Ce对耐热铝导体材料铸态组织和性能的影响

李红英,孙远,宾杰,刘洋,曹俊

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用电阻率测试、硬度测试、金相显微镜和扫描电镜观察等方法,研究添加不同含量稀土Ce对铸态耐热铝导体材料Al-0.15Zr合金的影响。研究结果表明:Ce能净化基体,与杂质相形成金属间化合物,改变杂质相的形态和分布;添加适量的Ce,显著细化了晶粒和枝晶组织,有利于导电性和强度的提高;随着Ce加入量的增大,晶粒细化效果更好;当Ce含量(质量分数)超过0.3%以后,二次枝晶间距继续减小,但晶粒尺寸细化不明显;当Ce含量为0.3%和0.4%时,Al-0.15Zr合金的导电性和强度均达到最大值。

关键词:Ce;耐热铝导体;细化;电导率;铸态组织

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2011)10-3026-07

Effect of cerium on as-cast microstructure and properties of heat-resistant aluminum conductor

LI Hong-ying, SUN Yuan, BIN Jie, LIU Yang, CAO Jun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The microstructure and properties of as-cast heat-resistant Al-0.15Zr conductor with different amounts of Ce were studied by means of electrical resistivity measurement, hardness test, optical microscopy and scanning electrical microscopy. The results show that metallic compound containing Ce and impurity are congregated at the grain boundary and dendritic boundary, which is beneficial to the electrical conductivity and strength. Alloying of Ce refines the grain and dendrite of Al-0.15Zr alloy. The refine effect is more significant with the increase of Ce amount. When the amount of Ce is more than 0.3%, the dendrite arm spacing decreases, but the grain size is not changed obviously. The electrical resistivity and strength of alloys reach the maximum values by adding 0.3% and 0.4% Ce, respeactively..

Key words: cerium; heat-resistant aluminum conductor; grain refinement; electrical resistivity; as-cast microstructure

随着我国电力工业突飞猛进的发展,输电线路向高压化、大容量化、远距离化方向发展,迫切需要大容量、大跨度、低密度、导电性优良的架空导线[1-2]。尽管普通铝导线的密度低、导电性好,但是,其强度低,耐热性差,线路的输电容量受到一定的限制。研究表明,加入微量Zr可有效提高铝导线的强度和耐热性,而且不会明显降低合金的导电性[3-4]。采用耐热铝合金导线可以提高线路运行温度约50 ℃,线路输送容量增加50%以上[5-6]。近年来,国内耐热铝导线的应用逐渐增加,如北京奥运会前的电网扩容改造工程就采用了国产耐热铝导线[7]。随着我国电网建设力度的加大,新建电力输送工程的电压等级朝高压或超高压方向发展,已有输变电工程也要进行扩容改造,开发新型耐热铝导线具有重大的意义[8-9]。

稀土在铝合金中起到净化、细化和合金化作用,从而提高铝合金的使用性能和工艺性能[10-12]。用稀土改善普通铝导线和Al-Mg-Si加强型输电线,都取得了良好的效果[13]。目前,对于稀土在导电铝中的微观作用机制研究较少,尚没有达成统一的观点[14-17],稀土对耐热铝导体材料组织和性能的影响及机理尚未见到公开报道。为此,本文作者研究Ce含量对耐热铝合金材料组织和性能的影响,以便为设计含稀土的高导耐热铝导体材料提供依据。

1 实验材料与方法

实验材料采用99.7%(质量分数,下同)的工业纯铝(含主要杂质Fe约0.16%,Si约0.04%),Al-Ce中间合金(Ce含量为18.83%)和Al-Zr中间合金(Zr含量为11.34%)配制。表1所示为实验材料成分,熔炼过程有一定烧损,为叙述方便,本文实验材料中Zr和Ce含量均用其名义成分表示。用石墨坩埚在电阻炉中熔炼,熔炼温度为720~730 ℃,采用1号熔剂覆盖,用六氯乙烷精炼,浇注温度为680~700 ℃,浇注到预热的钢环模中。

表1 实验材料的化学成分(质量分数)

