文章编号:1004-0609(2016)-11-2326-14

热蒸镀-原位反应法制备的Mo-Si-X-C(X=Al,Ti)复相陶瓷涂层的微观结构和力学性能

徐永龙1,郝安林2,孙 威1,熊 翔1,彭 铮1,陈耘田1,陈招科1,王雅雷1

(1. 中南大学 粉末冶金研究院,长沙 410083;

2. 安阳工学院,安阳 455000)

摘 要:采用热蒸镀-原位反应法制备Mo-Si-X-C(X=Al, Ti)碳基陶瓷涂层。利用X射线仪、扫描电子显微镜和纳米压痕测试仪对涂层的微观结构和力学性能进行表征,研究成分及热蒸镀工艺参数对涂层的物相组成、微观结构和力学性能的影响,并揭示涂层的形成机制。结果表明:不同组分蒸镀母料在1550 ℃、Ar气氛条件下,由于不同蒸气压诱发各异的扩散路径,从而使原位反应生成Mo-Si-X-C(X=Al,Ti)复相陶瓷涂层的形貌、相成分及分布明显不同。添加Ti和Al元素有利于分别生成(Ti0.8Mo0.2)Si2相和Mo(Si, Al)2相,促进热蒸镀过程;随着温度的升高,基体表面Si黏性减弱,同时流动性增强,涂层中钼硅化物消失;1800 ℃真空环境下涂层中的SiC晶粒异常长大,破坏涂层结构,导致涂层失效。力学性能表明:同时添加Al、Ti元素,形成复杂多相界面结构的23Mo-63Si-7Ti-7Al陶瓷涂层的力学性能最优,其抗压强度达到19.584GPa,显微硬度达到1848HV及弹性模量达到255.124 GPa。

关键词:热蒸镀法;原位反应法;SiC;(Ti0.8Mo0.2)Si2;涂层;碳基材料

中图分类号:TQ127.1 文献标志码:A

碳材料具有密度小、比模量高、导热性好、导电性强和耐腐蚀等特点,广泛运用于电子元器件、高温设备及核领域[1-3]。但在实际的使用中,常对材料提出如抗氧化、耐磨等一系列性能要求,所以需要制备涂层来实现。近年来,MoSi2作为难融金属硅化物,具有高熔点、低密度和优异的抗氧化性能,受到广泛关注。然而,单一的MoSi2由于具有低温脆性及高温强度低等问题,限制其在涂层中的运用[4-8]。复合涂层是解决MoSi2力学性能问题的有效途径之一。目前已有添加SiC、Al等文献报道。邓雄等[9]指出,SiC具有高熔点、高硬度,能够与MoSi2在高温下润湿,界面相容性好,提高涂层的力学性能。LI等[10]指出,在Mo-Si体系中添加Al能够形成Mo(Six, Al1-x)2。Mo(Six, Al1-x)2是一种金属化合物,具有比单一的MoSi2更优良的低温及高温段抗氧化性能。

近来制备Mo-Si-C体系陶瓷涂层方法较多,如化学气相沉积法、包埋法和涂刷法等[11-13]。但化学气相沉积法制备涂层时间长,反应物易腐蚀设备,涂层与基体的结合性能较差;包埋法制备的ZrC涂层与基体的结合性能虽然较好,但存在加工难等问题,即在加工的过程极易造成涂层的破坏;涂刷法是现今较为主流的在碳基体上制备Mo-Si-C体系陶瓷涂层的方法之一,但由于粘接剂在低温段分解等原因,制备的涂层与基体往往结合性能较差,裂纹难以避免。所以,为在较短时间内制备与基体结合性能好,易加工的Mo-Si-C体系陶瓷涂层,本文作者尝试采用热蒸镀-原位反应法在石墨基体表面制备涂层。这种方法是利用Mo、Si等组元的熔点不同,其蒸发压也不同,导致各成分的蒸镀速率不同,在高于部分组元熔点的温度下进行热蒸镀,蒸镀原子运动具有明显的方向性,蒸镀至基体表面产生原位反应。具有操作简单,涂层沉积速率快,涂层具有自组织花样等优势,是一种非常有前景的涂层制备方法。

本文作者采用热蒸镀-原位反应法制备高性能Mo-Si-X-C(X=Al, Ti)碳基陶瓷涂层,研究不同成分及工艺参数对涂层微观结构特征的影响,并揭示涂层的形成机制。

1 实验

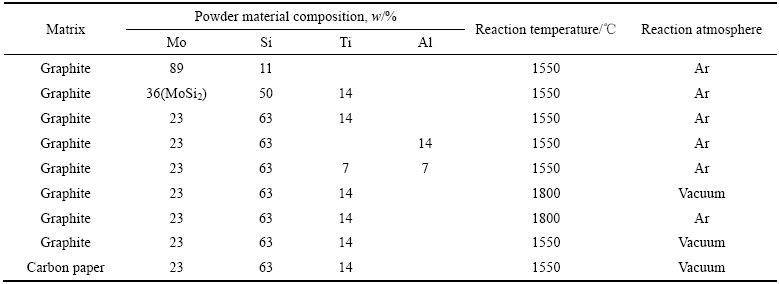

表1 蒸镀粉料配比

Table 1 Powder proportion of masterbatches

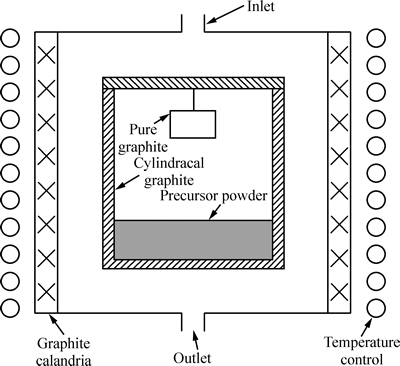

表1所列为蒸镀粉料的配比。实验采用不同成分的Mo-Si-C-X(X=Al, Ti)配比的混合粉末(粒度<75 μm)。为表示方便,采用粉末质量配比来表示不同涂层,如采用m(Mo):m(Si)=89:11的混合粉末制备的涂层表示为89Mo-11Si陶瓷涂层。混合粉末其在变频行星式球磨机上球磨8 h。选用真空感应加热炉制备Mo-Si-C-X(X=Al,Ti)体系涂层,将预涂层沉积石墨基体置于粉料上方,精确控制基体与粉料的距离(如图1所示)。制备涂层过程中,装料后将真空感应加热炉抽真空到2.5×10-2 Pa后开始加热,先加热到150 ℃保温0.5 h后以10 ℃/min升温至相应温度。Ar气氛条件与真空条件下实验步骤类似,在抽真空至2.5×10-2 Pa充氩气,后开始加热。降温时以5 ℃/min降至1000 ℃后随炉冷。对实验得到的10个涂层样品的表面进行XRD检测。石墨基体采用长沙宏升碳素有限公司制备的高纯石墨,石墨直径为55 mm,高度为45 mm。

