文章编号:1004-0609(2013)11-3048-08

6061-T4铝合金T型接头搅拌摩擦焊工艺

侯晓鹏,杨新岐,崔 雷,周 光

(天津大学 天津市现代连接技术重点实验室,天津 300072)

摘 要:采用搅拌摩擦焊方法成功获得3种不同组合形式(搭接/对搭接/对接)的6061-T4铝合金T型接头。对接头的焊接缺陷、微观组织、硬度分布及抗拉强度分别进行观察和测试。结果表明:在前进侧圆角过渡区或筋板焊核区,3种接头均容易出现隧道缺陷;弱结合缺陷由于塑性变形偏离原始连接界面而向筋板或者壁板前进侧偏移;与常规搅拌摩擦焊对接搭接接头不同,T型接头沿筋板方向出现热机影响区和两个圆角过渡区;软化区域和弱结合是导致沿壁板拉伸强度降低的主要原因,而弱结合和隧道缺陷是引起这3种T型接头沿筋板方向断裂的重要原因。

关键词:6061铝合金;搅拌摩擦焊;T型接头;组合形式;焊接缺陷

中图分类号:TG453.9 文献标志码:A

Friction stir welding process of 6061-T4 aluminum alloy T-joints

HOU Xiao-peng, YANG Xin-qi, CUI Lei, ZHOU Guang

(Tianjin Key Laboratory of Advanced Joining Technology, Tianjin University, Tianjin 300072, China)

Abstract: Three combination modes (T-lap/T-butt-lap/T-butt) of AA6061-T4 aluminum alloy T-joints were successfully jointed by friction stir welding. Welding defects, microstructure, hardness profiles and tensile strength of the obtained T-joints were observed and measured, respectively. The results show that tunnel defects are easily formed in the fillet zone of the advancing side or in stringer nugget zone for all the three modes of T-joints. Defects of kissing bond are extruded downward to the stringer or sideward from the original joining surfaces to the advancing side of the skin under severe plastic deformation. T-joints exhibit the thermo-mechanical affected zone and two fillet zones in the stringer, which are different from the conventional butt and lap joints of friction stir welding. Softening zones and kissing bond are the main reasons to reduce the tensile strength of T-joints along skin direction, and kissing bond and tunnel defects are the main reasons for the fractures of T-joints along stringer direction.

Key words: 6061 aluminum alloy; friction stir welding; T-joints; combination mode; welding defect

铝合金T型接头是一种在航空航天、高速客车、船舶建造及汽车车体等轻量化结构制造领域广泛应用的接头形式,它可以有效提高壁板稳定性而使整个构件的质量没有显著增加。目前,通常采用的熔焊方法容易出现铝合金常见的裂纹、气孔等焊接缺陷,较大的焊接热循环又会产生很大的残余变形,这些都会严重地降低接头质量。搅拌摩擦焊(Friction stir welding,简称FSW)是一项环保、节能、多用途的新型固相连接技术[1-2]。由于其焊接过程中接头部位不存在金属的熔化,因而可避免铝合金熔焊中常见的缺陷,并且具有焊后残余变形小等优点。因此,把FSW技术拓展到铝合金T型接头中将具有广泛的研究和应用价值。

最近几年,国外一些研究机构已对铝合金T型接头开展了基础性的研究并取得了初步的成果。BUFFA等[3-7]通过数值模拟与试验结合的方法,对搅拌摩擦焊T型接头中的金属流动[3-4]、温度场和应力场[5-6]及残余应力分布[7]等进行了探讨。分析探讨的结果对焊接工艺选择、接头性能提高及缺陷消除等有重要指导作用。另一些研究者对同种铝合金[8-9]和异种铝合金[7, 10-13]搅拌摩擦焊T型接头的焊接工艺进行了研究,并分析讨论工艺、焊缝组织及性能之间的相互影响规律。研究结果表明:6082铝合金T型接头的焊接性能明显好于2024铝合金;当轴肩尺寸较小时2024-T4与7075-T6异种铝合金组成的T型接头容易出现隧道或空洞缺陷,适当提高轴肩尺寸可有效减少缺陷;6056与7075异种铝合金组成的T型接头,沿壁板方向抗拉强度可与母材相当,但是伸长率和韧性明显降低。需要指出的是,关于FSW-T型接头的焊接缺陷还没有专门系统地分析讨论,而且只是针对T型接头某一种组合形式(搭接或对接T型接头)进行研究,也没有对接头沿着壁板和筋板两个方向的力学性能进行系统地分析和对比。而国内针对铝合金T型接头的搅拌摩擦焊研究更是少见。

