等离子喷涂制备Al2O3, ZrO2, Al2O3/ZrO2和ZrO2/Al2O3涂层的腐蚀性能

来源期刊:中国有色金属学报(英文版)2016年第5期

论文作者:S. SATHISH M. GEETHA

文章页码:1336 - 1344

关键词:双层涂层;Al2O3;ZrO2;大气等离子喷涂;腐蚀

Key words:bilayered coating; Al2O3; ZrO2; atmospheric plasma spraying; corrosion

摘 要:采用大气等离子喷涂技术在低碳钢表面制备Al2O3、ZrO2、ZrO2/Al2O3和Al2O3/ZrO2涂层。利用扫描电镜(SEM)和X射线衍射(XRD)技术对涂层的显微组织和相组成进行分析,采用极化、盐雾和浸泡等实验手段对涂层在3.5% NaCl溶液中的腐蚀行为进行研究。结果表明,双层Al2O3/ZrO2涂层比另外三种涂层具有更好的抗腐蚀性能,这主要归因于该涂层中非常少的内联孔洞和稳定的相组成。

Abstract: ZrO2, Al2O3, ZrO2/Al2O3 and Al2O3/ZrO2 coatings were fabricated on low carbon steel using atmospheric plasma spraying technique. The microstructure and phase composition of the as-sprayed coatings were examined by scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively. The polarization test, salt spray test and immersion test were used to investigate the corrosion behavior of the coatings in 3.5% NaCl solution. The results suggested that the bilayered Al2O3/ZrO2 coating exhibits superior corrosion resistance when compared with the other coatings. This is ascribed to the presence of very few interconnected pores and stable phases in the coating.

S. SATHISH1, M. GEETHA2

1. Department of Mechanical Engineering, Aalim Muhammed Salegh College of Engineering,

Avadi IAF, Chennai 600055, India;

2. School of Mechanical and Building Sciences, VIT University, Vellore 632014, India

Received 8 June 2015; accepted 19 October 2015

Abstract: ZrO2, Al2O3, ZrO2/Al2O3 and Al2O3/ZrO2 coatings were fabricated on low carbon steel using atmospheric plasma spraying technique. The microstructure and phase composition of the as-sprayed coatings were examined by scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively. The polarization test, salt spray test and immersion test were used to investigate the corrosion behavior of the coatings in 3.5% NaCl solution. The results suggested that the bilayered Al2O3/ZrO2 coating exhibits superior corrosion resistance when compared with the other coatings. This is ascribed to the presence of very few interconnected pores and stable phases in the coating.

Key words: bilayered coating; Al2O3; ZrO2; atmospheric plasma spraying; corrosion

1 Introduction

Low carbon steels are prone to corrosion and wear as it is often exposed to aggressive environments [1]. To protect the steel from the above aspects, ceramic coatings are widely employed [2-4]. Amongst all the ceramics, alumina (Al2O3) and zirconia (ZrO2) are preferred as they exhibit superior hardness, good chemical stability, excellent corrosion and wear resistance [5-7]. Several techniques such as chemical vapor deposition (CVD), plasma electrolytic oxidation (PEO) and atmospheric plasma spraying (APS) can be adopted for the fabrication of alumina and zirconia coatings [8-10]. Among these techniques, plasma spraying is chosen due to its simplicity, low cost, versatility and high deposition rate. However, it is well known that the ceramic coatings fabricated using plasma spraying technique possesses relatively high inherent porosity which in turn permits the electrolyte to attack the substrate thereby leading to corrosion. Hence, in order to effectively circumvent the above issue, there is a need for the inclusion of an intermediate layer between ceramic coating and the substrate which is henceforth referred as bilayered coating. GAO et al [11] have performed micro laminated ZrO2/Al2O3 coating on stainless steel substrate using electro deposition process and observed significant enhancement in the oxidation resistance and interfacial adhesion. The adhesion studies carried out by CHANG and YEN [12] revealed that ZrO2 can be considered as an underlying material for fabricating Al2O3 coating. It is evident from the work carried out by LIU et al [1] that the incorporation of metallic bond coat layers such as Ni60, NiAl and FeAl in the plasma sprayed Al2O3 coatings has resulted in higher corrosion resistance. Besides this, our earlier work on bilayered (ZrO2/Al2O3- 13TiO2) coating resulted in the remarkable improvement in wear and corrosion resistance of the biomedical Ti-13Nb-13Zr alloy [13,14]. Conversely, few research works performed by considering Al2O3 as an intermediate layer have also yielded considerable improvement in mechanical properties. LIMARGA et al [15] have observed significant improvement in the oxidation resistance of the super alloys by depositing Al2O3 as an intermediate layer. Furthermore, JAKOVLJEVIC et al [16] reported that the pores generated within the plasma sprayed Al2O3 coating can be sealed by depositing ZrO2 layer using dip coating. Despite the fact that few studies were carried out on the fabrication of bilayered coatings using several techniques, as of now, there are few reports with regard to the corrosion behavior of bilayered coatings fabricated using atmospheric plasma spraying. Hence, an attempt is made on the fabrication of bilayered coatings comprising of ZrO2 and Al2O3 as an intermediate layer (ZrO2/Al2O3 and Al2O3/ZrO2) on low carbon steel substrate using atmospheric plasma spraying. Furthermore, the corrosion behavior of the bilayered coatings was investigated by potentiodynamic polarization and immersion test in 3.5% NaCl solution and the results were compared with those of the monolayer Al2O3 and ZrO2 coatings. The salt spray test was also carried out in neutral fog and its corrosion mechanisms were discussed in detail.

