文章编号: 1004-0609(2005)06-0842-07

Ti-6Al-4V钛合金的激光弯曲成形特性

李俐群, 陈彦宾, 张立文, 封小松

(哈尔滨工业大学 现代焊接生产技术国家重点实验室, 哈尔滨 150001)

摘 要: 以Ti-6Al-4V薄板材料为研究对象, 研究了激光弯曲成形技术在钛合金上的应用特征。 通过实验描述了不同扫描参数对弯曲角的影响规律, 并对多次扫描下的板材弯曲动态特性进行了研究。 结果表明: 弯曲角随扫描次数呈近似的线性增加关系; 在扫描次数一定的情况下, 存在一个最优的累积线能量使弯曲角达到最大; 不同的材料状态在加热和冷却过程呈现出不同的弯曲动态特性。 此外, 对激光弯曲后的材料微观组织、 力学性能进行了测量和分析。 结果表明: 扫描参数的选择对发生相变的区域形状与相变区组织有较大影响; 多次扫描后, 加热区材料的强度与硬度均增加, 塑性降低。

关键词: 钛合金; 激光弯曲; 累积线能量; 微观组织

中图分类号: TG146 文献标识码: A

Laser bending characteristics of Ti-6Al-4V titanium alloy

LI Li-qun, CHEN Yan-bin, ZHANG Li-wen, FENG Xiao-song

(State Key Laboratory of Advanced Welding and Production Technology,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: Laser forming technology was employed in bending of Ti-6Al-4V sheets and the process characteristic was investigated. The influence of different laser scanning parameters on bending angle and the process dynamic behaviors were analyzed. The results indicate that the increase of bending angle with the scanning numbers is almost linear. Under the constant bending times, the biggest bending angle can be obtained with an optimal accumulative line energy value. Different dynamic bending behaviors with different material states during the heating and cooling process were observed. Moreover, the microstructure and the mechanical property of the material in heated area were measured and analyzed. The results show that the geometry and the microstructure of phase change zone are affected by scanning parameters, and the material tensile strength and hardness in heated area increase, while the plastic property decreases.

Key words: titanium alloy; laser bending; accumulative line energy; microstructure

Ti-6Al-4V合金是一种α+β型钛合金, 其综合性能优良, 塑性和冲击韧性高, 常被用于航空、 航天等领域的重要零部件。 但是钛合金高强度和高韧性的特点使得常温下的机械成形困难, 并且精度较低, 限制了钛合金材料在航空航天工业中的推广应用。 激光成形作为一种新兴的热加工工艺, 是以激光作为热源, 局部加热工件, 完全在热应力作用下使工件形成预定的形状[1-4]。 这一技术有望成为钛合金这种高强度比材料的成形方法。 近几年来, 国内外针对钛合金的激光成形工艺相继展开了研究[5-7]。 Magee等[8]研究了能量输入对Ti-6Al-4V合金几何形状及过程稳定性的影响并实现了简单形状零件的激光成形过程控制。 Marya与Edwards等[9, 10], 以近α和β钛合金为研究材料, 从工艺和数值模拟两方面研究了钛合金的成形工艺特点, 陈等[12]则采用不同的扫描路径实现Ti-6Al-4V合金的曲面成形。

激光成形技术完全依靠热应力, 完成一个工件的变形, 需要几十次、 上百次的扫描, 在多次加热的过程中, 热积累、 材料变形、 性能变化等诸多因素都会影响变形量的大小, 也就是说, 随扫描次数的增加, 材料的变形会呈现不同的规律[12-14]。 研究多次扫描下材料的变形特性对于将该技术推向实用化具有重要意义。 目前对于钛合金激光成形中的动态过程、 材料性能及组织形态对钛合金成形过程的影响还鲜有报道。 钛合金特殊的热物理性能与力学性能决定了其激光成形技术的特点, 有必要对其成形过程进行全面研究。

本文作者以Ti-6Al-4V薄板为实验对象, 研究了以不同热输入进行激光扫描时钛合金薄板弯曲变形规律以及材料微观组织、 力学性能的变化, 并在实验过程中, 同时对多次扫描下的弯曲角的动态变化过程进行了监测与分析, 为优化钛合金激光成形工艺、 进一步研究激光扫描下的钛合金弯曲变形机理提供依据, 并为激光成形技术应用于钛合金材料奠定基础。