本文作者针对工业上广泛应用的6061-T4铝合金,对3种壁板和筋板组合形式的T型接头进行了搅拌摩擦焊试验,并对接头缺陷、显微组织及力学性能进行了系统的研究,从而为工程应用提供理论基础。

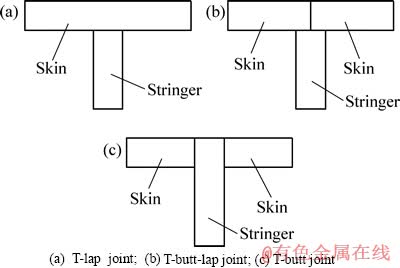

1 实验

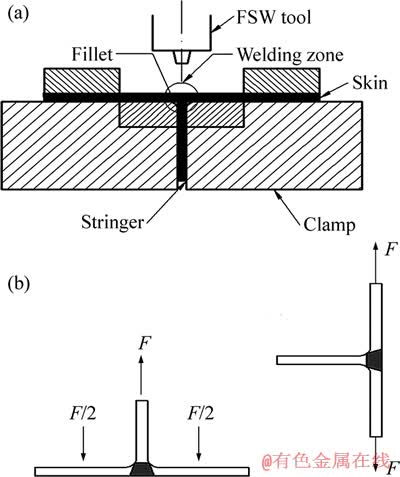

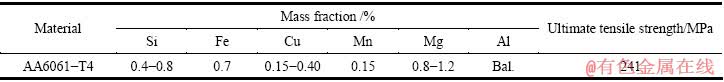

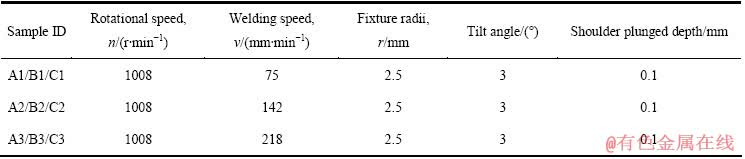

试验材料为3 mm厚的6061-T4铝合金,化学成分及力学性能见表1。采用H13工具钢加工圆形凹面轴肩和锥形搅拌针一体的搅拌头,轴肩直径15 mm,凹入角度为5°,搅拌针根部直径5.5 mm,顶端直径2 mm,长度为4.5 mm。如图1所示,搭接/对搭接/对接T型接头,3种不同组合形式的T型接头,分别用 A/B/C接头表示。焊件由尺寸为350 mm×90 mm和350 mm×45 mm的两种长方形壁板与350 mm×65 mm长方形筋板组成。如图2(a)所示,铝合金T型接头搅拌摩擦焊示意图,设计并使用了专用的夹具装置和拉伸卡具,夹具装置在壁板与筋板过渡部位设计为倒圆角,其主要目的是减少T型接头焊后残余应力与变形。焊接方向沿着轧制方向,焊接过程中的所有试验参数如表2所列。

焊后沿垂直焊缝的方向切取试样,每种工艺参数下制备6个宽度为25 mm拉伸试样(3个沿壁板加载,3个沿筋板加载,分别取3个拉伸载荷的平均值)和一个金相试样。

图1 不同组合形式的T型接头

Fig. 1 Combination modes of T-joint

图2 T型接头搅拌摩擦焊示意图和拉伸加载方式

Fig. 2 Schematic illustration (a) and loading methods (b) for FSWed T-joints

表1 AA6061-T4铝合金的化学成分及力学性能

Table 1 Chemical compositions and mechanical property of AA 6061-T4 aluminum alloy

表2 T型接头FSW试验参数

Table 2 Investigated parameters of FSWed T-joints

金相试样经磨光、抛光后使用Keller试剂(1ml氢氟酸,2.5 mL硝酸,1.5 mL盐酸,95 mL水)腐蚀,并在OLYMPUS-GX51光学显微镜下进行缺陷和显微组织观察;分别沿着壁板和筋板中心线进行硬度试验的检测;拉伸试验在CSS-44100电子万能试验机上进行,两个方向的拉伸示意图如图2(b)。

