DOI:10.19476/j.ysxb.1004.0609.2017.05.024

焦化废水还原浸出软锰矿动力学

冯雅丽1,康金星1,李浩然2,邓祥意1,孙 铭1

(1. 北京科技大学 土木与资源工程学院,北京 100083;

2. 中国科学院 过程工程研究所 生化工程重点实验室,北京 100190)

摘要:以焦化废水为还原剂,在硫酸介质中利用收缩芯模型研究焦化废水加压直接还原浸出软锰矿的动力学,考察搅拌速度、反应温度、软锰矿粒径、硫酸浓度和焦化废水CODcr浓度对锰浸出速率的影响。结果表明:锰浸出率随反应温度、硫酸浓度、焦化废水CODcr浓度的增加和软锰矿粒径的减小而增大。在393 K~423 K间,焦化废水还原浸出软锰矿受固膜扩散控制,表观活化能为15.2 kJ/mol,硫酸和焦化废水CODcr浓度的表观响应级数分别为1.21和0.98。机理分析表明:软锰矿氧化焦化废水中大分子有机物分解成小分子而被还原溶出,或被小分子直接还原溶出;反应过程中,软锰矿表面残留的Fe、Si、Al形成孔洞薄壁而影响锰的溶出过程。

关键词:焦化废水;软锰矿;还原浸出;动力学

文章编号:1004-0609(2017)-05-1051-10 中图分类号:TF111.31 文献标志码:A

早在20世纪60年代,含有以二氧化锰为主要形式的锰矿利用问题,就被人们所重视[1]。持续至今,软锰矿的还原工艺依然是国内外锰提取的一项重要攻关任务[2]。近年来,在酸性介质中,湿法还原软锰矿因环境污染少、工艺简单而成为研究热点[3]。直接还原浸锰的关键性问题是,寻找一种经济、实效的还原剂[4-5]。已有小分子有机物[6]、生物质[7]、糖蜜酒精废液[8]等湿法还原软锰矿的相关报道。有机物湿法还原软锰矿的动力学研究集中在小分子物质和生物质,如BEOLOCHINI等[9]、 等[10]、粟海峰等[11]、满瑞林等[12]分别用球形颗粒收缩芯模型研究了蔗糖、乳糖、焦糖色素、燕麦秸秆等还原浸出软锰矿的动力学。

等[10]、粟海峰等[11]、满瑞林等[12]分别用球形颗粒收缩芯模型研究了蔗糖、乳糖、焦糖色素、燕麦秸秆等还原浸出软锰矿的动力学。

焦化废水含有高浓度的酚类、氰化物和氨氮,以及难以生物降解的油类、吡啶等复杂化合物和联苯等多环芳香族化合物,一直是焦化行业废水处理的共性难题[13]。较通常采用的物化、生化治理工艺[14],将焦化废水中大量的化学能利用,即实现废水净化,同时又将废水资源化,是节约水资源、减少环境污染的有效路径。温度高于100 ℃的冶金技术作为一种清洁高效、强化浸出的湿法冶金新工艺发展迅速[15]。谢红艳等[16]以黄铁矿作为还原剂120 ℃从低品位软锰矿中提取了锰。本文作者通过焦化废水作为还原剂,研究软锰矿湿法浸出的工艺条件和动力学,为实现焦化废水高效溶出软锰矿,以及焦化废水资源化与综合治理,提供理论依据,并为富含CODcr污染物浸出软锰矿提供宏观动力学的理论参考。

1 实验

1.1 实验材料

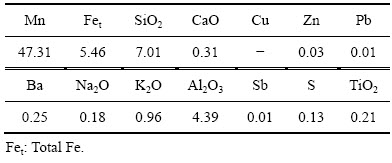

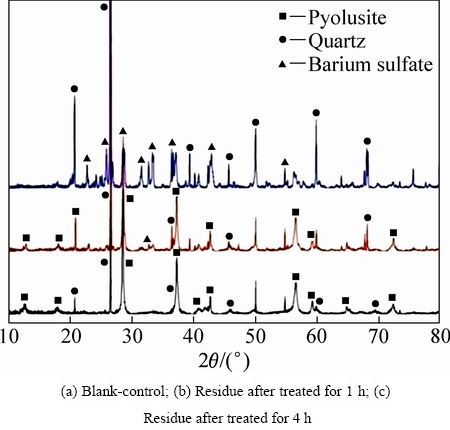

实验所用的软锰矿来自某高品位进口锰矿,其主要化学成分见表1,XRD谱如图1所示,软锰矿的物相如表2所列。从表1、2及图1中可以看出,该锰矿锰元素基本以高价氧化锰形式存在,金属矿物主要为软锰矿,脉石矿物以石英为主。