1 实验

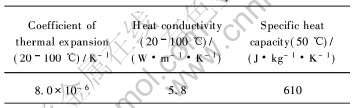

采用Ti-6Al-4V钛合金薄板为实验材料, 尺寸为130mm×55mm×1mm, 原始状态为冷轧退火态, 主要热物理性能列于表1。 热源为3kW射频激励CO2激光器。

表1 Ti-6Al-4V钛合金的热物理性能参数

Table 1 Thermal physical properties of Ti-6Al-4V alloy

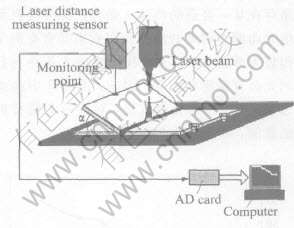

实验系统示意图如图1所示, 钛合金薄板置于材料为45号钢的底板上, 底板的导热系数为49.8W/(m·℃)左右。 成形过程中采用激光测距仪实时测量板材的弯曲角, 激光始终从板宽一侧进入, 重复扫描。 此外, 钛合金在较低的温度下就易与空气中的氧和氮发生反应, 400℃时开始吸氧, 600℃时开始吸氮, 成形过程中必须在较长一段的高温区实行保护。 本研究采用氩气为保护气, 激光头同轴喷嘴加后拖罩进行保护。

图1 Ti-6Al-4V钛合金的激光成形系统

Fig.1 Experimental system of laser bending of Ti-6Al-4V alloy

2 Ti-6Al-4V薄板的弯曲特性

2.1 热输入对材料弯曲特性的影响

Ti-6Al-4V热导率较低、 热膨胀系数较小, 强度高, 热量易在很小区域内积累, 易导致材料熔化, 并且不易变形。 保证钛合金可以进行有效变形又不至导致表面熔化的热输入范围非常有限, 不同的光斑直径, 其热输入的条件也不同。 本实验条件下, 当光斑直径为2mm时, 较为合适的弯曲工艺参数范围为: 扫描速度0.5~1.0m/min、 扫描功率0.35~0.7kW; 当光斑直径(D)为5mm时, 较为合适的弯曲工艺参数范围为: 扫描速度1.0~2.5m/min、 扫描功率1.0~2.0kW。 合理地选择扫描功率、 扫描速度、 光斑直径等参数, 对于得到理想的成形结果具有重要的意义。

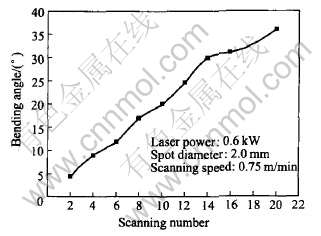

与其他金属的成形规律一样, 随扫描次数的增加, 钛合金板材的弯曲角近似呈线性变化(如图2所示)。 为综合分析不同工艺参数下的热输入对钛合金板弯曲特性的影响, 引入累积线能量的概念。 线能量为单位长度材料上的热输入, 累积线能量EALE定义为多次扫描的线能量累加, 由EALE=N·P/v表示。 它综合反映了扫描次数N, 激光功率P和扫描速度v的影响。

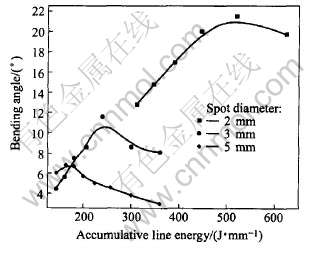

图3所示为相同扫描次数下, 不同光斑直径下累积线能量与板材弯曲角的关系。 可以看出, 弯曲角与累积线能量之间存在非线性关系, 不同光斑直径条件下, 弯曲角均是随着累积线能量的增加, 呈先增大后减小的趋势变化。 通常, 累积线能量较低时, 材料温度较低, 难以屈服, 不易获得较大弯曲角; 累积线能量过高, 对于薄板来说材料厚度方向温度梯度很容易达到均匀, 也不利于板材的弯曲。 通常是存在某一合适的热输入条件, 使得材料温度及厚度方向温度梯度的综合作用效果非常有利于板材获得较大弯曲角, 这一最佳的热输入条件与扫描激光的光斑直径密切相关。 因此, 由图3中曲线可以看出, 对于不同的光斑直径, 对应一个最佳的累积线能量值, 可获得最大的弯曲角。

图2 扫描次数与弯曲角的关系

Fig.2 Relationship between scanning times and bending angle

图3 累积线能量与弯曲角的关系

Fig.3 Relationship between accumulative line energy and bending angle

2.2 多次扫描下弯曲角的动态变化规律

激光沿板材中间直线扫描的过程中, 光斑处于不同的位置时材料的受热状况不同, 周围材料对扫描区的拘束作用也不同, 因此, 在光斑的移动过程中, 板材的弯曲量呈不均匀变化。

