文章编号: 1004-0609(2006)09-1534-05

碳膜刀具干式钻削Al-Si合金的切削性能及其

减摩机制

白力静1, 2, 朱晓东1, 肖继明2, 何家文1

(1. 西安交通大学 金属材料强度国家重点实验室, 西安 710049;

2. 西安理工大学 机械与精密仪器工程学院, 西安 710048)

摘 要: 采用非平衡磁控溅射离子镀技术制备碳膜, 通过对刀具后刀面磨损曲线、 切削力以及所加工孔精度的分析, 证明高硬度低摩擦因数碳膜高速钢刀具在干切削条件下钻削铝硅合金时具有良好的切削性能。 同时采用OM、 SEM、 XPS和EDS等方法对切削过程中碳膜的减摩效应进行探讨, 证明碳膜改善刀具抗粘结能力的本质在于碳元素对铝硅合金的润湿性较差, 而非在摩擦过程中生成碳转移膜。 切削过程中碳膜的热稳定性越好, 碳膜刀具的寿命就越长, 一旦碳膜破坏, 则刀具迅速发生粘结失效。

关键词: 碳膜; Al-Si合金; 干式切削; 减摩; 润湿性 中图分类号: TG501; TH117

文献标识码: A

Machinability and anti-adhesive wear performance of carbon coated tools in drilling of Al-Si alloy

BAI Li-jing1, 2, ZHU Xiao-dong1, XIAO Ji-ming2, HE Jia-wen1

(1. State Key Laboratory for Mechanical Behavior of Materials, Xian Jiaotong University, Xian 710049, China;

2. School of Machinery and Precision Instrument Engineering, Xian University of Technology, Xian 710048, China)

Abstract: Two kinds of carbon coatings with high hardness and low coefficient of friction were deposited by closed filed unbalanced magnetron sputtered ion plating techniques. By the analysis of flank wear, the cutting force curves and the dispersion of cutting holes and the carbon coated tools show excellent cutting performance in dry cutting of Al-Si alloys. Through OM, SEM, XPS and EDS, the low adherence of carbon coated tools can be attributed to the low wettability between the Al-Si alloys and carbon instead of forming carbon transfer film during wear. The higher the thermal stability of carbon coating is, the longer of the cutting tools life is. The catastrophic adhesive wear may occur once the carbon coating fails.

Key words: carbon coating; Al-Si alloy; dry cutting; low wear rate; wettability

Al-Si合金是现代工业用途最广的轻金属材料之一, 其密度大约为钢的1/3, 可以有效地减小系统内高速运动部件的自身质量, 提高系统运行速度, 同时Al-Si合金导热性好、 易成型, 适用于制造各种复杂的零部件[1, 2]。 特别是汽车行业, 预计到2010年将有25%的轿车车体结构材料和20%的底盘部分材料由铝硅合金制成[3]。

无润滑干切削因其低生产成本、 环保性以及对操作者身体的健康性等优点成为现代加工业的研究热点[4-6]。 Al-Si合金由于硬度和熔点低, 尽管在常规润滑加工时属于易加工材料, 但干式切削时, 在大塑性变形和切削热影响下, 刀具极易粘结失效。 因此, 人们普遍认为高速钢刀具无润滑干切削, 特别是常见的钻削铝硅合金是不可能实现的[7, 8]。

固体润滑可完全隔离刀-件的直接接触, 减少粘结面积, 提高刀具在切削过程中的摩擦磨损性能。 尤其是碳膜与铝合金具有良好的摩擦磨损性能, 因此目前加工铝合金的镀层刀具以碳膜为主[9, 10]。 由文献[1, 9-11]可看出, 碳膜提高刀具寿命的原因是由于在摩擦磨损过程中易生成转移膜从而改善刀具的磨损性能。 但同时碳元素本身和铝硅合金的润湿性极差, 1000℃以下与碳元素都不会发生粘结[12]。 在降低粘结磨损的过程中, 人们往往似乎更注重减摩效应中转移膜的生成[13, 14], 并非润湿性起着作用。 磁控溅射类金刚石(Diamond like carbon, DLC)和类石墨碳膜(Graphite like carbon, GLC)都具有高硬度和低摩擦因数[15-17], 因而可提高刀具加工Al-Si合金的切削性能。 本文作者研究了GLC和DLC碳膜干式钻削铝硅合金的性能, 讨论了加工铝硅合金所需镀层的性能, 并对碳膜在切削过程中减摩效应的本质原因做出探讨。

1 实验

1.1 切削实验

采用Kistler Type 9271A和信号采集仪(NEC Type RA1200)等测量和采集实验切削力信号, 并与计算机联接输出切削力波形。 切削实验为MCV-510立式加工中心, 钻头磨损量采用放大率为30倍的工具显微镜静态观察测量。

