文章编号:1004-0609(2015)-07-1815-07

6061-T6铝合金高温本构模型及温成形数值模拟

盈 亮1, 3,戴明华2, 胡 平3,闫巧云3

(1. 大连理工大学 材料科学与工程学院,大连116024;

2. 大连理工大学 机械工程学院,大连 116024;

3. 大连理工大学 汽车工程学院,大连 116024)

摘 要:基于6061-T6铝合金在高温变形过程中的动态回复、动态再结晶及变形硬化特性,分析其在不同温度阶段的黏塑性特征,在高温阶段进一步引入软化因子修正传统Field-Backofen模型,使之适用于铝合金温成形的热力本构描述。通过NAKAJIMA凸模胀形数值仿真及试验对比发现:高低温(25~400 ℃)相结合的软化型热拉伸本构方程可以准确地描述板料破裂前的集中软化特征,且可以有效满足6061铝合金高温成形性能的仿真需求。

关键词: 6061铝合金;温成形;热力拉伸;本构模型;数值仿真

中图分类号: TG146.2 文献标志码:A

Thermal constitutive model and numerical simulation of hot forming for 6061-T6 aluminum alloy

YING Liang1, 3, DAI Ming-hua2, HU Ping3, YAN Qiao-yun3

(1. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China;

3. School of Automotive Engineering, Dalian University of Technology, Dalian 116024, China)

Abstract: Based on the dynamic recovery, dynamic recrystallization and deformation hardening characteristics of 6061-T6 aluminum alloy happened in the high temperature deformation process, the viscoplastic features at different temperatures were analyzed. The modified Field-Backofen model introduced with a softening factor was put forward to describe the thermal mechanics and constitutive model of aluminum alloy for hot forming. Combined with the experimental and simulation comparison research of NAKAJIMA test, the softening constitutive equation in the temperature range of 25-400 ℃ for hot forming is obtained and especially suitable for describing the behavior of sheet concentrate softening before crack, which is verified to be effective while applied to numerical simulation of forming process for 6061 aluminum alloy in hot forming.

Key words: 6061 Al alloy; hot forming; thermal tensile; constitutive model; numerical simulation

铝合金板材因其密度低、比强度高的特点,已逐步成为了汽车车身轻量化研究和航空航天材料研究的重点对象,然而铝合金的应用推广受到其自身塑性的局限,铝合金温成形技术的提出,为铝合金板材的应用提供了新方法和新工艺,也引起了国内学者的广泛研究[1-10],然而铝合金板材牌号众多,热处理状态各异,要想通过温成形技术实现板材成形性和强度性能的双重提升,其对象的选择尤为重要。AA5754等5000系铝镁合金由于强度低,成形件表面质量难以保证,一直未能通过温成形技术实现产业化,再加上近年来研制的AA5182铝合金塑性显著提升,使得温成形技术逐渐应用在可热处理强化的铝合金上。近年来,一些研究者[11-14]对高强铝合金7075、7B04开展了温成形研究,然而7075铝合金价格高、成本大,主要用于航空航天领域,因此,可考虑选用强化态的6000系合金板材进行车身轻量化温成形技术研究。

金属板材本构方程的研究一直是冲压成形研究的重点,针对可热处理强化的6061-T6商业铝合金,目前的研究和应用仍主要集中在合金的时效处理[15]、铝型材的冷、热挤压成型和板材的常温成形上,例如,赵培峰等[16]主要研究了6061铝合金锻件的流变特性,得到了其在高温压缩稳态时的本构关系;巫荣海[17]和姚鹏[18]基于6061铝合金铸锭,分别开展了523~723K温度区间不同应变率条件和375~500℃条件下的热压缩实验,并基于Zener-Hollmon参数模型得到了本构方程。在国外,6061铝合金板材的热力本构模型研究也鲜见报道,MAHABUNPHACHAI等[6]为对比研究5052和6061铝合金的高温液压成形性,采用胀形实验和热拉伸实验分别得到了6061铝合金在23、100、200和300 ℃各温度下的本构方程,然而该本构模型仅是4个温度下的独立流变曲线,没有实现温度的耦合,局限性较大,而且不能表征更高温度下6061铝合金板材的高温流变特性。本文作者基于高温热力拉伸试验,通过分析6061铝合金在不同高温条件下的动 态回复和动态再结晶变化过程,分别引入传统Field-Backofen方程和修正的Field-Backofen方程构建低温动态回复型、高温动态再结晶型相结合的软化型热拉伸模型,并且对6061的T6强化态合金薄板进行了高温性能描述,并进一步将该本构模型和MAHABUNPHACHAI[6]推出的硬化型热拉伸本构模型分别应用于温成形有限元数值仿真分析过程,并进一步通过与试验结果对比分析了两种模型的优缺点、有效性和普适性。