Table 1 The chemical composition of investigated alloy %

采用QJ19型单双臂两用电桥测量试样电阻,标准电阻取1 mΩ,工作电流为300 mA。采用HW187.5型布洛维硬度计测定布氏硬度(HBS),试验力为625 N,持续时间30 s,取5个点的平均值。在离底面20 mm处锯开铸锭并磨平,采用混合酸(HCl,HNO3,HF)浸蚀表面,直到晶粒显露清晰为止,用Nikon S210相机对拍摄截面宏观组织。用WF-1型电解抛光仪进行电解抛光,抛光液的成分为无水乙醇、60%高氯酸、去离子水,其体积比为81:9:18,抛光电压为20 V,电流为2 A,时间为25~30 s。采用PLOYVAR-MET金相显微镜观察样品的铸态组织,采用带能谱分析(EDS)功能的FEI Quanta 2500扫描电镜进行组织观察和相分析。

2 实验结果与讨论

2.1 Ce对合金第二相的影响

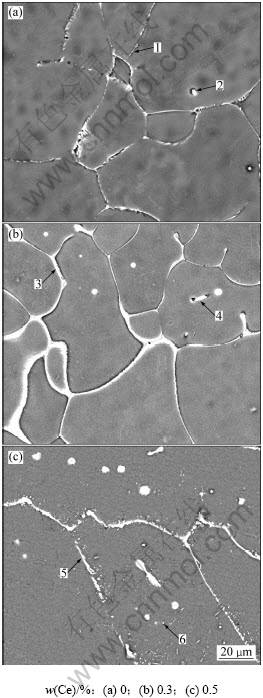

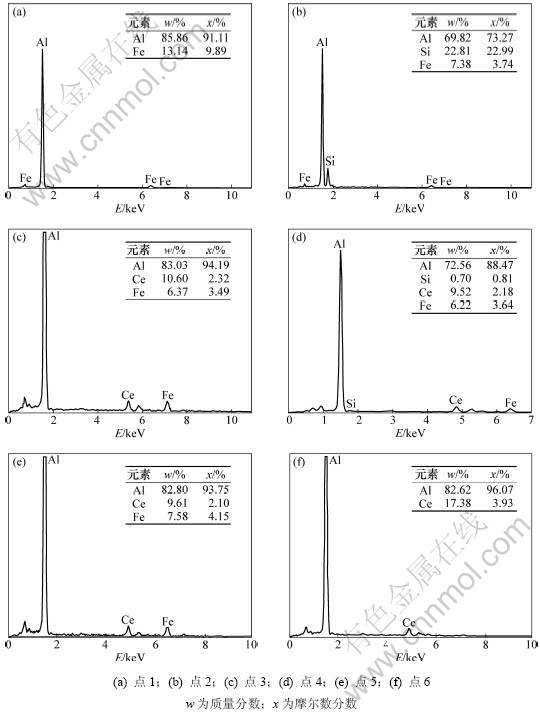

图1所示为利用扫描电镜观察到的添加不同Ce含量合金的铸态组织,图2所示为图1中不同点的能谱分析结果。由图1可以看出:铸态组织的主要组成相是α-Al固溶体、沿晶界分布的长条相、分布于树枝晶间隙的颗粒状相。其中:图1(a)所示为没有添加Ce的微观组织,在晶界可以看到针状或长条状的FeAl3相,晶内存在极少量含有Si的第二相,相应的能谱分析结果如图2(a)和2(b)所示。从图2(a)和2(b)可以看出:铝中的杂质Si主要溶解于基体中,而Fe的固溶度极小,与铝在晶界处形成FeAl3共晶相。由图1(b) 和1(c)可知:加入稀土Ce以后,晶界处和枝晶臂间的针状FeAl3逐渐消失,代之以沿晶界分布的断续长条相和枝晶臂间的球状或短柄状颗粒相。当Ce加入量达到0.3%时(图1(b)),在晶界形成了高Ce、高Fe含量的化合物,晶界变厚,枝晶臂间的点状相增多,Ce的加入形成了复杂的AlFeCe或AlFeSiCe相[18-19]。当Ce加入量到达0.5%时(如图1(c)所示),基体中的第二相进一步增多,枝晶界上密集排列着长条状相。图2(e)所示为枝晶界长条状相的能谱分析结果,表明点5对应的可能是Al10Fe2Ce相;同时,枝晶臂间也出现了仅含Ce和Al的颗粒状相,点6对应的可能是CeAl4。加入过量Ce以后,Ce将与铝基体形成金属间化合物。

图1 不同Ce含量合金析出相的SEM像

Fig.1 SEM images of precipitated phase of Al-0.15Zr alloy with different Ce contents

