文章编号:1004-0609(2011)11-2846-06

激光熔覆和重熔制备

Fe-Ni-B-Si-Nb系非晶纳米晶复合涂层

张培磊1, 闫 华1, 徐培全1, 于治水1, 李铸国2, 姚成武2

(1. 上海工程技术大学 材料工程学院,上海 201620;

2. 上海交通大学 上海市激光制造与材料改性重点实验室,上海 200240)

摘 要:采用激光熔覆和重熔的方法在低碳钢CCS-B上制备Fe-Ni-Si-B-Nb系非晶纳米晶复合涂层。利用X射线衍射、扫描电镜、EDAX能谱及透射电镜分析涂层的物相、组织结构,运用显微硬度计、纳米压痕仪及摩擦磨损试验机研究涂层的显微硬度分布、微观力学性能及摩擦磨损性能。结果表明:熔覆层的组织由表面至基体分为非晶纳米晶复合区、熔覆层与基体,其中,复合区为Fe2B、γ-(Fe, Ni)多晶和非晶相的混合组织;涂层的最高显微硬度达到了1 369 HV;涂层的平均摩擦因数为0.275;涂层的主要磨损形式是磨粒磨损和粘着磨损,具有良好的摩擦磨损性能。

关键词:激光熔覆;Fe-Ni- B- Si-Nb;树枝晶;摩擦磨损

中图分类号:TG156.99 文献标志码:A

Fe-Ni-B-Si-Nb amorphous and nanocrystalline composite coating

prepared by laser cladding and remelting

ZHANG Pei-lei1, YAN Hua1, XU Pei-quan1, YU Zhi-shui1, LI Zhu-guo2, YAO Cheng-wu2

(1. School of Materials Engineering, Shanghai University of Engineering Science, Shanghai 201620, China;

2. Shanghai Key Laboratory of Material Laser Processing and Modification,

Shanghai Jiaotong University, Shanghai 200240, China)

Abstract: The Fe-Ni-B-Si-Nb amorphous composite coating was fabricated on the CCS-B mild steel by laser cladding and laser remelting. The phases, microstructure and impacts on glasses forming ability of the amorphous coatings were studied using X-ray diffractometer, scan electron microscope, EDAX energy spectrometer and transmission electron microscope. The microhardness, micro mechanical properties and wear resistance were studied by microhardness tester, nanoindentor and friction wear testing machine. The results show that the microstructure of coating consists of amorphous composite zone, original cladding zone and base metal. The amorphous composite zone consists of Fe2B, γ-(Fe, Ni) and amorphous phase. The highest hardness of coating is 1 369 HV and the average fraction coefficient is 0.275. Suppressing the crystalline phases with simple structure and promoting the crystalline phases with complex structure are good for fabricating the amorphous phase.

Key words: laser cladding; Fe-Ni- B- Si-Nb; dendrite; wear

非晶态合金是当前新材料领域的研究热点之一。非晶态合金具有高屈服强度、大弹性应变极限、无加工硬化现象、高耐磨性、优良的耐腐蚀性等特点,已成为表面工程的理想材料[1]。Fe基非晶合金由于其优异的力学和物理性能及廉价性越来越受到人们的重 视[2-7]。