表1 软锰矿的主要化学成分

Table 1 Chemical compositions of pyrolusite(mass fraction,%)

图1 软锰矿的XRD谱

Fig. 1 XRD pattern of pyrolusite

表2 软锰矿中锰的物相

Table 2 Phase analysis of manganese in manganese ore

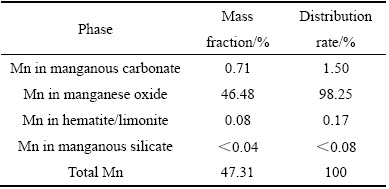

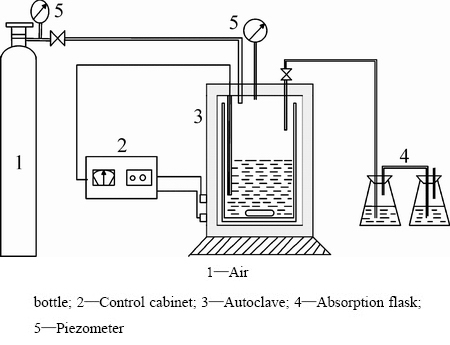

试验所用的焦化废水取自河北某焦化煤气厂废水,焦化废水水质如表3所列。焦化废水中CODcr含量为2.14×104 mg/L,BOD5浓度为8.5×103 mg/L,有机质以挥发酸和酚类为主。试验所使用的其他药剂均为分析纯。

表3 焦化废水水质

Table 3 Quality of coking-plant wastewater (concentration, mg/L)

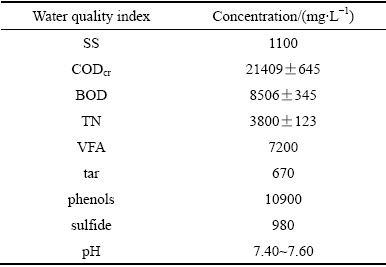

1.2 试验设备及检测仪器

试验装置示意图如图2所示。

图2 试验装置示意图

Fig. 2 Schematic diagram of experimental apparatus

主要的试验设备及仪器有:棒磨机(XMB-70型三辊四筒,武汉探矿机械厂生产);智能型微型反应釜(YZPR-500,岩征试验仪器有限公司生产);电子分析天平(AR1140,奥豪斯仪器上海有限公司生产);X射线衍射仪(D/max 2550VB+,日本理学生产);红外光谱仪(ALPHA,BRUKER公司生产);扫描电镜(ULTRA55,CarlzeissSMTrecLMD公司生产)。

1.3 试验方法

称取20 g软锰矿放入反应釜内,按液固比10:1加入设定浓度的焦化废水和硫酸混合溶液,装釜密封,用氮气排出釜内气体,关闭气阀,启动升温,当达设定温度时,开始计时;反应至设定时间,冷却降温至80 ℃,通氮气排出釜内气体,启釜取出矿浆,矿浆用真空泵抽滤进行固液分离,浸渣多次洗涤后干燥;用硫酸亚铁铵容量法测定浸出渣锰元素含量。

2 结果与讨论

2.1 浸出动力学分析

2.1.1 搅拌速率对锰浸出的影响

在温度423 K、硫酸浓度1.4 mol/L、焦化废水CODcr浓度20 g/L、平均粒径0.03 mm条件下反应120 min,考察搅拌速率对软锰矿浸出的影响,其结果见图3。由图3可知,搅拌速率由100 r/min 增大到200 r/min,锰浸出率提高21.2%,说明搅拌强度不足时,液膜扩散影响较大[17];充分搅拌后,锰浸出率受搅拌强度影响变小。考虑能耗,搅拌速度为200 r/min适宜。

图3 不同搅拌速度对锰浸出率的影响

Fig. 3 Effect of stirring speed on Mn leading rate

2.1.2 温度对锰浸出的影响

当硫酸浓度为1.4 mol/L、焦化废水CODcr浓度为20 g/L、平均粒径为0.03 mm、搅拌速度为200 r/min时,温度对锰浸出率的影响如图4所示。由图4可知,温度对锰的浸出有明显影响。373 K时,锰浸出缓慢,反应240 min后,浸出率低于80%,说明此时软锰矿被废水还原的化学反应推动力不足;393 K时,锰浸出量增加15%,浸出速率变快,这是由于废水中与软锰矿反应的有机物增加,反应变剧烈;423 K时,反应180 min后,浸出率大于97%,说明此时软锰矿基本被完全浸出;温度由423 K升高到433 K,锰浸出效果提高不明显;适宜的温度条件为423 K。