1 高温热力拉伸实验

温成形技术是指把合金板材加热到一定温度,使材料变软、流动性增大后放入模具中冲压成形,从而得到成形深度大、结构复杂的零部件的工艺过程。为得到适用于温成形数值仿真的本构模型,需要先开展材料的高温热力拉伸实验。试验材料为AA6061-T6,其化学成分为Si 0.40~0.80,Fe <0.70, Cu 0.15~0.40,Mn<0.15,Mg 0.80~1.20,Cr 0.04~0.35,Zn<0.25,Ti<0.15;其抗拉强度349 MPa,屈服强度288 MPa,熔点580~650 ℃。试验所用哑铃试样为根据国标 GB/T 4338—2006所设计。试验时,先将试样装夹到WDW100热力拉伸机,加热到设定温度保温1 min,然后采用位移加载直至断裂。试验温度区间为25~400 ℃,应变速率分别为0.01和0.1 s-1。温度和应变率由计算机系统自动控制,标距内变形经高温引伸计采集。

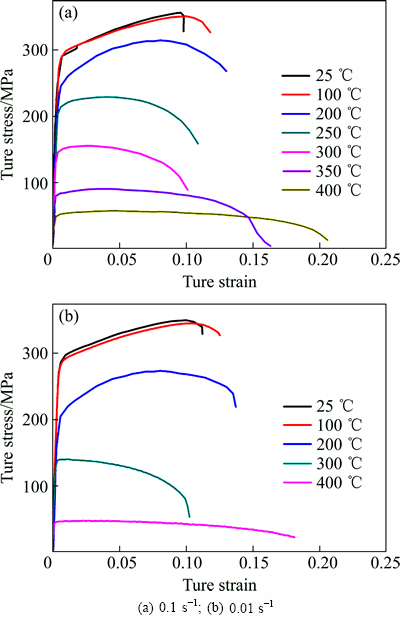

不同应变速率和温度下AA6061-T6铝合金的真应力-真应变曲线如图1所示。由图1可知,随应变增大,应力先迅速增大;发生屈服后,应力增大的趋势变缓,当应变超过一定值后,应力维持不变或者缓慢下降,直至断裂发生。在弹性阶段,各温度下材料的弹性模量(斜率)几乎保持不变,而当塑性变形发生时,合金材料组织才受到温度影响,且温度越高,屈服强度越低,抗拉强度也越低。

图1 不同应变速率和温度下AA6061-T6铝合金的真应力-真应变曲线

Fig. 1 True stress-strain curves of AA6061-T6 aluminum alloy at different strain rates and temperatures

AA6061-T6铝合金的室温强度高达350 MPa,但延展性较差;当温度升高到100 ℃时,材料的强度及延展性无明显变化,当温度上升到200 ℃时,成形极限应变提升,强度降低;温度继续升高时,其极限应变也降低,使得极限应变呈现先增大后降低最后再增大的现象,并在200 ℃时出现峰值,其结果与断后伸长率分析相一致。当温度为200 ℃、应变率为0.01 s-1时,6061铝合金的伸长率从10.75%提高到15.89%,提升47.75%,有效改善了强化铝合金的成形特性,该部分延展性的提升对其在车身覆盖件中的应用至关重要。此外,拉伸速度越低,延展性越好。

当温度低于200 ℃时,AA6061铝合金的应力随塑性应变增加而增大,曲线表现为“强化”特性;当温度高于200 ℃时,则表现出明显的“软化”现象,这是由于温度达到再结晶温度(0.4倍熔点温度)以上时,AA6061铝合金的显微组织发生第二相析出及晶粒长大等变化,产生了动态再结晶过程。

