文章编号:1004-0609(2008)06-0997-08

梯温楔压对喷射沉积SiCp/7090致密化的影响

王 凯,陈振华,张 昊,陈 刚

(湖南大学 材料科学与工程学院,长沙 410082)

摘要:采用一种新的楔压工艺—梯温楔压,对喷射沉积态SiCP/7090铝基复合材料进行致密化加工,并测定压制后坯料的密度和硬度。结果表明,坯料在模具中加热90 min后正面与侧面分别呈现出180 ℃和250 ℃的温度梯度,坯料在高向变形为25%时,致密化效果较好,密度与硬度均呈现出沿高向逐渐减小的趋势,相对密度最高达到98%,与恒温楔压时坯料的相对密度最高为95%相比,梯温楔压工艺有效提高了坯料的相对密度,硬度最高值达到HB92。在315T液压机上实现了高向为200 mm的多孔材料的致密化加工。

关键词:SiCp/7090铝基复合材料;梯温楔压;多层喷射沉积;致密化;

中图分类号:TG 146.2 文献标识码:A

Effect of temperature gradient cyclic pressing on densification of spray deposited SiCp/7090 composite

WANG Kai, CHEN Zhen-Hua, ZHANG Hao, CHEN Gang

(College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: A novel technique called temperature gradient cyclic pressing was developed to improve the formability of spray deposited aluminum alloy preforms. Spray deposited SiCp/7090 Al-base composite was densified by temperature gradient cyclic pressing, and the density, hardness and microstructure of the composite were studied. The results show that the temperature gradient on the front face of billet is 180 ℃, while 250 ℃ on the side face of the billet is got when heated in the die for 90 min. When the billet reduces by 25% in height, the effect of densification for the billet is better, the maximum relative density is 98%. However, the maximum relative density is 95% when the same billet is pressed with constant temperature gradient cyclic pressing. The maximum hardness is HB92. It is easier for temperature gradient cyclic pressing to densify the porous materials with the height of 200 mm through the 315T hydraulic press.

Key words: SiCp/7090 Al-base composite; temperature cyclic pressing; multi-layer spray deposition; densification

颗粒增强铝基复合材料具有密度低、比强度高、比刚度高、耐磨、耐疲劳、热稳定性好、热膨胀系数小等优异的力学性能与物理性能,是近年来铝基复合材料研究的热点。这种低密度高性能的特点使得颗粒增强铝基复合材料可以作为钢材和钛合金的代替材料,成为航空、航天、交通运输及其它工业部门广泛应用的结构材料[1-2]。采用喷射沉积技术制备颗粒增强复合材料时,增强颗粒分布均匀,而且具有快速凝固等一系列特点[3-6]。然而通过模压、锻造工艺对大尺寸喷射沉积态多孔坯料进行致密化后发现坯料的力学性能改善并不理想[7-8],并且此类大件材料锻造时存在致密化效果不佳的现象[9]。对高向尺寸达到200 mm 的大尺寸喷射沉积态材料致密化加工时,通常采用600 t以上的液压机或者1 250 t的挤压机进行致密化加工,这样大型设备的要求限制了大尺寸喷射沉积材料的应用,陈振华等[10]发明了楔形压制的致密化方法,很好地解决了在小吨位液流压机上对大尺寸喷射沉积材料致密化加工的问题。楔形压制工艺是在小变形量多道次累积的条件下使多孔材料逐步致密化的工艺,然而在恒温楔压时存在坯料底部致密化效果不佳的现象。鉴于在挤压过程中对挤压坯料进行梯温加热后,坯料挤压效果较好[11-12],本实验在恒温楔形压制工艺的基础上引入梯温工艺,采用梯温楔压技术在315 t液压机上对高向尺寸为200 mm的喷射沉积态SiCp/7090坯料进行致密化加工,并对压制工艺和材料性能进行研究。

