文章编号:1004-0609(2008)05-0777-06

含Sc超高强Al-Zn-Cu-Mg-Sc-Zr合金的热压缩变形流变应力

李文斌1, 2,潘清林1,梁文杰1,何运斌1,刘俊生1,李运春1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 湖南城市学院 土木工程学院,益阳 413000)

摘 要:采用Gleeble1500热模拟机在应变速率为0.001~10 /s、温度为380~470 ℃、真应变为0~0.7的条件下,研究了实验合金的流变应力行为。结果表明:该合金热压缩变形时存在较明显的稳态流变特征,当 <1 /s时,流变应力开始随应变增加而增加,达到峰值后趋于平稳,呈动态回复特征;当

<1 /s时,流变应力开始随应变增加而增加,达到峰值后趋于平稳,呈动态回复特征;当 ≥1 /s时,流变应力均出现了明显的峰值应力,为连续动态再结晶特征。带Zener-Hollomon参数的双曲正弦函数可描述合金高温变形时的流变应力,σ解析表达式中A、α和n值分别为5.952×108 /s、0.021 MPa-1和5.397;热变形激活能Q为157.9 kJ/mol。

≥1 /s时,流变应力均出现了明显的峰值应力,为连续动态再结晶特征。带Zener-Hollomon参数的双曲正弦函数可描述合金高温变形时的流变应力,σ解析表达式中A、α和n值分别为5.952×108 /s、0.021 MPa-1和5.397;热变形激活能Q为157.9 kJ/mol。

关键词:Al-Zn-Cu-Mg-Sc-Zr合金;热压缩变形;流变应力;Zener-Hollomon参数;热变形激活能

中图分类号:TG 146.21 文献标识码:A

Flow stress of super-high strength Al-Zn-Cu-Mg-Sc-Zr alloy

containing Sc under hot compression deformation

LI Wen-bin1, 2, PAN Qing-lin1, LIANG Wen-jie1, HE Yun-bin1, LIU Jun-sheng1, LI Yun-chun1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Civil Engineering, Hunan City University, Yiyang 413000, China)

Abstract: The flow stress of the studied alloy over the strain rate of 0.001-10 /s, the temperature of 380-470 ℃ and true strains of 0-0.7 was studied on Gleeble-1500 hot simulator. The experimental results show that the steady-state flow characteristics exist during hot compression deformation in the range of experiments. At lower strain rates( <1 /s), the flow stress increases with the increase of strain, then keeps steady and shows dynamic recovery. At high strain rates(

<1 /s), the flow stress increases with the increase of strain, then keeps steady and shows dynamic recovery. At high strain rates( ≥1/s), the flow stress decreases after the flow stress reaches obvious peak value with the increase of strain and shows dynamic recrystallization. The flow stress of the alloy during high temperature deformation can be represented by a Zener-Hollomon parameter in the hyperbolic Arrhenius-type equation. Structure factor A, stress level parameter α and stress index n in the analytical expressions of σ are turned to be 5.952×108 /s, 0.021 MPa-1 and 5.397. The average hot deformation activation energy of the alloy is 157.9 kJ/mol.

≥1/s), the flow stress decreases after the flow stress reaches obvious peak value with the increase of strain and shows dynamic recrystallization. The flow stress of the alloy during high temperature deformation can be represented by a Zener-Hollomon parameter in the hyperbolic Arrhenius-type equation. Structure factor A, stress level parameter α and stress index n in the analytical expressions of σ are turned to be 5.952×108 /s, 0.021 MPa-1 and 5.397. The average hot deformation activation energy of the alloy is 157.9 kJ/mol.

Key words: Al-Zn-Cu-Mg-Sc-Zr alloy; hot compression deformation; flow stress; Zener-Hollomon parameter; hot deformation activation energy

含Sc Al-Zn-Cu-Mg-Sc-Zr合金是一种新型超高强铝合金,被广泛用作航空和重要轻型结构材料,其热变形的工艺参数与高温变形时流变应力的变化规律有关,国内外对铝合金高温变形时流变应力的研究不 少[1-5],加Sc Al-Zn-Cu-Mg-Sc-Zr合金的高温流变应力行为的研究还未见报道。金属热变形流变应力是材料在高温下的基本性能之一,不仅受变形温度、变形程度、应变速率和合金化学成分的影响,也与变形体内部组织结构的演变有关。在热塑性工艺学中,金属流变应力是个基本参数,其数值的精确程度是提高理论计算精度的关键。近些年来,这方面的研究渐趋活 跃[6-8]。本文作者在Gleeble1500热模拟机上,采用圆柱体轴对称高温单道次压缩实验,对一种含Sc Al-Zn-Cu-Mg-Sc-Zr超高强铝合金流变应力进行了系统研究,回归分析出高温变形时流变应力的变化规律,获得了有关的材料常数值,为制定合理的热加工工艺,有效控制产品的组织性能,提高产品质量提供了实验依据。