2 本构模型

由铝合金板材温热变形机理[17]可知,铝合金晶粒在变形过程中会发生滑移而出现位错的纠结,产生“变形硬化”;与此同时,板材的塑性变形使组织处于不稳定状态,呈自发恢复到变形前组织状态的倾向,而加热则会使原子扩散能力增强,使金属发生回复、再结晶和晶粒长大等过程,进而抵消铝合金的“变形硬化”现象。

实验结果表明,低温情况下由于原子扩散能力低,金属组织变化不明显,但会由于金属中点缺陷及位错的近距离迁移而引起晶内发生动态回复过程。动态回复不能完全抵消“变形硬化”,使得其流变应力曲线仍呈现出“强化”特征,可采用Field-Backofen方程对其进行描述:

(1)

(1)

式中:εp为有效塑性应变;C为强化系数;n为应变强化指数;m为应变率敏感指数;其中,C、n、m均为温度T的函数,并将其称为“动态回复型”本构方程。在某特定温度下,应变强化指数n可根据实验数据由式(2)计算得到:

(2)

(2)

同理,应变率敏感指数m在一定温度下的值也可以由式(3)计算得到:

(3)

(3)

铝合金被加热到较高温度时,原子活力增大,晶粒形状发生变化,破碎拉长的晶粒变为完整的等轴晶粒,发生动态再结晶过程,完全消除了晶粒的“变形硬化”过程,使流动应力曲线表现出明显的软化特性,即达到峰值应力后,材料趋于一种稳定的流变应力状态。此时,采用传统Field-Backofen模型已不能准确描述其特性,而需采用张先宏等[19]提出的加入温度、应变率相关的软化系数Z的数学模型:

(4)

(4)

式中:p为温度补偿因子;q为软化因子。

进而得到修正的Field-Backofen模型为

(5)

(5)

3 模型参数的确定

3.1 低温阶段的动态回复型模型

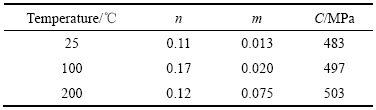

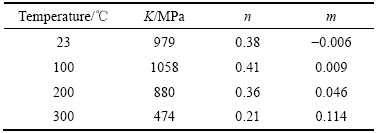

基于式(2)、(3)和实验数据,对板材在25~200 ℃温度区间的拉伸应变硬化指数n和应变率敏感系数(m)进行计算,结果如表1所列。

表1 AA6061铝合金板材在不同温度下的性能参数(25~ 200 ℃)

Table 1 Parameters of 6061 alloy at different temperatures

因此,根据表中数据可确定强化系数C,n,m随温度T变化的函数表达式为

(6)

(6)

(7)

(7)

(8)

(8)

3.2 高温阶段的动态再结晶模型

当温度在200 ℃以上时,采用修正的Field-Backofen模型进行参数计算。由于式(5)中未知量较多,可采用单变量假设法对各参数进行求解。首先,根据式(2)求得n值,并取其平均值得n=0.125。然后对式(5)取自然对数可得:

(9)

(9)

当温度和应变为定值时,令

(10)

(10)

则式(10)可变换为

(11)

(11)

则

(12)

(12)

式中: 、

、 分别为热力拉伸试验的不同应变率条件下的塑性应变;

分别为热力拉伸试验的不同应变率条件下的塑性应变; 、

、 分别为该应变率下特定温度条件下某应变对应的应力值。

分别为该应变率下特定温度条件下某应变对应的应力值。

通过改变温度和应变率的组合,可计算得到系列mi值,取平均即可得到应变率敏感系数m:

(13)

(13)

基于200 ℃温度以上工况的试验数据,求得最终m=0.662。

同理,当应变速率和应变为定值时,令

(14)

(14)

则

(15)

(15)

(16)

(16)

式中:Ti、Tj分别指不同的成形温度; 、

、 为该成形温度下特定应变率条件下某应变对应力值。根据试验数据计算得最终p=-0.0095。

为该成形温度下特定应变率条件下某应变对应力值。根据试验数据计算得最终p=-0.0095。

当应变率和温度为定值时,令

(17)

(17)

则

(18)

(18)

(19)

(19)

式中: 、

、 指特定应变率和温度下的不同应变值;

