文章编号:1004-0609(2011)08-1929-07

含Mo金属陶瓷微波吸收材料的制备与性能

俞 雨1, 2,程继贵1, 2,梁槟星1

(1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 安徽省粉末冶金工程技术研究中心,合肥 230009)

摘 要:以Mo、AlN以及TiO2粉末为原料,添加适当的烧结助剂,制备出成形混合料,通过模压成形和烧结分别得到了不同Mo含量的Mo/AlN和Mo/TiO2金属陶瓷烧结体。采用X射线衍射仪、扫描电镜、万能材料试验机和矢量网络分析仪等对烧结体的相组成、显微组织、力学性能和微波吸收性能等进行测试分析。结果表明:Mo/AlN和Mo/TiO2成形压坯分别在1 750 ℃和1 350 ℃下烧结4 h,可以获得相对密度分别高于97%和94%的Mo/AlN和Mo/TiO2金属陶瓷。Mo/AlN金属陶瓷的力学性能随Mo含量的增加而提高,而Mo/TiO2金属陶瓷的力学性能随Mo含量的增加先升高后降低。Mo的加入明显改善AlN和TiO2陶瓷的微波吸收性能,含40%Mo(质量分数)的Mo/AlN和Mo/TiO2试样在14~18 GHz频率范围最大反射衰减量分别达到22 dB和19 dB。

关键词:Mo/AlN;Mo/TiO2;金属陶瓷;显微组织;力学性能;微波吸收性能

中图分类号:TQ174.75 文献标志码:A

Preparation and performance of

Mo-contained microwave-absorbing cermets

YU Yu1, 2, CHENG Ji-gui1, 2, LIANG Bin-xing1

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Powder Metallurgy Engineering and Technology Research Center of Anhui Province, Hefei 230009, China)

Abstract: Mo/AlN and Mo/TiO2 cermets were manufactured by a conventional pressing-sintering process using Mo, AlN and TiO2 as raw materials. The phase composition, microstructure, mechanical and microwave-absorbing properties of the sintered cermets were characterized by XRD, SEM, universal testing machine and network analyzer,respectively. The results show that Mo/AlN and Mo/TiO2 cermets with relative density of more than 97% and 94% can be obtained by sintering their compacts at 1 750 ℃ and 1 350 ℃ for 4 h, respectively. While the mechanical properties of the Mo/AlN cermets increase with Mo contents increasing, the mechanical properties of the Mo/TiO2 cermets first increase and then decrease with Mo content increasing. Mo addition improves the microwave-absorbing behaviors of AlN and TiO2 ceramics. Mo/AlN and Mo/TiO2 samples with 40% Mo (mass fraction) show a maximum reflection loss of 22 dB and 19 dB, respectively, in the frequency range of 14-18 GHz.

Key words: Mo/AlN; Mo/TiO2; cermets; microstructure; mechanical property; microwave-absorbing property

微波吸波材料通常是将半导体材料或易于极化的材料分散于介质基体内,依靠半导体材料的电荷载流子或极化材料的偶极子在高频场中移动或摆动来消耗高频能量,转化为热量传输出去[1]。随着微波电真空器件功率的增大,对其工作稳定性等提出更高的要求,从而促使新型高热导吸波材料的研究开发。目前,高功率微波电真空器件(如行波管等)多采用高导热型的吸波材料,主要包括氧化铍基复合衰减陶瓷、SiC基材料、渗碳多孔陶瓷以及新型金属陶瓷等[2]。

金属陶瓷具有高温稳定性好、导热率高、机械强度高、易于机械加工、金属化和焊接等优点。金属陶瓷用作微波吸材料,其吸波性能不受居里温度限制,且多种吸波机理共同作用使其微波吸收性能更强、吸收频段更宽,更符合微波吸收材料的“轻、薄、强、宽”的发展要求。因此,高热导的金属陶瓷成为目前吸波材料研究开发的热点之一[3-4]。