图2 不同Ce含量试样的能谱

Fig.2 Energy spectrum of samples with different contents of Ce

Hume-Rothery等[20]认为有利于形成固溶体的原子半径差要低于15%,Ce 原子半径为0.182 4 nm,Al 原子半径为0.143 0 nm,两者的原子半径差很大(约28 %),只能形成固溶度很小的固溶体。为了减弱原子半径差所产生的晶格畸变,使系统自由能保持较低状态,Ce原子易于向原子排列不规则的晶界上富集并存在于杂质相中。元素间的交互作用强度取决于原子的直径和电负性。与稀土尺寸和电负性相差大的元素,稀土与其产生强烈的交互作用,形成化合物降低其在铝基体中的固溶量。铝中的主要杂质Fe和Si与Ce的交互作用比其他元素的要大,因此,适量Ce能够促使铝基体中的杂质Fe和Si形成二元或三元化合物析出,从而起到了净化基体、改变杂质相形态和分布的作用。

2.2 Ce对合金组织的影响

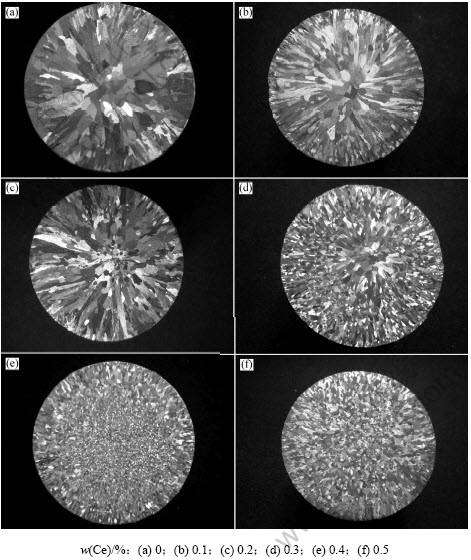

图3所示为不同Ce含量所对应的宏观组织。典型的铸锭组织由紧靠模壁表面的细晶区、垂直模壁表面生长的柱状晶区和铸锭中部的等轴晶区组成。由图3可以看出,加入Ce以后,铸锭等轴晶区扩大,柱状晶变短变细;随着Ce含量的增大,中心等轴晶逐渐增多,等轴晶区也不断扩大;当Ce的添加量大于0.3%以后,细化效果较好,主要为均匀细小的等轴晶。

图4所示为不同Ce含量对应的金相组织。从图4可以看到:加入Ce后,晶粒粒径明显减小,视场内的晶粒数目随着Ce含量的增加逐渐增多,当Ce含量增加到0.3%以后,枝晶更加明显,晶界和枝晶臂间出现了大量的第二相粒子;除晶界上细条状相和三叉晶界处的骨骼状相之外, 在枝晶臂间分布有圆形或椭圆形的颗粒相。

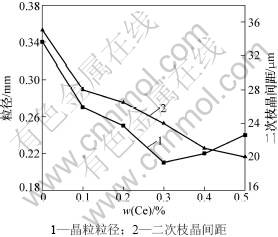

采用截点法测定铸态组织参数,通过计数给定长度测量线段与晶界和枝晶界的交点数量来测定晶粒尺寸和枝晶间距。为了获得合理的晶粒粒径和枝晶间距平均值,任意选取5个视场进行测量并进行计算。图5所示为统计出的Ce加入量对铸态组织参数的影响规律。从图5可以看出:稀土的加入既可以细化铸态晶粒,也可以明显细化枝晶组织;当Ce含量超过0.3%以后,二次枝晶间距继续减小,但晶粒尺寸细化不明显。

图3 不同Ce含量合金对应的宏观组织

Fig.3 Macrostructures of Al-0.15Zr alloy with different contents of Ce

图4 不同Ce含量合金的显微组织

Fig.4 Microstructures of Al-0.15Zr alloy with different Ce contents

添加稀土的铝合金结晶时,溶质组元重新分布,在固液相界面处形成溶质的浓度梯度,产生成分过冷,稀土Ce的细化作用可以通过其对凝固过程中过冷度的影响来解释。晶粒细化主要是要提高形核率(N)和控制晶粒的长大速度(G)。形核率和长大速率与过冷度有关,增大结晶时的过冷度,形核率和长大速率都随之增加,两者的增大速率不同,形核率的增长率大于晶粒长大速率的增长率,因此,在一般金属结晶的过冷度范围内,过冷度越大,N/G就越大,晶粒也越细小。形成成分过冷的临界条件可用式(1)来表示[21]:

(1)

(1)

式中:GL为界面前沿液相中的实际温度梯度;R为凝固速率;mL为相图上液相线的斜率;c0为原始浓度;DL为溶质在液相的扩散系数;k0为分配系数。

由式(1)可知:溶质在液相中的扩散系数DL越小,k0越小(k0<1),组分过冷倾向越大。合金凝固时,由于稀土Ce的分配系数远小于1,且在铝中的固溶度很小,大部分富集在界面前沿的液相边界层中,与杂质元素产生强烈交互作用,减小了Fe和Si等原子进入固溶体的概率。稀土元素的加入影响固-液界面前沿的溶质再分配,使得稀土和其他元素在界面前沿液相中的浓度梯度增加,产生一个成分过冷区,当成分过冷度大于形成新晶核所需的过冷度时,就会大大提高形核率。稀土的化学性质比较活泼, 能与其他合金元素或杂质元素形成多种化合物, 其中有的化合物也可作为异质晶核,大量新晶核限制柱状晶的成长,从而获得均匀细小的等轴晶。同时,稀土Ce是表面活性元素,稀土在固-液界面前沿的富集起到阻碍α-A1晶粒长大的作用,进一步促进了晶粒的细化[22]。

图5 Ce含量对合金铸态组织参数的影响

Fig.5 Effects of Ce content on dendrite arm spacing and grain size of as-cast alloy

2.3 Ce对合金性能的影响

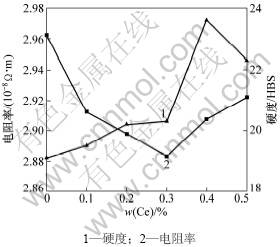

图6所示为合金电阻率和硬度随Ce含量的变化曲线。从图6可以看出:Ce对材料电阻率降低的作用较明显。过渡族金属元素对铝的导电性能产生不利影响,加入质量分数为0.15%的Zr会使工业纯铝的电阻率升高,升至约2.96×10-8 Ω·m,添加微量Ce后电阻率显著降低,当Ce含量为0.3%时,合金的电阻率降低至2.88×10-8 Ω·m;随着Ce含量的继续增加,电阻率开始提高。铝的导电性能与杂质及其存在形态有关,杂质元素在铝中以固溶态存在时,对导体电阻率的增大作用远大于析出态的增大作用。Fe和Si是影响铝电性能的主要杂质,未加Ce前, 杂质多呈游离状态分布,溶解于铝基体中。加入Ce以后,Ce与一些固溶于铝中的有害杂质形成了稳定的金属间化合物,降低了Fe和Si等杂质元素在基体中的固溶度, 从而可提高铝的导电性。同时,稀土还有净化的作用,可除去铝中的H,O和S等杂质,减少气孔数量,净化铝基体和晶界,有利于合金导电性的升高。

图6 Ce含量对合金电阻率和硬度的影响

Fig.6 Effects of Ce content on electrical conductivity and hardness of Al-0.15Zr alloy

当稀土元素含量达到一定值时,继续增加Ce的含量,过量的稀土元素与铝基体形成金属间化合物,这些化合物自身的电导率很小,比基体的电导率要小得多,其存在减小了铝的有效导电面积,使得合金的电阻率升高。此外,沿晶界的晶格畸变使得金属的电阻率升高,因此,金属中晶界数量对导电性能也有一定的影响[23]。随着稀土含量的增加,对Al-0.15Zr合金的晶粒细化作用增强,晶界增多,电子散射概率增大,这也导致电阻率升高。因此,加入过量的Ce,合金的导电性能会有所下降。

硬度在初始阶段随着Ce含量的增加而升高,但上升幅度不很明显。当Ce加入量达到0.4%时硬度显著上升,出现峰值,约23.6;Ce含量继续增加到0.5%时,硬度稍微有所下降。

稀土在铝合金中主要是固溶在基体α-Al中、偏聚在各种界面、固溶在化合物中,或以化合物等形式存在[10]。当稀土含量较低时,稀土主要以前2种形式分布。Ce固溶在基体中会产生较大的畸变场,但是,由于Ce在铝中的固溶度很小,起到的固溶强化作用有限,偏聚在相界、晶界和枝晶界处的稀土则增加了变形阻力,稀土沿枝晶和晶界分布,形成了连续和不连续的网膜,提高了铝合金晶界强度,使晶间裂纹不易扩展,进而提高了合金的强度。