2 Experimental

2.1 Fabrication of plasma spray coatings

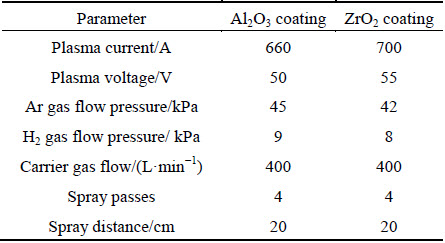

The steel substrates were cut into coupons with dimensions of 35 mm × 20 mm × 4 mm from AISI 1018 low carbon steel plate. Grit blasting was performed using 20 μm alumina grits prior to plasma spraying. The substrates were preheated to a temperature of 300 °C using plasma gun so as to enhance the adhesion between the coating and the substrate. Bilayered coatings consisting of alternate layers of alumina and zirconia namely Al2O3/ZrO2 (Bottom layer-Al2O3 and top layer- ZrO2) and ZrO2/Al2O3 (Bottom layer-ZrO2 and top layer-Al2O3) coatings were fabricated on the steel coupon using 9MB Metco plasma spray system (80 kW). The parameters for depositing monolayer and bilayer coatings are shown in Table1.

Table 1 Parameters used for plasma spraying alumina and zirconia powders

2.2 Characterization of plasma spray coatings

The microstructure and the cross section of the as-sprayed coatings were observed using scanning electron microscope (SEM, JEOL JSM-6360). Porosity measurements were carried out on the microstructures of the SEM images using CLEMEX VISION Image analysis software attached with optical microscope (Carl Zesis Make). Phase analysis of the as-sprayed coatings was performed on Philips 3121 X-ray diffractometer using Cu Kα radiation which was set at 40 kV and 20 mA for the XRD analysis and the data were recorded in the 2θ range of 10° to 80° in a step scan mode with a step of 2 (°)/min. Hardness measurements were carried out across the cross section of the samples using Vickers hardness tester (Chennai Metco) by applying a load of 200 g. The hardness values reported were the average of five readings made across the coated surface. The surface roughness (Ra) of the as-sprayed coatings was measured using Mitutoyo Surf test-211 profilometer.

2.3 Potentiodynamic polarization analysis

Potentiodynamic polarization studies were performed using potentiostat. It mainly consists of three electrode system, i.e., a conventional three-electrode cell with platinum foil as counter electrode, a saturated calomel electrode as reference electrode and the coated sample as working electrode. The sample surfaces were degreased by ultrasonic cleaning in distilled water prior to testing. Potentiodynamic polarization investigations were performed using a potentiostat (Gill AC, ACM make) with an initial potential of 500 mV below the open circuit potential (OCP) and the scan rate was 0.1666 mV/s. The potentiodynamic polarization curves were recorded after 4 h of immersing the coupons in 3.5% NaCl solution.