AlN陶瓷由于具有良好的力学性能、较高的导热率和适中的介电常数等,是优良的微波吸收基体材 料[5]。但其脆性大、介电常数可调范围小等也使其应用受到一定的限制。通过向AlN中填加适量的金属W等第二相,可以改善其微波性能,如研究表明,W、TiC和C等的加入可以明显改善材料AlN材料的微波吸收性能[6-7]。但高密度W的加入使成形料难以混合均匀,增大了材料制备的工艺难度。与W 相比,Mo密度较小、导热率较高,且热膨胀系数与AlN很接近(Mo和AlN在300~1 200 K范围内热膨胀系数分别为7×10-6 K-1与6.5×10-6 K-1)[8-9]。若复合Mo和AlN制得Mo/AlN复合吸波材料,可望进一步改善AlN性能,获得性能更为优异的吸波材料,同时减小制造工艺难度。目前,国内外对于Mo/AlN复合材料的研究主要集中在力学、电学和热学性能上,如通过热压烧结法制备出致密度超过97%,导热系数和抗弯强度分别达到100 W/(m?K)和500 MPa的AlN/Al复合材 料[8-9],而对于其微波吸收性能的研究却鲜有报道。由于AlN基(金属)陶瓷难以烧结致密化,而吸波材料通常要求较高的气密性(致密度),因此,为了获得高致密度AlN基陶瓷,国内外对此进行了较多的探索,如通过热压和添加烧结助剂等提高AlN基陶瓷的致密 度[9-10]。但热压工艺的成本较高,而烧结助剂若选择不当,则易导致材料导热性能等的降低。

TiO2作为一种禁带较宽、结构稳定的半导体材料也常用于改善材料的吸波性能[11]。如对添加TiO2的AlN-C复合材料吸波性能的研究结果表明:TiO2的加入明显改善AlN-C复相材料的吸波性能[12],但迄今有关以TiO2作为基体的金属陶瓷吸波材料的研究报道仍极少。因此,本文作者尝试以AlN和TiO2为基体,Mo为金属吸收剂,采用常规的压制成形和烧结工艺,制备高致密度的Mo/AlN和Mo/TiO2金属陶瓷,通过对其组织和性能进行测试分析,探索获得新型高性能Mo/AlN和Mo/TiO2金属陶瓷微波吸收材料的新途径。

1 实验

1.1 试样制备

实验采用的AlN、TiO2和Mo粉末的平均粒度分别为1.5、0.3和4.5 μm;复合烧结助剂由氧化钇(Y2O3,纯度99.95%)、氧化钙(CaO,纯度98.5%)和碳酸锂(Li2CO3,纯度99.99%)等组成;采用聚乙烯醇缩丁醛(PVB)为成形剂,乙醇为溶剂。实验中将AlN、TiO2和Mo粉末和烧结助剂按计量称取,与适量的成形剂(PVB)一起在无水乙醇中球磨24 h,干燥、造粒后,在100 MPa压力下压制成尺寸分别为d 15 mm×5 mm和40 mm×10 mm×5 mm的的圆柱状和条状压坯。所得Mo/AlN成形压坯先在N2气氛中预烧脱除成形剂后,再在碳管炉中于N2保护下进行烧结,烧结温度和保温时间分别为1 750 ℃和4 h。Mo/TiO2成形压坯先在H2气氛中预烧脱除成形剂,再在碳管炉中于Ar保护下烧结,烧结温度和保温时间分别为1 350 ℃和4 h。实验中分别制备了Mo含量为30%、35%及40%(质量分数)的Mo/AlN和Mo/TiO2金属陶瓷复合材料。同时制备了未添加Mo的纯AlN和TiO2陶瓷材料,与含Mo金属陶瓷试样作性能对比实验。

1.2 性能测试

采用Archimedes法对Mo/AlN和Mo/TiO2烧结体的密度进行测量,并计算其相对密度。采用DCS-5000型岛津万能材料试验机进行三点弯曲实验测试Mo/AlN和Mo/TiO2烧结体试样的抗弯强度和断裂韧性。分别采用Sirion200型场发射环境扫描电镜(美国FEI公司)以及D/Max-rB型X射线衍射仪(日本理学)对烧结体试样的微观组织和相组成等进行测试。采用Agilent8722ET 矢量网络分析仪测定不同Mo含量的Mo/AlN和Mo/TiO2试样在不同频率下的反射衰减率来表征其微波吸收性能。