指特定应变率和温度下的不同应变值; 、

、 指上述应变对应的应力值。根据试验数据计算得到最终q=-4.8。最后,将计算所得n、m、p、q的值代入式(5),然后与试验数据对比,求得参数C=22180。因此,基于修正的Field-Backofen模型的热拉伸方程为

指上述应变对应的应力值。根据试验数据计算得到最终q=-4.8。最后,将计算所得n、m、p、q的值代入式(5),然后与试验数据对比,求得参数C=22180。因此,基于修正的Field-Backofen模型的热拉伸方程为

(20)

(20)

3.3 显著性检测

综上所述,得到6061-T6铝合金的软化型热拉伸方程为

(21)

(21)

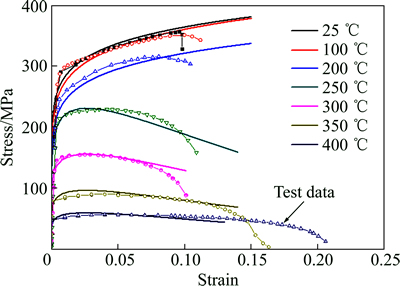

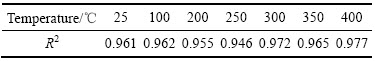

绘制25~400 ℃温度区间的真应力-真应变曲线如图2所示,并采用可靠性系数R2对拟合方程进行可靠性检验,R2定义如下:

(22)

(22)

式中: 为对应yi在i点的预测值;

为对应yi在i点的预测值; 为系列yi的平均值。

为系列yi的平均值。

R2越接近于1,曲线拟合效果越好。代入数据求得各温度下各R2值如表2所列,均接近于1,特别是在高温300 ℃以上仍能实现很好的匹配,说明采用动态回复和动态再结晶相结合的模型能很好地描述强化态铝合金的高温流变特性。

图2 25~400 ℃时6061铝合金的真应力-真应变曲线

Fig. 2 True stress-strain curves of 6061 aluminum alloy at temperatures of 25-400 ℃

表2 不同温度下的可靠性系数R2值

Table 2 Reliability coefficient value at different temperatures

4 本构模型的仿真应用

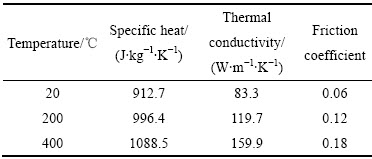

将所得本构方程应用于限元仿真软件Dynaform中,对凸模胀形试验开展仿真研究,并将其结果与文献[6]中硬化型本构的仿真结果进行比对分析。文献[6]的热拉伸本构参数如表3所列。

表3 文献[6]中基于 得到的6061铝合金的材料模型参数

得到的6061铝合金的材料模型参数

Table 3 Material constants of 6061 aluminum alloy based on model  extracted from Ref. [6]

extracted from Ref. [6]

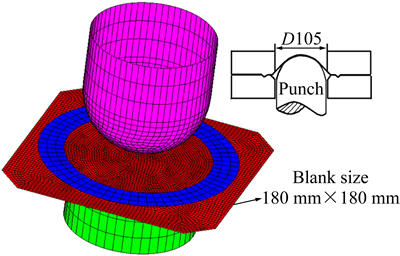

NAKAJIMA半球形凸模胀形试验仿真模型如图3所示,模型由7949个有限元壳单元网格组成,厚度方向上的积分点个数为5,材料模型选用热力耦合MAT#106模型。6061铝合金的接触热传导系数为1500 W/(m2·K),比热容、热传导系数和摩擦因数等温度敏感性参数如表4所列。

4.1 成形极限高度LDH分析

胀形仿真过程与实际试验过程一致,板料初始为某设定温度,模具为常温,在压边圈作用下,板料四周被压死,中部在冲头力作用下发生非等温胀形过程,冲头下行速度110 mm/s。为分析两种本构方程的异同,先对不同温度条件下成形件的最大成形高度LDH进行分析。

图3 NAKAJIMA半球形凸模胀形试验仿真模型

Fig. 3 NAKAJIMA hemispherical punch bulging test simulation model

表4 6061铝合金的高温热物理参数

Table 4 Thermal physical parameters of 6061 aluminum alloy at elevated temperatures

