文章编号:1004-0609(2014)01-0130-07

快速凝固过共晶铝硅合金粉末的形貌与显微组织

解立川,彭超群,王日初,蔡志勇

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用快速凝固气体雾化工艺制备Al-27%Si合金粉末,研究合金粉末形貌和热处理对组织的影响,利用X射线衍射仪和显微硬度计等对Al-27%Si合金粉末中硅相的析出与长大进行表征。结果表明:快速凝固Al-27%Si合金粉末由基体α(Al)相、块状β-Si相和枝晶状共晶硅相组成;经热处理后,β-Si相发生粗化,共晶硅相逐渐转变为块状相且发生粗化;在500 ℃下加热保温后,α(Al)相和β-Si相的衍射峰强度随时间延长而增大,α(Al)相衍射峰向低角度偏移;合金粉末显微硬度在500 ℃下加热,初期有下降趋势,但随时间延长,不再下降,而是维持相对稳定。

关键词:快速凝固;Al-27%Si合金粉末;形貌;组织;热处理;显微硬度

中图分类号:TG146 文献标志码:A

Morphologies and microstructures of rapidly solidified hypereutectic Al-Si alloy powders

XIE Li-chuan, PENG Chao-qun, WANG Ri-chu, CAI Zhi-yong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The rapidly solidified powders of Al-27%Si alloy were manufactured by gas atomization process. The effects of morphologies of alloy powders and heat treatment on the microstructure were studied. The precipitation and growth of silicon phase were investigated with X-ray diffractometer and microscope hardness tester. The results show that the rapidly solidified powders of Al-27%Si alloy are composed of α(Al) phase, β-Si bulk phase and dendritic structure eutectic silicon phase. After heat treatment, the β-Si bulk phase is coarsened and the eutectic silicon phase is changed to bulk phase and then coarsens. When held at 500 ℃, the diffraction peak intensities of the α(Al) phase and β-Si phase are enhanced with the time prolonging, and the position of the α(Al) phase peak shifts to lower angle. At the beginning of heat treatment at 500 ℃, the microhardness of the alloy powers decreases, followed by remaining relatively constant as the time prolonging.

Key words: rapid solidification; Al-27%Si alloy powders; morphologies; microstructures; heat treatments; microhardness

随着现代电子信息技术的不断发展,电子系统及设备向微型化、轻量化、高功效、低成本和高稳定性方向发展。由于电子器件集成电路的复杂性和密集性不断提高,发热量急剧上升导致寿命下降,这主要是由材料之间散热性能不佳引起的热疲劳以及热膨胀系数不匹配引起的热应力造成的,因此,迫切需求研究和开发性能优异、可满足各种需求的新型电子封装材料[1]。金属基复合材料可以将金属基体优良的热导性能和增强体材料低膨胀系数的特性结合起来,在微波通讯、自动控制、电源转换、航空航天等领域发挥着重要的作用[2]。因此,电子封装用金属基复合材料成为未来发展的主要方向。

新型高硅含量的铝硅复合材料(常称作过共晶铝硅合金)不仅具有较低的热膨胀系数、较高的热导率、较小的密度,并且还具有良好的力学性能、机械加工性能和电镀性,因此,越来越受到电子封装行业研究人员的重视[3-4]。不断提高过共晶硅含量对提高材料应用性能非常有利,但硅含量的增加通常会使初晶硅颗粒呈粗大的块状相,该组织特性降低合金材料的力学性能和机加工性能[5-6]。目前,采用传统的变质处理、合金化等工艺均不能有效地改变其组织粗化的缺陷,而利用快速凝固/粉末冶金法(冷却速度达102~106 ℃/s)制备过共晶铝硅合金,可以显著改善合金显微组织、减少成分偏析、提高合金固溶度,使合金性能大幅度提高[7-8]。但致密化工艺及相关理论尚未成熟,应加大研究力度,加快进入工业化应用是该方法未来发展方向。日本住友电器公司采用快速凝固粉末冶金法制备的Al-40%Si合金,其热膨胀系数为13×10-6 K-1,热导率为126 W/(m·K),密度为2.53 g/cm3[9]。