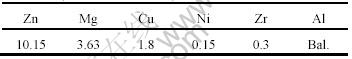

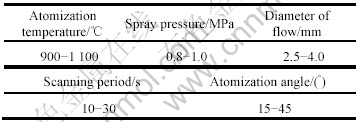

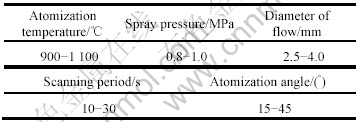

1 实验

采用多层喷射沉积技术制备SiCp/7090铝基复合材料,利用梯温楔压工艺对坯料进行致密化加工,对楔压后的坯料进行密度,微观组织及力学性能的分析。坯料制备:采用多层喷射沉积技术制备了L×W×H = 157 mm×112 mm×200 mm的方坯,其化学成分如表1所列,基体增强相为平均粒径为14 μm的SiC颗粒。沉积坯料的相对密度为85%。制备方坯时的工艺参数如表2所列,所制备的未进行致密化加工的方坯实物如图1所示。

表1 7090铝合成分

Table 1 Chemical constitution of 7090 aluminum alloy (mass fraction, %)

表2 制备SiCp/7090方坯的工艺参数

Table 2 Processing parameters of preparing SiCp/7090 square billet

图1 喷射沉积态SiCp/7090方坯

Fig.1 Square billet of as-spray deposited SiCp/7090

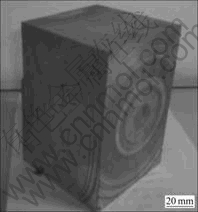

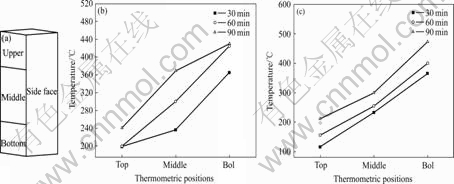

图2所示为喷射沉积态多孔材料的梯温楔压致密化装置。在压制之前,将坯料加热到350 ℃后放入模具中,同时开启模具底面的电热板4,以及模具侧壁的电管5与水管6,通过控制不同位置电管与水管的开关,使整个模具沿高度方向上呈现出一定的温度梯度。坯料在模具中分别放置30 、60和90 min后用激光测温仪沿高度方向对其正面和侧面进行温度测试,测温位置及测温结果如图3所示,测温时选取坯料的上、中、下3个部位进行测试,每个区域的测温误差范围为±5 ℃。

图2 梯温楔压装置

Fig.2 Schematic of temperature gradient cyclic pressing device: 1—Wedge shape pressure head; 2—Billet; 3—Die; 4—Bottom sheet; 5—Heating pipe; 6—Water pipe;

从图3中可以明显看出,随着加热时间的增加,试样每一个测温位置的温度都逐渐升高,并且呈现至上而下温度逐渐升高的趋势。当试样被加热90 min时,坯料的正面与侧面的最高温度分别为440和500 ℃,坯料的正面及侧面分别呈现出180 和250 ℃的温度梯度。对于SiCP/7090铝基复合材料而言,温度达到450 ℃以上,会出现明显的晶粒粗大现象,材料的力学性能急剧下降,所以在实验中坯料的加热时间不宜超过90 min。在对坯料进行循环压制时,楔形压头1压下后抬起,向右移动一个步进距,然后向下压制,如此循环使坯料2逐步致密化,梯温楔压工艺如表3所列。沉积态坯料共进行4次循环压制,最终得到的压制坯尺寸为162 mm×116 mm×150 mm。

图3 不同位置的温度测试示意图

Fig.3 Schematic plan of thermometric in different sites: (a) Thermometric site; (b) Relationship between time and thermal distribution at different positions on front face; (c) Relationship between time and thermal distribution at different positions on side face

表3 多层喷射沉积SiCP/7090复合材料梯温楔压工艺参数

Table 3 Processing parameters of temperature gradient cyclic pressing on multi-layer spray formed SiCp/7090 composite