激光熔覆的功率密度一般为104~106 W/cm2,冷却速度为104~106 K/s,作用区深度为0.2~2 mm[8]。如此高的功率密度和冷却速度,致使覆层材料完全熔化,而基材熔化层极薄,这就极大地避免了基体对熔覆层合金的稀释,可以获得高纯度的熔覆涂层。在激光熔覆的基础上,再利用大功率、超高速激光重熔产生的更大温度梯度,可以在熔覆层中形成非晶相[9]。同时,WONG和LIANG[10]的研究也发现,非晶和超晶格结构的存在有助于提高熔覆区的硬度和耐磨性;WU 和HONG[11]在45钢基体上激光熔履大厚度Fe57Co8Ni8Zr10Si4B13非晶复合涂层研究发现非晶表层的硬度呈梯度变化,最大硬度值达 1 120 HV;朱庆 军[9]采用预置法激光熔覆在低碳钢表面制备了Fe-Ni-B-Si-V系非晶纳米晶复合涂层,认为Fe基非晶层对提高材料表面的耐磨性有着重要的作用。鉴于Fe基非晶纳米晶涂层优良的耐磨性能及材料的廉价性,有必要对其形成机制和过程进行深入的研究,但其较弱的抗氧化能力和非晶形成能力制约了大厚度涂层的制备。为了增加激光制备Fe基非晶纳米晶复合涂层的厚度,使其尽早达到工业化应用标准,本文作者利用激光熔覆和重熔的方法在低碳钢基体上制备厚度达0.5 mm的Fe-Ni-B-Si-Nb非晶纳米晶复合涂层,对Fe基非晶复合涂层的相组成、组织结构、元素分布规律及形成机制进行分析和讨论,并研究涂层的微观力学性能和摩擦磨损性能。

1 试验材料与方法

基体材料为船用低碳钢CCS-B(碳的质量分数为0.1 3%),试板的尺寸为100 mm×50 mm×8 mm。涂层制备工艺分为两步:首先在基体上进行同步送粉激光熔覆,再在第一步获得的熔覆层表面进行激光快速重熔,冷却方式都为自然空冷,工艺参数如表1所示。为了减少激光熔覆和非晶化过程中的氧化,两种工艺都采用Ar气作为保护气。激光熔覆合金的名义成分为Fe31Ni31Si18B18Nb2(摩尔分数),所用金属粉末分别为纯镍粉(99.98%,质量分数)、硼铁粉(20.9% B)、硅铁粉(45% Si)、铌铁粉(50% Nb),不足的Fe元素以纯铁粉(99.95% Fe)加入;试验用激光器为德国TRUMPF生产的TLF15000 turbo 快速轴流型、最大输出功率为15 kW的CO2激光器,同步送粉器为北京航空制造工程研究所生产的DPSF-2B型双筒送粉器。

将制备好的涂层采用线切割沿纵向成金相试样。采用Rigaku D/max-rB型X射线衍射仪对涂层表面进行物相分析,电压为40 kV,Cu靶(λ=0.154 060 nm),扫描速度为4 (°)/min;采用JSM 6460型扫描电镜和Philips CM200透射电镜(加速电压为200 kV)观察熔覆层的微观组织,透镜取样时先用电火花沿熔覆层表面将涂层切下,厚度约为1 mm,接着用金相砂纸进行机械减薄,减薄至0.1 mm左右时再用离子减薄仪直至穿孔。采用HVS-10 型数显韦氏硬度计进行涂层的显微硬度测试,载荷为5 N。 摩擦磨损试验在MMW-1A 万能摩擦磨损试验机上进行,对磨偶件为GCr15,硬度(62±2)HRC,滑动速度1.93 m/s,采用载荷为50 N。采用CSM S/N6-140型纳米压痕仪,压头为三棱锥形金刚石压针,测试载荷为100 mN,加载速率为200 mN/min。

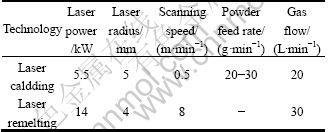

表1 激光熔覆和重熔的工艺参数

Table 1 Parameters of laser cladding and remelting

2 结果与分析

2.1 涂层的宏观形貌

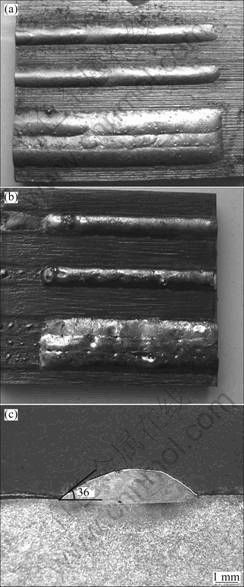

图1所示为Fe31Ni31Si18B18Nb2合金分别经激光熔覆和非晶化后的涂层宏观形貌和纵向截面图。在图 1(a)中,激光熔覆后获得的单道和搭接的熔覆层表面均无缺陷,呈灰色的金属光泽且表面无明显的氧化现象,说明熔覆合金有着良好的抗氧化能力。图1(b)中是熔覆层非晶化即激光重熔后获得的涂层,涂层表面光滑无明显氧化痕迹,与熔覆层相比光泽度明显增加,与块体非晶合金的金属光泽类似。熔覆层与基体的润湿角经标定为36°(见图1(c)),说明了熔覆层与基体良好的润湿性。