切削实验均在无润滑条件下进行, 切削速度为61m/min, 进给量f=0.13mm/r, 钻削深为19mm的盲孔。 实验中钻头的磨钝标准取刀具后刀面磨损值VB=0.128mm。 孔加工精度的用标准H7、 H8、 H9和H10的塞规来测量。

工件材料为Al-Si合金(HB66~67), 其主要化学成分为(质量分数, %): Si 4.95~4.96; Cu 3.58~3.65; Mg 0.024~0.030; Fe 0.34~0.33。 图1所示为Al-Si合金的金相组织。

刀具选用直径为6.35mm的M2高速钢标准麻花钻。

图1 Al-Si合金金相组织

Fig.1 Optical metallograph of Al-Si alloy

1.2 镀层性能检测

镀层的摩擦磨损实验采用BDW-3型球盘磨损实验机, 载荷为1050kg, Al-Si合金加工成d2.5的球面, 表面用1200#水砂纸打磨, 磨损时线速度为200mm/s。 实验测得GLC、 DLC和高速钢(High speed steel, HSS)与Al-Si合金的摩擦因数分别为0.57、 0.16和0.15。

镀层的退火实验采用普通箱式炉, 保温时间为1h; 硬度测试采用MH-5型显微硬度仪, 载荷20g, 加载时间10s。 GLC与DLC镀层的室温硬度分别为21.3和23.1GPa。

镀层的形貌观察与成分分析采用JEOL JSM-6460扫描电镜和INCAx-sight OXFORD INSTRUMENTS能谱仪。 对磨的Al-Si销成分分析采用AXIS UCTRA型X射线光电子能谱仪, 靶材为Kα线(E=1486.6eV), 采样步长为0.1; 背底真空为133MPa, 分析区域为300~700μm。

2 结果与讨论

2.1 切削实验

切削实验以刀具后刀面上的磨损值达到0.15mm为刀具寿命的判据。 实验结果表明碳膜刀具在加工Al-Si合金时, 加工寿命远远高于高速钢钻头, 其中加工孔数最多为: GLC镀层钻头可加工600个孔, DLC镀层可加工400个孔, 而高速钢钻头仅加工了80个孔。

一般而言, 切削铝硅合金由于其易粘刀, 所加工的孔大多数尺寸偏大, 因此考察刀具对铝硅合金的切削性能, 不仅考虑孔的个数, 同时还要考察所加工孔的精度。 图2所示为所加工孔的精度分布。

图2 合格钻削孔的尺寸分布

Fig.2 Average diameter distribution rate of eligible cutting holes

由图2可知, GLC、 DLC和高速钢所加工的孔中, 在H7、 H8、 H9、 H10范围内均是用GLC碳膜加工孔的合格率最大, 其中尺寸公差在H10以内的孔分别占到82%、 66.75%和26.25%(质量分数)。 这说明在加工过程中, 镀层明显改善了钻孔的效率和质量。

图3所示为不同镀层刀具的磨损曲线。 由图3可知, 白钻头几乎没有稳定磨损阶段, 很快进入剧烈磨损阶段。 DLC膜在加工至330孔之后, 也迅速进入加速磨损阶段, 而GLC膜尽管在稳态磨损阶段其相对磨损量略高于DLC膜, 但稳态区较长, 直至500个孔才开始进入磨损的第三阶段。 刀具磨损初期一般情况下为机械磨损, 硬度越高, 抗磨损性能越好, 3条磨损曲线也表现出该规律。 说明进入稳态以后镀层的低摩擦因数减轻了铝硅合金对刀具的粘结, 从而提高了刀具的耐磨损性能。

图3 不同镀层刀具的磨损曲线

Fig.3 Wear curves of different drills

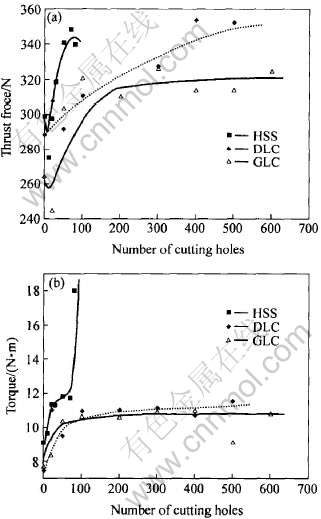

图4所示为不同刀具在切削过程中的切削力与扭矩的变化曲线。 由于切削力来源与材料的弹塑性变形以及刀屑、 刀-件之间的摩擦阻力有关, 而薄膜对材料的弹塑性变形影响很小, 因此摩擦因数应该是影响切削力变化的主要原因之一。 摩擦因数越小, 产生的摩擦力也越小, 但刀具轴向力的变化趋势与刀具的磨损曲线并不一致, 可知轴向力的变小并不是刀具磨损寿命的决定性因素, 当DLC膜刀具轴向力超过高速钢刀具时, 仍可加工近100个孔。 由此得到结论, 在加工类似于铝合金之类的塑性有色合金时, 降低镀层的摩擦因数比提高镀层的硬度更为有效。 切削过程中刀具上的扭矩与刀具上的粘结情况有着直接的关系, 从图4(b)中可明显看出镀层刀具的扭矩要小于高速钢刀具的。