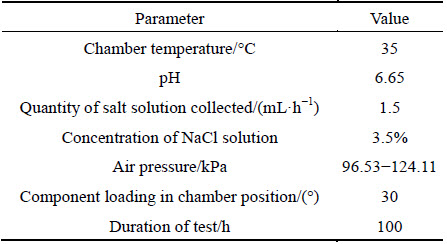

2.4 Salt spray test

The as-sprayed samples were suspended inside the test chamber using plastic strings in a free standing mode to ensure that all portions of the specimens got sprayed uniformly. Later, the as-sprayed samples were salt sprayed by 3.5% NaCl solution at 35 °C in a continuous manner at Micro Lab, Chennai, India. The parameters employed for salt spray test are shown in Table 2. The corroded surface of the as-sprayed coatings was examined using JEOL JSM-6360 scanning electron microscope (SEM).

Table 2 Parameters used for salt spray test

2.5 Immersion test

Immersion test was carried out in 3.5% NaCl solution as per the ASTM G-31-72 for 30 d (720 h). The coatings were exposed to NaCl solution and the uncoated regions of the specimens were masked with epoxy paint. The mass of the individual specimens was assessed before and after the immersion test and their surface was examined using SEM.

3 Results and discussion

3.1 Microstructure of coatings

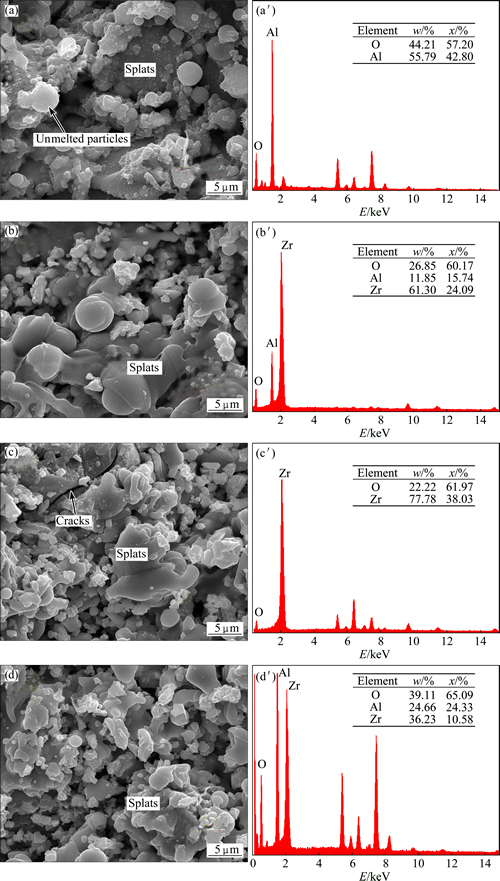

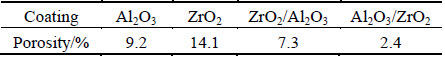

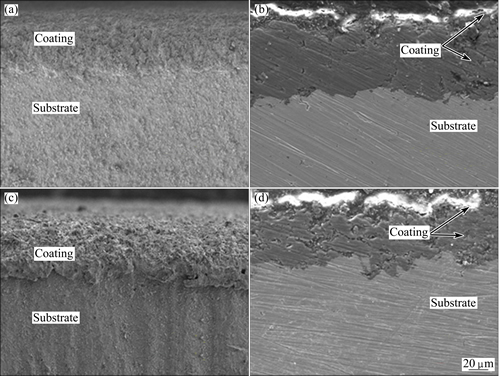

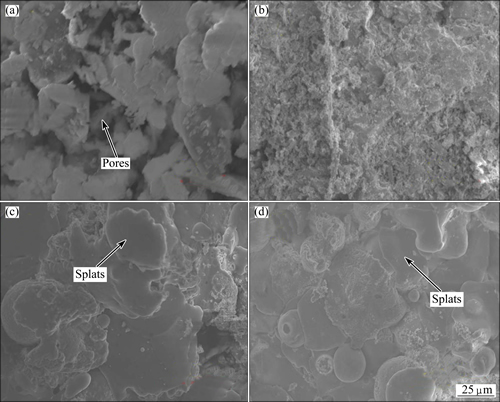

The microstructure of Al2O3 coatings shows the presence of lamellar splats with very few unmelted particles as shown in Fig. 1(a). Pores were also detected on the surface of the coating. On the other hand, the bilayered Al2O3/ZrO2 coating possesses a very uniform and dense microstructure as depicted in Fig. 1(b). This is due to the fact that the pores generated in the Al2O3 coating has been sealed by the topmost ZrO2 layer. However, the larger pores are not completely sealed. The ZrO2 coating exhibits very few splats with larger amount of poorly consolidated fine particles. This is due to the fact that the larger sized ZrO2 particles are heated at a lower rate in the plasma flame, therefore the grains are expected to grow and these larger grains impact the substrate with a higher momentum and finally form the overlapping splats in the microstructure, whereas the smaller particles of the ZrO2 powders undergo rapid melting, thereby limiting the grain growth, resulting in poorly consolidated structure. Few cracks were detected on the surface of the ZrO2 coating (Fig. 1(c)). The surface of the bilayered (ZrO2/Al2O3) coating was found to be smooth and dense with large number of fully melted splats. This is attributed to the fact that the ZrO2 layer with very low thermal conductivity plays a crucial role in melting the particles, thereby resulting in large number of splats with very few pores (Fig. 1(d)). The