测试仪器采用日本理学生产的D/max(2550)全自动(18 kW)转靶X射线仪对样品进行物相分析。电流20 mA、电压35 kV,2θ范围是23°~28°,扫面间隔0.02°,扫描速率0.01 (°)/s。对分别制备得到的8个涂层样品截面及9个表面通过荷兰Novtma NanoSEM230场发射扫描电镜进行形貌、微观结构和定性元素分析。电镜的二次电子成像分辨率在高真空环境中可达1.0 nm(发射电压15 kV)、1.6 nm(发射电压1 kV);低真空环境中可达1.5 nm(发射电压10 kV)、1.8 nm(发射电压1 kV);背散射电子成像模式可达2.5 nm。采用Switzerland CSM 纳米压痕硬度及对涂层的硬度和弹性模量进行分析,压痕测试是每个样品取6个点,最大载荷为500 mN,在最大载荷加载15 s后卸载。采用Oliver & Pharr的方法,通过弹塑性变形深度等计算涂层抗压强度、硬度及弹性模量[14]。

图1 热蒸镀反应示意图

Fig. 1 Schematic diagram of evaporation system

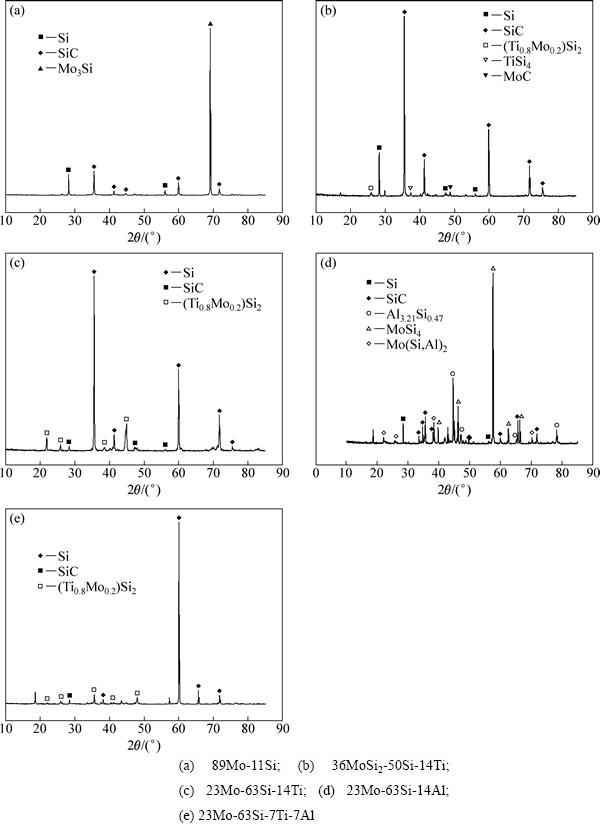

图2 氩气条件下1550 ℃时5种Mo-Si-C-X (X=Al,Ti)陶瓷涂层的XRD谱

Fig. 2 XRD patterns of different Mo-Si-C-X(X=Al,Ti) ceramic coating

2 结果与分析

2.1 蒸镀粉末成分对Mo-Si-X-C(X=Al,Ti)复相陶瓷涂层微观结构的影响

图2(a)~(e)分别为蒸发源不同的5种复相陶瓷涂层的XRD谱,5种复相陶瓷涂层都是在Ar气氛、1550 ℃条件下制备。涂层中均发现由于Si粉末过量造成的Si衍射峰。图2(a)所示为89Mo-11Si的涂层主要由Mo3Si、 SiC 和 Si相组成,其中最强衍射峰为Mo3Si峰。添加Ti成分后(见图2(b)和(c)),同时在36MoSi2-50Si-14Ti涂层和23Mo-63Si-14Ti中观察到(Ti0.8Mo0.2)Si2物相。采用MoSi2为原料的涂层物相为Si、SiC、TiSi4、MoC和(Ti0.8Mo0.2)Si2。采用纯Mo粉末为原料的涂层物相为Si、SiC和(Ti0.8Mo0.2)Si2。当采用Al粉代替Ti粉为原料时(见图2(d)),23Mo-63Si-14Al涂层检测到MoSi2、Al3.21Si0.47 和 Mo(Si, Al)2物相。同时添加Al和Ti粉末(见图2(e)),23Mo-63Si-7Ti-7Al涂层物相为Si、SiC和(Ti0.8Mo0.2)Si2。分析可得,添加Ti元素,SiC的晶面指数并未发生明显改变,图2(a)~(c)中涂层的SiC衍射峰晶面指数从左到右依次为(111)、(200)、(220)和(311)。随Al元素的加入,SiC衍射峰发生改变。23Mo-63Si-14Al涂层中SiC衍射峰晶面指数为从左到右为(100)、(101)、(004)、(104)和(110)。23Mo-63Si-7Ti-7Al涂层中SiC衍射峰晶面指数从左到右依次为(100)、(101)、(105)、(110)和(106)。