经快速凝固/粉末冶金法制备Al-Si合金粉末通常需要经过高温烧结、热挤压和热锻造等致密化成型过程,但在高温加热过程中有可能对合金组织带来不利影响,例如过饱和固溶体发生脱溶分解或组织发生粗化等,是导致材料塑性降低的主要原因[10-12]。为了更好地保持快速凝固合金的优势,确定合适的加热温度和保温时间等工艺是非常重要的。

本文作者采用快速凝固气体雾化装置制备合金粉末,研究Al-27%Si合金粉末的形貌及组织特征,并分析合金粉末在热处理后显微组织和显微硬度的演变机理。

1 实验

本实验所用原材料为高纯铝(纯度为99.995%)和单晶硅片,气体雾化装置由中南大学金属材料研究所提供。首先采用中频感应电炉进行母合金熔炼,再利用气体雾化法制备合金粉末,雾化气体选用氮气,气体压力为0.9 MPa,雾化温度为850 ℃,整个制粉过程在氮气保护下进行。

雾化粉末采用75 μm标准筛筛分,主要研究粒度小于25 μm的粉末。取等量合金粉末进行热处理,分别在300、450、500和550 ℃保温1 h,在500 ℃分别保温2 min、10 min、1 h、4 h和16 h。

合金粉末试样采用树脂镶嵌方法制作,用NaOH水溶液腐蚀试样。粉末形貌特征及显微组织分析在FEI QUANTA-200扫描电子显微镜上进行;采用D/Max2500VB+ X射线衍射线仪分析α(Al)相和β-Si相衍射峰变化,利用HVS-1000型显微硬度计测试较大粉末的显微硬度值。

2 结果与讨论

2.1 快速凝固Al-27%Si合金粉末的形貌特征

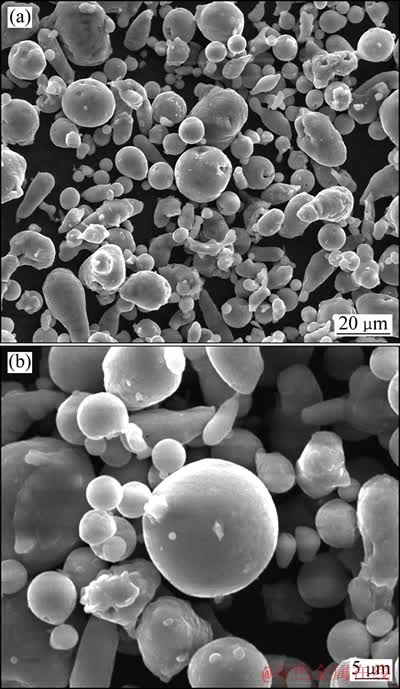

图1 快速凝固Al-27%Si合金粉末的形貌

Fig. 1 Morphologies of rapidly solidified Al-27%Si alloy powders

图1所示为气体雾化Al-27%Si合金粉末的形貌。由图1可看出,Al-27%Si雾化粉末的颗粒形状主要由球形、液滴形和不规则形状组成。粉末表面凹凸不平,并附带卫星颗粒和毛刺,但随着颗粒尺寸的减小,表面逐渐平整化,卫星颗粒和毛刺逐渐减少,但一些尺寸小于10 μm的颗粒,形状呈球形且表面光滑,无卫星颗粒和毛刺。合金粉末形状不规则主要与雾化后合金熔滴球化时间和凝固时间的相对大小有关,雾化熔滴的球化时间τsph可以用下述关系式表示[13]:

(1)

(1)

式中:d1为球化后熔滴直径;d2为球化前熔滴最小直径;μL为液态金属黏度;σ为液态金属表面张力;V为熔滴体积。考虑到r1远大于r2(r1/r2≈10),可以忽略r2的值, ,因此,式(1)可以简化为

,因此,式(1)可以简化为

(2)

(2)