1 实验

实验合金成分为Al-8.1Zn-2.3Cu-2.05Mg-0.2Sc- 0.12Zr(质量分数,%),合金采用坩埚炉按质量要求熔铸。铸锭在箱式电阻炉内进行均匀化处理:以40℃/ min升温至460 ℃保温24 h,炉冷至200 ℃出炉空冷。机械加工出尺寸为d10 mm×15 mm,两端留浅凹槽的压缩试样。在热压缩实验在Gleeble1500热模拟机上进行。热压缩实验前,在圆柱试样两端的浅槽内填充75%石墨+20%机油+5%硝酸三甲苯脂,以减小摩擦的影响。实验温度范围为380~470 ℃,应变速率范围为0.001~10 /s,总压缩真应变量为0.7。利用试样自身电阻进行加热,加热速度为1 ℃/s。用连接到试样表面上的热电偶测量试样的温度,到实验温度后保温5 min再开始热压缩变形。

2 结果与分析

2.1 热压缩变形的真应力—真应变曲线

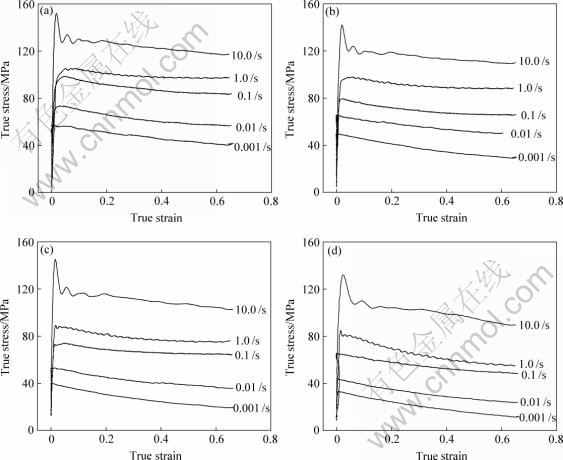

含Sc Al-Zn-Cu-Mg-Sc-Zr超高强铝合金热压缩变形时的实测真应力—真应变曲线如图1所示。由图1可见,在研究条件下,合金热压缩变形时均存在较明显的稳态流变特征:即在一定的温度和应变速率下,当真应变ε超过一定值后,真应力σ不随真应变的增大而发生明显变化;当应变速率一定时,真应力随温度升高而降低;当变形温度一定时,随着应变速率的增加,真应力水平升高;且随着应变速率的增大和温度的降低,进入稳态流变阶段所对应的真应力值逐渐增大。在 ≥1 /s的高应变速率下,各变形温度的流变应力均出现了明显的峰值应力,呈连续动态再结晶特征。不同温度和不同应变速率条件下的峰值应力如表1所列。

≥1 /s的高应变速率下,各变形温度的流变应力均出现了明显的峰值应力,呈连续动态再结晶特征。不同温度和不同应变速率条件下的峰值应力如表1所列。

图1 热压缩变形真应力—真应变曲线

Fig.1 True stress—true strain curves during hot compression deformation: (a) 380 ℃; (b) 410 ℃; (c) 440 ℃; (d) 470 ℃

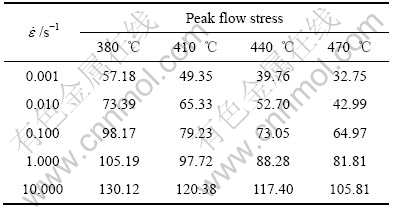

表1 不同变形条件下的峰值流变应力

Table 1 Peak flow stress under different conditions of hot compression (MPa)

2.2 热压缩变形流变应力方程

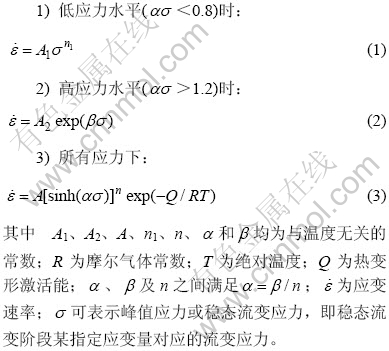

对金属高温变形时流变应力的研究主要是希望建立材料稳态流变时的本构方程。对应变速率 ,变形温度T与流变应力σ间的模拟数学表达式的研究结果主要有以下3种[9-13]:

