DOI: 10.11817/j.issn.1672-7207.2021.01.001

循环流化床油页岩半焦燃烧优化运行技术分析

孔皓,张缦,苗苗,邓博宇,刘贤东,黄逸群,杨海瑞,吕俊复

(清华大学 能源与动力工程系,电力系统及发电设备控制和仿真国家重点实验室,北京,100084)

摘要:针对目前油页岩生产页岩油时生成的副产物半焦难以处理的问题,在3.3 MWth循环流化床中试实验装置上分别进行油页岩、油页岩和半焦混合、半焦的燃烧实验研究。考察给料粒度、二次风份额和一二次风温对炉膛温度分布、污染物排放浓度、底渣与飞灰含碳量的影响。研究结果表明:油页岩和半焦混烧时,随着半焦的混烧比例增加,炉膛内温度整体下降,NOx排放量升高,SO2排放量下降;全半焦燃烧时,床温显著降低但炉膛温度分布仍然均匀,优化给料粒度、提高一二次风温可以显著提高炉膛内的燃烧温度;增加二次风份额可以降低NOx的排放。

关键词:油页岩;油页岩半焦;半焦燃烧;中试燃烧实验

中图分类号:TK16 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)01-0001-07

Technical analysis of optimal operation of combustion of oil shale semi-coke in circulating fluidized bed

KONG Hao, ZHANG Man, MIAO Miao, DENG Boyu, LIU Xiandong, HUANG Yiqun, YANG Hairui, LU Junfu

(State Key Laboratory of Power Systems, Department of Energy and Power Engineering, Tsinghua University, Beijing 100084, China)

Abstract: In view of the problem that the by-product semi-coke produced by oil shale in the production of shale oil is difficult to handle, the experimental study about the combustion of oil shale, mixture of oil shale and semi-coke, and semi-coke was conducted on a pilot-scale 3.3 MWth circulating fluidized bed(CFB) experimental device. The effects of the feed particle size, the secondary air share and the temperature of the primary and secondary air on furnace temperature distribution, pollutant emission concentration, carbon content of bottom ash and fly ash were analyzed. The results show that when oil shale and semi-coke are mixed burning, as the proportion of semi-coke increases, the furnace temperature decreases, the NOx emission value increases and the SO2 emission value decreases. When full semi-coke is burning, the bed temperature significantly reduces but the furnace temperature distribution is still uniform, and optimizing the feed particle size or increasing the temperature of the primary and secondary air can significantly increase the combustion temperature in the furnace. Increasing the secondary air share results in the decrease in NOx emissions.

Key words: oil shale; oil shale semi-coke; semi-coke combustion; pilot test combustion experiment

我国随着经济的发展,对能源的需求量日益增加。但我国贫油少气,急需研究替代能源来解决能源安全问题。油页岩是典型的非常规油气资源之一,主要分布在我国的20个省份47个盆地,而且储量十分丰富,如果合理利用可以解决我国的能源短缺问题[1-4]。目前,油页岩的主要利用方式有干馏制取页岩油、与其他燃料混合燃烧发电或利用页岩灰生产建筑材料等[5-9]。在油页岩干馏制取页岩油的过程中,提炼1 t的页岩油会同时生成10~30 t油页岩半焦,这种副产物因其低含碳量、低发热、灰分高、着火难的特点,被几乎所有的中国页岩油生产企业堆处理,占用了很大的土地面积,成为阻碍油页岩利用的困难之一[10]。针对油页岩半焦的处理问题,近年来国内外学者均认可在油页岩燃烧发电的锅炉中加入半焦混烧的处理方式,这种方式可以同时达到利用半焦余热、实现半焦的减量化、减少环境污染的目的。若控制燃烧后灰渣的含碳量小于2%,生成的灰渣可以应用于建筑行业,增加了油页岩利用的经济效益[11-13]。很多学者使用了多种自制反应器来研究油页岩半焦的燃烧特性[14-17]。循环流化床锅炉因具有燃料适应性广、燃烧效率高、污染物排放低等特点成为最适合油页岩半焦燃烧的反应器。ARRO等[18]通过分析油页岩半焦的燃烧特性提出使用循环流化床锅炉对油页岩和半焦混烧的可行性;王晓磊[19]在间歇式流化床实验台进行油页岩脱挥发分研究,并研究了油页岩质量、流化风速、床温、含水量对挥发分燃烧时间的影响;李孝杨[20]通过沉降炉实验得出了油页岩及半焦的燃烧特性,计算了灰分的扩散系数和反应的动力学参数,构建了半焦颗粒一维收缩未反应核模型。但目前的研究几乎都集中在实验室,且很少有学者研究半焦燃烧的工艺路线。本文作者采用中试实验台完成了油页岩的单独燃烧和油页岩与半焦的混烧实验,基于实验结果得到了燃料的燃烧特性,并通过提高炉膛温度实现了全半焦燃烧。结合实验结果,获得燃料种类、燃料粒度、二次风份额、一二次风温对炉膛温度分布、燃烧效率、污染物排放和底渣、飞灰及循环灰含碳量的影响规律,对油页岩和半焦在循环流化床燃烧的工业化应用有一定的参考价值。