2 结果与分析

2.1 焊接缺陷及分析

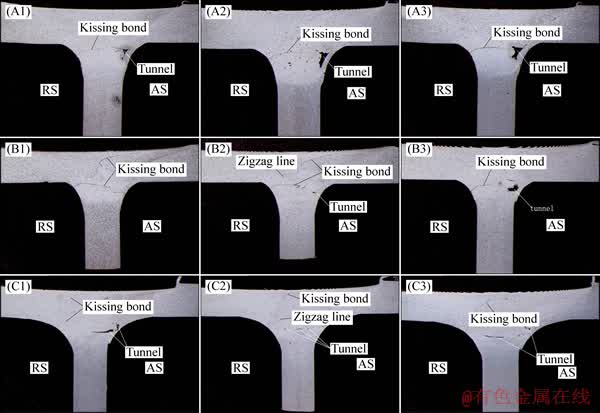

图3所示为9组试验参数的焊缝横截面宏观金相,观察发现,焊缝中均存在不同程度的缺陷,且在不同接头中分布形式不同。概括起来,主要包括隧道缺陷、弱结合缺陷和少量“Z”线。

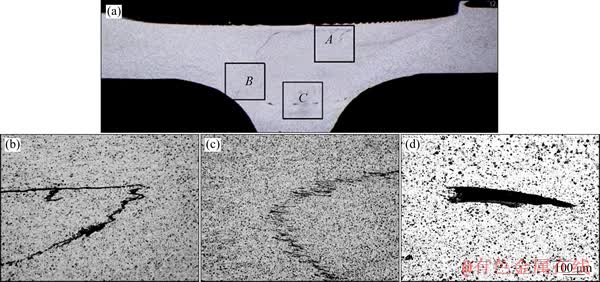

如图3所示,除了B1接头在圆角过渡区得到无隧道缺陷的焊缝外,其余A/B接头在前进侧圆角过渡区域都出现了不同程度的隧道缺陷,而C接头除了在前进侧圆角区域(C1接头)还在筋板焊核区附近沿水平方向分布一些较为分散的隧道缺陷(C2/C3接头)。如图4所示,在高放大倍数下隧道缺陷呈现为未填充的空洞(见图4(d))。T型接头中金属流动的不对称性和轴向流动不充分是引起隧道缺陷的主要原因[13]。焊接过程中前进侧圆角区域的塑性金属在搅拌针剪切力的作用下向后退侧转移,积累相对较多塑性金属的后退侧在搅拌工具向下推力的作用下可有效填充搅拌针行走留下的空腔。如果金属轴向流动不足的话,则前进侧留下的少量塑性金属和部分后退侧回流的金属无法完全填充搅拌针行走留下的空腔,随着焊接过程的一直进行,前进侧圆角区域就出现了隧道缺陷。

T型接头焊缝区另一个主要缺陷是弱结合。从图3可以看出,在搅拌工具的挤压和搅拌作用下,缺陷已偏离原始对接或搭接界面并发生弯曲变形。在A/B接头中可发现缺陷沿着原始搭接面向筋板焊核区偏移;另外,在B接头中,缺陷还沿着壁板的前进侧穿过焊缝中心线向后退侧的圆角区域延伸;对于C接头,壁板与筋板存在的两个原始纵向连接面,但是弱结合主要分布在后退侧一侧并向中心线偏移,这与搅拌摩擦焊焊缝两侧金属塑性变形的剧烈程度不对称有关。关于弱结合缺陷的形成,通常认为焊接热过程中热塑性状态金属主要围绕搅拌针做周向流动,而在Z轴方向上的运动较少,引起壁板和筋板之间的金属混合有限。因此,虽然经过塑性变形把连接材料挤压在一起,但未形成有效的冶金链接[14](见图4(b)),在加载过程中,存在弱结合缺陷的位置将是首先起裂的位置。

另外,在B2/C2接头中还出现少量的“Z”线,在高倍数显微镜下呈献为断断续续分布的线(见图4(c)),关于它的形成主要是铝合金表面残余氧化层破碎与搅拌不充分两方面原因造成的[15]。

通过接头宏观截面(A1~A3,B1~B3,C1~C3)的对比也发现,随着焊接速度的增大,隧道缺陷的面积也随之增大;而弱结合缺陷则随着焊接速度的增大,表现得更加连续和清晰,说明在低焊速下通过增加热输入有利于减少隧道和弱结合缺陷。