从式(2)中可以得出,熔滴球化时间主要取决于液态金属黏度、表面张力及熔滴尺寸,当熔滴黏度和表面张力一定时,大尺寸熔滴在凝固前不能进行充分球化,因此形成不规则状粉末颗粒;而小尺寸熔滴本身具有较大的表面张力,更加有利于球化。除上述原因外还需考虑熔滴易氧化、受雾化气体冲击和相互之间碰撞等因素对球化的不利影响。

2.2 快速凝固Al-27%Si合金粉末的内部微观组织特征

图2 快速凝固Al-27%Si合金粉末晶粒的微观组织

Fig. 2 Microstructures of rapidly solidified Al-27%Si powders with different grain sizes

采用气体雾化工艺制备的Al-27%Si合金粉末,其内部组织非常细小,不同粒度粉末内部组织表现出不同的形态特征。快速凝固Al-27%Si合金粉末内部微观组织如图2所示。从图2(a)可知,粉末内部组织由α(Al) 基体相、灰色块状β-Si相(呈多角状在颗粒中弥散分布,平均尺寸3~4 μm)和细小灰色枝晶状的非平衡共晶硅相组成。共晶硅相在基体上呈散乱分布特点,无方向性,其最大宽度不超过1 μm,最大长度约为3 μm。随着粉末颗粒尺寸减小,合金粉末中心组织与四周组织存在明显差异。由图2(b)可知,初晶硅相都聚集在粉末颗粒边缘。这是由于在雾化过程中,合金熔滴的凝固是由外向内的,熔滴的表层具有最大的温度梯度和较大的冷却速度,根据结晶规律β-Si相优先析出。其次,随着粉末粒度减小,组织中β-Si相和共晶硅相的尺寸也减小。这是由于在快速凝固过程中,大尺寸的粉末颗粒对应的过冷度较大,冷却速度较小,不能及时抑制β-Si相和共晶硅相在凝固过程中的析出,反之小尺寸粉末颗粒冷却速度较大,因此,其对应的β-Si相和共晶硅相的尺寸较细小[14]。

2.3 退火温度对粉末显微组织的影响

快速凝固Al-27%Si合金粉末在不同温度下保温 1 h后的显微组织如图3所示。由图3可看出,随着温度升高,组织变化特征主要表现为块状β-Si相发生显著粗化,共晶硅相由枝晶状逐渐转变为颗粒状相并有一定程度粗化。由图3(a)可知,与原始粉末相比,当加热温度较低时,其组织并没有发生明显变化。由图3(c)可知,在500 ℃保温1 h后,粉末组织中β-Si相和共晶硅相的颗粒数最多,且球化度最好,其β-Si相平均尺寸为4~5 μm,共晶硅相尺寸大约为1 μm。当温度继续升高至550 ℃后,组织中β-Si相和共晶硅相进一步长大,且一些大尺寸的β-Si相颗粒出现搭接,并逐渐团聚在一起形成一个硅颗粒,其β-Si相平均尺寸为5~6 μm,共晶硅相尺寸为2~3 μm,如图3(d)所示。

2.4 保温时间对快速凝固Al-27%Si合金显微组织的影响

快速凝固Al-27%Si合金粉末在500 ℃保温不同时间后的显微组织如图4所示。从图4可以看出,减小粉末颗粒尺寸,其内部组织变化趋势均与上述基本一致。在500 ℃下保温2 min后,β-Si相颗粒粗化不明显,共晶硅相逐渐从枝晶状转变为块状相,且粗化不明显。随着时间逐渐延长,β-Si相和共晶硅相不断析出长大,将保温10 min与1 h后的显微组织相比较可知,β-Si相和共晶硅相球化度均较好,但从图中明显看出,共晶硅相的粗化程度明显高于 β-Si相的。在500 ℃下保温4 h后,内部粗化现象非常严重,导致β-Si相和共晶硅相无法清晰地区分,但可以看出,β-Si相和共晶硅相颗粒均发生团聚。

图3 快速凝固Al-27%Si合金粉末在不同温度保温1 h后的显微组织(平均尺寸20 μm)