1 油页岩半焦高效燃烧中试实验

1.1 实验样品

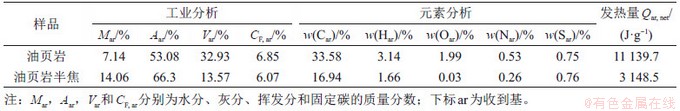

实验所用的油页岩和油页岩半焦由山东龙福油页岩公司生产,其元素分析和工业分析结果如表1所示。从表1可以发现油页岩特点为固定碳含量低、挥发分含量高。通过热重分析仪发现油页岩着火温度低于300 ℃,并且随着干馏时间增加,即发热量先降低后升高,所以油页岩在进入炉膛后能够很快被点燃;而半焦的热值极低、灰分较大,着火温度一般在400 ℃以上,属于不易燃的劣质燃料[21]。因此目前采用混烧处理半焦时,必须掺烧其他热值较大的燃料。

表1 油页岩和油页岩半焦的元素分析和工业分析

Table 1 Elemental analysis and industrial analysis of oil shale and oil shale semi-coke

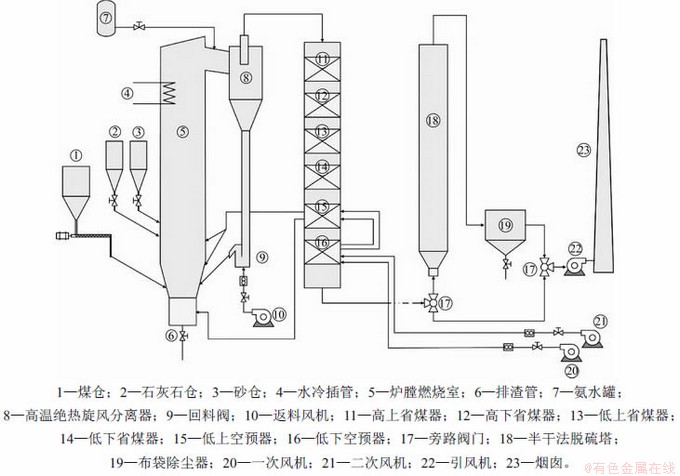

1.2 实验设备及方法

循环流化床中试实验台系统流程如图1所示,实验台的最高燃烧热负荷为3.3 MWth,实验锅炉为热水炉,给水温度为90 ℃,出水温度为130 ℃,出水压力为1 MPa,给水流量为70 t/h。炉膛中心高度为22.5 m,上部截面为边长1.01 m的正方形结构,下部截面长×宽为0.560 m×0.911 m的长方形结构。炉膛底部为风帽式布风板,上部布置有4层共8根水冷蛇形插管,可以通过调节投运数量来调节炉膛温度。二次风分上下两级给入,并可以单独进行风量调节。沿炉膛高度方向每间隔约1.5 m均布置有压力计、热电偶和取样点,可以测量温度、颗粒浓度和各气体组分沿炉膛高度的分布。在实验台的尾部烟道后依次接有半干法脱硫塔、布袋除尘器,并在分离器进口处装有SNCR喷枪,以满足污染物排放实验的要求。

图1 中试实验台示意图

Fig. 1 Schematic diagram of pilot test bench

实验过程中,先维持循环流化床锅炉稳定运行,在煤仓的煤基本耗尽的情况下,在煤仓中加入适量的油页岩。运行稳定后,设定一、二次风流量分别为2 300 m3/h和1 050 m3/h,并设定风室压力为8 kPa。油页岩燃烧完毕后,按照油页岩与半焦的质量比分别为3:1和2:1混合得到的燃料进行实验;实验中的油页岩粒度较粗,在1~10 mm之间,其中平均粒径d50为2.0 mm左右,大于8 mm的粗颗粒约占8%,半焦粒径均在0~8 mm之间,2种工况分别命名为S1和S2,并记录这2种工况下的实验数据。