图4 刀具在切削过程中切削力的变化曲线

Fig.4 Change curves of cutting force of drills during cutting

2.2 碳膜的作用

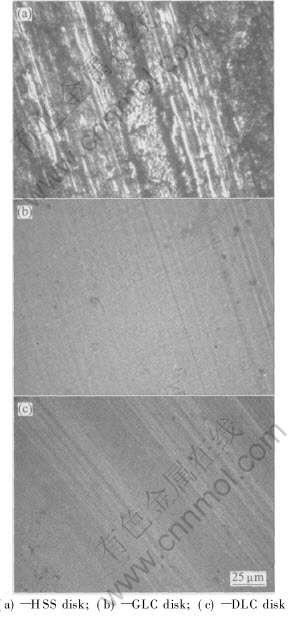

综上所述, 镀层提高刀具耐磨性能的主要原因是由于镀层具有减摩作用。 图5所示为镀层在Pin-on-Disk磨损实验后不同对磨幅与Al-Si销磨损后的图片。 由图5看出, 高速钢磨损表面出现典型的粘结特征, 而GLC碳膜表面粗糙度也明显要小于DLC碳膜, 说明由于较低的摩擦因数减缓了高速钢与铝的粘结。

图5 与Al-Si合金对磨后不同表面的金相照片

Fig.5 Metallographs of different disks against Al-Si pin

一般认为, 切削过程中碳膜的固体润滑作用是由于与对摩件产生了转移膜, 使得摩擦磨损发生在碳与碳之间。

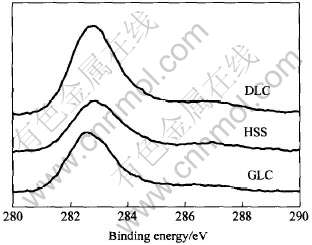

图6所示为Pin-on-Disk实验后对铝硅销摩擦表面做的XPS检测曲线。 由图6可知, 与GLC、 DLC和HSS对磨的Al-Si销表面都没有出现纯碳结构(金刚石为285.5eV, 石墨为284.15eV), 说明这时并没有出现转移膜。

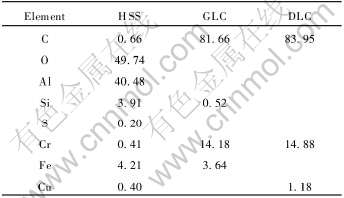

表1所列为对摩擦磨损后镀层表面的能谱分析结果。 由表1可知, 磨损后碳膜镀层的表面不存在铝元素, 而高速钢表面出现大量的铝元素, 说明镀层对铝硅合金具有良好的抗粘结性能。 由此可以断定, 碳膜起减摩作用的主要是碳元素与铝硅合金的润湿性较差而非转移膜的生成。

在切削实验中, 两种碳膜不仅切削寿命相差1.5倍, 加工孔的精度也有明显不同。 但这两种碳膜与铝硅合金的摩擦因数相差并不大, 而碳元素对

图6 与不同对磨副摩擦后的Al-Si销的XPS谱

Fig.6 XPS spectra of Al-Si alloy pins against different disks

表1 不同磨损表面的成分分析

Table 1 Elements distribution of different disks against Al-Si pin (mole fraction, %)

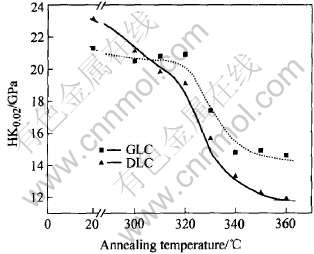

铝硅合金的润湿性基本相同, 固体润滑覆盖层的耐久性取决于摩擦裂化发展的程度, 即在摩擦时的发展温度和变形作用下引起的破坏, 摩擦镀层的失效大多是在服役条件下由于镀层的剥落、 分离以及剥层断裂而导致的[18]。 相对于普通的摩擦磨损, 刀具在钻削过程中, 本身具有高塑变与大剪切应力作用的特点, 同时钻削时的热量难以散发, 温度与形变对镀层和工件的影响更为剧烈。 而碳膜的最大不足之处就在于热稳定性, 不同碳膜切削寿命的大小, 必然取决于其热稳定性的大小。 在切削过程中, 一旦碳膜被破坏, 由于刀屑接触区中Al与Fe均为化学活性极强的清洁金属, 它们之间的粘着力高达2.5mN, 那么工件与刀具分离表面上发生强烈的粘着磨损, 高速钢刀具很快就达到失效。 从刀具的摩擦磨损曲线(图2)也可看出,DLC加工了330个孔以后,很快进入加速磨损阶段,这是由于在切削热的影响下镀层快速氧化失效。图7所示为Si基片上不同碳膜的退火硬度曲线.