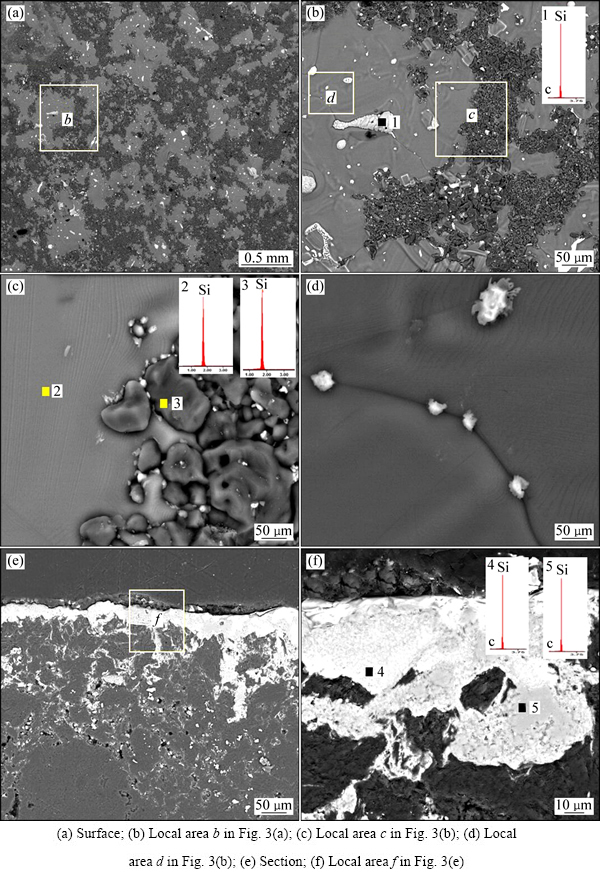

图3所示为89Mo-11Si陶瓷涂层的表面与截面的SEM像,涂层厚度为47.1 μm。图3(a)~(d)所示为陶瓷涂层表面形貌,能谱分析可得,点1主要元素为Mo和Si,点2、3主要元素都为Si。结合XRD分析可得,涂层表面主要由颗粒互相堆积而成的岛屿状黑色相Si、平滑的灰色相Si及镶嵌在晶界处的白色相Mo3Si小颗粒组成;图3(e)和(f)所示为涂层截面形貌,点4和5主要元素为Si与C。涂层分层现象明显,基体中的孔隙及裂纹也被Si填充,反应形成Si/SiC层。SiC/Si内层渗入基体很深,并在一定深度内相互连接。并呈现“瀑布状”,与基体具有较强的啮合力,起到“钉扎”作用。能谱分析发现,涂层截面并未有钼硅化物存在。这是由于蒸镀母料在反应过程中,形成较高熔点的钼硅化物在1550 ℃条件下难以热蒸镀,只有少量的较低熔点Mo3Si能够蒸镀至SiC/Si涂层表面。

图3 89Mo-11Si陶瓷涂层的SEM像

Fig. 3 SEM images of 89Mo-11Si ceramic coating

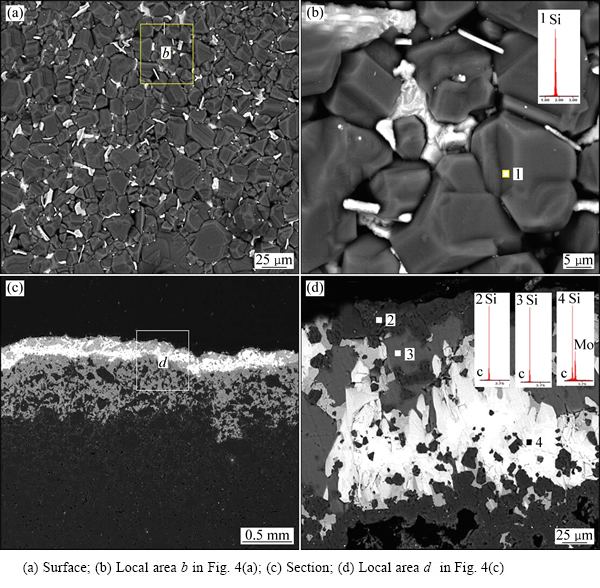

图4所示为36MoSi2-50Si-14Ti陶瓷涂层的SEM像。如图4所示,添加Ti元素后,相对于89Mo-11Si陶瓷涂层,36MoSi2-50Si-14Ti陶瓷涂层的显微形貌与的展现出较大差异,涂层的厚度达到644 μm。涂层表面主要为多面体块状Si覆盖(见图4(b)),晶粒与晶粒之间存在许多孔隙结构,白色(Ti0.8Mo0.2)Si2 和 MoSi2相仅一定量的填充孔隙较为均匀覆盖在涂层表面;图4(c)和(d)所示为陶瓷涂层截面形貌,点2主要元素是Si和C,点3主要元素是Si,点4主要元素是Mo、Ti和Si。结合XRD分析可得,涂层内部白色相组成成分与表面白色相组织成分一致,为复杂的(Ti0.8Mo0.2)Si2/MoSi2/TiSi4多相组织,在涂层内部聚集生长。涂层里层主要为Si/SiC组织,晶界处夹杂少量白色相成分。可以看到Si/SiC层渗入基体内部很深,且相互连接,“钉扎”现象明显。因此,整个涂层结构由外到内依次为Si/SiC为主的表层,SiC/Si/ (Ti0.8Mo0.2)Si2/MoSi2/TiSi4多相层以及Si/SiC为主的内层。

图4 36MoSi2-50Si-14Ti陶瓷涂层的SEM像

Fig. 4 SEM images of 36MoSi2-50Si-14Ti ceramic coating

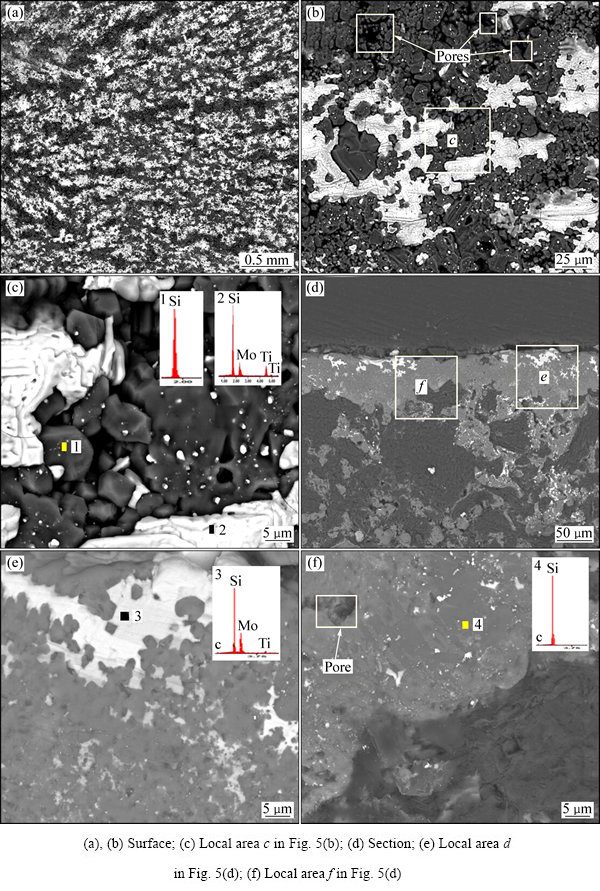

保持Mo、Si和Ti摩尔比不变,采用Mo粉末代替MoSi2粉末制备23Mo-63Si-14Ti陶瓷涂层,涂层厚度为77.67 μm。图5(a)~(c)所示为陶瓷涂层表面形貌,能谱分析可得,点1主要元素为Si,点2主要元素是Mo、Si和Ti。结合XRD分析可得,涂层表面存在各种多面体块状黑色相Si晶粒组织,晶粒与晶粒之间存在许多孔隙结构,大量白色(Ti0.8Mo0.2)Si2相从晶界和孔隙中聚集溢出;图5(d)~(f)所示为陶瓷涂层截面形貌,点3主要元素是Mo、Si、Ti和C,点4主要元素是Si和C。其中,涂层内层主要为内层组织为岛屿状分布的Si/SiC层,弥散分布有白色相(Ti0.8Mo0.2)Si2。所以整个涂层结构由外到内依次为Si/(Ti0.8Mo0.2)Si2外层以及Si/SiC为主的内层。可以观察到,当改用Mo粉末为蒸镀母料后,涂层形貌发生较大改变,这主要是由于Mo及MoSi2的扩散速率不同造成的。MoSi2粉末蒸镀时,首先需要分解成Mo及Si,造成过量的Si热蒸镀形成较厚的Si/SiC底层。

