图

Fig.4 Schematic diagram of cutting model of multi-tooth tool

各细齿切削层为平行四边形,单齿切削层面积(图4中阴影部分分别为刀齿N、P的切削层)为

A=Δf (4)

将与工件接触长度内的所有细齿的切削层进行组合,就是整个多齿刀具的切削层,已加工表面与待加工表面之间的过渡表面也因此成为多个微小阶梯组成的锥面。

图4实际上也表示了多齿刀具的分屑机理。多齿刀具之所以能同时加工出多条连续纤维,是由于与工件接触长度内的(n?1)个细齿同时参与切削,将多齿刀具总切削深度ap平均分担到(n?1)个细齿上,其中每个细齿都可加工出一条纤维,从而使多齿刀具同时加工出多根纤维,所得纤维当量直径也因此可以小很多。由式(5)计算可得纤维的理论当量直径。

由式(5)可知,纤维的理论当量直径D与m、θ和f有关,在固定m值及选定θ和f的条件下,各细齿切削出的多根纤维理论当量直径相等,从而保证了纤维粗细的均匀性。因此,只需选择合适的m、θ和f,即可获得所需当量直径的连续金属长纤维。由于D随着m、θ和f的增大而增大,所以从降低纤维当量直径的角度考虑,希望m、θ和f取较小值。

3 切削用量对铝纤维当量直径和表面形貌的影响

本试验是在刀具参数选定的情况下,通过调整工件转速n、进给量f、斜角θ,研究切削速度v、进给量f、单齿切削深度Δ对铝纤维当量直径和表面形貌的影响。本试验在C6132A车床上进行,刀具材料选用超硬高速钢W12Mo3Cr4V3N,工件材料为d39.0 mm×400 mm的7A04铝棒。由于纤维从刀具右侧流出,为方便收集,本试验中刀具安装在刀架右侧进行车削,纤维也选择在刀架右侧进行收集。并利用日本Hitachi公司S?520/INCA 300扫描电子显微镜/X射线能谱联用仪观察铝纤维的表面形貌。

3.1 切削速度v对铝纤维当量直径和表面形貌的影响

采用多齿刀具加工连续长纤维时,切削速度v不宜太高。速度太高,纤维容易缠绕在工件和刀具上,不易收集。根据文献[12]可知,切削速度应在30 m/min以下。多齿刀具切削时多个细齿同时参与切削,具有分纤作用,削弱了切削层金属的整体牵制作用,使排纤顺畅;而且由于多齿刀具前角较大,减小了纤维变形系数,使切削层金属粘结和冷焊现象大为减小,从而有利于形成连续稳定的金属长纤维。纤维在沿前刀面流出时受到前刀面的挤压而产生摩擦,发生剪切变形,尤其是纤维底部的滞流层的变形程度一般比切屑上层大几倍到几十倍。该塑性变形将导致纤维底面(即紧贴前刀面的纤维表面)呈光滑状,而纤维上表面(即背向前刀面的纤维表面)由于表层金属的挤压层积呈毛茸状,产生周期性的褶皱甚至裂纹。

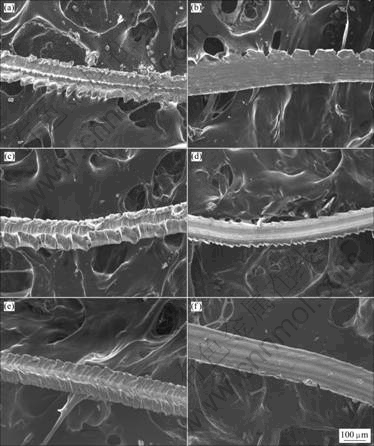

图5所示为多齿刀具在不同切削条件下所加工的铝纤维底面与上表面的SEM像,其中转速n分别为25,50和105 r/min,对点的切削速度V分别为3.06、6.12和12.86 m/min)。由图5可知,切削速度v对纤维粗细的影响较小;纤维底面在不同切削速度下都比较光滑,且底面都具有纤维流向的纹理。但切削速度v对纤维上表面形貌的影响较大。在低切削速度下,纤维上表面具有明显的褶皱,且纤维一侧具有较大的周期性出现的鳞片状毛刺。在高切削速度下,纤维上表面褶皱较浅,且纤维一侧周期性的鳞片状毛刺较小。这是由于低速下纤维流出速度较慢,被切削金属层在与母体脱离成为纤维流出之前发生充分的塑性变形,较大的塑性变形导致纤维上表面金属的挤压层积严重,纤维一侧的金属也由于较大的剪切变形发生周期性断裂而成为鳞片状毛刺。而在高切削速度下,由于纤维流动速度大于其塑性变形速度,且前刀面摩擦因数随速度升高而减小[15],因此纤维在流出前和流出后都未发生较大的塑性变形,纤维上表面金属也因此未发生严重的挤压层积,纤维一侧周期性出现的鳞片状毛刺也因此较小。但试验发现,如果转速增高,出纤速度相应加快时,纤维收集速度一旦小于出纤速度,纤维容易发生弯曲变形,使收集的成束纤维成膨松状,影响纤维的缠绕收集及后续使用。综合考虑,切削速度v约为6 m/min左右效果最好。