抗弯强度采用三点弯曲测试,试样尺寸b×h×L为3 mm×4 mm×35 mm(b为试样厚度,h为宽度,L为长度),跨距l为30 mm,加载速率为0.5 mm/min。由下式求抗弯强度σf:

(1)

(1)

式中:F为载荷;l为跨距。

断裂韧性采用单边切口梁法测试,试样尺寸b× h×L为3 mm×4 mm×35 mm,缺口深(a)为2.5 mm、缺口宽0.1 mm的凹槽,采用三点弯曲加载方式,跨距为30 mm,则断裂韧性 为

为

(2)

(2)

式中:Y为缺口几何因子。

(3)

(3)

2 结果与讨论

2.1 金属陶瓷压坯的烧结致密化

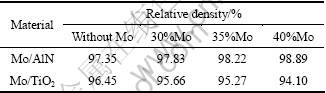

吸波材料必须有高的致密度,以保证其在真空环境下长期稳定地工作。表1所列为不同Mo含量Mo/AlN和Mo/TiO2烧结体的相对密度的测定结果。由表1可以看出,不同Mo含量Mo/AlN烧结体的相对密度都在97%以上,且相对密度随Mo加入量的增加而提高。这可能是由于在制备Mo/AlN试样时,成形料中添加了约2%(外加)的复合氧化物烧结助剂,而随着试样中Mo含量的增加,烧结助剂的体积含量相对增加,这有利于促进烧结致密化的进行[13]。相反地,Mo/TiO2烧结体的相对密度随Mo含量的增加有降低的趋势。这是由于Mo/TiO2金属陶瓷中Mo较TiO2难以烧结,Mo/TiO2金属陶瓷的致密化主要取决于TiO2 陶瓷的烧结,而随着Mo含量的增加,其对烧结致密化的阻碍作用增强,结果导致烧结体相对密度的降低。

表1 不同Mo含量的金属陶瓷的相对密度

Table 1 Relative density of cermets with different Mo contents

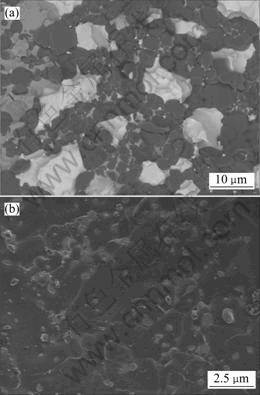

图1所示为Mo含量为35%的Mo/AlN和Mo/TiO2金属陶瓷样品的SEM像。由图1中可以看出,烧结体组织致密,没有明显的气孔。这与表1的测试结果相一致。图1(a)表明,Mo/AlN试样中,Mo颗粒(浅色)均匀分散于AlN(深色)基体中,且两相结合良好。图1(b)则显示Mo/TiO2金属陶瓷烧结体组织致密,Mo颗粒同样均匀分散于TiO2基体中。Mo/AlN和Mo/TiO2金属陶瓷高的烧结致密化和良好的晶粒结合有利于其力学性能的提高,并可以提高其在真空环境中工作的稳定性。

图1 Mo含量为35%的Mo/AlN和Mo/TiO2样品表面的SEM像

Fig.1 SEM images of Mo/AlN(a) and Mo/TiO2(b) cermets surfaces with 35% Mo

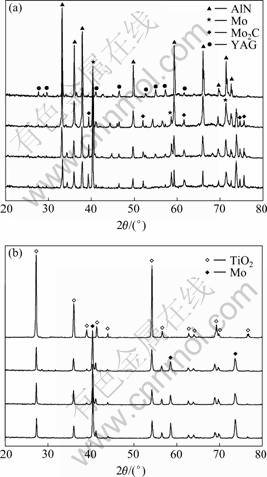

2.2 Mo/AlN和Mo/TiO2金属陶瓷的相组成分析

图2所示为不同Mo含量的Mo/AlN和Mo/TiO2金属陶瓷烧结体试样的XRD谱。图2(a)表明,Mo/AlN烧结体主要由AlN和Mo相所组成。同时,复合氧化物烧结助剂在烧结过程中通过反应生成了少量YAG(Y3Al5O12)相。另外,在含Mo的试样中出现少量的Mo2C相,这可能是由于实验中采用石墨烧舟,在高温烧结时,Mo发生碳化反应所致。由图2(b)可见,不同Mo含量Mo/TiO2试样仅由Mo和TiO2两相组成,且TiO2是以最稳定的金红石状态存在。在Mo/TiO2金属陶瓷的XRD谱中未出现Mo2C相,可能因其烧结温度较低,碳化反应程度较轻所致。