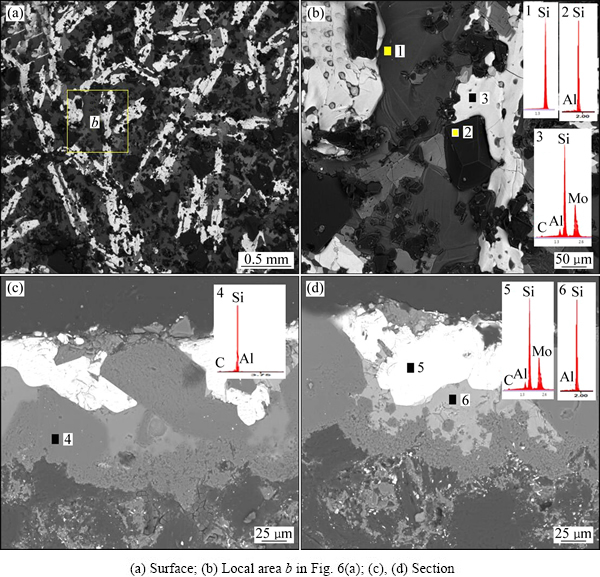

采用Al粉末代替Ti粉作为蒸镀母料,23Mo-63Si-14Al陶瓷涂层厚度为135 μm。图6(a)和(b)所示为涂层表面形貌,可以观察到涂层表面形貌复杂,明暗相间。能谱分析可得,点1主要元素为Si,点2主要元素为Si和微量的Al,点3主要元素为Si、C、Mo和Al。结合XRD分析可得,涂层表面存在平滑的灰色相Si与呈条带状分布的白色的MoSi2/Mo(Si, Al)2/SiC相,灰、白色相间界面明显。灰色相Si向白色相过渡的边界处多为块状黑色的少量Al固溶的Si颗粒[15]。图6(c)~(d)所示为涂层截面形貌,点4主要元素为Si和C和少量的Al,点5主要元素为Si、C、Mo和Al,点6主要元素为Al、和Si及少量的Mo。结合XRD谱分析可得,其中,白色多相组织主要成分为Si、SiC、MoSi2和Mo(Si,Al)2,在涂层表面主要以块状聚集分布,少量夹杂在涂层内部Si与SiC晶界处。内层Si渗入碳基体较深,形成的SiC多为不连续分布的零散岛屿状涂层结构。涂层由外到内依次为Si/SiC/MoSi2/Mo(Si, Al)2多相层以及Si/SiC为主的内层。

图5 23Mo-63Si-14Ti陶瓷涂层的SEM像

Fig. 5 SEM images of 23Mo-63Si-14Ti ceramic coating

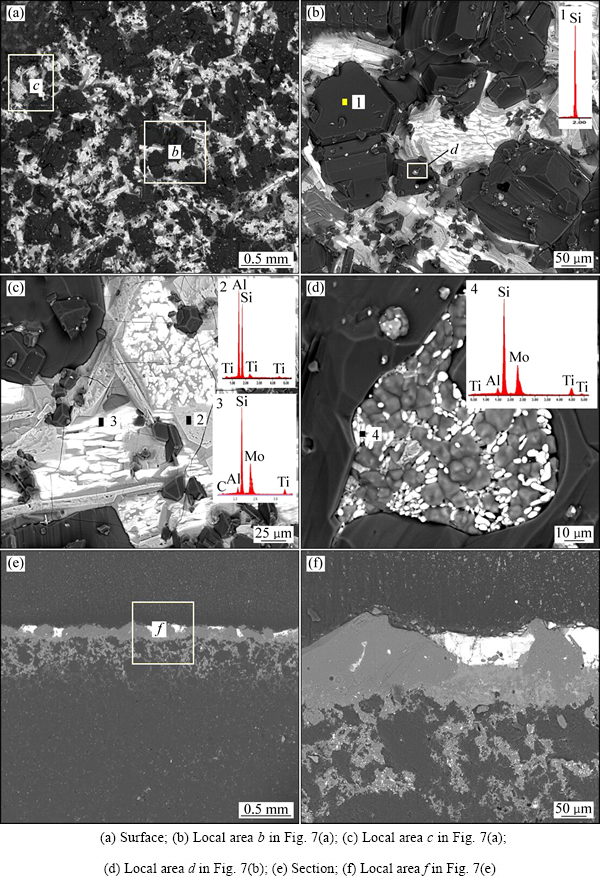

同时,添加Al和Ti粉末时,23Mo-63Si-7Ti-7Al陶瓷涂层厚度达到135 μm。图7(a)~(d)所示为陶瓷涂层表面形貌。能谱分析可得,点1主要元素为Si,点2主要元素为Si、Ti和Al,点3主要元素为Si、Mo、Ti和微量的Al,点4主要元素为Si、Mo、Ti和微量的Al。结合XRD可得,涂层表面存在多面体块状分布的黑色相Si,Si晶粒内存在白色相小颗粒“虫卵式”聚集并且晶界处大量生长云絮状的白色相及参杂的灰白色相。分析可得,白色相成分为(Ti0.8Mo0.2)Si2,灰白色相成分为AlSi4和Mo(Si, Al)2。图7(e)和(f)所示为陶瓷涂层截面,涂层主要由SiC与Si组成的黑色相构成,白色相聚集成块状分布在涂层表层,其成分主要为SiC与(Ti0.8Mo0.2)Si2及少量的Mo(Si, Al)2。涂层中的Si渗透进入基体中形成SiC,形成岛屿状组织,分布松散。因此,整个涂层结构由外到内依次为Si/SiC/(Ti0.8Mo0.2)Si2/Mo(Si, Al)2多相层以及Si/SiC为主的内层。