2 实验结果与分析

2.1 油页岩单独燃烧

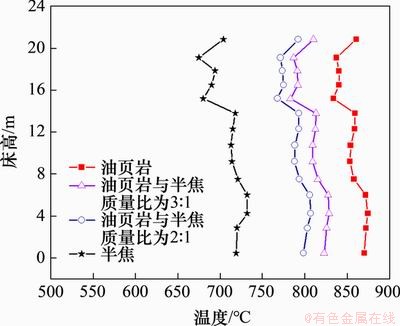

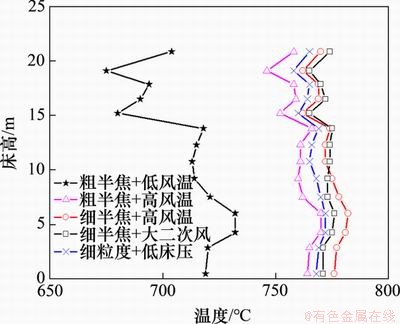

在燃烧油页岩的过程中测得温度分布如图2所示,炉膛内的温度沿高度均匀分布。由于该燃烧装置只有3.3 MWth,相对比表面积较大,因此炉膛散热的影响较大,这也是导致炉膛温度整体偏低的原因之一,如果在现在的工业级CFB进行纯烧,散热损失会有所降低。由于燃料的成灰磨耗特性,过渡区和稀相区的压差只有350 Pa,小于同样条件下煤燃烧的压差。由表1可知油页岩中的氮含量比煤中的小,所以,油页岩燃烧时NOx排放量应更低,但在分离器出口监测NOx原始排放量为130 mg/m3。其原因是油页岩的成灰磨耗特性较差的特点导致过渡区和稀相区的压差减小,燃烧份额降低,因此炉膛上部氧气浓度升高,不易形成还原性气氛,最终导致NOx排放量增加。

图2 油页岩、半焦燃烧床温分布对比

Fig. 2 Comparison of temperature distribution of oil shale and semi-coke combustion beds

燃烧油页岩时SO2测得的排放量小于理论排放量,其原因是油页岩具有硫含量低、灰分大的特点,导致SO2减少。且实验中所用油页岩中Ca质量分数为5.38%,且主要以CaCO3的形式存在,能够吸收燃烧过程中产生的SO2,因此SO2排放量较低。实验还测得大粒径底渣的含碳量远高于小粒径底渣的含碳量,大粒径的油页岩底渣的剖面图如图3所示,其中心的黑色物质即为含碳量较高的部分。因油页岩具有灰分高、成灰磨耗特性差、内部气体扩散性较差的特点,大颗粒的油页岩难以充分燃烧导致含碳量升高,可以减小油页岩的入炉粒径来降低底渣的含碳量从而提高循环流化床的燃烧效率。

图3 大粒径油页岩底渣剖面图

Fig. 3 Large-diameter oil shale bottom ash profile

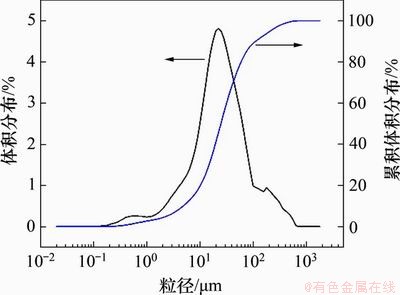

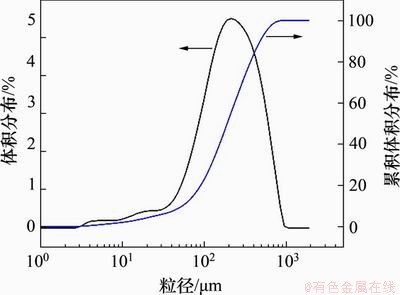

对飞灰和循环灰的粒径进行测定,结果分别如图4和图5所示。从图4和图5可知:循环灰粒径远大于飞灰粒径,说明分离器对小粒径的分离效率较低。实验测得飞灰的未燃尽碳质量分数为13.37%,一般飞灰高含碳量的是由炉膛温度过低、炉膛中部缺氧和燃料的停留较短等引起的,而本文的实验中炉膛温度合理、二次风扰动大,所以,飞灰含碳量高的原因可能是因分离器对小粒径分离效率低所引起的飞灰停留时间短。