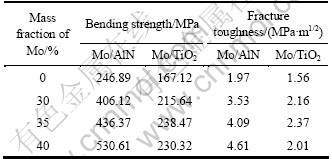

2.3 Mo/AlN和Mo/TiO2金属陶瓷的力学性能

表2所列为不同Mo的含量Mo/AlN和Mo/TiO2金属陶瓷试样抗弯强度与断裂韧性(KIC)的测量结 果。从表2中可以看出,Mo/AlN烧结体的抗弯强度与断裂韧性(KIC)均随着Mo含量的增加而提高。这主要是由于金属Mo颗粒可以阻碍材料断裂时裂纹的扩展,起到增韧补强的作用[14]。Mo含量为40%时Mo/AlN金属陶瓷的抗弯强度和KIC分别达到530.61 MPa和4.61 MPa·m1/2。Mo/TiO2试样的抗弯强度和KIC则在Mo含量为35%时最高,分别为238.47 MPa和2.37 MPa·m1/2。当Mo/TiO2金属陶瓷中Mo含量从30%增加到35%时,Mo/TiO2金属陶瓷的致密度仅下降了0.39%,Mo含量的增加起到增韧补强的作用并抵消少量气孔对于力学性能的不利影响,所以随着Mo含量增加,Mo/TiO2金属陶瓷的力学性能随之提高;当Mo/TiO2金属陶瓷中Mo含量从35%增加到40%时,Mo/TiO2金属陶瓷的致密度下降了1.17%,致密度的大幅下降不但抵消了Mo增韧补强的作用,还大大增加裂纹扩展的途径,从而导致Mo/TiO2金属陶瓷力学性能的下降[15]。

图2 不同Mo含量的金属陶瓷烧结体的XRD谱

Fig.2 XRD patterns of cermet sintered bodies with different Mo contents: (a) Mo/AlN; (b) Mo/TiO2

表2 不同Mo含量的金属陶瓷的力学性能

Table 2 Mechanical properties of cermets with different Mo contents

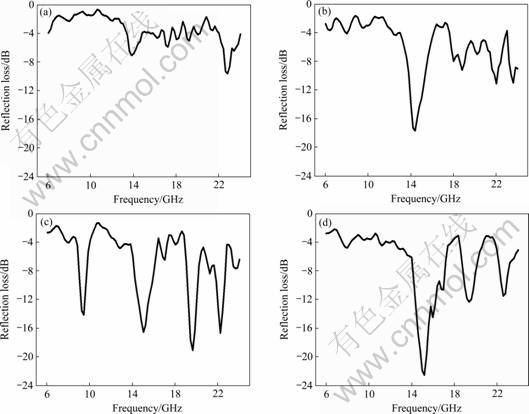

2.4 Mo含量对金属陶瓷的微波吸收性能的影响

金属陶瓷微波吸收材料是由基体材料与衰减剂复合而成,吸波性能可以通过反射衰减量来表征。把烧结体加工成3 mm厚的块状试样后,在Agilent8722ET 矢量网络分析仪上用测量线方程获得驻波系数(ρ)[16]

(Imax和Imin分别为检波最大和最小电流),计算出反射系数

(Imax和Imin分别为检波最大和最小电流),计算出反射系数 ,最后获得反射衰减量

,最后获得反射衰减量 。

。

图3所示为不同Mo含量Mo/AlN试样在6~24 GHz频段内的反射衰减量—频率(R—F)曲线。从图3可以看出,Mo的加入明显改善AlN材料的吸波性能。纯AlN的微波吸收性能较差,最大反射衰减量也只有10 dB。且随着Mo含量的增加,试样的吸收性能随之增 强,最低谐振频率向高频段偏移。当Mo含量为35%时,试样的最低谐振频段在9~10 GHz之间,且吸收频谱特性呈现多频段吸收特性,最大反射衰减量达 18 dB,表现出良好的选频吸收性。而当Mo含量为40%时,吸收频段最宽,在14~18 GHz的频段内,吸收效果较佳,最大反射衰减量达22 dB,表现出良好的宽频吸收特性。