图6 23Mo-63Si-14Al陶瓷涂层的SEM像

Fig. 6 SEM images of 23Mo-63Si-14Al ceramic coating

2.2 温度和气氛对23Mo-64Si-14Ti复相陶瓷涂层微观结构的影响

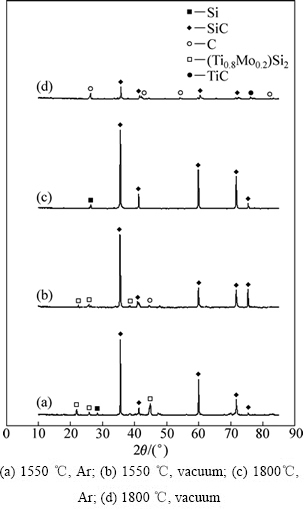

图8所示为不同工艺条件下23Mo-63Si-14Ti原始粉末热蒸镀-原位反应制备复相陶瓷涂层的XRD谱。对比图8(a)与(b)可以观察到,在1550 ℃,真空和Ar气氛条件下制备的陶瓷涂层都存在SiC相和(Ti0.8Mo0.2)Si2相。真空环境下SiC衍射峰强度较强;当温度升高到1800 ℃(见图8(c)和(d)),(Ti0.8Mo0.2)Si2相消失,Ar气氛条件下涂层只存在Si和SiC的物相,真空条件下涂层存在C、TiC、TiC0.02和SiC的物相,但整体衍射峰强度明显减弱。

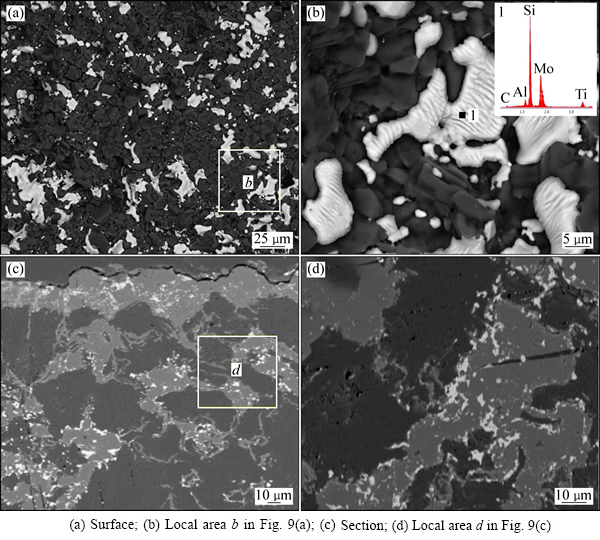

图9所示为1550 ℃真空条件下的23Mo-63Si-14Ti涂层的SEM像。观察涂层表面发现,相对于Ar气氛条件下制备的涂层(见图5),真空条件下制备的涂层中相成分分布更为分散均匀,涂层更为致密。涂层表面的SiC颗粒呈现聚集堆积的起伏结构,晶界处聚集白色相(Ti0.8Mo0.2)Si2。涂层内部主要由岛屿状分布的Si和SiC组成。(Ti0.8Mo0.2)Si2和MoSi2相成分等随液相Si的渗入广泛分布并在晶界处优先析出。

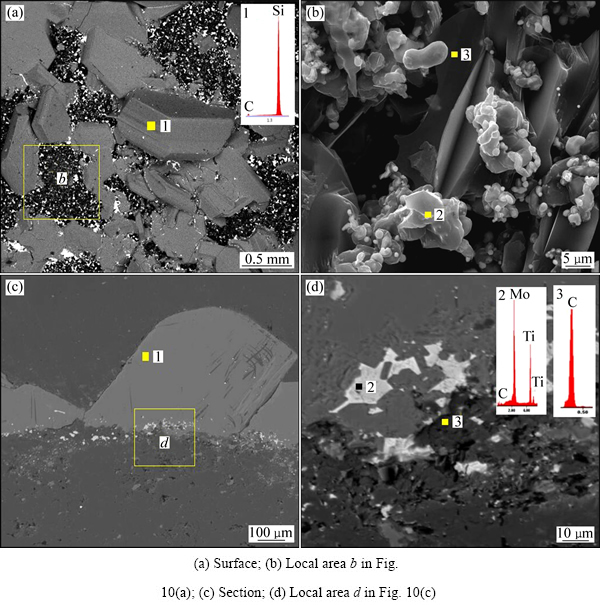

温度升高至1800 ℃,涂层形成的形貌如图10所示。能谱分析可得,点1主要元素为S i和C,点2主要元素为C、Mo、Ti和Si。点3主要元素为C。结合XRD分析可得,表面巨大的灰色相颗粒组织为SiC,SiC晶粒的晶界处有大量C颗粒聚集堆积,并存在成分为TiC及MoC的白色相附着C颗粒上。图10(c)和(d)所示为涂层截面形貌。可以发现,异常长大的SiC颗粒导致涂层有效部分十分薄,涂层失效,石墨基体直接暴露在空气中。

图7 23Mo-63Si-7Ti-7Al陶瓷涂层的SEM像

Fig. 7 SEM images of 23Mo-63Si-7Ti-7Al ceramic coating

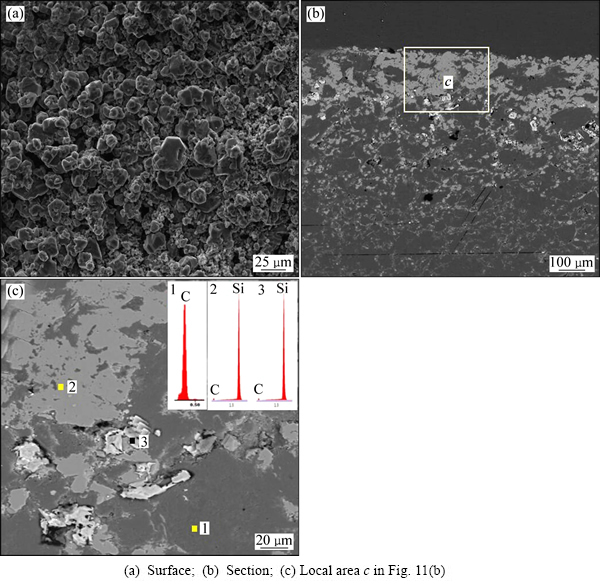

当气氛由真空改为氩气时,1800 ℃下涂层形貌如图11所示。能谱分析截面1、2和3处发现(见图11(c)),点1主要元素为C,点2主要元素为Si和C,点3主要元素为C与少量Si。结合XRD分析可得,涂层基本由Si和SiC组成。涂层表面为颗粒聚集堆积的连续起伏结构,晶粒上及晶粒之间形成了多孔隙组织,涂层中并未发现Mo和Ti相成分组织。