2.2 激光熔覆层重熔前后的物相构成

熔覆层的XRD谱如图2(a)所示,熔覆层中主要存在Fe23B6、(Fe, Ni)3B2、Ni4B3和γ-(Fe,Ni)相,说明熔覆层由晶相组成。熔覆层经激光重熔后的XRD谱如图2(b)所示,衍射曲线在衍射角为43°左右处出现了明显的非晶漫散射峰,另外,在漫散射峰上叠加了很弱的Fe2B晶相峰,重熔层中晶相主要为Fe2B和γ-(Fe, Ni)相。晶相峰很弱,说明重熔层中的晶相数量减少,而非晶数量增多。对比熔覆层在重熔前后的XRD谱结果可见,原先在熔覆层中出现的相,如Fe23B6、(Fe, Ni)3B2和Ni4B3相,在重熔层中都未再次发现,说明激光快速重熔抑制了大部分晶相的生成,尤其对于相结构比较复杂及单个晶胞所需原子数量较多的相,在快速凝固中由于原子的扩散被极大地抑制,原子重排难以完成。如Fe23B6相,由于其单个晶胞需要108个原子,其原子重排需要更长时间和更强的驱动力,激光重熔的快速冷却使得熔体的黏度急速增加,此时原子扩散变得更加困难,复杂结构晶相的难以生成,剩余熔体结构就有可能被保留下来而成为非晶相[12-14]。综上所述,合金的成分和冷却速度对于涂层中的相组成有着极大的影响:在激光熔覆过程中,容易出现较多具有复杂结构的相;而在激光重熔的快速凝固条件下,结构简单的亚稳相更容易生成。

图1 涂层的宏观形貌和截面图

Fig.1 Morphologies of appearance and cross section of coating: (a) Appearance of cladded layer; (b) Appearance of remelted layer; (c) Cross section of coating

图2 熔覆层和重熔层的XRD谱

Fig.2 XRD patterns of cladded (a) and remelted (b) layers

2.3 涂层的显微组织分析

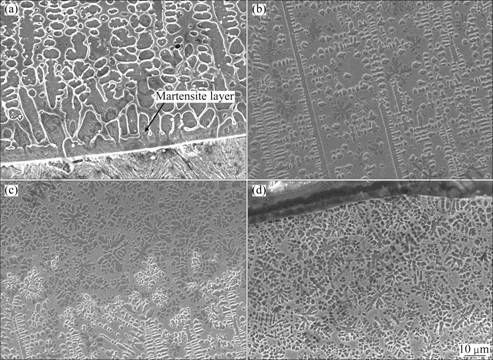

图3所示为涂层纵截面的组织形貌。从图3(a)中可以看出,熔覆层与基体在结合界面呈现出良好的冶金结合,由于激光熔覆本身就具有较快的冷却速度和良好的基体导热能力,故界面的温度梯度(G)很高,同时凝固的瞬间结晶速度(v)非常小,即G/v很高,界面呈现平面状结晶。即在基体表面上熔覆层发生了外延生长,形成了很薄的一层平面晶,厚度范围在10 μm以内[15]。由于基体被少量熔化,基体中碳元素进入熔覆层,在靠近母材处的熔覆层中形成了厚度为10~20 μm的扩散层,由于其中碳含量较高,这一层在扫描电镜下也呈板条状形貌,这也是形成了马氏体组织。随后,由于冷却速度的降低、结晶速度的加快及界面扰动的出现,扩散层上方熔覆层晶粒的生长转为胞状晶。胞状晶区的生长方向主要受热流的控制,为热流的反方向,因熔池底部热流方向垂直于固液界面,故其生长方向亦垂直于界面,为热流的反方向。再向上,熔覆层组织转变为树枝晶,尤其是在平面晶或胞状晶的前沿,由于溶质的富集而出现成分过冷,导致了树枝晶的生长所致,如图3(b)所示。由图3(c)和(d)可以看出,在熔覆层与重熔区域的界面处,原本是树枝晶的熔覆层被二次快速重熔之后,树枝晶被打断,凝固时生成了“花瓣状”黑色相和灰色基体,而黑色相是弥散分布在基体中。