microstructure thus obtained is well in corroboration with the results reported earlier [13]. The porosity of the as-sprayed coatings is shown in Table 3. The cross sectional morphologies of the Al2O3, ZrO2, ZrO2/Al2O3, and Al2O3/ZrO2 are shown in Fig. 2. No distinct interface between the coating and substrate was observed for all the as-sprayed coatings, signifying enhanced interfacial adhesion between the coating and substrate. At higher magnification, a large number of fully melted splats are observed on the cross sectional morphology of the plasma sprayed Al2O3 coating, whereas the ZrO2 coating possesses very fine poorly consolidated particles. In addition to this, few pores were also noticed (Figs. 3(a) and (b)). On the other hand, the cross sectional view of both bilayered ZrO2/Al2O3 and Al2O3/ZrO2 coatings shows the presence of dense microstructure with very few pores, indicating that the pores present in the monolayer coating have been effectively sealed by the intermediate ZrO2 and Al2O3 layers (Figs. 3(c) and (d)). However, few un-melted particles were also observed on the surface of both coatings.

Fig. 1 Surface morphologies and EDS analysis of Al2O3 (a, a′), Al2O3/ZrO2 (b, b′), ZrO2 (c, c′) and ZrO2/Al2O3 (d, d′) coatings

Table 3 Extent of porosity in various coatings

3.2 Microhardness

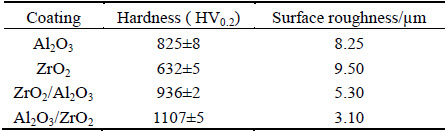

A significant enhancement in the hardness for both bilayered coatings was observed. This is mainly due to the presence of very few pores and lower surface roughness. On contrary, the lower hardness of ZrO2 and Al2O3 coatings is attributed to the higher porosity of the coatings. The hardness and average surface roughness (Ra) values of the plasma sprayed coatings are shown in Table 4.

3.3 Phase analysis

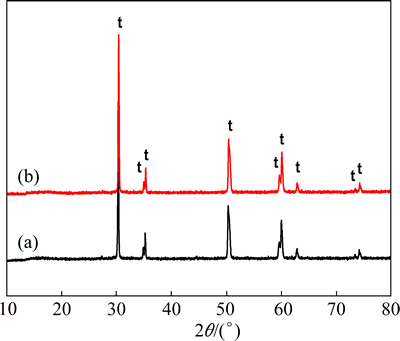

X-ray diffraction (XRD) analyses of the as-sprayed coatings are depicted in Figs. 4 and 5. The XRD patterns of both Al2O3 and bilayered ZrO2/Al2O3 coatings show the presence of highly stable α (corundum) phase. No peak corresponding to zirconia was detected in the bilayered ZrO2/Al2O3 coating. The XRD pattern of ZrO2 coating shows the presence of tetragonal phase. On the other hand, the bilayered Al2O3/ZrO2 coating possesses a peak corresponding to α phase together with the tetragonal zirconia. The existence of highly stable α (corundum) phase in Al2O3 and ZrO2/Al2O3 coatings is an indication of few un-melted particles observed in the microstructures of both coatings. Similar observations were made by GOBERMAN et al while depositing Al2O3-13%TiO2 powders on the mild steel substrate [17].