Fig. 3 Microstructures of rapidly solidified Al-27%Si powders at different temperatures for 1 h (average grain size 20 μm)

图4 快速凝固Al-27%Si合金粉末在500 ℃保温不同时间后的显微组织(平均尺寸10 μm)

Fig. 4 Microstructures of rapidly solidified Al-27%Si powders heated at 500 ℃ for different time (average grain size 10 μm)

快速凝固Al-27%Si合金粉末在500 ℃保温不同时间后的XRD谱如图5所示。由图5可知,随着保温时间延长,合金粉末组织成分与雾化态相比不发生变化,但雾化态粉末α(Al)相的衍射峰有一定程度的宽化。这是由于在快速凝固的作用下,大量的硅元素过饱和固溶在α(Al)基体中,造成晶格畸变,从而造成宽化效应。从图5还可以看出,基体α(Al)相和β-Si相的衍射峰随着保温时间延长,宽化程度有所缓和,且衍射峰强度一直呈增强的趋势,但增长速率随着时间延长不断减小。上述变化特征主要是由于α(Al)基体组织的回复和β-Si固溶体的脱溶析出引起的,与上述组织变化相对应,初晶硅和共晶硅随着保温时间延长不断粗化,增加粉末组织中β-Si相的体积分数,衍射峰强度提高。

图5 快速凝固Al-27%Si合金粉末在500 ℃保温不同时间后的XRD谱

Fig. 5 XRD patterns of rapidly solidified Al-27%Si powders heated at 500 ℃ for different times

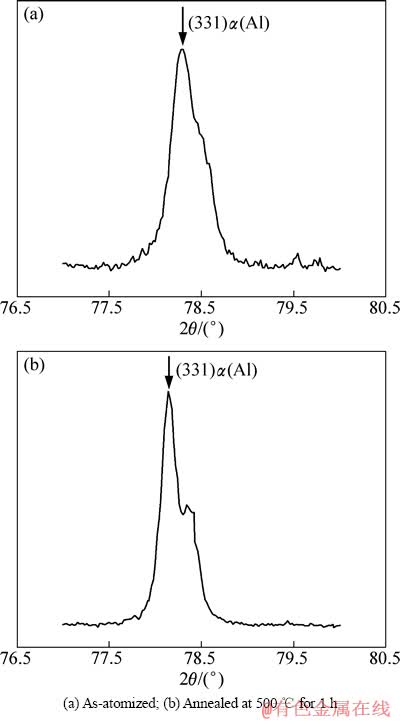

图6所示为(331)α(Al)相在高角度区间的XRD谱。由图6可知,快速凝固Al-27%Si合金粉末经500 ℃保温1 h后,基体α(Al)相的衍射峰尖锐化,且在主峰 右侧又出现一个

右侧又出现一个 峰。从图6还可以看出,与雾化态相比,经热处理后合金粉末的基体α(Al)衍射峰向低角度方向偏移,说明引起相应晶面间距增大,使Al基体晶格参数增加。该结果可表征为经快速凝固后,大量的Si元素固溶于α(Al)溶原子发生脱溶析出,引起的基体晶格收缩作用减弱,使α(Al)基体的晶格常数表现出增大的趋势。

峰。从图6还可以看出,与雾化态相比,经热处理后合金粉末的基体α(Al)衍射峰向低角度方向偏移,说明引起相应晶面间距增大,使Al基体晶格参数增加。该结果可表征为经快速凝固后,大量的Si元素固溶于α(Al)溶原子发生脱溶析出,引起的基体晶格收缩作用减弱,使α(Al)基体的晶格常数表现出增大的趋势。