图3 涂层的纵向显微组织

Fig.3 Microstructures of longitudinal section of coating: (a) Interface between base and cladded layer; (b) Microstructure of cladded layer; (c) Interface between cladded and remelted layer; (d) Microstructure on surface of coating

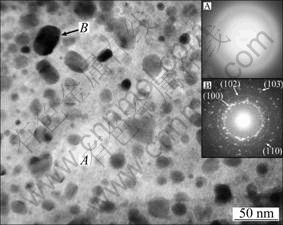

为进一步确认涂层的相结构,对涂层进行TEM形貌观察和选区电子衍射分析,如图4所示。由图4可知,白色的基体上弥散分布着黑色的纳米晶(10~20 nm)。分别对基体和纳米相进行选区电子衍射,可知白色基体为非晶相,而黑色纳米晶相为γ-(Fe, Ni)多晶相。 再结合XRD分析,可知图3(d)中的黑色相为Fe2B,灰色相是非晶和γ-(Fe, Ni)多晶的混合组织。综上所述,以Fe31Ni31Si18B18Nb2合金为熔覆层合金,并利用激光熔覆和重熔工艺可在低碳钢基体上获得非晶纳米晶复合组织的涂层。

2.4 涂层的摩擦磨损性能

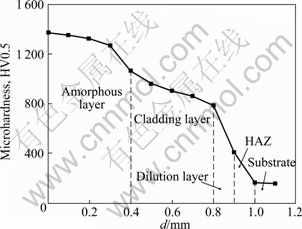

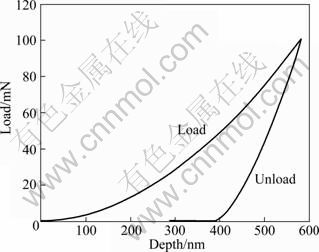

涂层的显微硬度如图5所示。由图5可见,涂层表面由于非晶含量较高,其硬度也较高,最高达到了1 369 HV,最低硬度也维持在1 200 HV左右;熔覆层的硬度比表面要低很多,在800~1 000 HV之间;再往下就是熔覆层的稀释区,由于基体中元素的熔入,这个区域的硬度比熔覆层的有很大的降低,只有400 HV左右。对涂层表面进行纳米压痕的测试,加载—卸载曲线如图6所示,其结果如表2所列。图6中照片为涂层中压痕在扫描电镜下的形貌图,在压头的周围没有出现裂纹,说明涂层具有良好的韧性。这是因为在Fe31Ni31Si18B18Nb2 重熔层中,存在着两种组织:一种为Fe2B相,此相为脆性相,具有较高的硬度,但其韧性较差;另一种为基体组织,包括非晶相和Fe-Ni 组成的面心立方固溶体,虽然非晶相塑性较差,但是与钢中的奥氏体类似,Fe-Ni 多晶相具有很好的塑性变形能力,在涂层变形过程中可以有效地吸收涂层的变形功,减少涂层裂纹的产生,所以,Fe31Ni31Si18B18Nb2涂层中的这种复合组织既具备较高的硬度又具备良好的韧性[16]。