图4 飞灰粒径分布

Fig. 4 Fly ash particle size distribution

图5 循环灰粒径分布

Fig. 5 Circulating ash particle size distribution

2.2 油页岩和半焦混烧

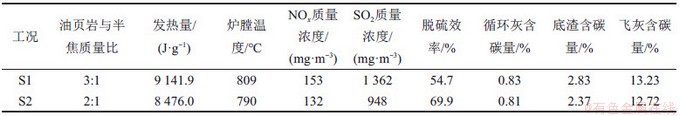

为了能与纯油页岩燃烧相比,实验中保证单位时间内加入炉膛燃料的发热量相等,并采用2种混合比例不同的燃料燃烧进行对比,其中工况S1和S2下的实验参数和结果如表2所示,工况S1和S2的炉膛温度分布如图2所示。由图2可知:随着混合燃料中半焦比例增加,燃料的燃烧性能进一步变差,炉膛内平均温度下降,但依然保持较均匀分布。过渡区和稀相区的压差较低,颗粒浓度较低,导致炉膛内易形成氧化氛围,所以相比于纯油页岩燃烧,混合燃烧时NOx排放量升高。且半焦的Ca质量含量较高,随着掺混比例的增加,炉内的脱硫效率也随之上升。

表2 工况S1和S2的实验参数及结果

Table 2 Experimental parameters and results of operating conditions S1 and S2

2种工况的测试结果如表2所示。与油页岩相比,半焦颗粒粒径较小且孔隙发达,所以易充分燃烧。由表2可知:随着半焦掺混比例的增加,飞灰中含碳量降低,但依然含碳量很高,可能由于飞灰仍含有未燃烧的挥发分。针对此问题,可以通过将飞灰回送进炉膛内继续燃烧进行解决,还可以增加二次风的扰动提高飞灰的燃烧效率。另外随着半焦掺混比例的提高,锅炉排渣量增加,热物理损失增加,锅炉的热效率降低。

2.3 全半焦燃烧

在油页岩、油页岩掺混半焦中试实验基础上,并根据前面的分析可知,可以采用以下措施来维持全半焦的燃烧。

1) 采用绝热炉膛燃烧,维持高的燃烧环境温度;

2) 采用较高的一二次风温,利于对燃料进行稳燃;

3) 减少高温灰渣的物理热损失,可使用飞灰回送燃烧技术;

4) 减少半焦给料粒度,减少灰壳厚度,从而提高半焦燃烧效率;

5) 适当增加二次风份额和增强穿透深度,强化扩散提高燃烧效率。

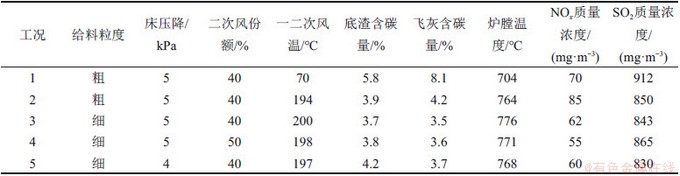

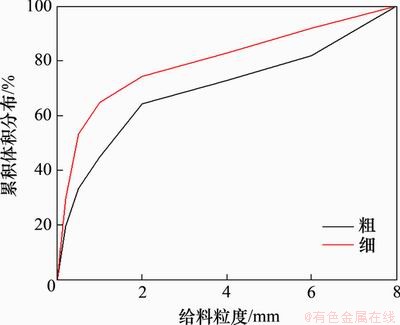

通过采用以上措施,提高炉膛温度,最终可以实现全半焦燃烧。4种工况下的床温曲线对比如图2所示。从图2可知:全半焦燃烧的炉膛温度明显比其他3种工况的低,但炉膛温度分布均匀。本文还对比研究燃料粒度、二次风份额、一二次风温对燃烧温度、燃烧效率和污染物排放的影响,其结果如表3所示。其中不同粒度不同风温工况下的床温分布如图6所示。给料粒度的累计体积分布如图7所示,其中粗颗粒的d50大于1 000 μm,细颗粒的d50小于500 μm。

表3 各影响因素对中试燃烧性能的影响

Table 3 Influence of various influencing factors on pilot test combustion performance

图6 不同工况下半焦燃烧温度分布

Fig. 6 Combustion temperature distribution of semi-coke under different working conditions