2.2 焊缝的显微组织

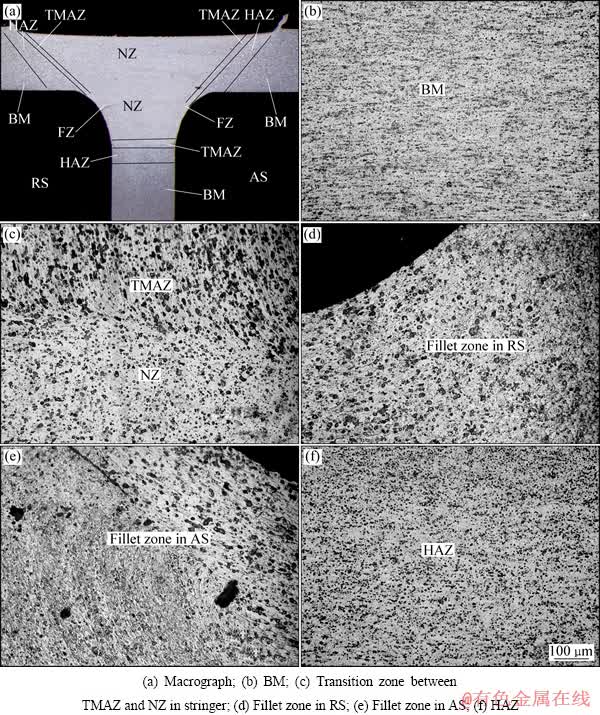

如图5(a)所示,搅拌摩擦焊T型接头微观组织包括焊核区(NZ)、热机影响区(TMAZ)、热影响区(HAZ)和母材(BM)。与常规对接或搭接接头不同之处在于,T型接头筋板上出现一个热机影响区(TMAZ)和两个圆角过渡区域(FZ),过渡区域的形成与夹具的倒圆角有直接关系。

如图5(b)所示,母材组织沿着轧制方向呈扁平状分布,黑色的强化相粒子弥散在基体中;筋板的焊核区和热机影响区过渡区域具有明显的分界线(见图5(c)),焊核区在搅拌头的搅拌和焊接热循环的共同作用下,经历了高温和剧烈的塑性变形,使母材的原始组织发生了动态再结晶,形成细小的等轴晶。而热机影响区的晶粒具有明显的沿着搅拌工具剪切应力方向的塑性流动痕迹。后退侧圆角过渡区域由细小等轴晶组成(见图5(d))。其原因是受到搅拌头挤压和顶锻作用的影响,经塑性变形后,发生动态再结晶的金属在夹具的快速冷却作用下形成细小晶粒结构。而前进侧圆角区域晶粒呈现多种形态,靠近壁板位置为较大的等轴晶,靠近筋板位置为较小的等轴晶以及靠近夹具倒圆角区域为狭长的圆弧状晶粒(见图5(e))。这与前进侧受到的剪切变形较大和两侧金属流动的不对称性有关[13]。热影响区由于只受到焊接热过程,强化相和晶粒尺寸较母材有变粗大的趋势(见图5(f))。

图3 T型接头FSW焊缝横截面宏观金相

Fig. 3 Macrographs of transverse sections for FSWed T-joints

图4 C2接头的焊接缺陷及各个缺陷的局部放大视图

Fig. 4 Appearance of C2 joint welding defects (a) and magnified images of selected regions A (b), B (c) and C (d) as selected in Fig.4(a)