图4 重熔层的TEM 像和选区电子衍射花样

Fig.4 TEM image and selected area electron diffraction patterns of remelted zone

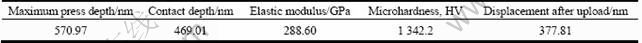

表2 涂层纳米压痕试验结果

Table 2 Nano-indentation results for coating

图5 涂层厚度方向上的显微硬度分布

Fig.5 Microhardness distribution of coating along cross section

图6 涂层的纳米压痕加载—卸载曲线

Fig.6 Nanoindentor load—unload curves of coating

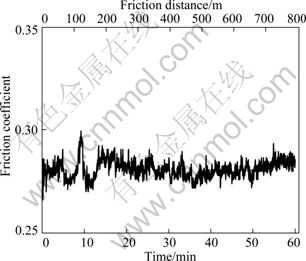

涂层的摩擦因数—时间变化曲线及摩擦形貌分别如图7和8所示。涂层的摩擦因数在刚开始摩擦时快速上升,但很快就趋于平稳,但在平稳阶段之初波动较大,15 min后波动幅度减小,摩擦过程稳定,如图7所示。摩擦因数变化较为激烈的这一阶段称为磨合阶段(此处约为15 min),较为平稳的阶段称为稳定摩擦阶段。开始磨合时对磨材料都有一定的粗糙度,由于涂层表面的硬度(>1 300 HV)远远高于钢球(GCr15,800 HV)的硬度,随着摩擦过程的进行,实际接触面积不断增加,导致摩擦因数的急剧增加。但钢球表面的微凸粗糙峰会被迁移、剪断而出现微抛光的效果,摩擦因数开始下降。当对磨表面的微区抛光达到最大限度且实际接触面积达到动态平衡时,摩擦因数趋于稳定。涂层的平均摩擦因数为0.275。

涂层的摩擦形貌如图8所示,表面有轻微的犁沟和粘着,说明涂层的主要磨损形式是磨粒磨损和粘着磨损。本研究中制备的非晶纳米晶复合涂层中以硬质相和非晶相为主,其具备较高的硬度和弹性模量,接触时会产生很高的弹性应力,当应力去除后,这些弹性应力能使粘着结合分开,所以涂层在磨合阶段的粘着磨损较小。涂层的硬度和强度越高,塑性变形的抵抗能力越强,越不容易发生粘着磨损,摩擦因数也就越低,因此,制备的高硬度和高强度Fe 基非晶纳米晶复合涂层具有良好的摩擦磨损性能。

图7 涂层的摩擦因数—时间曲线

Fig.7 Friction coefficient—time curve of coating

图8 涂层的磨擦形貌

Fig.8 Friction morphology of coating

3 结论

1) 用同步送粉激光熔覆+激光快速重熔制备了Fe基非晶纳米晶复合涂层,获得的涂层表面无缺陷,与基体润湿良好。

2) 涂层的组织由表面至低碳钢基体分为非晶纳米晶复合区、熔覆层和基体。复合区中为黑色相在灰白色基体上弥散分布,结合XRD、SEM和TEM分析可知,黑色相为Fe2B,而灰色相是非晶相和γ-(Fe,Ni)纳米多晶相的混合相。

3) 涂层表面由于非晶含量较高,硬度也最高,达到了1 369 HV;涂层的摩擦因数在开始摩擦时快速上升,但很快就趋于平稳;在平稳阶段之初波动较大,15 min后,波动幅度减小,摩擦过程稳定,涂层的平均摩擦因数为0.275; 涂层的主要磨损形式是磨粒磨损和粘着磨损。

REFERENCES

[1] Fornell J, González S, Rossinyol E. Enhanced mechanical properties due to structural changes induced by devitrification inFe-Co-B-Si-Nb bulk metallicglass[J]. Acta Materialia, 2010, 58(19): 6256-6266.

[2] JUNG H Y, YI S. Enhancedglassforming ability and soft magnetic properties through an optimum Nb addition to aFe-C-Si-B-P bulk metallicglass[J]. Intermetallics, 2010, 18(10): 1936-1940.

[3] GUO S F, LI N, ZHANG C, LIU L. Enhancement of plasticity ofFe-based bulk metallicglassby Ni substitution forFe[J]. Journal of Alloys and Compounds,2010, 504(S1): S78-S81.