图7 粗细给料粒度对比

Fig.7 Comparison of coarse and fine feeding size

由表3可知:优化给料粒度、提高一二次风温可以显著提高炉膛内的燃烧温度;增加二次风份额有利于NOx排放的降低。经过优化,飞灰底渣含碳量显著降低,未完全燃烧热损失降低超过20%。对于绝热炉膛,床压降降低,导致炉膛底部温度有所降低,底渣含碳量有所升高。

3 结论

1) 在油页岩和半焦混烧时,随着半焦的未燃烧挥发分的颗粒含碳量高的混烧比例增加,炉膛内温度整体下降。与纯油页岩燃烧相比,过渡区和稀相区的颗粒浓度低,NOx排放量升高;因半焦中Ca含量较高,燃料中的钙硫质量比增加,故SO2排放量下降;半焦孔隙结构发达,氧气扩散阻力小,故飞灰和底渣中含碳量有所降低。

2) 因全半焦灰分大、发热量低,在其燃烧时需采用绝热炉膛燃烧和较高的一二次风温,减少半焦给料粒度等方法来减少能量损失,从而维持全半焦燃烧。全半焦燃烧时,床温显著降低,炉膛温度分布仍然均匀。优化给料粒度、提高一二次风温可以显著提高炉膛内的燃烧温度;增加二次风份额有利于NOx排放的降低。

参考文献:

[1] 李术元, 唐勋, 何继来, 等. 世界油页岩开发利用的近况: 并记2012年国外两次油页岩国际会议[J]. 中外能源, 2013, 18(1): 3-11.

LI Shuyuan, TANG Xun, HE Jilai, et al. Global oil shale development and utilization today: two oil shale symposiums held in 2012[J]. Sino-Global Energy, 2013, 18(1): 3-11.

[2] 钱家麟, 尹亮, 王剑秋, 等. 油页岩: 石油的补充能源[M]. 北京: 中国石化出版社, 2011: 4-30.

QIAN Jialin, YIN Liang, WANG Jianqiu, et al. Oil shale: supplementary energy of petroleum[M]. Beijing: China Petrochemical Press, 2011: 4-30.

[3] 王清强, 马跃, 李术元, 等. 世界油页岩资源研究开发利用近况: 并记2016年国外两次油页岩国际会议[J]. 中外能源, 2017, 22(1): 23-29.

WANG Qingqiang, MA Yue, LI Shuyuan, et al. Global oil shale research, development and utilization today: two international oil shale symposiums held in 2016[J]. Sino-Global Energy, 2017, 22(1): 23-29.

[4] 胡文瑞, 翟光明, 李景明. 中国非常规油气的潜力和发展[J]. 中国工程科学, 2010, 12(5): 25-29.

HU Wenrui, ZHAI Guangming, LI Jingming. Potential and development of unconventional hydrocarbon resources in China[J]. Engineering Science, 2010, 12(5): 25-29.

[5] 韩向新, 姜秀民, 崔志刚, 等. 油页岩半焦热解特性[J]. 化工学报, 2006, 57(1): 126-130.

HAN Xiangxin, JIANG Xiumin, CUI Zhigang, et al. Pyrolysis behavior of oil shale semi-coke[J]. CIESC Journal, 2006, 57(1): 126-130.

[6] AL-QODAH Z, LAFI W. Adsorption of reactive dyes using shale oil ash in fixed beds[J]. Journal of Water Supply: Research and Technology-AQUA, 2003, 52(3): 189-198.

[7] JIANG X M, HAN X X, CUI Z G. Progress and recent utilization trends in combustion of Chinese oil shale[J]. Progress in Energy and Combustion Science, 2007, 33(6): 552-579.

[8] 熊耀, 马名杰, 黄山秀, 等. 国内油页岩干馏炼油技术发展现状[J]. 现代化工, 2013, 33(8): 40-44.

XIONG Yao, MA Mingjie, HUANG Shanxiu, et al. Current status of carbonization process of oil shale in China[J]. Modern Chemical Industry, 2013, 33(8): 40-44.

[9] 刘德勋, 赵群, 王红岩, 等. 国内外小颗粒油页岩干馏工艺现状与展望[J]. 广州化工, 2010, 38(12): 7-11.

LIU Dexun, ZHAO Qun, WANG Hongyan, et al. Current status and prospect of small-size oil shale retort process[J]. Guangzhou Chemical Industry, 2010, 38(12): 7-11.

[10] 候祥麟. 中国油页岩工业[M]. 北京: 石油工业出版社, 1984:1-6.

HOU Xianglin. China oil shale industry [M]. Beijing: Petroleum Industry Press, 1984: 1-6.