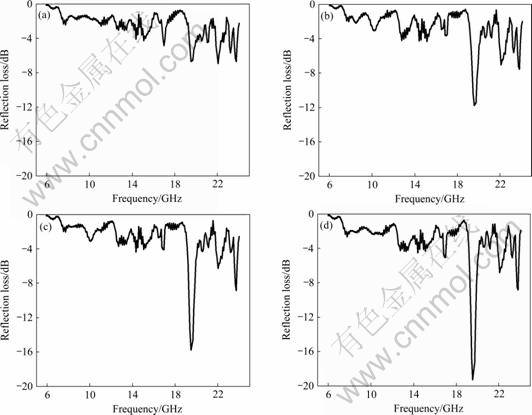

图4所示为不同Mo含量的Mo/TiO2试样在6~24 GHz频段内的R—F曲线。由图4可以看出,试样最低谐振峰都在19~20 GHz之间,吸收性能随着Mo含量的增加而提高,反射衰减量含Mo量为40%时,最大反射衰减量达19 dB。和Mo/AlN试样相比,Mo/TiO2在19~20 GHz之间有着很强的微波衰减性能,但在其他的波段,并没有表现出宽屏吸收。

2.5 含Mo金属陶瓷微波吸收机理

在含Mo金属陶瓷吸波材料中,Mo是很好的导电相,属于电阻型损耗吸波材料[17-18]。因此,吸收剂的Mo含量是影响金属陶瓷复相材料微波吸收性能的主导因素。由于电磁波在损耗只取决于电损耗而没有磁损耗的媒质中传播的复波数k为[19]

,

,

式中:k′为实波数;k″为衰减系数;σ为电导率;ω为角频率;μ为介质磁导率;μ0为真空磁导率。

图3 不同Mo含量Mo/AlN金属陶瓷的R—F曲线

Fig.3 R—F curves of Mo/AlN cermets with different Mo contents: (a) Without Mo; (b) 30%Mo; (c) 35%Mo; (d) 40%Mo

图4 不同Mo含量Mo/TiO2金属陶瓷的R—F曲线

Fig.4 R—F curves of Mo/TiO2 cermets with different Mo contents: (a) Without Mo; (b) 30%Mo; (c) 35%Mo; (d) 40%Mo

由此可见,媒质的电导率增大,衰减系数增大。但金属是微波的导体,微波只能在其表面反射电磁波,电磁波不能到达导体的深处,电磁波会在材料表面激发高频振荡电流向外辐射电磁波,形成反射波。因此,完全的高电导率金属材料很难成为微波吸收材料,且将全部反射电磁波。

AlN和TiO2陶瓷介质属于微波绝缘体可透过微波且对微波的吸收也很少[8],这和图5和6中纯AlN和TiO2所反映出的吸波性能不佳是一致的。Mo/AlN和Mo/TiO2金属陶瓷是通过在陶瓷介质AlN和TiO2中添加金属相Mo弥散质点。导电颗粒相当于偶极子,微波在其间产生多次反复的阻尼震动,使得电磁波损耗转化成热能传导出去。另一方面,Mo/AlN和Mo/TiO2金属陶瓷是由晶粒和晶界相、位错、反相畴界和多型体等多种结构缺陷形成的非均质体系,主晶相AIN或TiO2与晶界相间和Mo相间电导率的差异会成为自由电荷(间隙离子、空位和引入的电子等)运动的障碍[17]。因此,当Mo/AlN和Mo/TiO2金属陶瓷处于微波电磁场中,必将在不同相的界面上产生电荷堆积,形成空间电荷极化,这种极化形式致使Mo/AlN和Mo/TiO2金属陶瓷在电磁场的弛豫时间较长,同时需要吸收一定的微波能量,从而能起到一定的微波衰减作用。