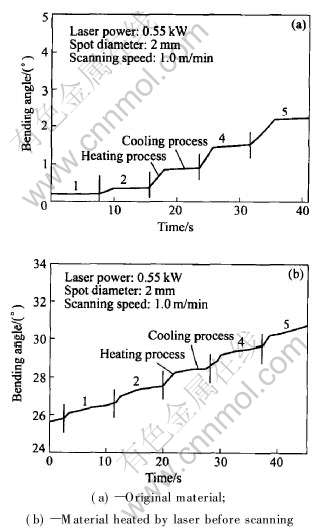

图4所示为两种不同初始条件下进行激光扫描, 板材弯曲角在连续5次的加热与冷却过程中动态变化规律。 图4(a)所示为原始母材状态下连续进行5次扫描获得的弯曲角, 图4(b)所示为板材已经过25次扫描, 材料组织性能发生变化且存在一定预弯角的状态下连续进行5次扫描获得的弯曲角。 激光作用于板材上为加热过程, 当激光离开板材重新回到起点的一段时间为冷却过程。 可以看出, 对于原始板材(图4(a)), 激光在板材中间扫描的加热过程, 弯曲角持续增长, 当激光离开板材, 即两次扫描间隔间的冷却过程, 弯曲角基本保持不变。 当板材经过多次扫描材料存在一定预弯角度后(图4(b)), 不仅是加热过程, 在激光离开板材的冷却过程中, 弯曲角也保持上升趋势。 但从弯曲量来看, 材料经过多次加热后, 可获得更大的弯曲角。

图4 不同条件下材料的动态弯曲特性

Fig.4 Bending dynamic behaviors of different material states

产生这一现象的影响因素很多, 如材料预弯角变化会影响材料对扫描区的拘束作用; 多次加热后扫描区增厚对板材温度梯度及弯曲阻力的影响以及材料组织性能变化的影响等等, 目前还很难给出一种准确的解释, 但了解钛合金板材的这一动态变形规律, 对改进工艺, 提高成形效率无疑是有很大帮助。

3 激光成形对 Ti-6Al-4V合金力学性能的影响

3.1 材料相变区及微观组织

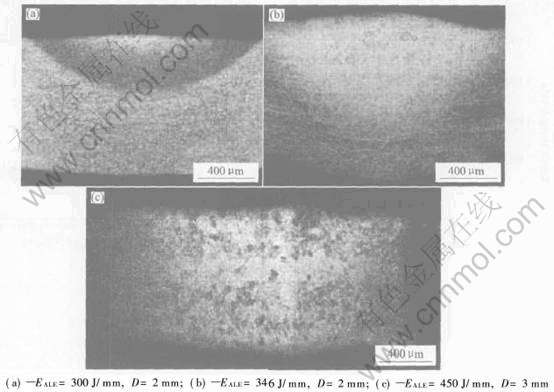

在激光成形钛合金过程中, 采用不同的热输入的形式, 在扫描区的横截面上可以得到不同的发生相变的区域形状, 图5所示为不同热输入条件下的相变区形状。 光斑直径较小和热输入较小条件下, 板料成形后相变区都较小, 且集中在板料的上表面(图5(a)); 增加热输入, 板料成形后相变区深度、 宽度增加, 在板厚方向上呈倒三角形(图5(b)); 采用较大光斑直径和热输入时, 成形后材料的相变区贯穿整个板厚, 呈梯形(图5(c))。

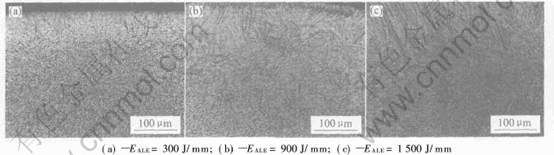

图6所示为不同热输入条件下的材料组织状态。 随着累积线能量的增加材料的组织逐渐发生变化, 当累积线能量比较小的情况下, 材料的组织没有明显变化(图6(a)), 随着累积线能量进一步增加材料的组织转变为钛马氏体α′, 但是其晶粒尺寸较小(图6(b))), 当累积线能量增加到一定程度时, 材料的组织转变为粗大的钛马氏体α′组织(图6(c)) 且可以看出, 在厚度方向上材料的组织分布极不均