[4] TERAJIMA T, TAKEUCHI F, NAKATA K. Composite coating containing WC/12Co cermet and Fe-based metallic glass deposited by high-velocity oxygen fuel spraying[J]. Journal of Alloys and Compounds,2010, 504(S1): S288-S291.

[5] TORRENS-SERRA J, BRUNA P, RODRIGUEZVIEJO J. Effect of minor additions on theglassforming ability and magnetic properties ofFe-Nb-B based metallic glasses[J]. Intermetallics, 2010, 18(5): 773-780.

[6] SALAHINEJAD E, AMINI R, MARASI M. The effect of nitrogen on theglass-forming ability and micro-hardness ofFe-Cr-Mn-N amorphous alloys prepared by mechanical alloying[J]. Materials Chemistry and Physics,2009, 118(1): 71-75.

[7] JANG J C, JIAN S R, LI T H. Structural and mechanical characterizations of ductile Fe particles-reinforced Mg-based bulk metallicglasscomposites[J]. Journal of Alloys and Compounds,2009, 485(1/2): 290-294.

[8] 钟敏霖, 刘文今, 任家烈, 姚可夫, 刘志刚, 张红军. FeCSiB合金连续激光非晶化的研究[J]. 金属热处理学报, 1998, 19(1): 42-47.

ZHONG Min-lin, LIU Wen-jin, REN Jia-lie, YAO Ke-fu, LIU Zhi-gang, ZHANG Hong-jun. Laser glazing of Fe-C-Si-B alloy and forming condition of metallic glasses[J]. Transactions of Materials and Heat Treatment, 1998, 19(1): 42-47.

[9] 朱庆军. Fe基非晶-纳米晶激光熔覆涂层研究[D]. 济南: 山东大学, 2008.

ZHU Qin-jun. The composite coating with amorphous and nanocrystalline fabricated by laser cladding[D]. Jinan: Shandong University, 2008.

[10] WONG T T, LIANG G Y. Formation and crystallization of amorphous structure in the laser-cladding plasma-sprayed coating of Al-Si alloy [J]. Materials Characterization, 1997, 38(1): 85-89.

[11] WU X L, HONG Y S. Fe-based thick amorphous-alloy coating by laser cladding[J]. Surface and Coatings Technology, 2001, 141: 141-144.

[12] LU Z P, LIU C T. Role of minor alloying additions in formation of bulk metallic glasses: A review[J]. Journal of Materials Science, 2004, 39: 3965-3974.

[13] LI F S, SHEN B L, MAKINO A, INOUE A. Excellent soft- magnetic properties of (Fe, Co)-Mo-(P, C, B, Si) bulk glassy alloys with ductile deformation behavior[J]. Appl Phys Lett, 2007, 91: 234101.

[14] INOUE A. Classification of bulk metallic glasses by atomic size difference [J]. Materials Transactions, 2005, 46(12): 2817-2829.

[15] 斯松华, 何宜柱, 袁晓敏. 激光熔覆含B4Cp, SiCp钴基合金涂层的组织与耐磨性能[J]. 中国有色金属学报, 2003, 13(2): 454-459.

SI Song-hua, HE Yi-zhu, YUAN Xiao-min. Microstructure and wear-resistance of laser clad Co-based alloy coatings with B4Cp and SiCp[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 454-459.

[16] 程江波. 面向再制造的高速电弧喷涂铁基非晶纳米晶涂层制备与表征[D]. 上海: 上海交通大学, 2010.

CHENG Jiang-bo. Synthesis and characterization of wire arc sprayed Fe-Based amorphous/nanocrystalline coatings for remanufacturing [D]. Shanghai: Shanghai Jiao Tong University, 2010.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50875160, 51105240);上海市自然科学基金资助项目(10ZR1412900);上海市重点学科建设项目(J51402);上海工程技术大学校基金资助项目(A-0501-11-009, A-0501-11-008); 上海高校青年教师培养资助计划(gjd11015, gjd11021)

收稿日期:2010-11-11;修订日期:2011-02-20

通信作者:张培磊,讲师,博士;电话:021-67791474;E-mail: oxidpl@gmail.com