图7 碳膜的退火硬度随退火温度的变化曲线

Fig.7 Change curves of hardness of carbon film with annealing temperature

由图7可知, 尽管GLC膜的硬度在初期小于DLC膜的, 但随退火温度的升高, 硬度下降得更慢, 说明GLC的热稳定性优于DLC的, 因而在切削过程中其寿命也更长。

3结论

高硬度低摩擦因数的碳膜可以用于干式无润滑钻削铝硅合金, 切削过程中镀层的高硬度有效地防止了低温粘结, 而低的摩擦因数降低了切削过程中的摩擦热, 提高了刀具的抗高温粘结能力, 提高了刀具干切削铝硅合金的寿命。

REFERENCES

[1]曾苏民. 我国铝加工业发展趋势[J]. 中国有色金属学报, 2004, 14(S1): 179-181.

ZENG Su-min. Development of aluminium working industry in China[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 179-181.

[2]Gowri S, Samuel F H. Effect of Mg on the solidification behavior of two Al-Si-Cu-Fe-Mg(380) diecasting alloys[J]. AFS Trans, 1993, 101: 611-618.

[3]Kimberley W. Enlightened process[J]. Automotive Engneer, 2003, 11: 50-51.

[4]Harris S G, Vlasveld U A C, Doyle E D, et al. Dry machining-commercial viability through filtered arc vapor deposited coatings[J]. Surface and Coatings Technology, 2000, 133-134: 383-388.

[5]Derflinger V, Brndle H, Zimmermann H. New hard/lubricant coating for dry machining[J]. Surface and Coatings Technology, 1999, 113: 286-292.

[6]Leep H R, Halbleib E D, Jiang Z. Surface quality of holes drilled into aluminum 390[J]. Int J Prod Res, 1991, 29(2): 391-400.

[7]Braga D U, Diniz A E, Miranda G W A, et al. Using a minimum quantity of lubricant (MQL) and a diamond coated tool in the drilling of aluminum-silicon alloys[J]. Journal of Materials Processing Technology, 2002, 122: 127-138.

[8]Vandevelde T C S, Vandierendonck K, Stappen M V, et al. Cutting applications of DLC, hard carbon and diamond films[J]. Surface and Coatings Technology, 1999, 113: 80-85.

[9]Zhang W, Tanaka A. Tribological properties of DLC films deposited under various conditions using a plasma-enhanced CVD[J]. Tribology International, 2004, 37: 975-982.

[10]Jarratt M, Field S K, Yang S. Graphite-like and carbon coatings with exceptional tribological properties[J]. Transactions of Materials and Heat Treatment, 2004, 25(5): 796-802.

[11]Liu H W, Tanaka A, Kumagai T. Influence of sliding materials on the tribological behavior of diamond-like carbon films[J]. Thin Solid Films, 1999, 352: 145-150.

[12]Landry K, Kalogeropoulou S, Eustathopoulos N. Wettability of carbon by aluminum and aluminum alloys[J]. Mater Sci Eng A, 1998, 254: 99-111.

[13]Uglov V V, Kuleshov A K, Rusalsky D P, et al. Wear-resistant metal-carbon composite coating[J]. Surface and Coatings Technology, 2000, 128-129: 150-155.

[14]Donnet C, Erdemir A. Solid lubricant coatings: recent developments and future trends[J]. Tribology Letters, 2004, 17(3): 389-396.

[15]Grimanelis D, Yang S, Bohme O, et al. Carbon based coatings for high temperature cutting tool applications[J]. Diamond and Related Materials, 2002, 11: 176-184.

[16]Yang S, Teer D G. Investigation of sputtered carbon and carbon chromium multi-layered coatings[J]. Surface and Coatings Technology, 2000, 131: 412-416.

[17]Yang S, Lib X, Reneviera N M, et al. Tribological properties and wear mechanism of sputtered C-Cr coating[J]. Surface and Coatings Technology, 2001, 142-144: 85-93.

[18]Hogmark S, Jacobson S, Larsson M. Design and evaluation of tribological coatings[J]. Wear, 2000, 246: 20-33.

收稿日期: 2006-03-01; 修订日期: 2006-05-30

通讯作者: 朱晓东, 副教授; 电话: 029-82668696; E-mail: xdzhu@mail.xjtu.edu.cn

(编辑 李艳红)