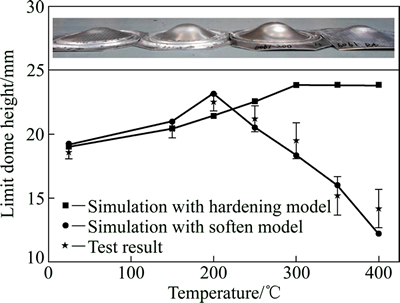

仿真采用20%的厚度减薄率作为破裂判断标准,当板料的任一位置减薄达20%时,则认为破裂发生,仿真和实验所得最大成形高度如图4所示。由实验可知,随着成形温度的提高,快速胀形所得样件的高度并不是一直增高,而是呈现一个先增高后降低的现象,当成形温度较高时,铝合金会由于局部软化而发生破裂。对比本文作者得到的软化型本构模型及文献[6]提出的硬化性本构模型可知,硬化型本构只适用于低温成形阶段,因而具有一定的局限性和较低的准确性,而软化型本构模型则能更加准确地描述高温材料的成形破裂特性,特别是在高温阶段,能对成形破裂过程中的软化特性进行有效表征。

图4 不同温度下6061铝合金的成形极限高度

Fig. 4 Limit dome height of 6061 aluminum alloy at different temperatures

4.2 成形件厚度情况分析

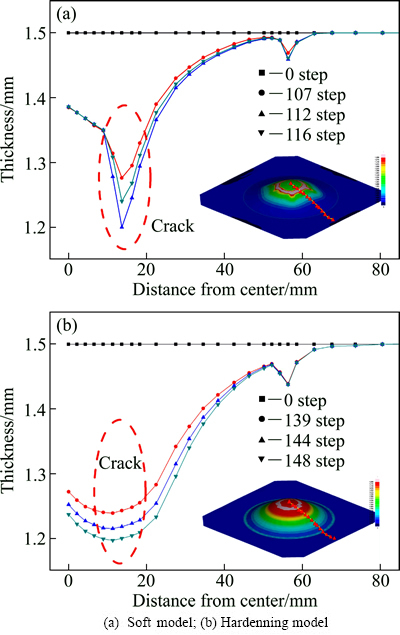

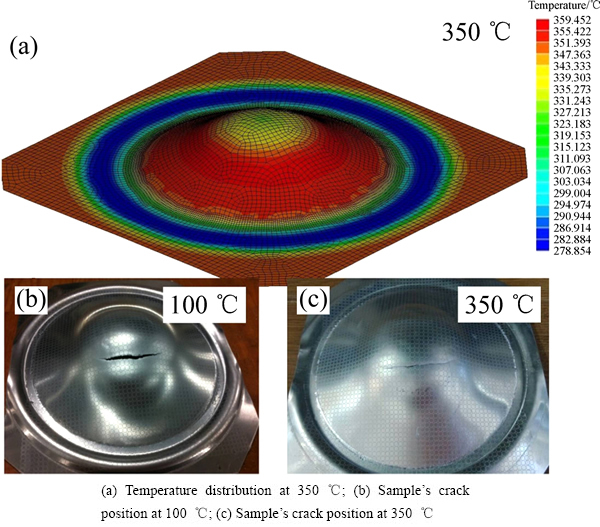

图5所示为铝合金6061在350 ℃胀形过程径向厚度分布情况。由图5可知,成形过程中板料最大变形减薄部位出现在靠近顶点的外环处,并率先发生破裂。这是由于压边圈部分和冲头顶部都率先与板料接触,出现明显降温,而环形部位处于悬空而降温较慢,且板料在变形过程中会产生变形热,因而会出现如图6所示的顶点附近温度较高的现象,且仿真出现破裂的位置和实验基本一致。