2 有限元模拟

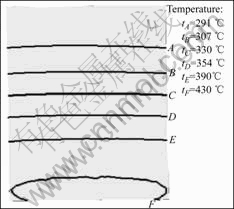

为了优化实验条件及对实验过程进行有效预测,利用有限元分析软件对实验过程进行了有限元模拟,所选材料以及模拟条件均与实验一致。在模拟过程中首先利用呈现一定温度梯度的模具对坯料进行加热,加热90 min后坯料中心部位的温度分布如图4所示。

图4 模拟软件生成的坯料温度分布

Fig.4 Temperature distribution of billet generated by simulation software

对形成上述温度梯度的坯料按照表3的实验参数进行楔形压制过程模拟,高向变形分别为5%、10%、15%、20%、25%及30%的坯料相对密度分布模拟结果如图5所示。

图5 不同高向变形量的相对密度模拟结果

Fig.5 Relative density in height generated by simulation: (a) Deformation of 5%; (b) Deformation of 10%; (c) Deformation of 15%; (d) Deformation of 20%; (e) Deformation of 25%; (f) Deformation of 30%

从图4可以看出,坯料在加热90 min后沿高向自上而下呈现出291~430 ℃的温度梯度。从图5可以看出,对此坯料进行压制时,随着高向变形量的增大,坯料的相对密度在同一高向位置呈现出逐渐增大的趋势,坯料整体的相当密度也随之增大,当坯料的高向变形量为25%时,坯料整体的相对密度达到99.5%以上。当高向变形量达到30%时,坯料的相对密度没有明显的增大,坯料体积不再发生变化,继续变形坯料的相对密度不再发生明显变化。从模拟的结果来看,将坯料在模具中加热90 min,使坯料在楔压过程中高向变形达到25%时,坯料的致密化效果较好,在实验中遂选取此条件为实验条件。

3 结果与分析

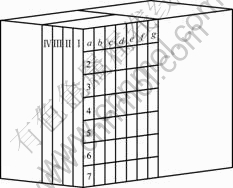

3.1 密度变化规律

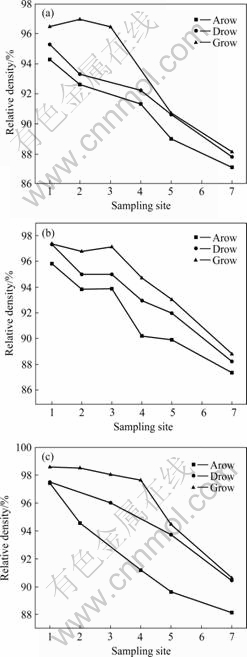

为了研究压制后的坯料的密度及硬度变化情况,对高向变形为25%的坯料在高向上沿不同截面取样进行密度及硬度测试,取样位置及试样标号如图6所示,对坯料的Ⅰ、Ⅱ及Ⅳ面沿高向在不同位置进行取样进行密度测试,测试结果如图7所示。

图6 取样位置示意图

Fig.6 Positions for density samples of temperature gradient cyclic pressing billet

图7 坯料梯温楔压后沿高向的相对密度分布

Fig.7 Relative density distribution of temperature gradient cyclic pressing billet in height: (a) Relative density of each row in faceⅠ; (b) Relative density of each row in faceⅡ; (c) Relative density of each row in face Ⅳ

从图5和图7的比较可知,实验所得的相对密度较模拟结果偏小,这主要是由于在实验过程中,坯料的散热导致本身的温度下降较多,这样在压制后期坯料表面温度过低,坯料无法进行致密化变形;其次在实验中坯料表面与模具内壁的摩擦较模拟条件中的摩擦大,在实验中压制力沿高向损失较多。这两个因素是导致在实验中所得坯料相对密度较模拟结果低的主要原因。