当稀土加入量足以形成金属间化合物时,与合金中的元素形成许多新相,大部分含稀土的第二相都出现了粒子化、球化和细化的特征,这些呈弥散分布的高熔点化合物具有很高的热稳定性。同时,稀土与杂质形成化合物析出,改变了杂质原来的固溶存在方式,消除了分布在晶界处微量杂质的有害作用,同时又强化了晶界,提高了材料的强度。

3 结论

(1) 适量的Ce和固溶于基体的Fe和Si等形成金属间化合物,降低了基体中杂质元素的固溶量,改变了杂质相的形态和分布。

(2) Ce在枝晶网络和晶界分布,加大了合金凝固时的成分过冷程度,从而细化晶粒,也细化了枝晶组织,这种细化作用对改善导体材料的力学性能是有利的。

(3) 适量的Ce可以提高耐热铝导体材料的导电性和强度。当Ce含量为0.3%时,电阻率降低至最小,约为2.88×10-8 Ω·m;当Ce含量为0.4%时,强度到达最高值,约为23.6HBS。加入过多的Ce反而会使合金性能下降。

参考文献:

[1] 李文浩, 徐睿, 刘斌. 用于大跨越的高强度耐热铝合金导线的研制[J]. 电线电缆, 2008(1): 21-25.

LI Wen-hao, XU Rui, LIU Bin. Development of a high strength heat resistant aluminium alloy conductor for large span installation[J]. Electric Wire & Cable, 2008(1): 21-25.

[2] Du X D. Study on ageing and creep of Al-0.1Zr alloy[J]. Materials Science and Engineering A, 2006, 432(1/2): 84-89.

[3] 杜晓东, 刘永炘, 李合琴. 微量锆对架空铝合金导线耐热性和导电性的影响[J]. 金属热处理, 1995(4): 21-22.

DU Xiao-dong, LIU Yong-xin, LI He-qing. Influence of zirconium on the heat-resistance and conductivity of aluminium-alloy cable[J]. Heat Treatment of Metals, 1995(4): 21-22.

[4] 杜晓东. Zr-Al合金的时效过程与析出相研究[J]. 矿冶工程, 2003, 23(3): 73-75.

DU Xiao-dong. A Study on aging process and separated phase of aluminum alloy containing trace Zr[J]. Mining and Metallurgical Engineering, 2003, 23(3): 73-75.

[5] 刘真云, 马立群, 丁毅. 新型耐热铝合金架空导线的发展和应用[J]. 电线电缆, 2008(3): 25-27.

LIU Zhen-yun, MA Li-qun, DING Yi. Development and application of new type of heat resistant overhead conductors[J]. Electric Wire & Cable, 2008(3): 25-27.

[6] 尤传永. 耐热铝合金导线的耐热机理及其在输电线路中的应用[J]. 电线电缆, 2004(4): 3-8.

YOU Chuan-yong. Mechanism of the heat-resistant aluminium alloy conductor and its application in power transmission lines[J]. Electric Wire & Cable, 2004(4): 3-8.

[7] 张学哲, 王计朝. 北京电网中耐热导线的应用与探讨[J]. 电力设备, 2005, 6(5): 52-55.

ZHANG Xue-zhe, WANG Ji-chao, Discussion on application of heat-resisting wire in beijing power network[J]. Electric Equipment, 2005, 6(5): 52-55.

[8] 游洲, 杨永明, 何为. 耐热架空导线在重庆市110kV电网改造中的应用研究[J]. 电线电缆, 2008(3): 8-11.

YOU Zhou, YANG Yong-ming, HE Wei. Investigation of the application of the heat resistant overhead conductors in the renovation of Chongqing 110 kV networks[J]. Electric Wire & Cable, 2008(3): 8-11.

[9] YOU Chuan-yong. Heat-resistant mechanism of heat-resistant aluminum alloy conductor and its application in transmission line[J]. Electric Power Construction, 2003, 24(8): 4-8.

[10] LIU Zhi-yong, WANG Ming-xing, WENG Yong-gang. Grain refinement effects of Al based alloys with low titanium content produced by electrolysis[J].Transactions of Nonferrous Metals Society of China, 2002, 12(6): 1121-1126.

[11] 杨遇春. 稀土在有色金属合金中应用的新进展[J]. 稀有金属材料与工程, 1993, 22(4): 1-6.