球形颗粒收缩芯模型的固膜扩散控制模型[18-19]:

1-2x/3-(1-x)2/3=kdt (1)

化学反应控制模型:

1-(1-x)1/3=krt (2)

图4 不同温度时锰浸出率随时间的变化

Fig. 4 Change of Mn leaching rate with time at different stirring temperatures

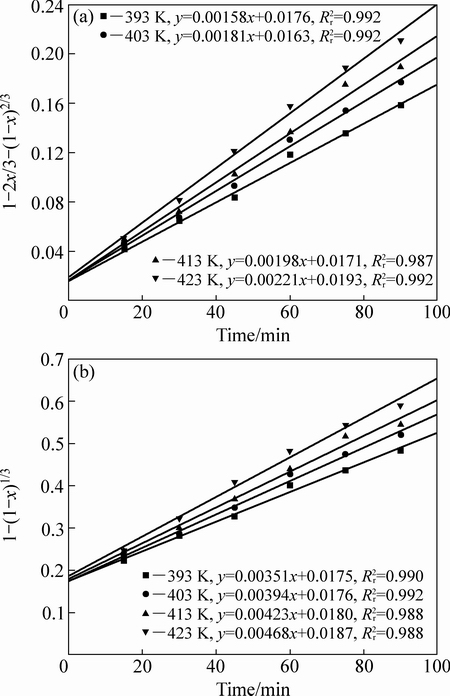

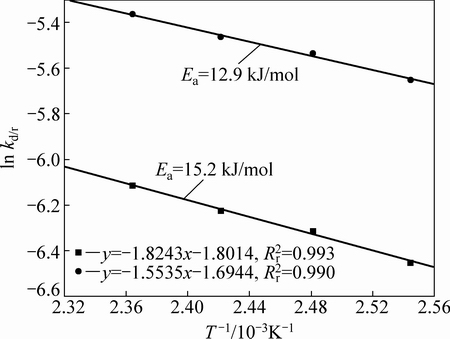

在393~423 K范围内,将1-2x/3-(1-x)2/3和1-(1-x)1/3对时间t进行线性拟合,其结果如图5所示。由图5(a)和(b)可知,所得的直线斜率即为反应速率常数k。以lnk对1/T作图,可得焦化废水浸出软锰矿的阿伦尼乌斯曲线,如图6所示。由方程(1)和(2)分别计算得到浸出过程的表观活化能(Ea)为15.2 kJ/mol和12.9 kJ/mol。化学反应控制一般活化能大于40 kJ/mol,扩散控制不大于15 kJ/mol[20],因此,当温度为393~ 423 K时,焦化废水加压浸出软锰矿更倾向于受固膜扩散控制[21]。

图5 不同温度下1-2x/3-(1-x)2/3和1-(1-x)1/3曲线

Fig. 5 1-2x/3-(1-x)2/3 (a) and 1-(1-x)1/3 (b) curves vs time at different temperatures

图6 lnkd/r和1/T关系

Fig. 6 Relationship between lnkd/r and 1/T

2.1.3 软锰矿粒径对锰浸出的影响

锰元素在各个粒级均匀分布(见表4),平均粒径对锰浸出率的影响如图7所示。由图7可知,软锰矿浸出率随平均粒径的减小而增大,这主要是由于有机物与软锰矿接触面积增大,扩散层变薄,促进了反应的进行[22]。

表4 不同粒级的锰元素分布

Table 4 Manganese mass content of different particle size range of pyrolusite

图7 不同粒径时锰浸出率随时间的变化

Fig. 7 Change of Mn leaching rate with time at different particle sizes

不同平均粒径对软锰矿浸出过程1-2x/3-(1-x)2/3和时间关系曲线见图8。对图8中曲线作线性回归,得出每条曲线反应速率常数kd,以kd与r0-2作图,结果见图9。由图9可以看出,kd与r0-2呈线性关系。

2.1.4 硫酸浓度对锰浸出的影响

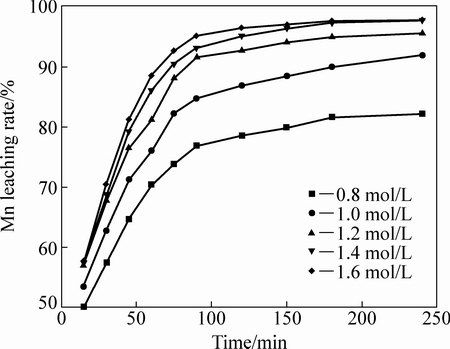

硫酸初始浓度(0.8~1.6 mol/L)对锰浸出的影响如图10所示。从图10可以看出,软锰矿的浸出率受硫酸初始浓度影响较大。硫酸初始浓度由0.8 mol/L增大到1.4 mol/L时,反应180 min后,锰浸出率提高15.7%;继续提升至1.6 mol/L对锰浸出促进较小;这是基于溶液中酸度对锰浸出有较大影响,当酸度增大到一定程度后,其对锰浸出影响变小[23],硫酸浓度1.4 mol/L适宜。