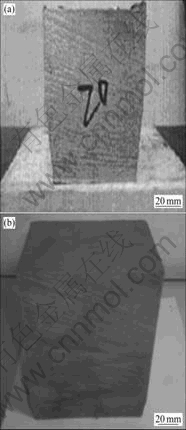

从图7中可以看出,各面的相对密度均呈现出由压头至上而下逐渐减小的趋势,面Ⅰ相对密度最小为87%,最大为97%;面Ⅱ相对密度最小为88%,最大为98%,面Ⅳ最小密度为88%,最大为99%。在每一个面同一高度上,列点a的相对密度最低,列点g的相对密度最高,由此可以看出,靠近模壁坯料的相对密度低于坯料中心相对密度。靠近压头部分坯料的相对密度均达到98%以上,这主要是由于此处坯料直接与压头接触,所受到的压制力较大。而在远离压头的部位由于在压制过程中随着坯料的横向流动,坯料与模具的接触面积增大,坯料与模具间的摩擦力也相应增大,使得压制压力的损失增大。这样就使得靠近模壁处坯料的相对密度小于中心处坯料的相对密度,压制力沿高向呈现出逐渐减小的趋势,因而使得坯料的相对密度沿高向也呈现出逐渐减小的趋势。在此实验中坯料的高向变形量为25%,相对密度在88%~98%之间,使沉积坯的相对密度提高了3%~10%。虽然此实验并没有使坯料整体得到较高的相对密度,但与恒温楔压(坯料整体温度一致)相比,在高向变形量相同时,其变形程度还是有很大的提高。有文献报道[13],对同样尺寸、初始密度为85%的喷射沉积SiCp/7090复合材料进行恒温楔压时,当高向变形量为25%时,坯料的相对密度也呈现出沿高向逐渐变小的趋势,但相对密度最小处为86%,最大为95%。在相同高度位置,梯温楔压的相对密度均高于恒温楔压,这主要是由于在同一高向上梯温楔压时坯料的温度高于恒温楔压时坯料的温度,在同样的压制力条件下,高温使得梯温楔压坯料更易于变形。恒温与梯温楔压后的坯料如图8所示。

图8 楔压坯料实物像

Fig.8 Pictures of cyclic pressing billets: (a) Billet prepared by constant cyclic pressing; (b) Billet prepared by temperature gradient cyclic pressing

从图8可以明显看出,恒温楔压后的坯料下部呈现出明显的尖角状,这说明此时坯料的下部并没有发生金属的流动与变形;而通过梯温楔压方法压制的坯料只有底部一小部分呈现出尖角状,这说明只有这一小部分没有发生金属的流动与变形。据文献[13]报道,恒温楔压在高向变形达到25%时,只有沿压头向下1/3高向区间内坯料的变形较为明显。这说明在楔压工艺中引入了梯温技术对喷射沉积材料的致密化工艺有很大的改进,可以在相同的变形量情况下沿高向更加深入地变形。其原因在于虽然在压制过程中模壁与坯料的摩擦损失了一部分压制压力,但是由于坯料存在温度梯度,坯料底部温度较高,变形抗力小,因此较小的压制力就可以使坯料发生塑性变形。当坯料的高向变形达到一定数量后继续变形时,恒温楔压的坯料下部不再发生变形,坯料局部受压向下变形时,坯料的其它部分表现为向上变形,表现为体积不变。而在梯温楔压时,由于受压部分坯料的高向向下温度高于坯料横向两侧的温度,坯料向下变形的抗力小于横向变形的抗力,因此梯温楔压工艺在一定程度上解决了恒温楔压过程中压不透的问题。

3.2 硬度变化规律

为了了解梯温楔压后坯料的力学性能及坯料沿高向力学性能的变化,对面Ⅰ、Ⅱ和Ⅳ沿高向在a、d和g列取样进行硬度测试,取其平均值作为高向硬度变化规律的依据,其硬度变化如图9所示。从图中可以明显看出,沿高向硬度值呈现出与相对密度一样的沿压头向下逐渐减小的趋势,从HB92减小到HB64,这主要与沿高向坯料的密度逐渐减小有关。从各列来看,在同一高向上g列的硬度值最大,a列的硬度值最小。产生此现象的原因是坯料的边缘与模壁的摩擦作用使得压制力损失较大,致使其致密效果不好,材料内部空洞较多,硬度较低。