,变形温度T与流变应力σ间的模拟数学表达式的研究结果主要有以下3种[9-13]:

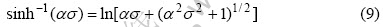

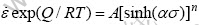

大量的研究结果表明[9],式(3)能较好地描述常规热变形加工过程中的流变应力变化规律。这一关系式是由SELLARS和TEGART提出的,包含材料热变形激活能Q和温度T的双曲正弦形式的Arrhenius关系,用于描述热激活稳态变形行为。该式还广泛用于估算各种金属及合金的热变形激活能Q[13]。在低应力和高应力条件下,式(3)分别简化为[9]

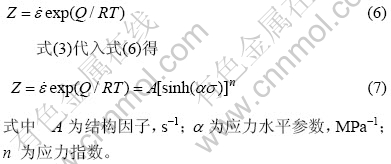

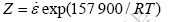

ZENER和HOLLOMON提出并验证了应变速率 和温度T的关系可用一项参数Z表示,称为Z参数或Zener-Hollomon参数。其定义为[13]

和温度T的关系可用一项参数Z表示,称为Z参数或Zener-Hollomon参数。其定义为[13]

为了研究材料在高温变形时的力学行为,先应了解与应变速率和温度有关的流变应力σ的变化规律。从式(7)可推出:

根据双曲正弦函数的反函数公式,有:

由此通过Z参数定义式可将流变应力σ表达成应变速率和温度的函数,从而可表达成Zener-Hollomon参数Z值的函数:

由式(8)和(9)有:

由式(7)和(9)可知,只要知道A、Q、α和n等材料参数,便可求得材料在任意变形条件下的流变应力值。式(3)和(10)未考虑应变 对流变应力的影响,但由图1可知,合金高温塑性变形时,在稳态变形阶段流变应力对应变是不敏感的,因而可忽略应变大小对流变应力的影响。下面先计算A、Q、α和n等材料参数值。

对流变应力的影响,但由图1可知,合金高温塑性变形时,在稳态变形阶段流变应力对应变是不敏感的,因而可忽略应变大小对流变应力的影响。下面先计算A、Q、α和n等材料参数值。

对式(1)和(2)两边分别求对数得:

依据式(11)和(12),取流变应力为峰值应力,分别作ln —lnσ、ln

—lnσ、ln —σ曲线,用最小二乘法线性回归(见图2)。n1可取图2(a)中380~470 ℃ 4条直线斜率的平均值,得n1=9.578 2;β可取图2(b)中4条直线斜率的平均值,得β=0.126 7,α=β/n1=0.013 2。

—σ曲线,用最小二乘法线性回归(见图2)。n1可取图2(a)中380~470 ℃ 4条直线斜率的平均值,得n1=9.578 2;β可取图2(b)中4条直线斜率的平均值,得β=0.126 7,α=β/n1=0.013 2。

图2 应变速率与峰值应力之间的关系

Fig.2 Relationships between strain rate and peak stress

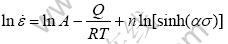

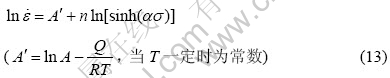

对式(3)两侧取自然对数,并假定热变形激活能与温度无关,可以得到:

可写成:

将不同变形温度下合金变形时的应变速率和峰值流变应力分别代入式(13),绘制ln ~ln[sinh(ασ)]关系曲线,再用最小二乘法线性回归,可看出应变速率的对数和流变应力双曲正弦的对数较好地满足线性关系。图3所示为直线的斜率即为应力指数n。由4条直线斜率的平均值求得n=7.164 3。这种双曲正弦函数关系可用于描述合金所有应力水平下流变应力σ和应变速率

~ln[sinh(ασ)]关系曲线,再用最小二乘法线性回归,可看出应变速率的对数和流变应力双曲正弦的对数较好地满足线性关系。图3所示为直线的斜率即为应力指数n。由4条直线斜率的平均值求得n=7.164 3。这种双曲正弦函数关系可用于描述合金所有应力水平下流变应力σ和应变速率 之间的关系,为控制应变速率和热加工的应力水平及工艺参数提供了实验依据。