图8 不同粒径下1-2x/3-(1-x)2/3与时间的关系

Fig. 8 Relationship between 1-2x/3-(1-x)2/3 and time at different particle sizes

图9 kd与r0-2关系

Fig. 9 Relationship between kd and r0-2

图10 硫酸初始浓度对锰浸出率的影响

Fig. 10 Effect initial H2SO4 concentrations on Mn leaching rate

不同硫酸初始浓度中锰浸出率1-2x/3-(1-x)2/3与时间t关系曲线,如图11所示。1-2x/3-(1-x)2/3与时间t基本线性相关。对图11中曲线作线性回归求得各曲线反应速率常数kd,以lnkd对lncH作图(见图12),硫酸初始浓度的表观响应级数为1.21。

图11 不同初始硫酸浓度下1-2x/3-(1-x)2/3与时间的关系曲线

Fig. 11 Relationship between 1-2x/3-(1-x)2/3 and time at different initial H2SO4 concentrations

图12 lnkd与lncH的关系

Fig. 12 Relationship between lnkd and lncH

2.1.5 焦化废水CODcr浓度对锰浸出的影响

焦化废水CODcr浓度(12~20g/L)对软锰矿浸出的影响见图13。由图13可知,焦化废水CODcr浓度对锰浸出效率影响较大,CODcr浓度增大,化学反应推动力增大,锰浸出效率越好。CODcr浓度为20 g/L,反应120 min后,锰浸出率达到95.1%,反应时间和焦化废水CODcr继续增加对锰浸出作用变小,CODcr浓度为20 g/L可满足要求。

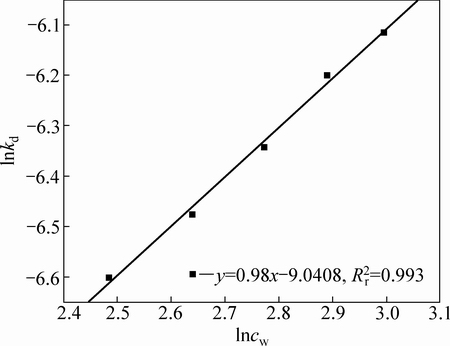

不同焦化废水CODcr浓度中锰浸出率1-2x/3-(1-x)2/3与时间t的关系曲线如图14。由图14可以看出,1-2x/3-(1-x)2/3与时间t基本呈线性相关关系。以lnkd对lncw作图得图15,焦化废水CODcr浓度的表观响应级数为0.98。

图13 焦化废水CODcr浓度对锰浸出率的影响

Fig. 13 Effect of CODcr concentrations on Mn leaching rate

图14 不同焦化废水CODcr浓度下1-2x/3-(1-x)2/3与时间的关系

Fig. 14 Relationship between 1-2x/3-(1-x)2/3 and time at different concentrations of CODcr

2.1.6 浸出动力学方程

由反应速率常数

,根据以上分析可得,k0的平均值为5.30×10-6。因此,焦化废水还原浸出软锰矿的宏观动力学模型可表达为

,根据以上分析可得,k0的平均值为5.30×10-6。因此,焦化废水还原浸出软锰矿的宏观动力学模型可表达为

(3)

(3)

锰浸出率随颗粒粒径减小、硫酸及焦化废水CODcr浓度增大而逐渐增大。图16所示为不同条件再验证试验,实验值与计算值的关系曲线。

图15 lnkd与lncw的关系

Fig. 15 Relationship between lnkd and lncw

图16 锰浸出计算值(xcal)与理论值(xexp)的比较

Fig. 16 Comparison between calculated data (xcal) and experimental data (xexp)

2.2 浸出机理分析

2.2.1 浸出液分析

焦化废水不同温度浸出软锰矿4 h,浸出液的FIRT分析如图17所示。由图17可知,温度由90 ℃升高到120 ℃时,3196 cm-1处的羟基吸收峰减弱,vOH向高频方向移至3405 cm-1,这是基于焦化废水中,含羟基的高聚体大分子分解成小分子,引起了羟基特征吸收峰的定向移动;之前试验结果中,温度由90 ℃升高到120 ℃,锰浸出率提高36%,说明大分子的分解提高了锰的浸出率。