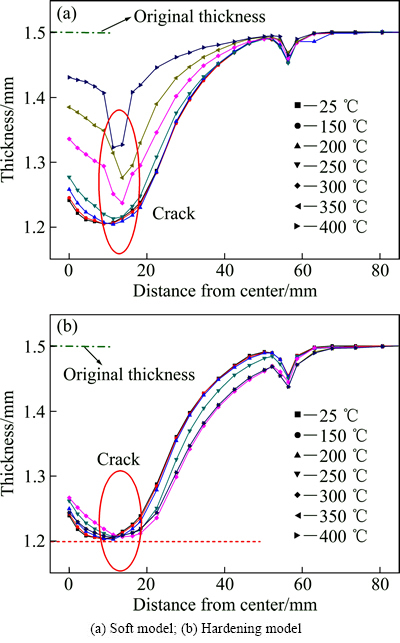

图7所示为不同温度下胀形样件破裂时的径向厚度分布对比。由图7可知,基于两种本构模型得到的不同温度下的样件厚度分布情况也存在很大区别,主要表现在破裂位置的厚度规律。由图7(a)可知,成形温度越高,板料的整体减薄越小,但集中减薄现象越明显;300 ℃以上时,最小厚度不是1.2 mm,说明在附近的某个位置率先发生破裂,最小厚度离1.2 mm越近,说明率先破裂越早,集中失稳越明显;而图7(b)所示的厚度规律则没有集中破裂现象的出现,而表现为顶点厚度随温度升高而增大,外环厚度随温度升高而降低的趋势。结果表明(图6中所示的100 ℃和350 ℃情况),样件在低温胀形过程发生破裂时,裂口呈脆性断裂模式,裂口比较整齐,裂口较大;而高温胀形破裂时,裂口则呈韧性断裂模式,裂口厚度很小,呈楔形,裂口也较小,与图5(a)所述厚度变化过程吻合。

图5 基于两种模型得到的6061铝合金在350 ℃胀形过程径向厚度分布对比

Fig. 5 Comparison of thickness distribution of 6061 alumimum alloy along radial direction at 350 ℃

图6 不同温度成形结束时AA6061的温度分布情况及样件破裂情况

Fig. 6 Temperature distribution and crack position of AA6061 after formed at different temperatures

图7 基于两种模型得到的不同温度下胀形件破裂时的径向厚度分布对比

Fig. 7 Comparison of thickness distribution when cracking along radius of dome specimen when crack happening at different temperatures

5 结论

1) 通过铝合金板材的热力拉伸实验可知,在温度低于200 ℃时,应力随塑性应变增加而增大,曲线表现为“强化”特性;当温度高于200 ℃时,则表现出明显的“软化”现象。根据其在不同温度下的黏塑性特征,提出了低温阶段采用动态回复型模型、高温阶段采用动态再结晶模型进行材料热拉伸建模的方案,并确定了6061-T6铝合金在低温25~200 ℃温度区间的动态回复型和高温250~400 ℃温度区间的动态再结晶型相结合的软化型热拉伸本构方程。

2) 将所获得6061铝合金的软化型本构方程应用于数值仿真,通过与硬化型模型及试验结果进行对比,发现该本构模型能更好地描述板材的温成形过程,并能准确地描述板料破裂前的集中软化特征。

REFERENCES

[1] 黄电源. 汽车用5182铝合金温变形行为及其拉深成形性能的研究[D]. 长沙: 中南大学, 2008.

HUANG Dian-yuan. The research of warm deformation behavior and deep drawing performance of automotive 5182 aluminum alloy[D]. Changsha: Central South University, 2008.

[2] 张 志, 郎利辉, 李 涛, 刘合军. 高强度铝合金7B04-T6板材温拉伸本构方程[J]. 北京航空航天大学学报, 2009, 35(5): 600-603.

ZHANG Zhi, LANG Li-hui, LI Tao, LIU He-jun. Constitutive equations of high strength aluminum alloy sheet 7B04-T6 under warm tension[J]. Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(5): 600-603.

[3] LIN Gao-yong, ZHANG Hui, ZHANG Xing-jian, HAN Dong-feng, ZHANG Ying, PENG Da-shu. Influences of processing routine on mechanical properties and structures of 7075 aluminum alloy thick-plates[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(4): 809-813.

[4] ABEDRABBO N, POURBOGHRAT F, CARSLEY J. Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models[J]. International Journal of Plasticity, 2007, 23(5): 841-875.

[5] SHEHATA F, PAINTER M J, PEARCE R. Warm forming of aluminium/magnesium alloy sheet[J]. Journal of Mechanical Working Technology, 1978, 2(3): 279-290.

[6] MAHABUNPHACHAI S, KOC M. Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures[J]. Materials & Design, 2010, 31(5): 2422-2434.