之间的关系,为控制应变速率和热加工的应力水平及工艺参数提供了实验依据。

图3 峰值应力的ln 与ln[sinh(ασ)]的关系

与ln[sinh(ασ)]的关系

Fig.3 Relationships between ln of peak stress and ln[sinh(ασ)]

of peak stress and ln[sinh(ασ)]

当应变速率一定时,假定一定温度范围内Q值不变,由式(7)的 ,两边取对数可得:

,两边取对数可得:

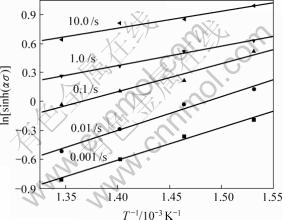

将不同变形条件下峰值应力的ln[sinh(ασ)]值代入上式,绘制相应的ln[sinh(ασ)]—T -1曲线,进行线性回归,如图4所示,可求得斜率Q/Rn。图中5条直线斜率的平均值可计算出Q/Rn,从而求得合金的平均热变形激活能Q。图4所示为在相同应变速率条件下,流变应力的双曲正弦对数项和温度的倒数间满足线性关系。这种线性关系说明合金高温塑性变形稳态流变应力和变形温度之间满足Arrhenius关系,可用Z参数来描述合金高温塑性变形的流变应力。

图4 峰值应力的ln[sinh(ασ)]与温度的关系

Fig.4 Relationships between ln[sinh(ασ)] of peak stress and deformation temperature

考虑到Q不随T 变化,对式(13)两边取微分得:

上式括号中的项为应变速率一定时 ln[sinh(ασ)]—T -1数据线性回归的斜率。应力指数n为7.164 3,图4中直线斜率的平均值(即Q/Rn)为2.721。代入式(14)中,即可求出实验合金平均热变形激活能Q值为162.1 kJ/mol。

对式(6)两边求对数得:

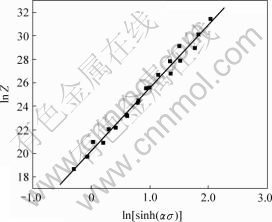

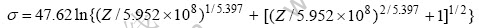

将Q值和变形条件逐个代入式(7)求出Z值,再绘制lnZ—ln[sinh(ασ)]关系曲线,进行线性回归,如图5所示。由式(15)式和图5可知,该回归直线的斜率即为应力指数n值,而其截距为ln A,于是可求出结构因子A=4.712 1×1010/s、应力指数n=7.047 2。将此n值代入α=β/n,便可求出新的α值,再依前面同样步骤可求出第二计算循环的A、n、α和Q值。如此迭代计算,求得的材料常数A、n、α和Q值更为真实和可靠[14-16]。根据以上方法,经3个计算循环求得应力水平因子α=0.021 MPa-1,平均热变形激活能Q=157.9 kJ/mol,应力指数n=5.397,结构因子A=5.952×108/s。第三计算循环ln Z与ln[sinh(ασ)]的关系如图6所示,两者在实验应变速率和变形温度范围内的线性关系吻合得相当好,这进一步说明了实验合金高温塑性变形时的流变应力σ、应变速率 和温度T之间的关系可用式(3)加以描述。

和温度T之间的关系可用式(3)加以描述。

图5 第一计算循环Z参数与流变应力的关系

Fig.5 Relationship between Z parameter and flow stress during first numeration circle

图6 第三计算循环Z参数与流变应力的关系

Fig.6 Relationship between Z parameter and flow stress during third numeration circle

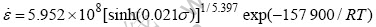

将A、n、α和Q等值代入式(3),得合金热压缩变形时的流变应力方程为:

其Z参数可表述为

用Z参数表述的流变应力方程为

该方程适用于应变速率为0.001~10 /s、温度为380~470 ℃、真应变为0~0.7范围内实验合金的流变应力行为,可为控制热加工时应变速率、应力水平及工艺参数提供实验依据。

3 结论

1) 热压缩变形时,实验合金流变应力在低应变速率( <1 /s)条件下,初始阶段随应变增加而增加,达到峰值后趋于平稳,呈动态回复特征;在高应变速率(

<1 /s)条件下,初始阶段随应变增加而增加,达到峰值后趋于平稳,呈动态回复特征;在高应变速率( ≥1 /s)条件下,每个变形温度的流变应力达到峰值后均逐渐下降,表现出动态再结晶特征。

≥1 /s)条件下,每个变形温度的流变应力达到峰值后均逐渐下降,表现出动态再结晶特征。

2) 采用Zener-Hollomon参数的双曲正弦函数形式来描述实验合金高温压缩变形时的流变应力行为,获得的流变应力σ解析表达式中A、α和n值分别为5.952×108 /s、0.021 MPa-1和5.397,合金的平均热变形激活能Q为157.9 kJ/mol。

REFERENCES

[1] CHO J R, BAE W B, HWANG W J, HARTLEY P. A study on the hot-deformation behavior and dynamic recrystallization of Al-15wt.% Mg alloy[J]. Journal of Materials Processing Techonology, 2001, 118(1/3): 356-361.