3.2 进给量f对铝纤维当量直径和表面形貌的影响

由式(5)可知,进给量f增大,所切出纤维的当量直径也增大,因此要获得当量直径小的纤维,进给量f不宜太大。而且f过大将导致切削层的厚度大于刀具细齿的有效切削长度而不能分屑。但进给量f过小,生成的纤维过细,容易拉断以致难以形成连续长纤维。根据文献[12]可知,f应小于0.2 mm/r。

图5 不同切削速度下铝纤维底面与上表面的SEM像

Fig.5 SEM images of aluminum fiber surface formed at different cutting speeds: (a) Upper surface of aluminum fiber, n=25 r/min (v=3.06 m/min); (b) Bottom surface of aluminum fiber, n=25 r/min (v=3.06 m/min); (c) Upper surface of aluminum fiber, n=50 r/min (v=6.12 m/min); (d) Bottom surface of aluminum fiber, n=50 r/min (v=6.12 m/min); (e) Upper surface of aluminum fiber, n=105 r/min(v=12.86 m/min); (f) Bottom surface of aluminum fiber, n=105 r/min(v=12.86 m/min) (θ=7?; f=0.10 mm/r)

图6所示为多齿刀具在不同进给量下所加工的铝纤维上表面的SEM像,其中进给量f分别为0.05、0.10和0.14 mm/r。由图可知,进给量f对纤维粗细具有一定影响,纤维当量直径随着进给量f的增大而增大,与式(5)吻合,而且进给量对纤维上表面形貌也具有一定影响。在小进给量下,纤维上表面褶皱不明显,纤维一侧也几乎无周期性的鳞片状毛刺产生;而随着进给量的增大,表面褶皱渐渐明显,周期性的鳞片状毛刺也慢慢生成并逐渐增大。这是由于随着进给量f的增大,切削力也相应增大,纤维从细齿切出时已发生较大的塑性变形。而且由于进给速度较大时,纤维拉出收集之前已沿前刀面向右侧快速滑移流动一段距离。流动过程中,由于前刀面的挤压摩擦,纤维又发生一次较大的塑性变形,这最终导致纤维上表面金属的挤压层积加剧,引起褶皱的加大与周期性的鳞片状毛刺的生成。虽然褶皱与周期性的鳞片状毛刺的产生对于提高纤维表面粗糙度及比表面积具有一定促进作用,但试验发现,由于铝弹性较差,随着进给速度的增大,纤维沿前刀面向右侧流动的速度也加快,这导致纤维朝刀架右后侧方向拉出时极易断裂,甚至难以收集。因此综合考虑,进给量为0.10 mm/r左右最好。

图6 不同进给量下铝纤维上表面的SEM图

Fig.6 SEM images of aluminum fiber upper surface formed at different federates: (a) f=0.05 mm/r; (b) f=0.10 mm/r; (c) f=0.14 mm/r (θ=4?; n=105 r/min)

3.3 单齿切削深度Δ对铝纤维当量直径和表面形貌的影响

多齿刀具切削时,各细齿属于微量切削,符合切削法制造金属纤维对切削用量的要求。由式(5)可知,所切出纤维的当量直径随着Δ的增大而增大。而由式(3)可知,Δ随刀具斜角θ而变化,因此纤维当量直径可通过调节θ进行控制。θ过小时,Δ将过小,纤维容易因过细而断裂以致无法收集。而θ过大,Δ将过大,纤维过粗,加工意义不大。而且试验发现,在θ较大时,纤维之间极易缠绕成团,形成麻绳状,尤其在低速、小进给量下情况更加严重。这是由于θ增大,Δ也增大,切削力相应上升。在大切削力作用下,尤其在低速时,纤维剪切变形很大。而且在θ较大时前刀面向右倾斜较大,成束纤维因受到前刀面挤压将发生严重的扭转弯曲,并集中滑向前刀面右侧,滑移过程中纤维之间将碰撞缠绕成团,形成麻绳状。与大进给量相比,小进给量下纤维相对较薄,其抗扭刚度和抗弯刚度相对较小,纤维更易形成麻绳状。