Fig. 2 Cross sectional observations of Al2O3 (a), Al2O3/ZrO2 (b), ZrO2 (c) and ZrO2/Al2O3 (d) coatings at lower magnification

Fig. 3 Cross sectional observations of Al2O3 (a), ZrO2 (b), ZrO2/Al2O3 (c) and Al2O3/ZrO2 (d) coatings at higher magnification

Table 4 Hardness and surface roughness of as-sprayed coatings

Fig. 4 XRD patterns of Al2O3 (a) and ZrO2/ Al2O3 (b) coatings

Fig. 5 XRD patterns of ZrO2 (a) and Al2O3/ZrO2 (b) coatings

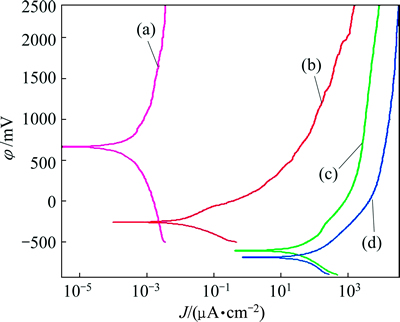

3.4 Electrochemical polarization test

Representative potentiodynamic polarization curves obtained for all the coatings are displayed in Fig. 6.

Fig. 6 Representative potentiodynamic polarization curves of Al2O3/ZrO2 (a), ZrO2/Al2O3 (b), Al2O3 (c) and ZrO2 (d) coatings in 3.5% NaCl solution

Among all the coatings, the corrosion potential (φcorr) of the bilayered Al2O3/ZrO2 coating is positive signifying better stability and high corrosion resistance. Also, the bilayered Al2O3/ZrO2 coating possesses the lowest current density (Jcorr) indicating higher corrosion resistance compared with the other coatings. The φcorr and Jcorr values of all the coatings are shown in Table 5. From the polarization plots, it is obvious that passivation has occurred for all the coatings. However, the passive layer formed on the bilayered Al2O3/ZrO2 coating was found to be steady and stable throughout the entire potential. This is attributed to the presence of very few pores on the coatings. Further, it should be noted that though passivation occurs for both the monolayer ZrO2 and Al2O3 coatings, there is a slight increase in the current density at higher potential (+200 mV). This is mainly due to the presence of few pores and cracks on the surface which enhances the dissolution by applying anode potential in 3.5% NaCl solution. Besides this, it is noteworthy to mention that the corrosion resistance of the bilayered Al2O3/ZrO2 coating (1.69×10-4 μA/cm2) obtained using atmospheric plasma spraying is considerably higher than that of the same coating fabricated using electrolytic deposition process (25 μA/cm2) [12]. This significant enhancement in the corrosion resistance of the plasma sprayed bilayered Al2O3/ZrO2 coating is due to the presence of very few pores. Furthermore, the improvement in the corrosion resistance of bilayered Al2O3/ZrO2 coating when compared to that of the monolayer ZrO2 coating is due to the fact that the pores generated in the monolayer ZrO2 coating has been sealed by the underlying Al2O3 layer present in the bilayered Al2O3/ZrO2 coating. Besides this, the presence of highly stable α phase and tetragonal zirconia in the bilayered Al2O3/ZrO2 coating has resulted in the substantial increase in hardness and corrosion resistance.

Table 5 Corrosion potential and current density of as-sprayed coatings

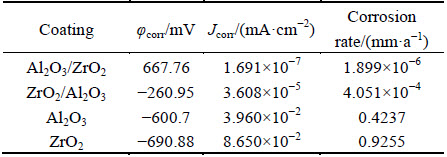

3.5 Corrosion behavior in salt spray test

The macro morphologies of the coatings before and after salt spray test are shown in Fig. 7. Red rust formation was noticed for both monolayer ZrO2 and Al2O3 coatings indicating severe corrosion. Conversely, the surface of both bilayered (Al2O3/ZrO2 and ZrO2/Al2O3) coatings remained unaltered even after salt spray test, depicting excellent resistance to salt mist corrosion. This is mainly due to the presence of very few pores. The results thus obtained are well in accordance with that of the Jcorr values reported earlier.