图17 不同温度浸出液的红外图谱

Fig. 17 FIRT patterns of lixivium after leaching at different temperatures

图18 不同条件下废水和浸出液的红外图谱

Fig. 18 FIRT patterns of coking wastewater and lixivium under different conditions

图19 不同条件下废水和浸出液的CODcr浓度

Fig. 19 Concentrations of coking wastewater and lixivium CODcr at different conditions

焦化废水不同条件处理后FIRT分析和CODcr浓度分别如图18和19所示。由图18和19可知,未加软锰矿90 ℃加热4 h时,主要由挥发性酚类及有机酸分解引起焦化废水中CODcr浓度的降低,大分子基本不分解;与软锰矿反应后CODcr浓度降低接近一倍,说明废水中有机物被软锰矿氧化而降解;150 ℃时,未加软锰矿废水的羟基吸收峰为3114 cm-1,低温(90 ℃)时,与软锰矿反应的废水较150 ℃未与软锰矿反应的废水CODcr浓度低0.7 g/L且vOH向高频方向移动了75 cm-1,这是由废水中大分子与软锰矿反应分解引起,而试验范围内废水中大分子随温度升高分解不明显;150 ℃时,与软锰矿反应后vOH也向高频方向移动,1 h 和4 h后,浸出液 vOH向高频方向分别移至3227 cm-1、3356 cm-1,CODcr去除率分别提高14.0%、20.0%,说明随时间延长废水中大分子被软锰矿氧化分解量增多,锰浸出量也因此增大;150 ℃下,废水中 2500~2700 cm-1段羧酸缔合—OH吸收峰在与软锰矿反应后消失,说明羧基是与软锰矿反应后降解,不是被加热分解。

图20 不同浸出时间浸渣XRD谱

Fig. 20 XRD patterns of pyrolusite and its residue after leaching

2.2.3 浸渣分析

不同时间的浸出渣XRD分析结果见图20。由图20可看出,软锰矿被焦化废水还原后,浸渣以石英与硫酸钡为主,且反应过程中,无其锰矿物的沉淀产生。因此,焦化废水还原浸出软锰矿可认为是,软锰矿氧化大分子有机物分解成小分子,而被还原溶出;或被小分子有机物直接还原溶出,反应过程可概括为[24-25]:

(4)

(4)

(5)

(5)

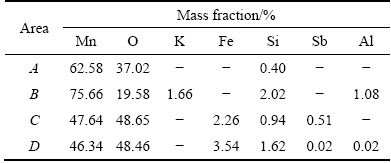

MnO+H2SO4→MnSO4+H2O (6)

浸渣的SEM分析如图21所示,浸渣的EDS能谱化学检测结果如表5所示。150 ℃未加入焦化废水加压处理1 h的浸渣中,软锰矿呈块状,表面光滑平整,棱角分明,见图21(a);加入焦化废水反应1 h后,如图21(b),表面被腐蚀,并被致密覆盖。由表5可知,焦化废水与软锰矿反应1 h后,软锰矿表面被Fe、Sb、Si等残留物覆盖[25]。由此可以认为,焦化废水还原浸出软锰矿过程中,矿石表面与还原剂发生反应;部分Mn、Fe、Al、Si等残留物覆盖在颗粒表面,形成孔洞薄壁;还原剂与表面残留Mn反应,同时,需通过覆盖层扩散到内核表面,与Mn等继续反应。

图21 焦化废水还原软锰矿SEM像

Fig. 21 SEM images of pyrolusite after coking wastewater reducing leaching

表5 浸渣的能谱化学组分

Table 5 Chemical composition of leaching residue tested by EDS

3 结论

1) 以焦化废水为软锰矿浸出还原剂,实现了废水的净化与资源化,为废水处理提供新方法,是解决水资源短缺与环境污染问题的有效路径。

2) 软锰矿在温度为423 K,初始硫酸浓度为1.4 mol/L,平均粒径为0.03 mm,焦化废水CODcr浓度为20 g/L,搅拌速度为200 r/min,反应180 min后,锰浸出率可达97%以上。

3) 在393~423 K间,焦化废水还原浸出软锰矿的宏观动力学方程为

由以上公式可见,锰浸出率随温度、硫酸浓度、焦化废水CODcr浓度的提高及粒径的减少而增大。

4) 软锰矿氧化焦化废水中大分子分解成小分子而被还原溶出,或被小分子直接还原溶出;矿石表面残留的Fe、Si、Al等形成孔洞薄壁,影响锰浸出过程。

REFERENCES

[1]  周留根. 用硫酸铁和黄铁矿将二氧化锰转变为硫酸盐法[J]. 化学世界, 1955(1): 25-31.