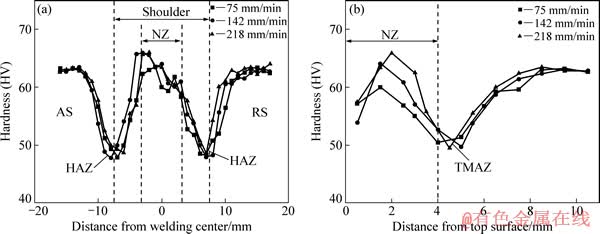

2.3 接头的硬度分布

图6所示为所有A接头沿壁板和筋板的硬度分布。沿着壁板方向成W型分布(见图6(a)),最低硬度位于轴肩下方软化的热影响区,这与热影区组织粗化和强化相长大有关;随着距离焊缝中心线距离减少,硬度逐渐增大,最高硬度位于由动态再结晶形成的细晶焊核区,并且由于前进侧晶粒变形大,畸变能增加,加工硬化显著等原因致使靠近前进侧的焊核区硬度稍高于靠近后退侧的焊核区硬度;T型接头硬度沿着筋板方向呈现N型分布(见图6(b)),包括由于热输入较大造成强化相大量溶解的轴肩下方低硬度区组织粗大及强化相部分溶解的热机影响区低硬度区以及两个低硬度区之间由动态再结晶形成的高硬度焊核区。另外,随着焊接速度的增大,软化区域有变窄的趋势,当焊接速度为218 mm/min时,沿壁板和筋板接头硬度值都最大。

图5 6061-T4铝合金T型接头FSW焊缝的微观组织

Fig. 5 Microstructure of FSWed T-joints of 6061-T4 aluminum alloy

图6 A接头沿壁板和筋板的硬度分布

Fig. 6 Vickers hardness distribution of A joints along skin direction (a) and stringer direction (b)

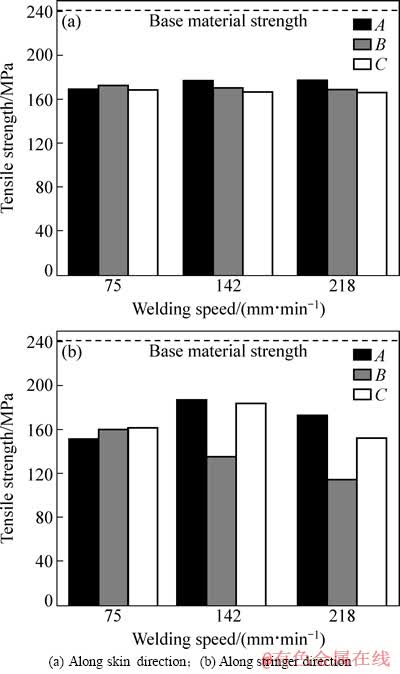

图7 3种T型接头沿壁板和筋板的拉伸强度

Fig. 7 Tensile strength of three types T-joints

2.4 接头的拉伸性能

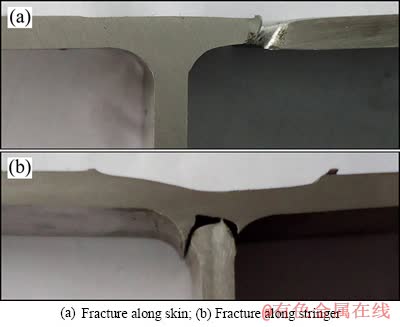

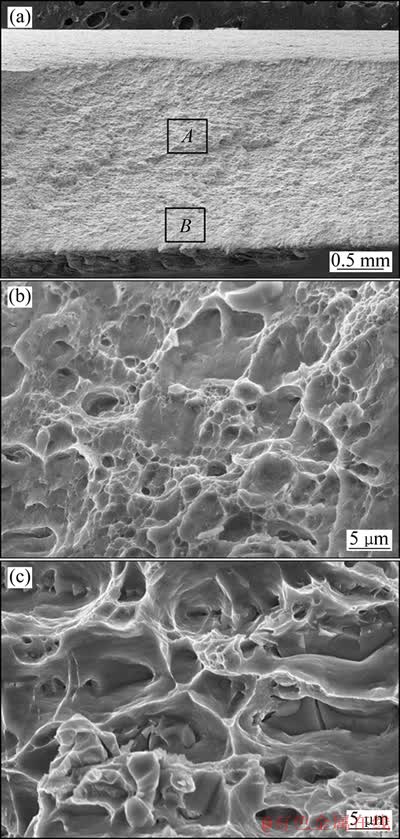

图7(a)所示为T型接头沿壁板方向加载的抗拉强度。发现焊接速度对同一种接头的抗拉强度无显著影响。A接头的平均拉伸强度(174.7 MPa)稍高于B接头的平均拉伸强度(170.3 MPa)和C接头(166.8 MPa)的平均拉伸强度。这与A接头壁板在焊接前本身就是一块完整的板材有关,而弱结合缺陷在B和C接头中垂直于拉伸方向分布,因此导致拉伸强度降低。拉伸时,这3种接头断裂多发生在轴肩的下方热影响区,即最低硬度分布周围,断口与受力方向成45°夹角,并伴有少量的颈缩(见图8(a))。通过SEM观测(见图9),断口微观形貌为典型韧窝,在某些较大韧窝底部,第2项粒子或者痕迹清晰可见,断裂方式属于典型的微孔聚集型断裂。因此,弱结合和软化作用是3种接头沿壁板强度降低的主要原因,而Z线的存在对3种接头沿壁板方向拉伸强度几乎没有影响。