Fig. 7 Macro morphologies of ZrO2 (a), Al2O3 (b), Al2O3/ZrO2 (c) and ZrO2/Al2O3 (d) coatings

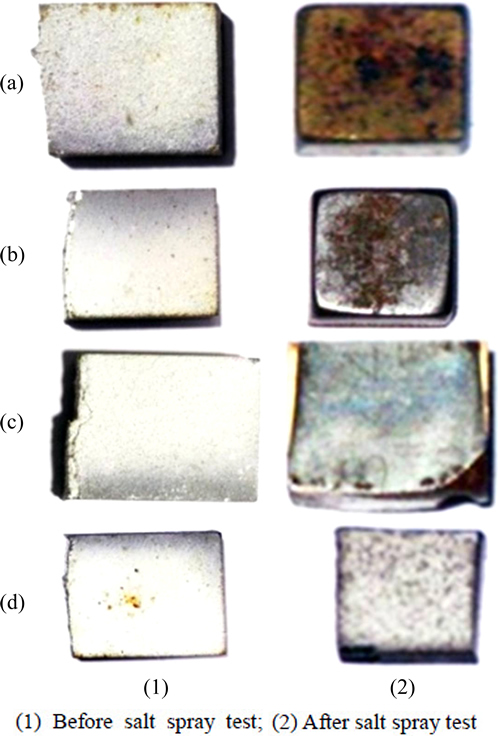

3.6 Characterization of samples after salt spray test

The SEM images of the as-sprayed coatings after salt spray testing are shown in Fig. 8. It is obvious from Figs. 8(a) and (b) that a larger quantity of corrosion products were accumulated on both ZrO2 and Al2O3 coatings. In addition to this, the salt spraying on the coated samples resulted in the formation of dense salt containing moisture film. This film has been adsorbed on the coated surface, thereby dissolving more oxygen. This active oxygen has diffused easily through the coatings, thereby attacking the substrate and leading to severe corrosion. On the contrary, the salt sprayed surface of both bilayered coatings exhibited meager amount of corrosion products (Figs. 8(c) and (d)). No cracks were detected on the surface of the corroded products and few whiskers were observed on the bilayered Al2O3/ZrO2 coating. The possible reason for the formation of whiskers could be attributed to the presence of large number of tetragonal phases in the coating. In view of the fact that the corroded products are crack free, the oxygen atom cannot diffuse through the coating and attack the substrate. Furthermore, the presence of an intermediate Al2O3 and ZrO2 layers of both Al2O3/ZrO2 and ZrO2/Al2O3 coatings has acted as an insulator thereby hindering the oxygen atom to attack the substrate thereby resulting in excellent corrosion resistance.

Fig. 8 SEM images of Al2O3 (a), ZrO2 (b), ZrO2/Al2O3 (c) and Al2O3/ZrO2 (d) coatings after salt spray testing