图6 (331)α(Al)相在高角度区间的XRD谱

Fig. 6 XRD patterns of high index plane (331) α(Al) phase

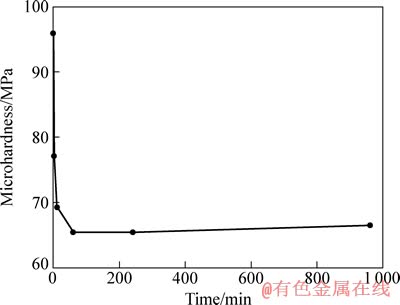

2.5 保温时间对合金显微硬度的影响

快速凝固Al-27%Si合金粉末显微硬度在500 ℃

保温不同时间的变化曲线如图7所示。由图7可看出,在保温初期,随着时间的延长,合金粉末显微硬度呈下降趋势,当保温时间超过240 min后,继续延长保温时间,合金显微硬度不再继续降低,而是保持相对稳定。

合金粉末在保温初期引起显微硬度下降的原因主要有两个方面:1) 粉末加热后基体中过饱和Si原子在热激活作用下脱溶析出,对基体的固溶强化作用逐渐减弱;2) 快速凝固使基体晶格严重畸变,存在大量高密度位错,对组织起晶格错配强化和位错强化作用,但粉末加热后会使基体晶格畸变发生一定松弛并释放一定量错配畸变能,同时位错发生滑移和重新排列,异号位错相互抵消,位错密度降低,造成晶格配错和高密度位错对合金组织的强化作用减弱,使合金发生软化,表现为合金显微硬度下降[15]。随着保温时间延长,过饱和固溶原子的脱溶和组织回复过程已充分完成,因此,合金粉末显微硬度下降到一定程度后便不再继续下降,维持相对稳定。

图7 快速凝固Al-27%Si合金粉末在500 ℃保温不同时间后的显微硬度

Fig. 7 Microhardness of rapidly solidified Al-27%Si powders heated at 500 ℃ for different times

3 结论

1) 利用快速凝固气体雾化法制备Al-27%Si合金粉末颗粒,其形状基本呈不规则形状;随着粉末粒度减小,表面逐渐平整化,一些尺寸小于10 μm的颗粒其形状呈球形且表面光滑。粉末内部组织由α(Al)基体相、灰色块状β-Si相和细小灰色枝晶状的非平衡共晶硅相组成。随着粉末颗粒尺寸减小,块状β-Si相和枝晶状的共晶硅相数量越少,尺寸也越小,且块状β-Si相聚集在粉末颗粒的边缘。

2) 在热处理过程中,随加热温度升高或保温时间延长,合金粉末中过饱和固溶体Si逐渐脱溶析出,导致β-Si相发生粗化,共晶硅相逐渐转变为块状相且发生粗化;当温度过高或时间过长时,β-Si相和共晶硅相开始发生团聚。

3) 在500 ℃下保温不同时间后,基体α(Al)相和β-Si相衍射峰宽化程度有所减弱,其衍射峰强度随时间延长逐渐增大。

4) 在500 ℃下保温不同时间,在保温初期,合金粉末显微硬度呈下降的趋势;当保温时间超过240 min后,继续延长保温时间,合金显微硬度不再继续降低,而维持相对稳定。

REFERENCES

[1] 解立川, 彭超群, 王日初. 高硅铝合金电子封装材料研究现状[J]. 中国有色金属学报, 2012, 22(9): 2579-2587.

XIE Li-chan, PENG Chao-qun, WANG Ri-chu. Research progress of high aluminum-silicon alloys in electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2579-2587.

[2] 刘正春, 王志法, 姜国圣. 金属基电子封装材料进展[J]. 兵器材料科学与工程, 2001, 24(2): 49-53.

LIU Zheng-chun, WANG Zhi-fa, JIANG Guo-sheng. Advances in metal-matrix material for electronic packaging[J]. Ordnance Material Science and Engineering, 2001, 24(2): 49-53.

[3] YU K, LI S J, CHEN L S. Microstructure characterization and thermal properties of hypereutectic Si-Al alloy for electronic packaging applications[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1412-1417.

[4] YOON S C, HONG S J, HONG S L. Mechanical properties of equal channel angular pressed powder extrudates of a rapidly solidified hypereutectic Al-20wt%Si alloy[J]. Materials Science and Engineering A, 2007, 449/451: 966-970.