[7] POURBDGHRAT F, VENKATESAN S, CARSLEY J E. LDR and hydroforming limit for deep drawing of AA5754 aluminum sheet[J]. Journal of Manufacturing Processes, 2013, 15(4): 600-615.

[8] ABEDRABBO N, POURBOGHRAT F, CARSLEY J. Forming of aluminum alloys at elevated temperatures -Part 2: Numerical modeling and experimental verification[J]. International Journal of Plasticity, 2006, 22(2): 342-373.

[9] ABEDRABBO N, POURBOGHRAT F, CARSLEY J. Forming of aluminum alloys at elevated temperatures – Part 1: Material characterization[J]. International Journal of Plasticity. 2006, 22(2): 314-341.

[10] TOROS S, OZTURK F, KACAR I. Review of warm forming of aluminum-magnesium alloys[J]. Journal of Materials Processing Technology, 2008, 207(1/3): 1-12.

[11] WANG Hui, LUO Ying-bing, FRIEDMAN P, CHEN Ming-he, GAO Lin. Warm forming behavior of high strength aluminum alloy AA7075[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 1-7.

[12] SUH D W, SOHN S M, LEE M Y, LEE S Y. Deformation behaviors of 6061 and 7075 aluminum tubes at elevated temperatures for warm hydroforming[J]. Materials Science Forum, 2005, 475/479: 373-376.

[13] 黄 华, 李大永, 彭颖红. 7075-T6铝合金板温热成形极限图实验[J]. 塑性工程学报, 2010, 17(1): 93-97.

HUANG Hua, LI Da-yong, PENG Ying-hong. Experimental study on the forming limit diagrams(FLD) of 7075-T6 aluminum alloy sheet at warm state[J]. Journal of Plasticity Engineering, 2010, 17(1): 93-97.

[14] 周国伟, 李大永, 彭颖红. 7075-T6高强度铝合金温热条件下的拉深成形性能[J]. 上海交通大学学报, 2012, 46(9): 1482-1486.

ZHOU Guo-wei, LI Da-yong, PENG Ying-hong. Deep drawability of 7075-T6 high strength aluminum alloy at warm condition[J]. Journal of Shanghai Jiao Tong University, 2012, 46(9): 1482-1486.

[15] MOSTAFA M, BAHMAN M. Influence of sequence of cold working and aging treatment on mechanical behaviour of 6061 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2072-2079.

[16] 赵培峰, 任广升, 沈 智, 徐春国. 6061铝合金热压缩变形条件对流变应力的影响及其本构方程的研究[J]. 塑性工程学报, 2007, 14(6): 130-133.

ZHAO Pei-feng, REN Guang-sheng, SHEN Zhi, XU Chun-guo. Influence of hot compressive deformation conditions of 6061 aluminum alloy on flow stress and research on its constitutive equation[J]. Journal of Plasticity Engineering, 2007, 14(6): 130-133.

[17] 巫荣海. 6061铝合金的热变形行为及各向异性研究[D]. 长沙: 中南大学, 2013.

WU Rong-hai. An investigation on hot deformation behavior and anisotropy of 6061 aluminum alloy[D]. Changsha: Central South University, 2013.

[18] 姚 鹏. 6061铝合金热变形及时效行为研究[D]. 秦黄岛: 燕山大学, 2013.

YAO Peng. An investigation on hot deformation and aging behavior[D]. Qinhuangdao: Yanshan University, 2013.

[19] 张先宏, 崔振山, 阮雪榆. 镁合金塑性成形技术—AZ31B成形性能及流变应力[J]. 上海交通大学学报, 2003, 37(12): 1874-1877.

ZHANG Xian-hong, CUI Zhen-shan, RUAN Xue-yu. Warm forging of magnesium alloys: the formability and flow stress of AZ31B[J]. Journal of Shanghai Jiao Tong University, 2003, 37(12): 1874-1877.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2010CB832700);中国博士后科学基金资助项目(2014M561223);中央高校基本科研业务费专项资金资助项目(DUT14RC(3)032)

收稿日期:2014-12-01;修订日期:2015-04-10

通信作者:胡 平,教授,博士;电话:0411-84702775;E-mail:pinghu@dlut.edu.cn