2.3 基体类型对23Mo-64Si-14Ti复相陶瓷涂层微观结构的影响

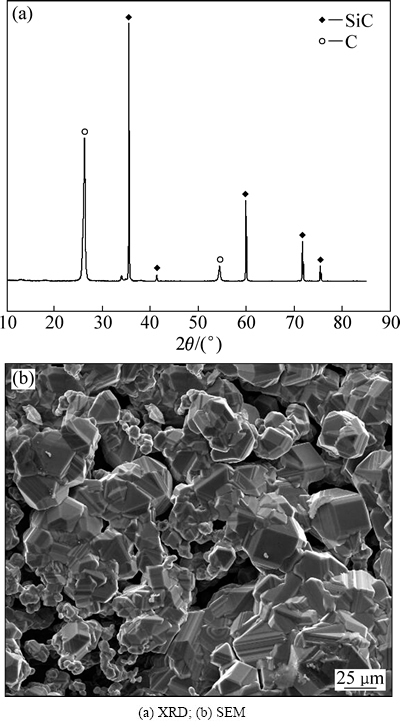

图12所示为在碳纸基体制备23Mo-63Si-14Ti涂层XRD谱及SEM像。由图12可以观察到,XRD谱中并未发现钼硅相存在,同时,涂层中发现明显的C衍射峰。从SEM像中可以观察到涂层表面基本由SiC组成,表面孔隙较多,检测到的C衍射峰为碳纸基体。

图8 工艺条件不同23Mo-63Si-14Ti涂层的XRD谱

Fig. 8 XRD patterns of 23Mo-63Si-14Ti coating at different conditions

2.4 Mo-Si-X-C(X=Al,Ti)复相陶瓷涂层形成机制

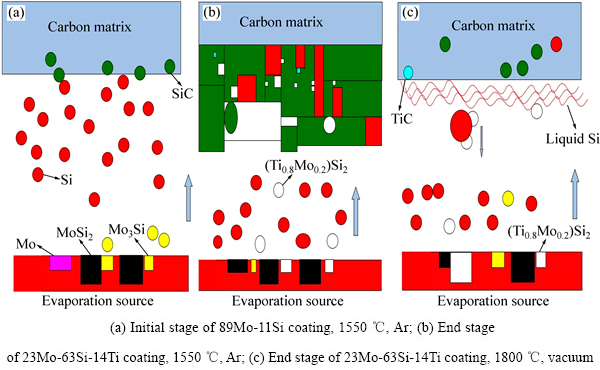

图13所示为热蒸镀-原位反应法制备Mo-Si-C-X(X=Ti,Al)复相陶瓷涂层形成机制示意图,其主要包括蒸镀母料的蒸发、扩散、基体表面物理吸附、表面化学吸附、互扩散反应等过程。其中蒸镀母料的蒸气压、反应过程温度等是关键影响因素。

由于硅元素的蒸气压极高(5.12 Pa,1800 K)[16],且蒸镀母料中硅含量较高,在热蒸镀-原位反应初期(见图12(a)),Si蒸气首先扩散至基体表面并有效吸附,与基体炭发生互扩散反应生成SiC晶核并长大,形成SiC底层。在热蒸镀-原位反应中后期(见图12(b)),其他母料元素(Mo、Ti、Al)与Si同时蒸镀至基体表面并吸附,彼此及与扩散至表面的碳元素之间,反应生成各类碳化物和硅化物等,最终形成具有复杂相排列的自组织花样结构且致密的多元陶瓷复相表层。由于所凝聚在表层的Si未全部反应,因此,该层靠近表面处含有残留Si相。需要注意的是,各类蒸气原子在未到底基体表面部分提前相遇反应,生成陶瓷相颗粒(Ti0.8Mo0.2)Si2(见图12(b))并吸附。同时,后3种母料中Si、Ti、Mo、Al蒸镀速度不同,形成各相晶粒相互抑制长大,形成极为光滑的表面。而直接采用MoSi2粉末代替Mo粉作为蒸镀母料,MoSi2需先分解生成Mo和Si高活性小分子后再蒸镀,原有的Si大量蒸镀并反应,形成较厚的SiC/Si涂层。

图9 1550 ℃真空条件下制备的23Mo-63Si-14T陶瓷涂层的SEM像

Fig. 9 SEM images of 23Mo-63Si-14Ti coating at 1550 ℃ and vacuum condition

图10 1800 ℃真空条件下制备的23Mo-63Si-7Ti-7Al陶瓷涂层的SEM像

Fig. 10 SEM images of 23Mo-63Si-7Ti-7Al ceramic coating at 1800 ℃ and vacuum condition

图11 1800 ℃氩气条件下制备的23Mo-63Si-7Ti-7Al陶瓷涂层的SEM像

Fig. 11 SEM images of 23Mo-63Si- 7Ti-7Al ceramic coating at 1800 ℃ and Ar condition

图12 石墨基体的XRD谱及SEM像

Fig. 12 XRD pattern (a) and SEM image (b) of 23Mo-63Si-14Ti coating prepared in carbon paper substrate in argon at 1550 ℃

同时,反应过程的大气压也会对涂层形貌分布造成较大影响。根据以前的研究表明,原子在热蒸镀过程的运动跟其分子运动的平均自由程有关[17]。而分子的平均自由程与分子在运动中发生碰撞的可能性成反比。在Ar气氛中热蒸镀,蒸镀原子,特别是Si 原子,极易与Ar原子发生碰撞,改变其运动方向,易聚集成大分子或者大颗粒,然后凝聚在基体表面。在真空条件下,原子及分子之间的碰撞大大减小,聚集成大分子的概率较小,分散在基体表面较为均匀,呈现出如图9所示的大范围分散和小部分团聚的现象。

此外,反应过程温度也是热蒸镀-原位反应法制备23Mo-63Si-14Ti涂层的重要影响因素之一。可以观察到,温度对涂层的影响主要是对Si和SiC的影响。在1550 ℃下制备涂层时,蒸镀表面的Si处于熔融状态,具有一定流动性和较强的黏性,所以涂层分层现象明显,钼硅化物聚集性较强(见图3)。温度升高至1800 ℃时,如图12(c)所示,由于蒸镀表面的Si基本处于液态,流动性强而黏性较弱,蒸镀过程中除了少量与碳基体反应形成的TiC和MoC等外,其余Mo,Ti系化合物在重力作用下分布在液态Si表面,并随之滴落剥离。