YANG Yu-chun. The new evolution of application of rare-earth on nonferrous metal and alloy[J]. Rare Metal Materials and Engineering, 1993, 22(4): 1-6.

[12] 曹大力, 石忠宁, 杨少华, 等. 稀土在铝及铝合金中的作用[J]. 稀土, 2006, 27(5): 88-93.

CAO Da-li, SHI Zhong-ning, YANG Shao-hua, et al. Effects of rare earth on aluminium and its alloys[J]. Chinese Rare Earths, 2006, 27(5): 88-93.

[13] 王庆良, 王大庆. 稀土铝导线工业试验研究[J]. 金属热处理, 2000(9): 18-20.

WANG Qing-liang, WANG Da-qing. Industrial experiments of aluminium conductor containing rare earth elements[J]. Heat Treatment of Metals, 2000(9): 18-20.

[14] 刘顺华, 王桂芹, 吴爱民, 等. 稀土元素对工业纯铝导电性的影响[J]. 中国有色金属学报, 2000, 10(3): 334-339.

LIU Shun-hua, WANG Gui-qin, WU Ai-min, et al. Effects of rare earth elements on electrical conductivity of industrial aluminum[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 334-339.

[15] 康福伟, 王丽萍, 张显有. 微量稀土元素对工业纯铝电阻率的影响[J]. 哈尔滨理工大学学报, 2003, 8(6): 112-114.

KANG Fu-wei, WANG Li-ping, ZHANG Xian-you. Effects of microscale rare earth elements on electrical resistivity of industrial pure aluminium[J]. Journal of Harbin University of Science and Technology, 2003, 8(6): 112-114.

[16] 王丽萍, 康福伟, 郭二军, 等. 单一稀土Ce, La和混合稀土在工业纯铝中的作用[J]. 中国稀土学报, 2003, 21(2): 218-221.

WANG Li-ping, KANG Fu-wei, GUO Er-jun, et al. Role of single rare earths Ce, La and mischmetal in commercial pure aluminum[J]. Journal of The Chinese Rare Earth Society, 2003, 21(2): 218-221.

[17] 刘顺华, 王桂芹, 高洪吾, 等. 稀土元素对铝导体导电性能的影响[J]. 机械工程材料, 2005, 29(10): 46-49.

LIU Shun-hua, WANG Gui-qin, GAO Hong-wu, et al. The influence of RE on the electric properties of aluminum conductors[J]. Materials for Mechanical Engineering, 2005, 29(10): 46-49.

[18] FU Gao-sheng, SUN Feng-shan, REN Li-ying, et al. Modification behavior of trace rare earth on impurity phases in commercial purity aluminum[J]. Journal of Rare Earths, 2002, 20(1): 61-66.

[19] 傅高升, 孙锋山, 任立英, 等. 微量稀土对工业纯铝中杂质相的变质行为[J]. 中国稀土学报, 2001, 19(2): 133-137.

FU Gao-sheng, SUN Feng-shan, REN Li-ying, et al. Modification behavior of trace rare earth on impurity phases in commercial pure aluminum[J]. Journal of the Chinese Rare Earth Society, 2001, 19(2): 133-137.

[20] Hume-Rothery W, Raynor G V. Structure of metals and alloys[M]. London: Institute of Metals, 1962: 225.

[21] 余永宁. 金属学原理[M]. 北京: 冶金工业出版社, 2000: 249.

YU Yong-ning. Physical metallurgy[M]. Beijing: Metallurgy Industry Press, 2000: 249.

[22] 孙伟成, 张淑荣, 侯爱芹. 稀土在铝合金中的行为[M]. 北京: 兵器工业出版社, 1992: 231.

SUN Wei-cheng, ZHANG Shu-rong, HOU Ai-qin. Behaviors of RE elements in aluminum alloys [M]. Beijing: Weapon Industry Press, 1992: 231.

[23] 范新会, 李建国, 傅恒志. 单晶连铸铝线材的导电性能[J]. 中国有色金属学报, 1999, 9(1): 87-90.

FAN Xin-hui, LI Jian-guo, FU Heng-zhi. Electrical property of CCSC aluminum wire[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1):87-90.

(编辑 陈灿华)

收稿日期:2010-10-25;修回日期:2011-01-05

基金项目:长沙市科技计划项目(K0802093-11)

通信作者:李红英(1963-),女,湖南湘乡人,博士,教授,从事金属材料的强韧化研究;电话:0731-88879832;E-mail:lhying@csu.edu.cn