图5 不同热输入条件下的相变区形状

Fig.5 Shapes of phase-change area in different heat inputs

图6 累积线能量对微观组织的影响

Fig.6 Influence of accumulative line energy on microstructure (spot diameter D=2mm)

匀, 上表面材料组织为比较粗大的板条钛马氏体α′, 中部为比较细小的针状的马氏体α′, 底部为长大的等轴α+β组织。

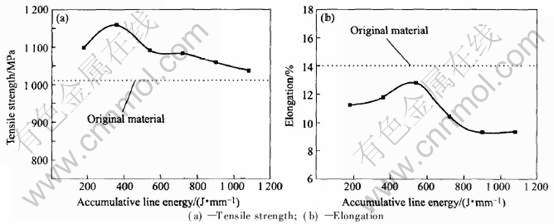

3.2 材料力学性能变化

在激光加热的过程中, 材料性能发生了变化, 而这种变化反过来会影响激光成形过程。 为了获得激光成形过程中材料性能改变对激光成形的影响, 有必要知道激光成形过程中, 材料加热区域的力学性能变化规律。 本研究采用线切割的方法, 将激光扫描区域内的材料沿着扫描方向切取, 进行力学性能测试。 图7所示为累积线能量对材料抗拉强度及延伸率的影响规律。 可以看出, 经过激光加热后, 材料的强度得到提高, 随累积线能量的增加, 钛合金的抗拉强度呈先增大后减小的趋势变化, 由于组织转变得到钛马氏体α′组织。 钛马氏体由于本身过饱和固溶钒, 又具有极高的位错密度使得其强度很高, 因此组织强化会提高接头的强度, 在扫描的后续阶段由于晶粒尺寸变大, 对接头强度产生一定影响, 导致材料强度下降。 最终扫描区的强度取决于组织转变与晶粒尺寸综合影响的结果。 由图中可以看出, 随累积线能量的增加, 延伸率呈先增大后下降趋势, 与母材相比有所降低。

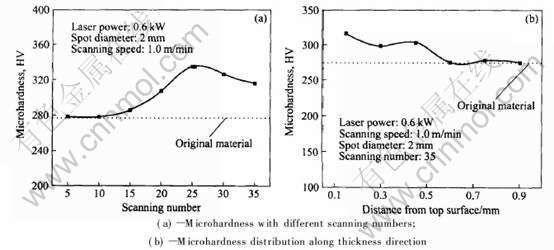

图8所示为激光加热后材料的硬度变化规律, 可以看出, 激光加热后, 扫描区变硬, 随扫描次数增加, 材料的硬度值先增大后减小, 整体硬度略高于母材, 因此在厚度方向上, 材料的硬度值从表面到底面是呈减小趋势。 材料在激光多次扫描后, 强度、 硬度提高, 延伸率下降, 主要是由于加热过程中形成了淬硬的马氏体导致。

图7 激光成形对材料拉伸强度与延伸率的影响

Fig.7 Influence of laser bending on tensile strength and elongation of heated material

图8 激光成形对材料硬度的影响

Fig.8 Influence of laser bending on material microhardness

图9 不同累积线能量下激光加热合金及母材的拉伸断口形貌

Fig.9 Fracture texture of base metal and heated material with different accumulative line energies

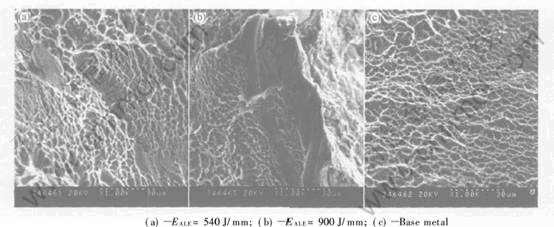

为了进一步分析钛合金板材激光成形后韧性的变化规律, 又对拉伸试样及母材做了断口分析, 结果如图9所示。 当累积线能量为540J/mm时, 其拉伸试样断口形貌特征是: 表面主要由大小不均的韧窝和少量的河流花样组成(图9(a)), 属于韧窝和部分解理型断裂; 当累积线能量增加到900J/mm时, 韧窝减少而出现了较大的河流花样(图9(b)), 说明解理断裂所占的比例增加, 材料的韧性降低。 由图9(c)可以看出, 母材的拉伸试样断口形貌是典型的韧窝型断裂, 断口表面有两类韧窝, 其中一类韧窝尺寸稍大, 被略小一些的韧窝分开, 小韧窝约占断口表面的80%。