在1800 ℃条件下,不同气氛对涂层微观形貌的影响主要取决于临界形核能、临界形核半径、和临界形核速率。下列式分别是最大形核自由能ΔG*、临界形核半径rc以及临界晶核形核速率I的关系[14]:

(4)

(4)

(5)

(5)

(6)

(6)

式中:σ 为晶核表面张力;M 为摩尔质量;ρ 为液体密度;ΔHv为蒸发热;T0为液相沸点。

温度较低时,最大形核能和临界晶核半径较小,临界形核速率较大,热蒸镀过程以形核为主。当温度较高时,最大形核能和临界晶核半径变大,蒸镀过程以晶体长大为主。

当温度升高,涂层表面的SiC颗晶粒存在长大现象。真空条件下晶核表面张力远远大于Ar气氛的晶核表面张力,使同等状态下真空条件的最大形核能和临界晶核半径远大于Ar气氛的,因此,涂层表面的SiC颗粒晶粒长大远比Ar气氛条件下长大明显,但异常长大的SiC晶粒无法的完全覆盖基体表面,破坏涂层结构,导致失效。

不同于1800 ℃高温导致制备23Mo-63Si-14Ti涂层中钼硅化物消失,在碳纸基体上制备23Mo-63Si-14Ti涂层失败的主要影响因素是基体表面的粗糙度及润湿性。石墨基体表面粗糙,孔隙极多,毛细管力强,所以有利于Si渗入基体内部。同时,发生Mo、Ti、Si与C之间的多相反应,生成的新相偏聚或分散在基体孔隙内部;而碳纸基体表面较为光滑,孔隙较少,热蒸镀的Si原子主要聚集堆积在基体表面,其中的Mo和Ti等组元与及其反应物与碳纸基体润湿性差,由于重力的作用下分布在液相Si表面,并随之滴落剥离。

图13 Mo-Si-X-C(X=Al,Ti)陶瓷涂层形成机制

Fig. 13 Formation mechanism of Mo-Si-X-C(X=Al,Ti) coating

3 不同成分的Mo-Si-X-C(X=Al,Ti)涂层的力学性能

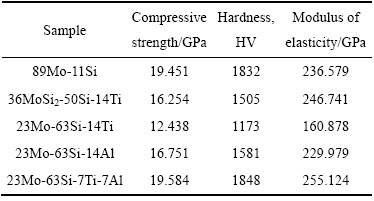

表2所列为1550 ℃、氩气条件下制备的不同涂层的力学性能。由表2可看出,23Mo-63Si-7Al-7Ti陶瓷涂层展现出最高的力学性能。这是由于同时添加Al和Ti元素后涂层形成大量复杂的多相界面结构,有利于力学性能的提升;而较多的孔隙和孔洞是23Mo-63Si-14Ti陶瓷涂层力学性能较低的主要原因;对比89Mo-11Si 和 36MoSi2-50Si-14Ti陶瓷涂层,前者主要由较为平滑致密的SiC/Si组成,有利于提高其力学性能。后者生成的钼硅化物及钼钛化物导致涂层的抗压强度和硬度的降低,但会提高涂层的弹性模量。而在文献[10]报道中指出,添加Al会导致涂层的室温硬度降低,但23Mo-63Si-14Al陶瓷涂层中硬度降低幅度不大,这也是由于形成复杂的晶界导致。

表2 不同成分涂层的力学性能

Table 2 Mechanical properties of different coatings at 1550 ℃ in argon

4 结论

1) 热蒸镀-原位反应法制备Mo-Si-X-C(X=Al,Ti)陶瓷涂层主要受蒸镀母料成分和热蒸镀温度影响,呈现多层多相显微结构特征。

2) 单一的Mo和Si粉末形成的钼硅化物熔点较高,蒸汽压较低,在1550 ℃难以热蒸镀。而添加Al和Ti元素有利于促进热蒸镀过程,能够形成 (Ti0.8Mo0.2)Si2和Mo(Si, Al)2等复杂金属间化合物。

3) 当热蒸镀温度达到1800 ℃时,由于基体表面Si处于液相状态,Mo、Ti化物难以吸附。当真空条件下,异常长大的SiC会破坏涂层结构,导致涂层失效。

4) 23Mo-63Si-7Al-7Ti陶瓷涂层由于具有复杂多相界面结构,从而显示最优的力学性能,其显微硬度可达1848 HV,抗压强度可达19.584 GPa,弹性模量可达255.124 GPa。

REFERENCES

[1] WEN Zhong-liu, XIAO Peng, LI Zhuan, HONG Wen, LUO Heng, YU Xiao-yu, LI Yang, CHEN Wen-bo. Microstructure and oxidation behavior of sol-gel mullite coating on SiC-coated carbon/carbon composites[J]. Journal of the European Ceramic Society. 2015, 34(14): 3789-3796.

[2] SUN Wei, XIONG Xiang, HUANG Bai-yun, LI Guo-dong, ZHANG Hong-bo, CHEN Zhao-ke, ZHENG Xiang-lin. ZrC ablation protective coating for carbon/carbon composites[J]. Carbon, 2009, 47(14): 3365-3380.

[3] SU Zhe-an, YANG Xin, HUANG Qi-zhong, HUANG Bai-Yun, LI Jian-li, ZHANG Ming-yu, XIE Zhi-yong. Effect of SiC coating on ablation resistance of C/C composites under oxyacetylene torch flame[J]. Transactions of Nonferrous Metals Society in China, 2011, 21(11): 2838-2845.

[4] CASCALES A, TABARES N,  J F, CERPA A, SMIRNOV A, MORENO R, NIETO M I. Processing and mechanical properties of mullite and mullite-alumina composites reinforced with carbon nanofibers[J]. Journal of the European Ceramic Society, 2015, 35(13): 3613-3621.

J F, CERPA A, SMIRNOV A, MORENO R, NIETO M I. Processing and mechanical properties of mullite and mullite-alumina composites reinforced with carbon nanofibers[J]. Journal of the European Ceramic Society, 2015, 35(13): 3613-3621.

[5] LI He-jun, XUE Hui, WANG Yong-jie, FU Qian-gang, YAO Dong-jia. A MoSi2-SiC-Si oxidation protective coating for carbon/carbon composites[J]. Surface and Coatings Technology, 2007, 201(24): 9444-9447.