研究结果显示,不同Mo含量的Mo/AlN和Mo/TiO2复合材料表现出不同的微波吸收性能,其原因可能在于AlN是一种电绝缘材料,而TiO2是一种半导体材料。Mo的加入增加了微波在AlN陶瓷中的阻尼震动,从而提高了微波吸收性能;而在TiO2陶瓷中,Mo的加入不仅增加了微波的阻尼震动,还增加了TiO2陶瓷的电导,使得电阻损耗增加,从而提高陶瓷的微波吸收性能。随着Mo含量的增加,Mo/AlN表现出一定的宽屏吸收,而Mo/TiO2却没有,这主要是由于Mo/AlN金属陶瓷中含有一定的烧结助剂,这些烧结助剂增加Mo/AlN金属陶瓷中的非均质体系,从而使得Mo/AlN金属陶瓷具有一定宽屏吸收的特点。

3 结论

1) 通过添加复合烧结助剂,以常规的压制烧结工艺,在较低的烧结温度下可以制备出相对密度分别高于97%和94%的Mo/AlN和Mo/ TiO2金属陶瓷烧结体。

2) Mo含量对Mo/AlN和Mo/TiO2金属陶瓷的力学性能有明显的影响,Mo/AlN金属陶瓷的力学性能随Mo含量的增加而提高,而Mo/TiO2金属陶瓷的力学性能随Mo含量增加呈现先提高后下降的趋势。

3) Mo的加入明显改善AlN和TiO2的微波吸收性能。含40%Mo的Mo/AlN试样的最大反射衰减量可达22 dB,且吸收频段较宽。含40%Mo的Mo/TiO2试样的最大反射衰减量为19 dB,表现选频吸收的特性。因此,Mo/AlN材料的微波吸收性能优于Mo/TiO2材料的。

REFERENCES

[1] 王海滨, 刘树信, 霍翼川, 吕淑珍. 无机吸波材料研究进展[J]. 硅酸盐通报, 2008, 27(4): 754-758.

WANG Hai-bin, LIU Shu-xin, HUO Ji-chuan, L? Shu-zhen. Progress on inorganic wave-absorbing materials[J]. Bulletin of The Chinese Ceramic Society, 2008, 27(4): 754-758.

[2] 孟建华, 杨桂琴, 严乐美, 王秀宇. 吸波材料的研究进展[J]. 磁性材料与器件, 2004, 35(4): 11-14.

MENG Jian-hua, YANG Gui-qin, YAN Le-mei, WANG Xiu-yu. Research progress in microwave absorbing materials[J]. Journal of Magnetic Materials and Devices, 2004, 35(4): 11-14.

[3] 高陇桥. 高热导率陶瓷材料的进展[J]. 真空电子技术, 2003(2): 49-53.

GAO Long-qiao. The progress of high thermal conductivity ceramic materials[J]. Vacuum Electronics, 2003(2): 49-53.

[4] 孙晶晶, 李建保, 张 波, 翟华嶂, 孙格靓. 陶瓷吸波材料的研究现状[J]. 材料工程, 2003(2): 43-47.

SUN Jing-jing, LI Jian-bao, ZHANG Bo, ZHAI Hua-zhang, SUN Ge-liang. Current status of ceramics materials in electromagnetic wave absorbing[J]. Journal of Materials Engineering, 2003(2): 43-47.

[5] 郜玉含, 李晓云, 丘 泰. 氮化铝基微波衰减材料在高频行波管中的应用[J]. 材料导报, 2008, 22(10): 22-27.

GAO Yu-an, LI Xiao-yun, QIU Tai. AlN-based microwave loss materials used for high frequency traveling wave tube[J]. Materials Review, 2008, 22(10): 22-27.

[6] 陈贵巧, 李晓云, 丘 泰. AlN-W复相微波衰减材料的性能研究[J]. 中国陶瓷工业, 2006, 13(4): 22-25.

CHEN Gui-qiao, LI Xiao-yun, QIU Tai. Study on performance of AlN-W composites with microwave attenuation characteristics[J]. China Ceramic Industry, 2006, 13(4): 22-25.

[7] 程卫华, 李晓云, 丘 泰, 贾杪蕾. AlN-TiC复相微波衰减材料性能的研究[J]. 电子元件与材料, 2008, 27(1): 26-25.

CHENG Wei-hua, LI Xiao-yun, QIU Tai, JIA Miao-lei. Study on performance of AlN-TiC composites with microwave attenuation characteristics[J]. Electronic Components and Materials, 2008, 27(1): 26-25.