[11] 卢茂奇. 油页岩半焦流化燃烧反应动力学研究[D]. 吉林: 东北电力大学能源与动力工程学院, 2018: 1-5.

LU Maoqi. Research on fluidized combustion reaction kinetics of oil shale semi-coke[D]. Jilin: Northeast Electric Power University. School of Energy and Power Engineering, 2018: 1-5.

[12] 杨庆春, 周怀荣, 杨思宇, 等. 油页岩开发利用技术及系统集成的研究进展[J]. 化工学报, 2016, 67(1): 109-118.

YANG Qingchun, ZHOU Huairong, YANG Siyu, et al. Research progress on utilization and systemic integration technologies of oil shale[J]. CIESC Journal, 2016, 67(1): 109-118.

[13] 韩向新. 油页岩半焦燃烧机理与循环流化床燃烧利用[D]. 上海: 上海交通大学热能工程学院, 2007: 1-4.

HAN Xiangxin. Combustion mechanism of oil shale semi-coke and combustion utilization in CFB boilers[D]. Shanghai: Shanghai Jiao Tong University. School of Thermal Engineering, 2007: 1-4.

[14] LU X F, HAY J N. Isothermal crystallization kinetics and melting behaviour of poly(ethylene terephthalate)[J]. Polymer, 2001, 42(23): 9423-9431.

[15] BRUNELLO S, FLOUR I, MAISSA P, et al. Kinetic study of char combustion in a fluidized bed[J]. Fuel, 1996, 75(5): 536-544.

[16] PY X, DAGUERRE E. Pitch Pyrolysis kinetics: isothermal heat treatment experiment and model[J]. Fuel, 2000, 79(6): 591-598.

[17] BOCKHORN H, HORNUNG A, HORNUNG U. Mechanisms and kinetics of thermal decomposition of plastics from isothermal and dynamic measurements[J]. Journal of Analytical and Applied Pyrolysis, 1999, 50(2): 77-101.

[18] ARRO H, PRIKK A, PIHU T, et al. Utilization of semi-coke of Estonian shale oil industry[J]. Oil Shale, 2002, 19(2): 117-125.

[19] 王晓磊. 油页岩燃烧机理及动力学模型研究[D]. 吉林: 东北电力大学能源与动力工程学院, 2010: 6-22.

WANG Xiaolei. Research on oil shale combustion mechanism and kinetic model[D]. Jilin: Northeast Electric Power University. School of Energy and Power Engineering, 2010: 6-22.

[20] 李孝杨. 油页岩热解半焦燃烧特性及热解/燃烧耦合工艺研究[D]. 北京: 中国科学院大学过程工程研究所, 2019: 23-56.

LI Xiaoyang. Combustion characteristics of oil shale pyrolysis semi-coke and pyrolysis/combustion coupling technology[D]. Beijing: University of Chinese Academy of Sciences. Institute of Process Engineering, 2019: 23-56.

[21] 李晓栋, 樊保国, 金燕, 等. 油页岩半焦燃烧特性试验研究[J]. 煤炭学报, 2016, 41(10): 2473-2478.

LI Xiaodong, FAN Baoguo, JIN Yan, et al. Experimental study on combustion characteristics of oil shale semi-coke[J]. Journal of China Coal Society, 2016, 41(10): 2473-2478.

(编辑 杨幼平)

收稿日期: 2020 -06 -01; 修回日期: 2020 -07 -02

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2014CB744300);国家自然科学基金资助项目(U1810126);华能集团总部科技项目基础能源科技研究专项(HNKJ20-H50) (Project(2014CB744300) supported by the National Basic Research Development Program(973 Program) of China; Project(U1810126) supported by the National Natural Science Foundation of China; Project(HNKJ20-H50) supported by Huaneng Group Headquarters Science and Technology Project Basic Energy Technology Research Program)

通信作者:杨海瑞,博士,教授,从事循环流化床燃煤技术研究;E-mail:yhr@mail.tsinghua.edu.cn

引用格式: 孔皓, 张缦, 苗苗, 等. 循环流化床油页岩半焦燃烧优化运行技术分析[J]. 中南大学学报(自然科学版), 2021, 52(1): 1-7.

Citation: KONG Hao, ZHANG Man, MIAO Miao, et al. Technical analysis of optimal operation of combustion of oil shale semi-coke in circulating fluidized bed[J]. Journal of Central South University(Science and Technology), 2021, 52(1): 1-7.