图8 T型接头断裂位置宏观图

Fig. 8 Macrographs of fracture locations for T-joints

图9 T型接头沿壁板拉伸断口的宏观和微观SEM像

Fig. 9 SEM image of macro-fracture surface of skin (a) and higher magnification SEM images of region A (b) and region B (c) as selected in Fig. 9(a)

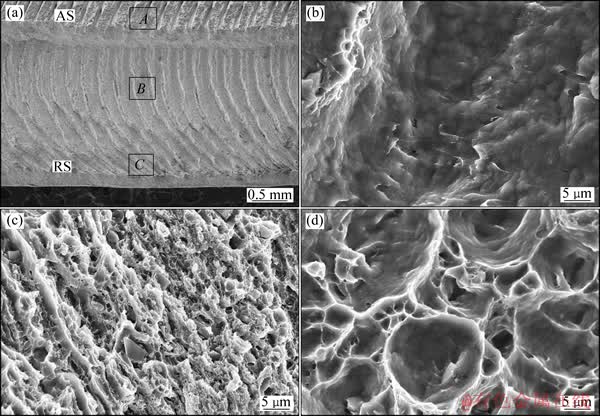

由于T型接头前进侧圆角过渡区域几乎都出现了不同程度的隧道缺陷以及延伸到筋板后退侧圆角区域的弱结合缺陷,使得沿筋板方向拉伸时接头强度数据较为分散 (见图7(b))。对A接头来说,随着焊接速度的增加,抗拉强度先增后减,在焊速142 mm/min时,A2接头尽管焊缝中存在缺陷但此时强度达到最高187.5 MPa,达到母材强度的77.8%。B接头的强度随着焊速的增加逐渐下降,这与之前讨论的隧道缺陷的面积逐渐增大有关,随着隧道缺陷面积增大,拉伸时有效承载面积减少,导致拉伸强度大大降低;当在焊速为75 mm/min得到的无隧道缺陷接头的强度仅为母材的66.7%,这主要与弱结合缺陷导致起裂有关。C接头的强度与A接头的变化规律一致,在焊速为142 mm/min时,抗拉强度达到母材的76.3%。这3种接头几乎都不是断裂在筋板的软化区,而是从后退侧圆角区域的弱结合处开始起裂并最终断裂在两板的结合面处(见图8(b))。通过SEM观测,断面为与拉伸轴垂直的粗糙面,并有搅拌工具行走留下的凸凹不平的痕迹(见图10(a)),前进侧表现为沿晶脆性断裂(见图10(b)),后退侧则呈现大量韧窝(见图10(d)),中间部分为塑性与脆性混合的准解理断裂模式(见图10(c)),这种断裂模式的差异与隧道缺陷和弱结合的分布有直接关系。

3 结论

1) 若焊接参数或者搅拌工具选择不合适,隧道缺陷和弱结合极易在铝合金搅拌摩擦焊T型接头中出现,并且在不同组合形式的T型接头中分布特征不同,通过减少焊接速度提高焊接热输入有助于此类缺陷的减少。

2) 搅拌摩擦焊T型接头除了包括焊核区、热机影响区、热影响区和母材,在筋板区域还包括两个圆角过渡区域,各个区域由于热循环和塑性变形的差异呈现不同的晶粒形态。

3) 3种组合形式的T型接头沿壁板硬度呈W型分布,沿筋板呈N型分布。硬度的变化与晶粒尺寸及强化相的状态有关,是二者共同作用的结果。

4) 壁板方向断裂主要是由热影响区软化与弱结合垂直于拉伸方向分布引起的,而“Z”线对 T型接头沿壁板方向拉伸的静载强度无明显影响;弱结合和隧道缺陷是沿筋板方向发生断裂的主要原因。

5) 当焊接工艺参数一定时,A接头的综合拉伸性能相比B接头和C接头的好,其中沿壁板方向的平均拉伸强度为174.7 MPa;焊速为142 mm/min时,沿筋板方向的拉伸强度最高可达到187.5 MPa,接头系数达到母材的77.8%。

图10 T型接头沿筋板拉伸断口的宏观和微观SEM像

Fig. 10 SEM image of macro-fracture surface of stringer (a) and higher magnification SEM images of regions A (b), B (c) and C (d) as selected in Fig.10(a)

REFERENCES

[1] FENG A H, CHEN D L, MA Z Y. Microstructure and cyclic deformation behavior of a friction-stir-welded 7075 Al alloy[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science, 2010, 41(4): 957-971.