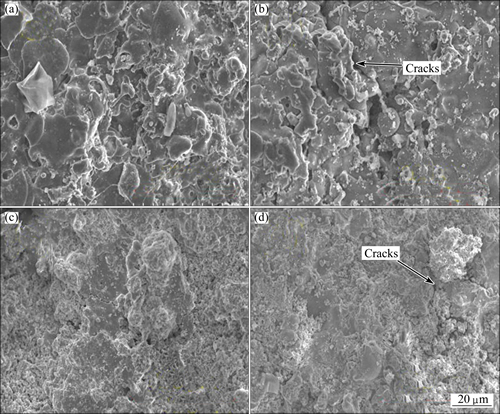

3.7 Microstructure of samples after immersion test

The cumulative mass loss for all the as-sprayed coatings is depicted in Table 6. It is well evident that there are no significant changes in the mass losses of the coatings, suggesting that these systems have undergone localized corrosion. Few pits were observed on the surface of the Al2O3 coating. Further, few sodium chloride crystals were also accumulated on its surface (Fig. 9(a)). On the other hand, severe damage with larger pits and cracks was noticed on the surface of ZrO2 coating, indicating the highest mass loss among other coatings. This is due to the fact that the presence of poorly consolidated splats in the microstructure has provided path for the NaCl solution to attack the substrate, leading to severe corrosion (Fig. 9(b)). Small corrosion pits were detected on the surface of bilayered Al2O3/ZrO2 coating (Fig. 9(c)). This is due to the fact that the presence of highly stable alumina layer between the ZrO2 coating and the substrate has hindered the penetration of NaCl solution towards the substrate, leading to excellent corrosion resistance. Similar effect was observed on the bilayered ZrO2/Al2O3 coating also. Nevertheless, minute cracks were detected on its surface (Fig. 9(d)) and this may be due to the thermal stresses developed during plasma spraying. Also, it is apparent that unlike Al2O3/ZrO2 coating, the topmost Al2O3 layer present in the ZrO2/Al2O3 coating was not able to completely prevent the NaCl solution from reaching the substrate and this is mainly due to the existence of minute cracks. These results are well in concurrent with that of the polarization studies reported earlier.

Table 6 Cummulative mass loss after 720 h immersion test in 3.5% NaCl solution

4 Conclusions

1) The surface morphology of bilayered Al2O3/ZrO2 and ZrO2/Al2O3 coatings demonstrates the presence of dense and uniform microstructure with very low porosity when compared with that of ZrO2 and Al2O3 coatings.

Fig. 9 SEM images of Al2O3 (a), ZrO2 (b), Al2O3/ZrO2 (c) and ZrO2/Al2O3 (d) coatings after immersion test for 720 h in 3.5% NaCl solution

2) There is a significant increase in the hardness of both bilayered coatings when compared with that of the monolayer ZrO2 and Al2O3 coatings. This is mainly due to the presence of low porosity.

3) The presence of highly stable tetragonal phases in the bilayered Al2O3/ZrO2 coating is responsible for the increase in hardness and corrosion resistance.

4) Potentiodynamic polarization studies reveal that the Jcorr value obtained for the bilayered Al2O3/ZrO2 coating was found to be the lowest when compared with that of the other three coatings, depicting excellent corrosion resistance. This is attributed to the presence of very few pores and dense microstructure.

5) The salt spray test results suggest that the corrosion products accumulated on both the bilayered coatings were very less and an intermediate Al2O3 and ZrO2 layers present on the bilayered Al2O3/ZrO2 and ZrO2/Al2O3 coatings have hindered the oxygen atoms attacking the substrate, leading to excellent corrosion resistance.

6) The immersion test results revealed that the bilayered Al2O3/ZrO2 coating exhibited the highest corrosion resistance among other coatings. This is attributed to the hindrance afforded by the stable Al2O3 layer for the penetration of NaCl solution towards the substrate.

References

[1] LIU Zhe, CHU Zhen-hua, DONG Yan-chun, YANG Yong, CHEN Xue-guang. The effect of metallic bonding layer on the corrosion behavior of plasma sprayed Al2O3 ceramic coatings in simulated sea water [J]. Vacuum, 2014, 101: 6-9.

[2] WANG Y, JIANG S, WANG M, WANG S, XIAO D T, STRUTT P R. Abrasive wear characteristics of plasma sprayed nanostructured alumina/titania coatings [J]. Wear, 2000, 237: 176-185.

[3] YAN Dian-ran, HE Ji-ning, WU Jian-jun, QIU Wan-qi, MA Jing. The corrosion behavior of plasma spraying Al2O3 ceramic coating in dilute HCl solution [J]. Surface and Coatings Technology, 1997, 89: 191-195.

[4] SINGH V P, SIL A, JAYAGANTHAN R. A study of sliding and erosive wear behavior of atmospheric plasma sprayed conventional and nanostructured alumina coatings [J]. Materials and Design, 2011, 32: 584-591.

[5] RAMACHANDRAN K, SELVARAJAN V, ANANTHAPADMANABHAN P V, SREEKUMAR K P. Microstructure, adhesion, microhardness, abrasive wear resista-ce and electrical resistivity of the plasma sprayed alumina and alumina-titania coatings [J]. Thin Solid Films, 1998, 315: 144-152.

[6] MINDIVAN H, TEKMEN C, DIKICI B, TSUNEKAWA Y, GARGALI M. Wear behavior of plasma sprayed composite coatings with in situ formed Al2O3 [J]. Materials and Design, 2009, 30: 4516-4520.