周留根. 用硫酸铁和黄铁矿将二氧化锰转变为硫酸盐法[J]. 化学世界, 1955(1): 25-31.

ZHOU Liu-gen. The extraction of Mn from pyrolusite by using ferric sulfate and pyrite[J]. Chemistry World, 1955(1): 25-31.

ZHOU Liu-gen. The extraction of Mn from pyrolusite by using ferric sulfate and pyrite[J]. Chemistry World, 1955(1): 25-31.

[2] 李同庆. 低品位软锰矿还原工艺技术与研究进展[J]. 中国锰业, 2008, 26(2): 4-13.

LI Tong-qing. Technology of low grade pyrolusite ore reduction process and recent advances[J]. China’s Manganese Industry, 2008, 26(2): 4-13.

[3] MOHAMMAD S B, ALIREZA Z, ZAHRA G,MANDANA A. Reductive dissolution of manganese ore in sulfuric acid in presence of iron metal[J]. Hydrometallurgy, 2008, 90: 207-212.

[4] 牛莎莎, 王志兴, 郭华军, 李新海, 彭文杰, 胡启阳, 张云河. 电解锰阳极渣还原浸出锰[J]. 中国有色金属学报, 2012, 22(9): 2662-2666.

NIU Sha-sha, WANG Zhi-xing, GUO Hua-jun, LI Xin-hai, PENG Wen-jie, HU Qi-yang, ZHANG Yun-he. Reductive leaching of manganese from manganese anode slag[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2662-2666.

[5] 常 伟. 低品位软锰矿还原浸出过程及其动力学研究[D]. 长沙: 中南大学, 2014: 4-8.

CHNAG Wei. Study on reductive leaching of low-grade pyrolusite ores and leaching kinetics[D]. Changsha: Central South University, 2014: 4-8.

[6] FURLANI G, PAGNANELLI F, TORO L. Reductive acid leaching of manganese dioxide with glucose: Identification of oxidation derivatives of glucose[J]. Hydrometallurgy, 2006, 81: 234-240.

[7] 冯雅丽, 易爱飞, 李浩然, 王维大. 玉米秸秆还原浸出高铁低品位锰矿研究[J]. 东北大学学报(自然科学版), 2015, 36(8): 1184-1187.

FENG Ya-li, YI Ai-fei, LI Hao-ran, WANG Wei-da. Reductive leaching of high iron low-grade manganese ore with pre-processed cornstalk[J]. Journal of Northeastern University (Natural Sciences), 2015, 26(8): 1184-1187.

[8] SU Hai-feng, LIU Huai-kun, WANG Fan,  Xiao-yan, WEN Yan-xuan. Kinetics of reductive leaching of low-grade pyrolusite with molasses alcohol wastewater in H2SO4[J]. Chinese Journal of Chemical Engineering, 2010, 18(5): 730-735.

Xiao-yan, WEN Yan-xuan. Kinetics of reductive leaching of low-grade pyrolusite with molasses alcohol wastewater in H2SO4[J]. Chinese Journal of Chemical Engineering, 2010, 18(5): 730-735.

[9] BEOLCHINI F, PETRANGELIPAPINI M, TORO L, TRIRONO M, VEGLIO F. Acid leaching of manganiferous ores by sucrose: Kinetic modelling and related statistical analysis[J]. Minerals Engineering, 2001, 14(2): 175-184.

[10]  F, TRIFONI M, PAGNANELLI F, TORO L. Shrinking core model with variable activation energy: A kinetic model of manganiferous ore leaching with sulphuric acid and lactose[J]. Hydrometallurgy, 2001, 60(2): 167-179.

F, TRIFONI M, PAGNANELLI F, TORO L. Shrinking core model with variable activation energy: A kinetic model of manganiferous ore leaching with sulphuric acid and lactose[J]. Hydrometallurgy, 2001, 60(2): 167-179.

[11] 粟海锋, 吕奕菊, 崔勍焱, 王 凡, 吕小艳, 文衍宣. 糖蜜酒精废液中大分子焦糖色素模拟物浸出软锰矿的动力学[J]. 高校化学工程学报, 2011, 25(1): 43-48.

SU Hai-feng,  Yi-ju, CUI Qing-yan, WANG Fan,

Yi-ju, CUI Qing-yan, WANG Fan,  Xiao-yan, WEN Yan-xuan. Leaching kinetics of pyrolusite by macromolecular caramel of molasses alcohol wastewater[J]. Journal of Chemical Engineering Colleges and Universities, 2011, 25(1): 43-48.