[2] IHARA K, MIURA Y. Dynamic recrystallization in Al-Mg-Sc alloys[J]. Mater Sci Eng A, 2004, 387-389: 647-650.

[3] ZHANG H, LI L X, YUAN D, PENG D S. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperatures[J]. Materials Characterization, 2007, 58(2): 168-173.

[4] MALAS J C, VENUGOPAL S, SESHACHARYULU T. Effect of microstructural complexity on the hot deformation behavior of aluminum alloy 2024[J]. Mater Sci Eng A, 368(1/2): 41-47.

[5] KIM J H, KIM J H, YEOM J T, LEE D G. Effect of scandium content on the hot extrusion of Al-Zn-Mg-(Sc) alloy[J]. Journal of Materials Processing Technology, 2007, 187/188: 635-639.

[6] SHEPPARD T, JACKSON A. Constitutive equations for use in prediction of flow stress during extrusion of aluminum alloys[J]. Mater Sci Technol, 1997, 13(3): 203-209.

[7] SHI H, MCLAREN A J, SELLARS C M, SHAHANI R. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Mater Sci Technol, 1997, 13(3): 210-216.

[8] 韩冬峰, 郑子樵, 蒋 呐, 李劲峰. 高强可焊2195铝-锂合金热压缩变形的流变应力[J]. 中国有色金属学报, 2004, 14(12): 2090-2095.

HAN Dong-feng, ZHENG Zi-qiao, JIAN Na, LI Jing-feng. Flow stress of high-strength weldable 2195 aluminum-lithium alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2090-2095.

[9] POIRIER J P. 晶体的高温塑性变形[M]. 关得林, 译. 大连: 大连理工大学出版社, 1989.

POIRIER J P. High temperature plastic deformation of crystals[M]. GUAN De-lin, transl. Dalian: Dalian University of Science and Technology Press, 1989.

[10] 沈 键. 2091铝合金高温塑性变形的研究[D]. 长沙: 中南工业大学, 1996.

SHEN Jian. Study of hot compression deformation of 2091 aluminum alloy[D]. Changsha: Central South University, 1996.

[11] JONAS J J, SELLARS C M, TEGART M W J. Strength and structure under hot-working conditions[J]. Int Metall Reviews, 1969, 14: 1-24.

[12] 吴文祥, 孙得勤, 曹春艳, 王战锋, 张 辉. 5083铝合金热压缩变形流变应力行为[J]. 中国有色金属学报, 2007, 17(10): 1667-1671.

WU Wen-xiang, SUN De-qing, CAO Chun-yan, WANG Zhan-feng, ZHANG Hui. Flow stress behavior of aluminum alloy under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1667-1671.

[13] SHEPPARD T, PARSON N C, ZAIDI M A. Dynamic recrystallization in Al-7Mg[J]. Met Sci, 1983, 17(10): 481-490.

[14] ZENER C, HOLLOMON J H. Effect of strain-rate upon the plastic flow of steel[J]. J Appl Phys, 1944, 15(1): 22-32.

[15] 林启全, 张 辉, 彭大署, 林高用, 王振球. 5182铝合金热压缩变形流变应力[J]. 湘潭大学自然科学学报, 2002, 24(3): 84-88.

LIN Qi-quan, ZhANG Hui, PENG Da-shu, LIN Gao-yong, WANG Zhen-qiu. Flow stress behavior of 5182 aluminum alloy under hot compression deformation[J]. Natural Science Journal of Xiangtan University, 2002, 24(3): 84-88.

[16] 林高用, 张 辉, 郭武超, 彭大暑. 7075铝合金热压缩变形流变应力[J]. 中国有色金属学报, 2001, 11(3): 412-415

LIN Gao-yong, ZHANG Hui, GUO Wu-chao, PENG Da-shu. Flow stress of 7075 aluminum alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z523)

收稿日期:2007-08-29;修订日期:2007-12-17

通讯作者:潘清林,教授,博士;电话:0731-8830933;E-mail: pql@mail.csu.edu.cn

(编辑 李艳红)