图9 坯料沿高向的硬度分布

Fig.9 Hardness distribution of billet in height

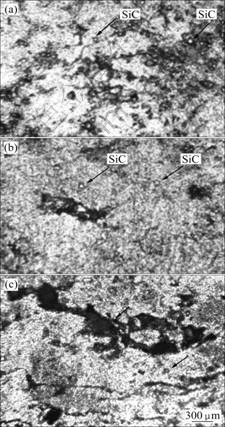

3.3 坯料沿高向内部孔洞分析

为了研究在压制过程中坯料在高向上的组织变化情况,沿压头方向而下在上、中、下部取点,对取样点横向平面进行金相组织的观察,图10所示为各取样位置的金相组织照片。

图10 不同位置试样的孔洞金相照片

Fig.10 Pore metallographs of test sample in different position (a) Upper portion ; (b) Centre portion; (c) Bottom portion

从图中可以明显看出,在靠近压头部位坯料内部仍存在一定数量弥散分布的孔洞,这些孔的尺寸较小,约为15 μm。沿高向远离压头的坯料内部孔洞较大,坯料底部的孔洞最大,并且孔洞连成一个整体。这主要是由于上部的坯料在压制过程中受到压制力的作用发生了横向的流动,产生了剪切力,剪切力使得孔洞拉长、分散成尺寸较小的孔洞,然后使压扁的孔洞的相对面之间发生摩擦[14]。由为可以机械地破坏氧化膜,形成新鲜表面,从而达到很好的致密效果[15]。而在坯料的下部由于所受压制力较小,只产生了较小横向的流动或没有产生横向流动,剪切力作用不明显,这样就形成了图10(c)中被拉长并且连在一起的大孔洞。从图10中箭头所指部分可以看出,梯温楔压后SiC颗粒的尺寸约为6 μm,沉积态时SiC颗粒为14 μm,这说明梯温楔压工艺破坏了大尺寸的SiC颗粒,使坯料中的SiC颗粒更加细小。从图10(a)中还可以看出压制后SiC颗粒分布较为均匀,流线分布并不明显。

4 结论

1) 梯温楔压工艺在315 t液压机上实现了200 mm高的喷射沉积SiCp/7090坯料的致密化加工,利用自制楔压装置在坯料正面与侧面分别形成了180和250 ℃的温度梯度。

2) 梯温楔压后坯料的密度呈现出由压头自上而下逐渐减小的趋势,相对密度在88%~98%之间,靠近模壁坯料的相对密度低于坯料中心相对密度。

3) 梯温楔压后坯料的硬度值呈现出沿压头向下逐渐减小的趋势,从HB92减小到HB64,在同一高向上中心部位的硬度值最大,靠近模壁处坯料的硬度值最小。

4) 梯温楔压后坯料中仍分布一定数量的约为15 μm小孔洞,SiC颗粒得到了细化并且分布均匀。

REFERENCES

[1] SUN Zhi-qiang, ZhANG Di, LI Guo-bin. Evaluation of dry sliding wear behavior of silicon particles reinforced aluminum matrix composites[J]. Materials & Design, 2005, 26(5): 454-458.

[2] EUH K, KANG S B. Effect of rolling on the thermo-physical properties of SiCp/Al composites fabricated by Plasma spraying[J]. Mater Sci Eng A, 2005, 395(1/2): 47-52.

[3] ZHAN Mei-yan, CHEN Zhen-hua, YAN Hong-ge, XIA Wei-jun. Deformation behaviors of porous 4032 Al alloy preform prepared by spray deposition during hot rolling[J]. Journal of Materials Processing Technology, 2007, 182(1/3): 174-180.

[4] SINGER A R E. The principle of spray rolling of metals[J]. Met Mater, 1970, 4: 246-250, 257.