Xiao-yan, WEN Yan-xuan. Leaching kinetics of pyrolusite by macromolecular caramel of molasses alcohol wastewater[J]. Journal of Chemical Engineering Colleges and Universities, 2011, 25(1): 43-48.

[12] 满瑞林, 常 伟, 吴 奇, 薛建荣. 燕麦秸秆还原浸出低品位软锰矿及其动力学[J]. 中国有色金属学报, 2014, 24(8): 2158-2163.

MAN Rui-lin, CHANG Wei, WU Qi, XUE Jian-rong. Reductive leaching and leaching kinetics of low-grade pyrolusite ores using oat straw as reductant[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2158-2163.

[13] 张春晖, 何绪文, 章丽萍, 王春荣. 电化学技术在水处理中的研究与应用[M]. 北京: 中国环境出版社, 2013: 11-25.

ZHANG Chun-hui, HE Xu-wen, ZHANG Li-ping, WANG Chun-rong. Research and application of electrochemical technology in water treatment[M]. Beijing: China Environmental Science Press, 2013: 11-25.

[14] 刘尚超, 薛改凤, 张 垒, 段爱民, 张 楠. 焦化废水处理技术研究进展[J]. 工业水处理, 2012, 32(1): 15-17.

LIU Shang-chao, HUE Gai-feng, ZHANG Lei, DUAN Ai-min, ZHANG Nan. Research progress in the treatment technology of wastewater for coke plants[J]. Industrial Water Treatment, 2012, 32(1): 15-17.

[15] 谢 刚, 李怀仁, 和晓才, 田 林. 加压湿法冶金技术应用现状及发展趋势[C]//第十六届中国科协年会-分10全国重有色金属冶金技术交流会论文集. 北京: 中国科学技术协会, 2014: 1-4.

XIE Gang, LI Huai-ren, HE Xiao-cai, TIAN Lin. Application status and development trend on pressure hydrometallurgy technology[C]//The 16th Session of Annual Meeting of the Association of China-10 Proceedings of the National Symposium on heavy non-ferrous metal metallurgy. Beijing: China Association for ScienceandTechnology, 2014: 1-4.

[16] 谢红艳, 王吉坤, 路 辉, 嵇晓沧, 杨世诚. 加压浸出低品位锰矿的工艺[J]. 中国有色金属学报, 2013, 23(6): 1701-1711.

XIE Hong-yan, WANG Ji-kun, LU Hui, JI Xiao-cang, YANG Shi-cheng. Technique of pressure leaching low grade manganese ore[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1701-1711.

[17] 李绍英, 王海霞, 袁喜振, 赵留成, 孙春宝. 金精矿碘化浸出过程动力学[J]. 中国有色金属学报, 2014, 24(3): 814-819.

LI Shao-ying, WANG Hai-xia, YUAN Xi-zhen, ZHAO Liu-cheng, SUN Chun-bao. Leaching dynamics of gold concentrates by iodine-iodide solution[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 814-819.

[18] 张 纯, 闵小波, 张建强, 王 蜜, 李辕成. 锌冶炼中浸渣锌还原浸出机制与动力学[J]. 中国有色金属学报, 2016, 26(1): 197-203.

ZHANG Chun, MIN Xiao-bo, ZHANG Jian-qiang, WANG Mi, LI Yuan-cheng. Mechanisms and kinetics on reductive leaching of zinc from neutral leaching residue[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 197-203.

[19] 刘静欣, 郭学益, 刘 旸. 废弃电路板多金属粉末碱性熔炼产物分形浸出动力学[J]. 中国有色金属学报, 2015, 25(2): 545-552.

LIU Jing-xin, GUO Xue-yi, LIU Yang. Fractal leaching kinetics of alkaline smelting product with metal enrichment from waste printed circuit boards[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 545-552.

[20] 李洪桂, 郑清远, 张启修, 郑蒂基. 湿法冶金学[M]. 长沙: 中南大学出版社, 2002: 69-87.

LI Hong-gui, ZHENG Qing-yuan, ZHANG Qi-xiu, ZHENG Di-ji. Science of hydro-metallurgy[M]. Changsha: Central South University Press, 2002: 69-87.

[21] 贺实月, 李会泉, 李少鹏, 李勇辉, 解 强. 煤粉炉高铝粉煤灰碱溶脱硅反应动力学[J]. 中国有色金属学报, 2014, 24(7): 1888-1894.

HE Shi-yue, LI Hui-quan, LI Shao-peng, LI Yong-hui, XIE Qiang. Kinetics of desilication process of fly ash with high aluminum from pulverized coal fired boiler in alkali solution[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1888-1894.

[22] 葛 琦, 王 恒, 满 毅, 李富杰, 庞立伟. 粒度对赤泥直接还原动力学的影响[J]. 化工进展, 2014, 33(12): 3215-3220.