[7] AFRASIABI A, SAREMI M, KOBAYASHI A. A comparative study on hot corrosion resistance of three types of thermal barrier coatings: YSZ, YSZ+Al2O3 and YSZ/Al2O3 [J]. Materials Science and Engineering A, 2008, 478: 264-269.

[8] GUIDI F, MORETTI G, CARTA G, NATALI M, ROSSETTO G, PIERINO Z, SALMASO G, RIGATO V. Electrochemical anticorrosion performance evaluation of Al2O3 coatings deposited by MOCVD on an industrial brass substrate [J]. Electrochimica Acta, 2005, 50: 4609-4614.

[9] SUNDARARAJAN T, KURODA S, ABE F. Steam oxidation resistance of two-layered Ni-Cr and Al APS coating for USC boiler applications [J]. Corrosion Science, 2005, 47: 1129-1147.

[10] YAO Zhong-ping, XU Yong-jun, LIU Yun-fu, WANG Da-li, JIANG Zhao-hua, WANG Fu-ping. Structure and corrosion resistance of ZrO2 ceramic coatings on AZ91D Mg alloys by plasma electrolytic oxidation [J]. Journal of Alloys and Compounds, 2011, 509: 8469-8474.

[11] GAO Jun-guo, HE Ye-dong, WANG De-ren. Fabrication and high temperature oxidation resistance of ZrO2/Al2O3 micro laminated coatings on stainless steel [J]. Materials Chemistry and Physics, 2010, 123: 731-736.

[12] CHANG C C, YEN S K. Characterization of electrolytic ZrO2/Al2O3 double layer coating on AISI 440 C stainless steel [J]. Surface and Coatings Technology, 2004, 182: 242-250.

[13] SATHISH S, GEETHA M, ARUNA S T, BALAJI N, RAJAM K S, ASOKAMANI R. Sliding wear behavior of plasma sprayed nano ceramic coatings for biomedical applications [J]. Wear, 2011, 271: 934-941.

[14] SATHISH S, GEETHA M, ARUNA S T, BALAJI N, RAJAM K S, ASOKAMANI R. Studies on plasma sprayed bilayered ceramic coating on biomedical Ti-13Nb-13Zr alloy [J]. Ceramics International, 2011, 37: 1333-1339.

[15] LIMARGA A M, WIDJAJA S, YIP T H. Mechanical properties and oxidation resistance of plasma sprayed multilayered Al2O3/ZrO2 thermal barrier coatings [J]. Surface and Coatings Technology, 2005, 197: 93-102.

[16] JAKOVLJEVIC S, HENDRIX W, HAVERMANS D, MENEVE J. Characterization of ZrO2 layers deposited on Al2O3 coating [J]. Wear, 2009, 266: 417-423.

[17] GOBERMAN D, SOHN Y H, SHAW L, JORDAN E. Microstructure development of Al2O3-13%TiO2 plasma sprayed coatings derived from nanocrystalline powders [J]. Acta Materialia, 2002, 50: 1141-1152.

S. SATHISH1, M. GEETHA2

1. Department of Mechanical Engineering, Aalim Muhammed Salegh College of Engineering,

Avadi IAF, Chennai 600055, India;

2. School of Mechanical and Building Sciences, VIT University, Vellore 632014, India

摘 要:采用大气等离子喷涂技术在低碳钢表面制备Al2O3、ZrO2、ZrO2/Al2O3和Al2O3/ZrO2涂层。利用扫描电镜(SEM)和X射线衍射(XRD)技术对涂层的显微组织和相组成进行分析,采用极化、盐雾和浸泡等实验手段对涂层在3.5% NaCl溶液中的腐蚀行为进行研究。结果表明,双层Al2O3/ZrO2涂层比另外三种涂层具有更好的抗腐蚀性能,这主要归因于该涂层中非常少的内联孔洞和稳定的相组成。

关键词:双层涂层;Al2O3;ZrO2;大气等离子喷涂;腐蚀

(Edited by Sai-qian YUAN)

Corresponding author: S. SATHISH; Tel: +91-44-26842627; Fax: +91-44-28418787; E-mail: mechhh_er@rediffmail.com

DOI: 10.1016/S1003-6326(16)64236-X