[6] HOU Shi-xiang, LIU Zong-de, LI Bao-rang, ZHANG Nai-qiang. Microstructure and oxidation resistance of Mo-Si and Mo-Si-Al alloy coatings prepared by electrothermal explosion ultrahigh speed spraying[J]. Materials Science and Engineering, 2009, 158(1): 108-117.

[7] WU Zhi-hong, ZHOU Wan-cheng, LUO Fa, ZHU Dong-mei. Effect of MOSi2 content on dielectric and mechanical properties of MoSi2/Al2O3 composite coating[J]. Transactions of Nonferrous Metals Society in China, 2012, 22(1): 111-116.

[8] LIU Jun, GONG Qiang-ming, SHAO Yang, ZHUANG Da-ming, LIANG Ji. In-situ fabrication of MoSi2/SiC-Mo2C gradient anti-oxidation coating on Mo substrate and the crucial effect of Mo2C barrier layer at high temperature[J]. Applied Surface Science, 2014, 308(30): 261-268.

[9] 邓 雄, 彭 可, 周文艳, 易茂中, 冉丽萍, 葛毅成. 熔盐法在石墨表面中温制备MoSi2-SiC复合涂层[J]. 粉末冶金材料科学与工程,2014, 19(1): 89-94.

DENG Xiong, PENG Ke, ZHOU Wen-yan, YI Mao-zhong, RAN Li-ping, GE Yi-cheng. Salt pack cementation synthesis of MoSi2-SiC composite coating on graphite surface at mid-temperature[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(1): 89-94.

[10] LI Ting, LI He-jun, SHI Xiao-hong, CHENG Jing, LIU Lei. Mo-Si-Al-C multiphase oxidation protective coating for carbon/carbon composites[J]. Applied Surface Science, 2013, 276(1): 154-158.

[11] HE Zi-bo, LI He-jun, SHI Xiao-hong, FU Qian-gang. Formation mechanism and oxidation behavior of MoSi2-SiC protective coating prepared by chemical vapor infiltration/reaction[J]. Transactions of Nonferrous Metals Society in China, 2013, 23(7): 2100-2106.

[12] 曾燮榕, 郑长卿, 李贺军, 杨 峥. 碳/碳复合材料 MoSi2 涂层的防氧化研究[J]. 复合材料学报, 1997(3): 37-40.

ZENG Xie-rong, ZHENG Chang-qing, LI He-jun, YANG Zheng. Anti-oxidation of MoSi2 coating on carbon/carbon composites[J]. Journal of Composite Materials, 1997(3): 37-40.

[13] 杨 鑫, 邹艳红, 黄启忠, 苏哲安, 王秀飞, 张明瑜. C/C 复合材料 MoSi2-Mo5Si3/SiC 涂层的制备及组织结构[J]. 无机材料学报, 2008(4): 780-783.

YANG Xin, ZOU Yan-hong, HUANG Qi-zhong, SU Zhe-an, WANG Xiu-fei, ZHANG Ming-yu. Preparation and organization structure of MoSi2-Mo5Si3/SiC coating on carbon/carbon composites[J]. Journal of Inorganic Materials, 2008(4): 780-783.

[14] 郝振华, 孙 威, 熊 翔, 但奇善, 李江鸿. 常压化学气相沉积ZrO2涂层的显微结构与微观力学性能[J]. 中国有色金属学报, 2013, 23(7): 1937-1943.

HAO Zhen-hua, SUN Wei, XIONG Xiang, DAN Qi-shan, LI Jiang-hong. Microstructure and micro-mechanical properties of zirconia coating by atmospheric pressure chemical vapor deposition[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1937-1943.

[15] YANG J F, PRAKASH B, JIANG Y, WANG X P, FANG Q F. Effect of Si content on the microstructure and mechanical properties of Mo-Al-Si-N coatings[J]. Vacuum, 2012, 86: 2010-2013.

[16] MESSNER R P, CHIANG Y M. Liquid-phase reaction-bonding of silicon carbide using alloyed silicon-molybdenum melts[J]. Journal of the American Ceramic Society, 1990, 73: 1193-1200.

[17] 唐伟忠. 薄膜材料制备原理、技术及应用[M]. 北京: 冶金工业出版社, 1998: 1-3.

TANG Wei-zhong. Preparation principle, technology and application of thin film materials[M]. Beijing: Metallurgical Industry Press, 1998: 1-3.

Microstructure and mechanism of Mo-Si-X-C(X=Al,Ti) ceramic coating by thermal evaporation-in situ reaction

XU Yong-long1, HAO An-lin2, SUN Wei1, XIONG Xiang1, PENG Zheng1, CHEN Yun-tian1, CHEN Zhao-ke1, WANG Ya-lei1

(1. State key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China;

2. Anyang Institute of Technology, Henan 455000, China)

Abstract: Mo-Si-X-C (X = Al, Ti) ceramic coatings were prepared by thermal evaporation—in situ reaction in order to investigate the impact of different process parameters and compositions on the microstructure and its mechanism. The phase compositions, microstructural features and micro-mechanial properties were studied by X-ray diffractometer (XRD), scanning electron microscopy (SEM) and commercially available micro-indentation device (CSM), respectively. The results show that, the differences of the morphology, phase composition and distribution are attributed to different diffusion paths of various masterbatches at 1550 ℃ in argon. Adding Ti and Al elements is beneficial for the forming of the (Ti0.8Mo0.2)Si2 and Mo(Si, Al)2, respectively, which can accelerate their evaporation process. As temperature increases to 1800℃, the fluidity of the surface Si increases, however, its viscosity decreases, accompanied by disappearance of molybdenum silicon. Further research shows that SiC grains will grow up unusually, destroy the coating structure and finally lead to coating failure when the atmosphere changes to vacuum. The mechanical properties show that adding Al and Ti elements simultaneously to the masterbatches, the 23Mo-63Si-7Ti-7Al ceramic coating shows the highest value. The compressive strength reaches to 19.584 GPa, hardness reaches 1848HV and elastic modulus reaches 255.124 GPa.

Key words: thermal evaporation; in situ reaction; SiC; (Ti0.8Mo0.2)Si2; coating; carbon-based material

Foundation item: Project(51405522) supported by National Natural Science Foundation of China; Project supported by Independent Research Project of Powder Metallurgy Institute Of Central South, China

Received date: 2016-01-25; Accepted date: 2016-06-21

Corresponding author: SUN Wei; Tel: +86-13808478540; E-mail: sunweimse@csu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51405522);中南大学粉末冶金研究院自主课题

收稿日期:2016-01-25;修订日期:2016-06-21

通信作者:孙 威,副研究员,博士;电话:13808478540;E-mail:sunweimse@csu.edu.cn