GE Qi, WANG Heng, MAN Yi, LI Fu-jie, PANG Li-wei. Effect of particle size on kinetics of direct reduction of red mud[J]. Chemical Industry and Engineering Progress, 2014, 33(12): 3215-3220.

[23] 严 浩, 彭文杰, 王志兴, 李新海, 郭华军, 胡启阳. 响应曲面法优化点解锰阳极渣还原浸出工艺[J]. 中国有色金属学报, 2013, 23(2): 528-534.

YAN Hao, PENG Wen-jie, WANG Zhi-xing, LI Xin-hai, GUO Hua-jun, HU Qi-yang. Reductive leaching technology of manganese anode slag optimized by response surface methodology[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 528-534.

[24] TRIFONI M,TORO L,VEDLIO F. Reductive leaching of manganiferous ores by glucose and H2SO4: Effect of alcohols[J]. Hydrometallurgy, 2001, 59(1): 1-14.

[25] 马华菊, 卢友志, 陈东莲, 明宪权, 李维健, 袁爱群, 韦冬萍, 韦诗晴. 乳酸还原浸出低品位软锰矿[J]. 过程工程学报, 2015, 15(6): 976-981.

MA Hua-ju, LU You-zhi, CHEN Dong-lian, MING Xian-quan, LI Wei-jian, YUAN Ai-qun, WEI Dong-ping, WEI Shi-qing. Reductive leaching of low grade pyrolusite ore with lactic acid[J]. The Chinese Journal of Process Engineering, 2015, 15(6): 976-981.

[26] 袁明亮, 梅贤功, 庄剑鸣, 陈 荩, 蒋汉瀛. 菱锰矿酸浸过程杂质行为[J]. 中南工业大学学报, 1996, 27(1): 40-43.

YUAN Ming-liang, MEI Xian-gong, ZHUANG Jian-ming, CHEN Jin, JIANG Han-ying. The behavior of impurities in the leaching process of manganese carbonate ore[J]. Journal of Central South University of Technology, 1996, 27(1): 40-43.

Leaching kinetics of pyrolusite ores using coking wastewater as reductant

FENG Ya-li1, KANG Jin-xing1, LI Hao-ran2, DENG Xiang-yi1, SUN Ming1

(1. School of Civil and Resource Engineering, University of Science and Technology, Beijing 100083, China;

2. National Key State Laboratory of Biochemical Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China)

Abstract: Using the coking wastewater as reducing agent to pressure leaching the pyolusite, the shrinking core model was used to investigate the kinetics of the manganese reductive leaching process in the sulfuric acid solution. The effects of stirring speed, reaction temperature, the particle size of the pyrolusite and the concentrations of H2SO4 and coking wastewater on the leaching rate were investigated. The results show that the leaching of manganese increases with the increase of the temperature, the concentrations of H2SO4 and coking wastewater, whereas decreases with the increase of particle size. The kinetic equation for the manganese pressure reduction is presented at the temperature ranging from 393 K to 423 K, with the apparent activation energy of the leaching process is obtained to be 15.2 kJ/mol and the reaction orders for the concentration of H2SO4 and coking wastewater are 1.21 and 0.98, respectively. It suggests that the reduction of manganese from pyrolusite is controlled by the diffusion through the ash-inert layer. The mechanism analysis shows that pyrolusite is reduced by the multikey macromolecules of coking wastewater through providing the oxygen atom for the macromolecular organic compounds decomposition, or is reduced directly by small organic molecules. The thin-walled with holes superficial layer constituted by residual of Fe, Si, Al affects the Mn leaching.

Key words: coking wastewater; pyrolusite ore; reductive leaching; kinetics

Foundation item: Project(2015ZX07205-003) supported by the Major Science and Technology Program for Water Pollution Control and Treatment, China; Project(DY 125-15-T-08) supported by the China Ocean Mineral Resources Research & Development Program; Projects(21176026, 21176242) supported by the National Natural Science Foundation of China

Received date: 2016-05-26; Accepted date: 2016-10-21

Corresponding author: LI Hao-ran; Tel: +86-10-82627063; E-mail: hrli@home.ipe.ac.cn

(编辑 李艳红)

基金项目:水体污染与治理科技重大专项资助项目(2015ZX07205-003);中国大洋矿产资源研究计划资助项目(DY 125-15-T-08);国家自然科学基金资助项目(21176026,21176242)

收稿日期:2016-05-26;修订日期:2016-10-21

通信作者:李浩然,副研究员,博士;电话:010-82627063;E-mail:hrli@home.ipe.ac.cn