[5] BROOKS R G, LEATHAM A G, COOMBS J S. A novel method for the production of forgings[J]. Metallurgia and Metal Forming, 1977, 4: 157.

[6] 陈振华, 贺毅强, 陈志钢, 尹显觉, 陈 刚. SiCP/Al-8.5Fe- 1.3V-1.7Si复合材料的显微组织及室温力学性能[J]. 中国有色金属学报, 2007, 17(6): 858-864.

CHEN Zhen-hua, HE Yi-qiang, CHEN Zhi-gang, YIN Xian-jue, CHEN Gang. Microstructure and ambient temperature mechanical properties of SiCP/Al-8.5Fe-1.3V-1.7Si composite [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 858-864.

[7] 肖于德, 谭敦强, 黎文献. 喷射沉积AlFeVSi合金模压致密化工艺与模锻制品组织性能研究[J]. 材料与冶金学报, 2004, 3(3): 213-218.

XIAO Yu-de, TAN Dun-qiang, LI Wen-xian. Investigation on die-compacting processing of spray deposited AlFeVSi heat-resistant aluminum alloy and microstructures and tensile properties of its die-forged pieces[J]. Journal of Materials and Metallurgy, 2004, 3(3): 213-218.

[8] SEE K S, DEAN T A. The effects of pre-forge processing on forgeability and mechanical properties of co-sprayed aluminum-based MMCs[J]. Journal of Materials Processing Technology, 1997, 71: 314-321.

[9] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1982: 361-385.

HUANG Pei-yun. Powder metallurgy theory[M]. Beijing: Metallurgy Industry Press, 1982: 361-385.

[10] 陈 刚, 刘鹏飞, 范才河, 陈振华. 大型喷射沉积环件的楔压致密化加工[J]. 矿冶工程, 2006, 26(2): 100-102.

CHEN Gang, LIU Peng-fei, FAN Cai-he, CHEN Zhen-hua. Densification of large-size spray-deposited rings by wedge pressing[J]. Mining and Metallurgical Engineering. 2006, 26(2): 100-102.

[11] 尹丽丽. 国外铝挤压技术及其装备的进展[J]. 轻合金加工技术, 2000, 28(10): 8-11.

YIN Li-li. The development of aluminium extrusion technology and equipment in the world[J]. Light Alloy Fabrication Technology, 2000, 28(10): 8-11.

[12] HERBA E M, MC QUEEN H J. Influence of particulate reinforcements on 6061 materials in extrusion modeling[J]. Materials and Engineering, 2004, 372(1/2): 1-14.

[13] 袁武华, 吉 喆, 陈振华. 循环压制对喷射沉积7075/SiCp致密化的影响[J]. 湖南大学学报: 自然科学版, 2006, 33(2): 81-85.

YUAN Wu-hua, JI Zhe, CHEN Zhen-hua. Effects of cyclic pressing on densification of spray formed 7075/SiCP composite[J]. Journal of Hunan University: Natural Sciences, 2006, 33(2): 81-85.

[14] 詹美燕, 匡 勇, 周 明, 夏伟军. 多孔金属及合金成形过程中的致密化与变形理论研究[J]. 稀有金属与硬质合金. 2002, 30(4): 42-47.

ZHAN Mei-yong, KUANG Yong, ZHOU Ming, XIA Wei-jun. Research on density and deformation mechanisum of porous metal and alloys during processing[J]. Rare Metals and Cemented Carbides, 2002, 30(4): 42-47.

[15] 薛永春, 周光垓, 柯尔巴什尼可夫. 颗粒材料[M]. 北京: 国防工业出版社, 1986.

XUE Yong-chun, ZHOU Guang-gai. Particle materials[M]. Beijing: National Defence Industry Press. 1986.

基金项目:国家自然科学基金资助项目(50304008)

收稿日期:2007-12-09;修订日期:2008-03-12

通讯作者:陈振华,教授;电话:0731-8821648;E-mail: wangding88888888@163.com

(编辑 何学锋)