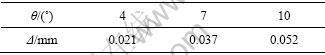

表1所列为不同斜角对应的单齿切削深度Δ。

表1 斜角θ及其对应的单齿切削深度Δ

Table 1 Oblique angles (θ) and their corresponding cutting depths (Δ) for per tooth

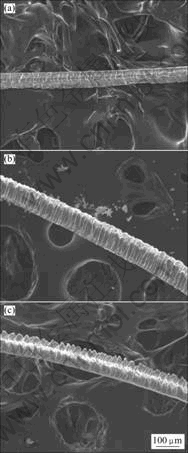

图7所示为多齿刀具在不同斜角(θ)下所加工的铝纤维上表面的SEM像,θ分别为4?、7?和10?。由图可知,θ角对纤维粗细影响很大,纤维的当量直径随着θ角的增大而增大,与式(5)吻合。试验发现,实际纤维当量直径比理论当量直径要大,这是由于铝纤维较大的塑性变形所致。从图8中还发现,θ角对纤维上表面形貌的影响也很大。θ角较小时,纤维上表面褶皱不明显,周期性的鳞片状毛刺也很小。随着θ角增大,纤维上表面褶皱变得十分明显,甚至出现裂纹,周期性的鳞片状毛刺也变得很大。这是由于随着θ角增大,Δ增大,切削厚度相应增大,切削力也急剧上升,纤维切出时发生严重的剪切变形所致。试验发现,θ角过大时,切削力很大,且切削过程也不平稳,刀具磨损严重,纤维也极易断裂。因此为了得到连续稳定的微细铝纤维,θ角不宜太大。综合考虑θ角为7?即单齿切削深度Δ约为0.037 mm)左右最好。

图7 不同单齿切削深度下铝纤维上表面的SEM像

Fig.7 SEM images of aluminum fiber upper surface formed at different cutting depths per tooth: (a) θ=4?(Δ=0.021 mm); (b) θ=7?(Δ=0.037 mm); (c) θ=10?(Δ=0.052 mm) (f=0.10 mm/r, n=50 r/min)

4 结论

1) 多齿刀具切削时,多个细齿同时参与切削,可同时制造出多根当量直径在100 μm以内的连续金属长纤维,提高了纤维的生产效率。

2) 纤维理论当量直径D与相邻两细齿齿间间距m、刀具斜角θ、进给量f有关,选择合适的m、θ和f,即可获得所需当量直径的连续金属长纤维。

3) 铝纤维表面形貌与切削速度v、进给量f、单齿切削深度Δ都有关,其中Δ影响最大,v次之,f最小。本试验中v、f和Δ的最佳数值分别约为6 m/min、0.10 mm/r、0.037 mm。

REFERENCES

[1] 奚正平, 周 廉, 李 建, 廖际常, 毋录建, 李亚录, 李建平, 张燕荣. 金属纤维的发展现状和应用前景[J]. 稀有金属材料与工程, 1998, 27(6): 317?321.

XI Zheng-ping, ZHOU Lian, LI Jian, LIAO Ji-chang, WU Lu-jian, LI Ya-lu, LI Jian-ping, ZHANG Yan-rong. Current status of development and application of metal fibres[J]. Rare Metal Materials and Engineering, 1998, 27(6): 317?321.

[2] 汤慧萍, 朱纪磊, 王建永, 葛 渊, 李 程, 邸小波. 不锈钢纤维多孔材料的吸声性能[J]. 中国有色金属学报, 2007, 17(12): 1943?1947.

TANG Hui-ping, ZHU Ji-lei, WANG Jian-yong, GE Yuan, LI Cheng, DI Xiao-bo. Sound absorbing properties of stainless steel fiber porous materials[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1943?1947.

[3] 韩 冬, 张俊红, 张 英, 张树朝. 金属铝纤维的性能研究及其应用进展[J]. 轻金属, 2007(12): 67?70.

HAN Dong, ZHANG Jun-hong, ZHANG Ying, ZHANG Shu-chao. Development of research and application of aluminum fibre[J]. Light Metals, 2007(12): 67?70.

[4] 万珍平, 刘亚俊, 汤 勇, 叶邦彦. 多齿刀具的切削模型及其分屑机理[J]. 机械工程学报, 2005, 41(3): 211?215.

WAN Zhen-ping, LIU Ya-jun, TANG Yong, YE Bang-yan. Cutting model of multi-tooth tool and its chip-splitting mechanism[J]. Chinese Journal of Mechanical Engineering, 2005,41(3): 211?2215.