[2] MISHRA R S, MA Z Y. Friction stir welding and processing[J]. Materials Science & Engineering R-Reports, 2005, 50(1/2): 1-78.

[3] BUFFA G, FRATINI L, MICARI F, SHIVPURI R. Material flow in FSW of T-joints: Experimental and numerical analysis[J]. International Journal of Material Forming, 2008, 1(Suppl): 1283-1286.

[4] BUFFA G, FRATINI L, MICARI F, SHIVPURI R. On the material flow in FSW of T-joints: Influence of geometrical and technological parameters[J]. International Journal of Advanced Manufacturing Technology, 2009, 44(5/6): 570-578.

[5] FRATINI L, BUFFA G, SHIVPURI R. Influence of material characteristics on plastomechanics of the FSW process for T-joints[J]. Materials & Design, 2009, 30(7): 2435-2445.

[6] FRATINI L, BUFFA G, PALMERI D. Using a neural network for predicting the average grain size in friction stir welding processes[J]. Computers and Structures, 2009, 87(17/18): 1166-1174.

[7] BUFFAL G, FRATINI L, RUISI V, Friction stir welding of tailored joints for industrial applications[J]. International Journal of Material Forming, 2009, 2(Suppl 1): 311-314.

[8] DONATI L, TOMESANI L, MORRI A. Structural T-joint produced by means of friction stir welding (FSW) with filling material[J]. International Journal of Material Forming, 2009, 2 (Suppl 1): 295-298.

[9] FLEMING P A, HENDRICKS C E, WILKES D M, COOK G E, STRAUSS A M. Automatic seam-tracking of friction stir welded T-joints[J]. International Journal of Advanced Manufacturing Technology, 2009, 45(5/6): 490-495.

[10] FRATINI L, BUFFA G, LO MONACO L. Improved FE model for simulation of friction stir welding of different materials[J]. Science and Technology of Welding and Joining, 2010, 15(3): 199-207.

[11] TAVARES S M O, CASTRO R A S, RICHTER-TRUMMER V, VILACA P, MOREIRA P M G P, de CASTRO P M S T. Friction stir welding of T-joints with dissimilar aluminum alloys: mechanical joint characterization[J]. Science and Technology of Welding and Joining, 2010, 15(4): 312-318.

[12] TAVARES S M O, AZEVEDO P C M, EMILIO B, RICHTER-TRUMMER V, FIGUEIREDO M A V, VILACA P, DE CASTRO P M S T. Friction stir welding of t-joints in dissimilar aluminum alloys[C]//American Society of Mechanical Engineers. Proceedings of the ASEM International Mechanical Engineering Congress and Exposition. New York: American Society of Mechanical Engineers, 2009: 265-273.

[13] FRATINI L, ACERRA F, BUFFA G, TROIANO G. On the FSW of AA2024-T4 and AA7075-T6 T-joints: An industrial case study[J]. International Journal of Advanced Manufacturing Technology, 2010, 48(9/12): 1149-1157.

[14] 王 磊, 谢里阳, 李 兵. 铝合金搅拌摩擦焊焊接过程缺陷分析[J]. 机械制造, 2008, 46(2): 5-9.

WANG Lei, XIE Li-yang, Li Bing. Defects analysis of friction stir welding process for aluminum alloy[J]. Mechanical Manufacture, 2008, 46(2): 5-9.

[15] LIU H J, CHEN Y C, FENG J C. Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al-Cu alloy[J]. Scripta Materialia, 2006, 55(3): 231-234.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50775159);高等学校博士学科点专项科研基金资助项目(20110032110027)

收稿日期:2013-01-04;修订日期:2013-04-07

通信作者:杨新岐,教授,博士;电话:022-27406261;E-mail:xqyang@tju.edu.cn