[5] 俞 佳, 姚继蓬, 郦 剑. 快速凝固/粉末冶金高硅铝合金的研究进展[J]. 热处理技术与装备, 2008, 29(2): 4-7.

YU Jia, YAO Ji-peng, LI Jian. A review on the research progress of high Si-Al alloys by rapid solidification/powder metallurgical technology[J]. Heat Treatment Technology and Equipment, 2008, 29(2): 4-7.

[6] DINDA G P, DASGUPTA A K, MAZUMDER J. Evolution of microstructure in laser deposited Al-11.28%Si alloy[J]. Surface and Coatings Technology, 2012, 206(8): 2152-2160.

[7] 谢状德, 沈 军, 董寅生. 快速凝固铝硅合金的制备、组织特征及断裂行为[J]. 粉末冶金技术, 2000, 18(2): 111-116.

XIE Zhuang-de, SHEN Jun, DONG Yin-sheng. Rapidly solidified aluminum-silicon alloys production, microstructure and fracture behavior[J]. Powder Metallurgy Technology, 2000, 18(2): 111-116.

[8] 赵爱民, 毛卫军, 甄子胜. 冷却速度对过共晶铝硅合金凝固组织和耐磨性能的影响[J]. 中国有色金属学报, 2001, 11(5): 827-833.

ZHAO Ai-min, MAO Wei-jun, ZHEN Zi-sheng. Effects of cooling rate on solidification microstructures and wear resistance of hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 827-833.

[9] 甘卫平, 陈招科, 杨伏良. 高硅铝合金轻质电子封装材料研究现状及进展[J]. 材料导报, 2004, 18(6): 79-82.

GAN Wei-ping, CHEN Zhao-ke, YANG Fu-liang. Research status and development of high silicon aluminum alloy for light weight electronic package materials[J]. Materials Review, 2004, 18(6): 79-82.

[10] SRIVASTAVA V C, MANDAL R K, OJHA S N. Microstructure and mechanical properties of Al-Si alloys produced by spray forming process[J]. Materials Science and Engineering A, 2001, 304/306: 555-558.

[11] ZHOU J, DUSZCAYK J, KOREVAAR B M. As-spray-deposited structure of an Al-20Si-5Fe spray perform and its development during subsequent processing[J]. Journal of Materials Science, 1991, 26: 5275-5291.

[12] 杨伏良, 甘卫平, 陈招科. 快速凝固/粉末冶金制备高硅铝合金材料的组织与力学性能[J]. 中国有色金属学报, 2004, 14(10): 1717-1722.

YANG Fu-liang, GAN Wei-ping, CHEN Zhao-ke. Microstructure and mechanical properties of high-silicon aluminum alloy fabricated by rapid solidification/powder metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1717-1722.

[13] LAVERNIA E J, AYERS J D, SRIVATSAN T S. Rapid solidification processing with specific application to aluminum alloys[J]. International Materials Reviews, 1992, 37(1): 1-44.

[14] 李元元, 张大童, 夏 伟. 高压水雾化法制备的高硅铝合金粉末特性[J]. 金属学报, 1998, 34(1): 95-99.

LI Yuan-yuan, ZHANG Da-tong, XIA Wei. Properties of a high silicon aluminium alloy powder prepared by high pressure water atomization[J]. Acta Metallurgica Sinica, 1998, 34(1): 95-99.

[15] 谢壮德, 沈 军, 孙剑飞. 超音速雾化高硅铝合金粉末高温加热组织及性能演变[J]. 粉末冶金技术, 2002, 20(4): 205-208.

XIE Zhuang-de, SHENG Jun, SUN Jian-fei. Development of microstructure and property of powders of a high Si-Al alloy manufactured by ultrasonic gas atomization process after different heat treatment[J]. Powder Metallurgy Techonology, 2002, 20(4): 205-208.

(编辑 李艳红)

基金项目:国家军品配套项目(JPPT-125-GH-039)

收稿日期:2013-03-29;修订日期:2013-09-29

通信作者:彭超群,教授,博士;电话:0731-88877197;E-mail:pcqpcq@csu.edu.cn