[5] 谭松庭, 章明秋, 容敏智, 曾汉民, 黎宝恩. 金属纤维/聚合物导电复合材料的性能研究[J]. 材料工程, 1998(12): 15?17.

TAN Song-ting, ZHANG Ming-qiu, RONG Min-zhi, ZENG Han-min, LI Bao-en. Study on properties of metal fibre filled polymer composites[J]. Journal of Materials Engineering, 1998(12): 15?17.

[6] 谭松庭, 章明秋, 容敏智, 曾汉民. 金属纤维填充聚合物复合材料的导电性能和电磁屏蔽性能[J]. .材料工程, 1999(12): 3?5, 38.

TAN Song-ting, ZHANG Ming-qiu, RONG Min-zhi, ZENG Han-min. Electroconductivity and electromagnetic interference shielding effectiveness of metal fiber filled polymer composites[J]. Journal of Materials Engineering, 1999(12): 3?5, 38.

[7] 周 娟, 肖于德. 金属纤维行业发展趋势[J]. 湖南有色金属, 2008, 24(2): 38?40.

ZHOU Juan, XIAO Yu-de. Development research of metal fibre industry[J]. Hunan Nonferrous Metals, 2008, 24(2): 38?40.

[8] BAIK N I, CHOI Y, KIM K Y. Fabrication of stainless steel and aluminum ?bers by PDME method[J]. Journal of Materials Processing Technology, 2005, 168(1): 62?67.

[9] 周 伟, 汤 勇, 万珍平, 陆龙生, 潘敏强. 多齿刀具制造铜纤维时表面形貌的成形[J]. 华南理工大学学报: 自然科学版, 2008, 36(4): 23?28.

ZHOU Wei, TANG Yong, WAN Zhen-ping, LU Long-sheng, PAN Min-qiang. Surface formation of copper fibers fabricated by multi-edge tool[J]. Journal of South China University of Technology: Natural Science Edition, 2008, 36(4): 23?28.

[10] WAN Zhen-ping, TANG Yong, LIU Ya-jun, LIU Wang-yu. High efficient production of slim long metal fibers using bifurcating chip cutting[J]. Journal of Materials Processing Technology, 2007, 189(2): 273?278.

[11] WAN Zhen-ping, TANG Yong, ZHANG Fa-ying. On manufacturing of long stainless steel fiber with fin by multi-tooth tool and mechanical properties of the fiber[J]. Key Engineering Materials, 2006, 315/316: 666?670.

[12] 陈泽飞, 曾志新, 汤 勇, 李 勇. 一种用于加工金属纤维的新型刀具的研究[J]. 华南理工大学学报: 自然科学版, 2001, 29(6): 31?35.

CHEN Ze-fei, ZENG Zhi-xin, TANG Yong, LI Yong. New-type cutting tool used for manufacturing long metal fiber[J]. Journal of South China University of Technology: Natural Science Edition, 2001, 29(6): 31?35.

[13] 万珍平, 叶邦彦, 汤 勇, 张发英. 多齿刀具切削机理及其在金属纤维制造中的应用[J]. 机械科学与技术, 2003, 22(6): 951?953.

WAN Zhen-ping, YE Bang-yan, TANG Yong, ZHANG Fa-ying. On cutting mechanism of a multi-tooth tool and its application in manufacturing metal fibre[J]. Mechanical Science and Technology, 2003, 22(6): 951?953.

[14] 明冬兰, 万珍平, 张发英, 汤 勇, 陈澄洲. 连续型金属长纤维切削加工的研究[J]. 工具技术, 1998, 32(7): 9?11.

MING Dong-lan, WAN Zhen-ping, ZHANG Fa-ying, TANG Yong, CHEN Cheng-zhou. A study on manufacturing process of continuous metal fibre[J]. Tool Engineering, 1998, 32(7): 9?11.

[15] 明冬兰, 刘华联, 张发英, 陈澄洲. 车削制造金属长纤维时速度对纤维特性的影响[J]. 华东交通大学学报, 1998, 15(4): 11?15.

MING Dong-lan, LIU Hua-lian, ZHANG Fa-ying, CHEN Cheng-zhou. The influence of the cutting speed on the properties of long metal fibre by self-propelled cutting tool[J]. Journal of East China Jiaotong University, 1998, 15(4): 11?15.

基金项目:国家自然科学基金资助项目(50675070;50805052);广东省自然科学基金重点资助项目(07118064)

收稿日期:2008-11-19;修订日期:2009-03-18

通讯作者:贺占蜀,博士;电话:13570586957;E-mail: hezhanshu2004@126.com

(编辑 何学锋)