上述结果表明, 钛合金板材经过激光成形后韧性降低, 并且累积线能量对拉伸试样断口形貌特征有显著影响, 随着累积线能量的增加, 拉伸试样断口形貌特征由均匀分布的韧窝向大小不均匀的韧窝和河流花样混合型转变。

4 结论

1) 连续扫描过程中, 钛合金板材的弯曲角随扫描次数的增加而增大; 与常规金属相比, Ti-6Al-4V合金材料进行有效的变形且不至熔化的热输入条件更为严格; 累积线能量与弯曲角之间存在非线性关系, 不同光斑直径下, 均存在一个最优的累积线能量值, 可获得较大的弯曲效率。

2) 与原始板材相比, 经过多次激光扫描加热后Ti-6Al-4V薄板, 在成形过程中板材弯曲效率增加, 且两种条件下板材的动态弯曲特性存在明显差异: 原始板材仅在激光加热过程中弯曲角上升, 而多次加热后的板材在激光加热与冷却过程中均存在弯曲角上升情况。

3) Ti-6Al-4V合金激光成形后的组织为钛马氏体, 相变区的形状与光斑直径有关, 尺寸随能量输入增大而增大; 当能量输入较大的情况下, 相变区的组织出现分层现象: 上表层位粗大的钛马氏体, 中间层为细小的钛马氏体, 底层为长大的等轴α+β组织。

4) 经过激光多次扫描后, 扫描区材料的抗拉强度与硬度增加, 塑性降低。 随着累积线能量的增加, 拉伸试样断口形貌特征由均匀分布的韧窝向大小不均匀的韧窝和河流花样混合型转变。

REFERENCES

[1]Namba Y. Laser forming in space[A]. Proceeding of International Congress on Lasers 85[C]. USA: STS Press, 1986. 403-407.

[2]Hsiao Y C. Finite element modeling of laser forming[A]. The laser Materials Proceeding of Conference(ICALEO 97)[C]. San Diego: 1997. 31-40.

[3]Chan K C, Liang J. Thermal expansion and deformation behavior of aluminum-matrix composites in laser forming[J]. Composites Science and Technology, 2001, 61(9): 1265-1270.

[4]Merklin M, Hennige T, Gerger M. Laser forming of aluminum and aluminum alloys-microstructureal investigation[J]. Journal of Materials Processing Technology, 2001, (115): 159-165.

[5]CHEN Dun-jun, WU Shi-chun. Study on laser bending of titanium alloys sheets[J]. Acta Aeronautica et Astronaurtica Sinica, 2001, 22(2): 187-189.

[6]LIU Shun-hong, HU Qian-wu. Investigation on microstructure and property of laser bent Ti-7Al-2Zr-2Mo-2V[J]. Chinese Journal of Lasers, 2002, 29(11): 1049-1053.

[7]CHEN Dun-jun, XIANG Yi-bin, WU Shi-dun. Curved laser bending of titanium alloy sheets and effects of heat radiation on its microstructure and property[J]. Acta Metallurgica Sinica, 2001, 37(6): 643-646.

[8]Magee J, Sidhu J, Coole R L. A prototype laser forming system[J]. Optics and laser in Engineering, 2000, 33(4): 339-353.

[9]Marya M, Edwards G R. A study on the laser forming of near-alpha and metastable beta titanium alloy sheets[J]. Journal of Materials processing Technology, 2001, 108(3): 376-383.

[10]Marya M, Edwards G R. An analytical model for the optimization of the laser bending of titanium Ti-6Al-2Sn-4Zr-2Mo[J]. Journal of Material Processing Technology, 2002, 124(3): 337-344.

[11]Chen D J, Wu S C, Li M Q. Studies on laser forming of Ti-6Al-4V alloy sheet[J]. Journal of Materials Processing Technology, 2004, 152(1): 62-65.

[12]Thomas. Development of irradiation strategies for 3D-laser forming[J]. Journal of Materials Processing Technology, 2000, 103(1): 102-108.

[13]Geiger M. Rapid prototyping in profile forming by means of laser-induced thermal stresses[A]. Laser Assisted Net Shape Engineering Proceedings[C]. Meisenbach Bamberg, 1994. 249-261.

[14]Thomson G, Pridham M. Material property changes associated with laser forming[J]. Journal of Materials Processing Technology, 2001, 118(1): 40-44.

(编辑陈爱华)

收稿日期: 2004-11-02; 修订日期: 2005-03-16

作者简介: 李俐群(1970- ), 女, 副教授.

通讯作者: 李俐群, 电话: 0451-86415374; 传真: 0451-86418645; E-mail: liliqun@hit.edu.cn