[8] KHAN A A, LABBE J C. Aluminium nitride/molybdenum ceramic matrix composites. influence of molybdenuum addition on electrical, mechanical and thermal properties[J]. Journal of the European Ceramic Society, 1997, 17: 1885-1890.

[9] KHAN A A, LABBE J C. Aluminium nitride/molybdenum ceramic matrix composites: Characterization of ceramic-metal interface[J]. Journal of the European Ceramic Society, 1996, 16: 739-744.

[10] 乔 梁, 周和平. Li2O对低温烧结AlN陶瓷热导率的影响[J]. 材料科学与工程, 2002, 20(4): 490-498.

QIAO Liang, ZHOU He-ping. Effect of Li2O on the thermal conductivity of AlN ceramics sintered at low temperature[J]. Materials Science and Engineering, 2002, 20(4): 490-498.

[11] 田雨霖. TiO2陶瓷的复合功能特性[J]. 硅酸盐通报, 1994, 13(6): 32-34.

TIAN Yu-lin. Composite function characteristics of TiO2 ceramic[J]. Bulletin of the Chinese Ceramic Society, 1994, 13(6): 32-34.

[12] 吴华忠, 李晓云, 丘 泰. TiO2对AlN-C复相材料性能的影响[J]. 电子元件与材料, 2009, 28(7): 61-64.

WU Hua-zhong, LI Xiao-yun, QIU Tai. Effect of TiO2 on characteristics of AlN-C composite material[J]. Electronic Components and Materials, 2009, 28(7): 61-64.

[13] QIU J Y, HOTTA Y, WATARI K, MITSUISHI K, YAMAZAKI M. Low-temperature sintering behavior of the nano-sized AlN powder achieved by super-fine grinding mill with Y2O3 and CaO additives[J]. Journal of the European Ceramic Society, 2006, 26(4/5): 385-390.

[14] SBAIZERO O, PEZZOTTI G. Residual stresses and R-curve behavior of AlN/Mo composite[J]. Journal of the European Ceramic Society, 2001, 21(3): 269-275.

[15] 王业亮, 傅正义, 王 皓, 张金咏. TiB2-TiC复相陶瓷的结构与性能研究[J]. 复合材料学报, 2003, 20(1): 22-26.

WANG Ye-liang, FU Zheng-yi, WANG Hao, ZHANG Jin-yong. Study on the structure and properties of TiB2-TiC multiphase ceramics[J]. Acta Material Compositae Sinica, 2003, 20(1): 22-26.

[16] 吴明忠, 赵振声, 何华辉. 结构型RAM对斜入射电磁波的反射和透射[J]. 功能材料, 1999, 4(30): 366-368.

WU Ming-zhong, ZHAO Zhen-sheng, HE Hua-hui. The reflection and transmission coefficients of structural RAM on oblique incidence electromagnetic wave[J]. Journal of Functional Materials, 1999, 4(30): 366-368.

[17] 马会娜, 杨志民, 杜 军. 氮化铝/导电颗粒复合微波衰减陶瓷的研究现状[J]. 材料导报, 2008, 22(4): 5-9.

MA Hui-na, YANG Zhi-min, DU Jun. Research situation of AlN/conductive particles microwave attenuation composite ceramics[J]. Materials Review, 2008, 22(4): 5-9.

[18] 李黎明, 徐 政. 吸波材料的微波损耗机理及结构设计[J]. 现代技术陶瓷, 2004, 25(2): 31-34.

LI Li-ming, XU Zheng. Physical mechanisms of the absorbing function in microwave-absorbing material and its composite design[J]. Advanced Ceramics, 2004, 25(2): 31-34.

[19] 康 青. 新型微波吸收材料[M]. 北京: 科学出版, 2006: 1-2.

KANG Qing. Novel microwave-absorbing materials[M]. Beijing: Science Press, 2006: 1-2.

(编辑 李艳红)

基金项目:国家特种显示工程中心资金项目(042301D2)

收稿日期:2010-07-16;修订日期:2011-01-12

通信作者:程继贵,教授,博士;电话:0551-2901793;E-mail: jgcheng63@sina.com